Quick filters:

Carding engine Stock Photos and Images

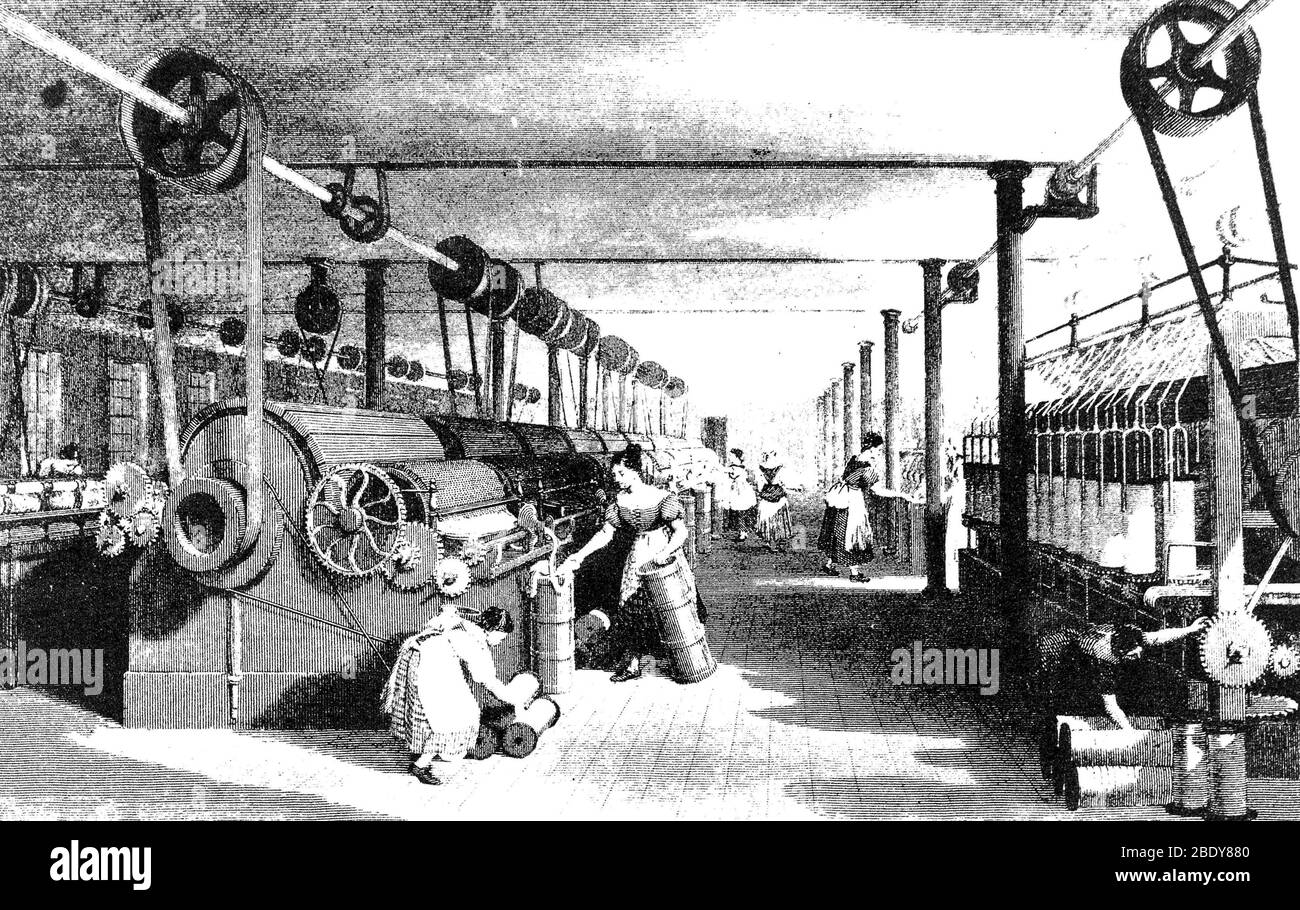

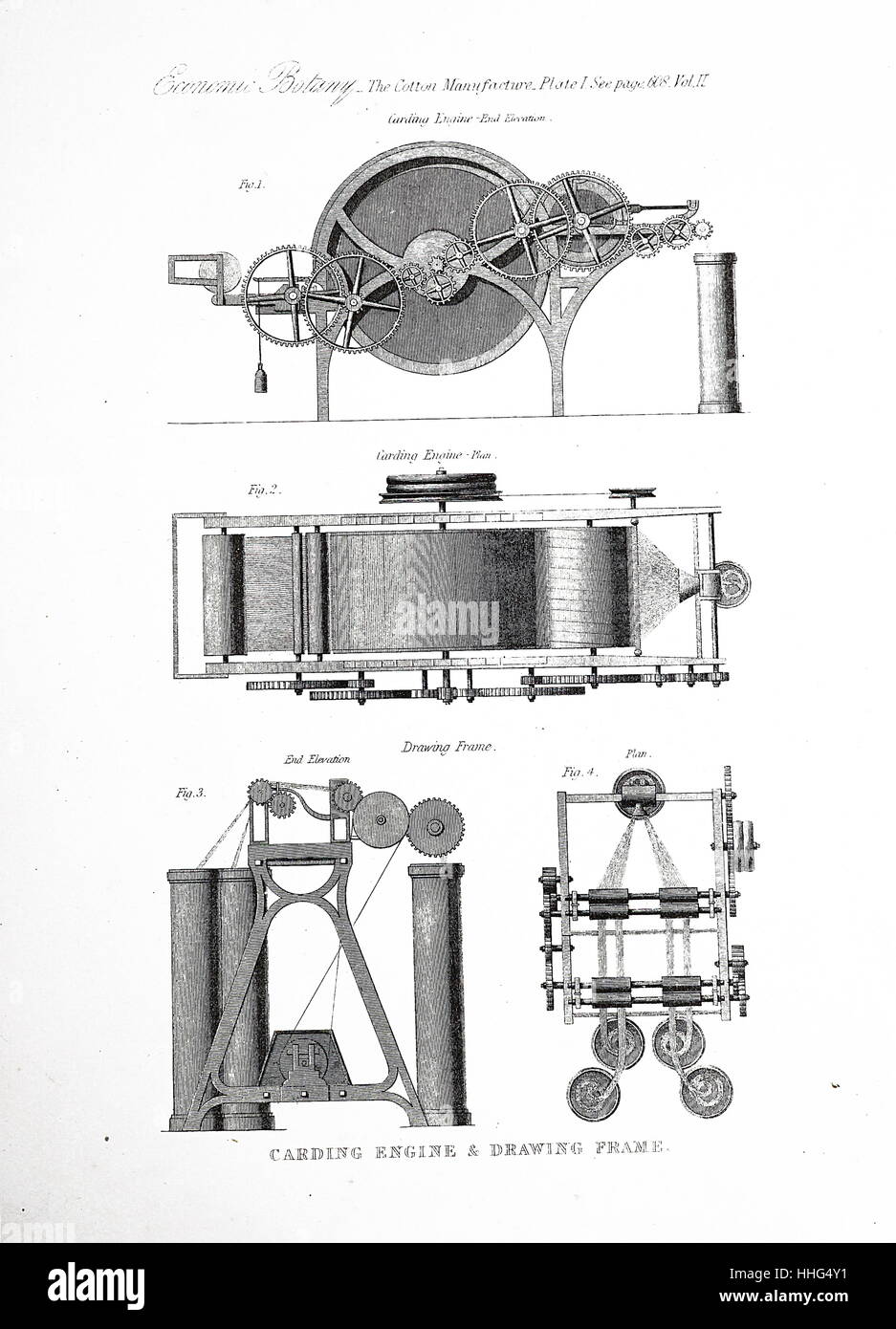

Carding Engine and Drawing Frame, 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-engine-and-drawing-frame-1835-image352797088.html

