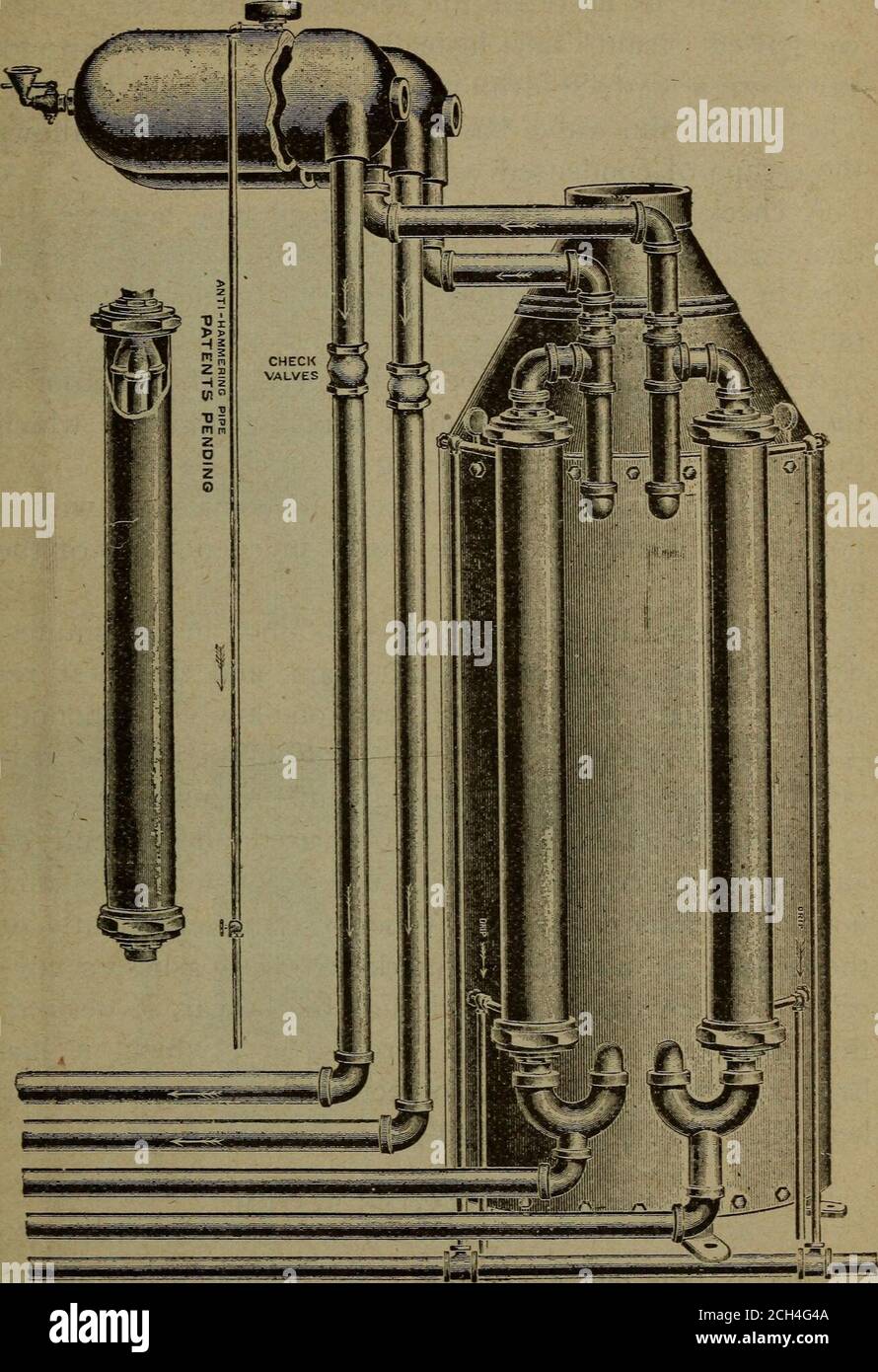

. Operation of trains and station work and telegraphy . FIG. 8. BAKER STEAM ATTACHMENT SHOWN FITTED TO HEATER. CUT TO THE RIGHT SHOWS THE ATTACHMENT DETACHED FROM HEATER. HEATING AN1> LIGHTING CARS 59. FIG. 9. DETAILS OF IMPROVED BAKER STEAM ATTACHMENT.(See Fig. 8 for Same Shown Attached to Heater.) 60 RULES FOR MOVEMENT OF TRAINS Xo trap is used for the release of the water of thecondensed steam, but instead a simple blow-throughvalve on a ^-inch drip pipe, operated inside the car.The seat of this valve has a small groove, which allowsthe escape of condensed water, even if closed. <! A

Image details

Contributor:

Reading Room 2020 / Alamy Stock PhotoImage ID:

2CH4G4AFile size:

7.1 MB (491.1 KB Compressed download)Releases:

Model - no | Property - noDo I need a release?Dimensions:

1308 x 1909 px | 22.1 x 32.3 cm | 8.7 x 12.7 inches | 150dpiMore information:

This image is a public domain image, which means either that copyright has expired in the image or the copyright holder has waived their copyright. Alamy charges you a fee for access to the high resolution copy of the image.

This image could have imperfections as it’s either historical or reportage.

. Operation of trains and station work and telegraphy . FIG. 8. BAKER STEAM ATTACHMENT SHOWN FITTED TO HEATER. CUT TO THE RIGHT SHOWS THE ATTACHMENT DETACHED FROM HEATER. HEATING AN1> LIGHTING CARS 59. FIG. 9. DETAILS OF IMPROVED BAKER STEAM ATTACHMENT.(See Fig. 8 for Same Shown Attached to Heater.) 60 RULES FOR MOVEMENT OF TRAINS Xo trap is used for the release of the water of thecondensed steam, but instead a simple blow-throughvalve on a ^-inch drip pipe, operated inside the car.The seat of this valve has a small groove, which allowsthe escape of condensed water, even if closed. <! A check valve is placed in the feed pipe between thedrum and the radiating pipes, insuring positive circula-tion in the right direction when the heater coil is cutout. An anti-hammering pipe is connected to the top ofthe circulating drum to relieve any air pressure whichthereby prevents the hammering. In using this steam attachment in connection with adouble coil heater, each side works independently of theother. It is claimed that circulation is obtained in 40 minutes, with only 15 or 20 pounds of steam, and that best re-sults are obtained by turning steam on slowly at 5 pounds—and up to 15 or 20.