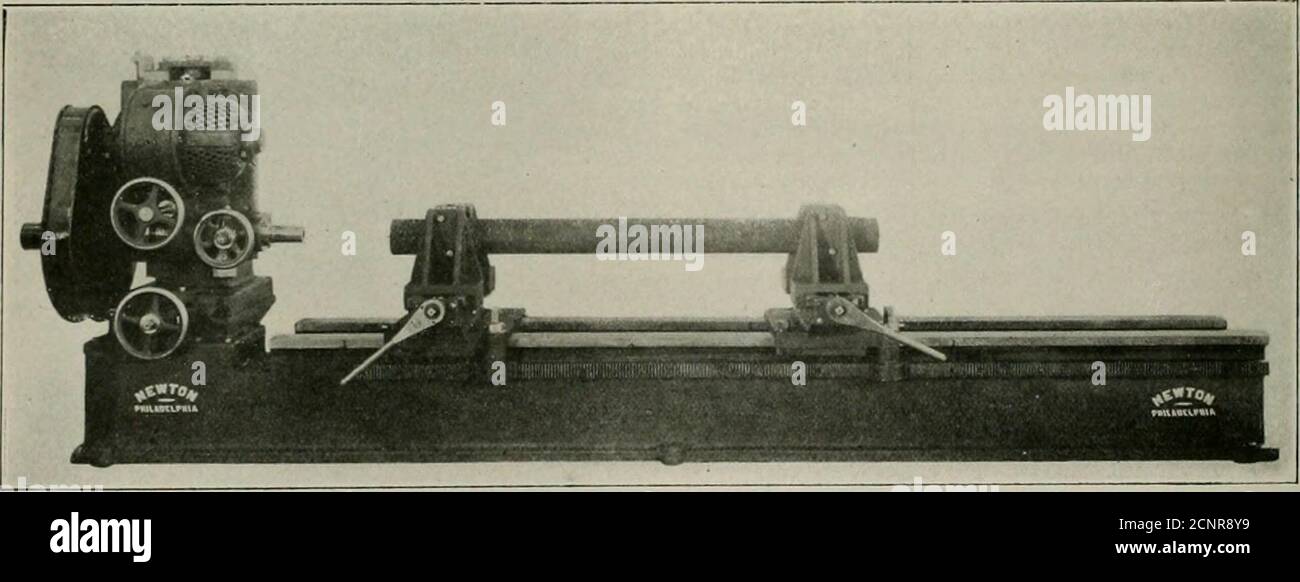

. Railway mechanical engineer . oris attached to a motor plate hinged from the cabinet base ofthe machine and provided with an adju.stable jack for main-taining the desired belt tension. A con.stant speed motor .V.C. or DC. running preferably1,200 r.p.m. is recommended. NEWTON CENTERING MACHINE The centering machine shown in the illustration is a re-cent development of the Newton Machine Tool Works,Philadelphia, Pa. It is designed for centering rough andirregular castings. The spindle is of forged steel .i in. indiameter, running in bronze bushed bearings and havingan 8-in. horizontal hand fee

Image details

Contributor:

Reading Room 2020 / Alamy Stock PhotoImage ID:

2CNR8Y9File size:

7.2 MB (221.1 KB Compressed download)Releases:

Model - no | Property - noDo I need a release?Dimensions:

2570 x 973 px | 21.8 x 8.2 cm | 8.6 x 3.2 inches | 300dpiMore information:

This image could have imperfections as it’s either historical or reportage.

. Railway mechanical engineer . oris attached to a motor plate hinged from the cabinet base ofthe machine and provided with an adju.stable jack for main-taining the desired belt tension. A con.stant speed motor .V.C. or DC. running preferably1, 200 r.p.m. is recommended. NEWTON CENTERING MACHINE The centering machine shown in the illustration is a re-cent development of the Newton Machine Tool Works, Philadelphia, Pa. It is designed for centering rough andirregular castings. The spindle is of forged steel .i in. indiameter, running in bronze bushed bearings and havingan 8-in. horizontal hand feed. The maximum distance fromthe center of the spindle to the top of the base is 17^2 in.and the minimum distance 13;4 in., giving a vertical ad-justment of 4 in. The spindle also has a cross adjustmentof 4 in., equally divided each side of the center line ofthe work. Pwo universal centering vises of the interlockingtype and adjustable on the bed are supplied with the ma-chine. The jaws are adju.stable by means of a screw giving. The Newton Centering Machine with Round Stock in the Vises work at any desired pressure, by a conveniently placed lever, further movement of the same lever rigidly locking the tail-stock barrel and clamping the spindle. The bed is of a special anvil section, with broad slidesfor the carriage and bearings for the head and tailstock, andis strongly ribbed internally and mounted on a cabinet base, in which the pan and chamber for cutting compound is cast.The pan becomes an integral part of the bed, and greatlystiffens the entire machine. A strainer separates the chipsfrom the cutting compound, which flows back to the baseof the machine. A geared rotary pump and piping for cir-culating the compound is supplied as regular equipment. A cover plate is provided for cleaning out the base. The carriage is a broad slide extending practically the fulllength of the bed and scraped to a bearing its entire length.The cross slide for mounting the compound or plain rest i