Carding Engine and Drawing Frame, 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-engine-and-drawing-frame-1835-image352797088.htmlRM2BDY880–Carding Engine and Drawing Frame, 1835

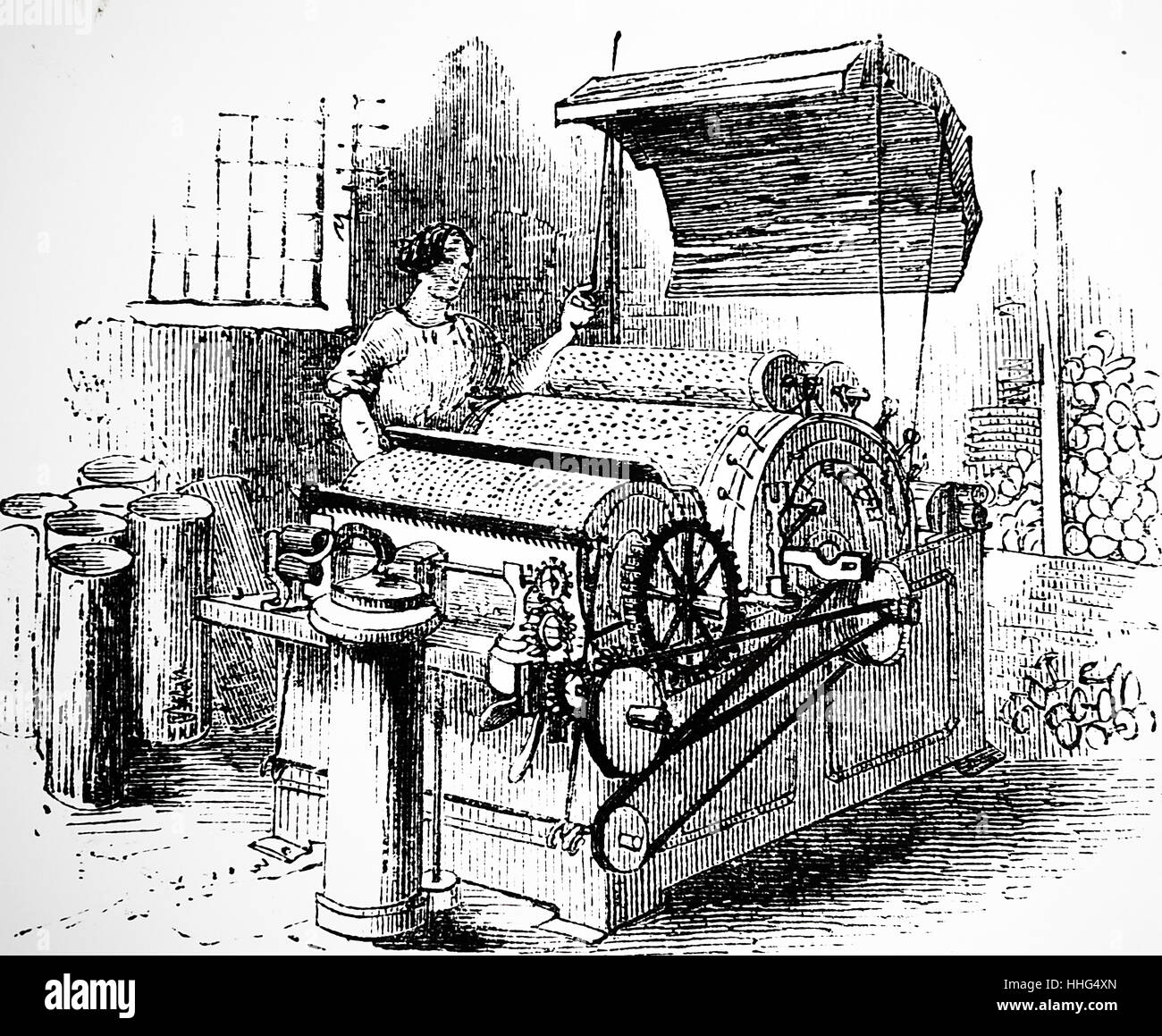

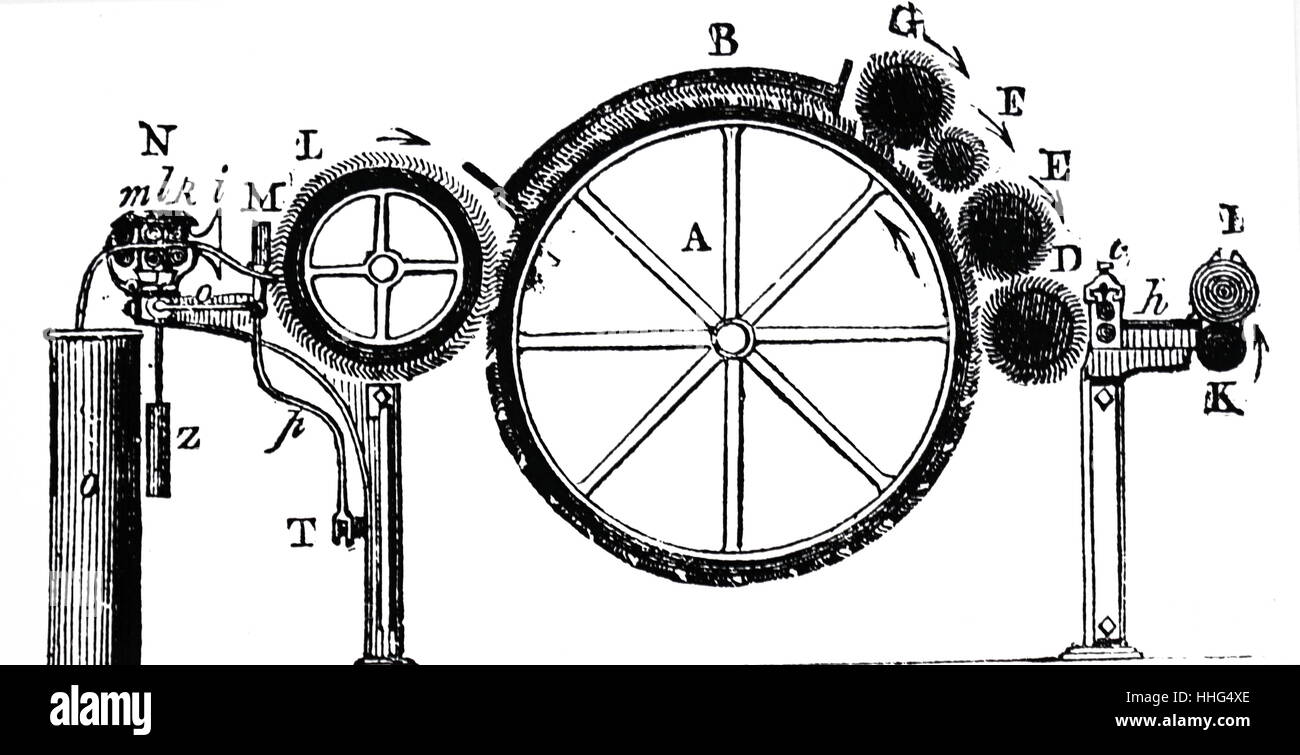

Cotton carding engine: this machine brushed and separated the cotton fibres. London, dated 1866. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-cotton-carding-engine-this-machine-brushed-and-separated-the-cotton-131276845.html

Cotton carding engine: this machine brushed and separated the cotton fibres. London, dated 1866. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-cotton-carding-engine-this-machine-brushed-and-separated-the-cotton-131276845.htmlRMHHG4XN–Cotton carding engine: this machine brushed and separated the cotton fibres. London, dated 1866.

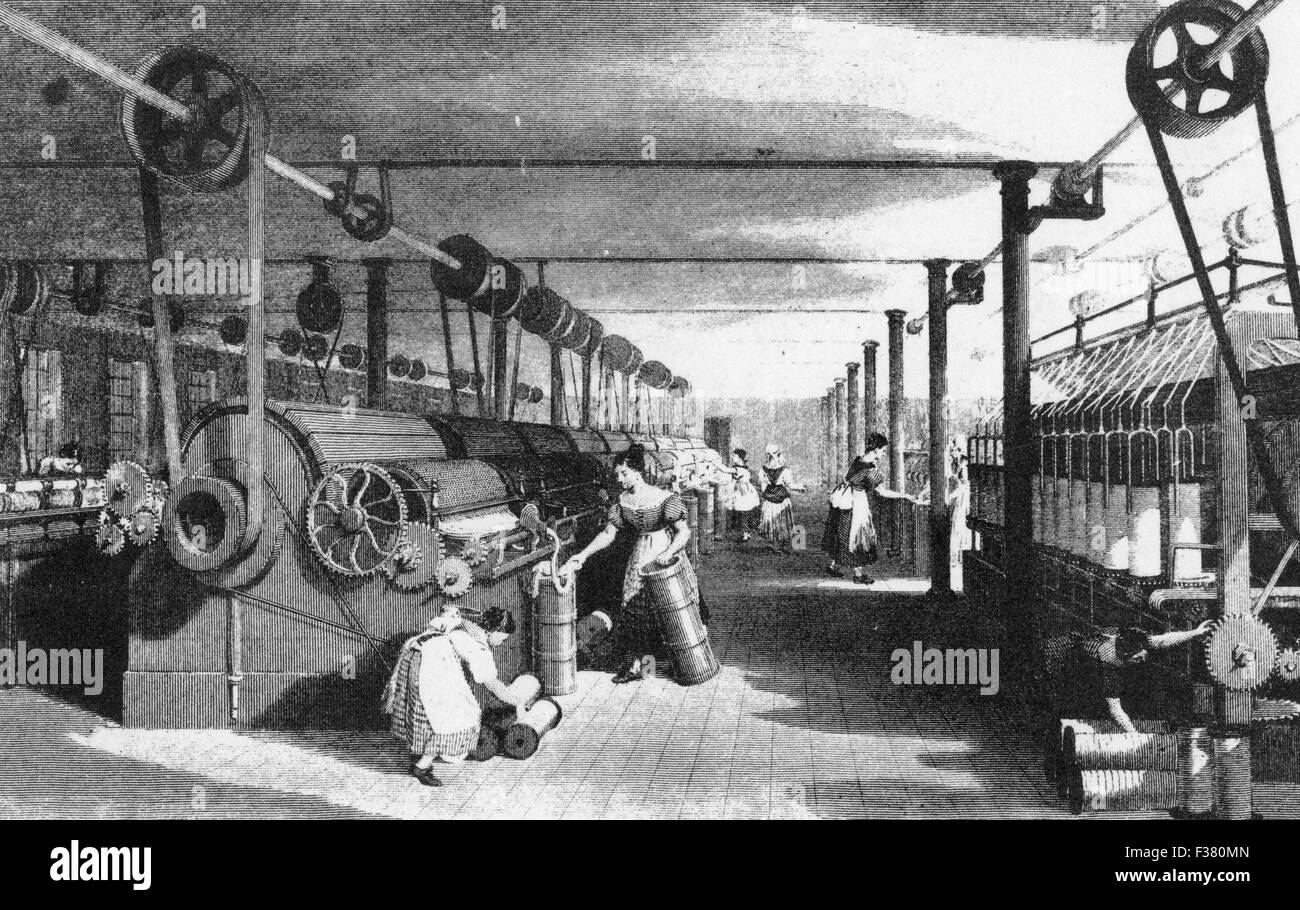

CARDING ENGINE AND DRAWING FRAME from E Baines' book History of the Cotton Manufacture, 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-carding-engine-and-drawing-frame-from-e-baines-book-history-of-the-88072005.html

CARDING ENGINE AND DRAWING FRAME from E Baines' book History of the Cotton Manufacture, 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-carding-engine-and-drawing-frame-from-e-baines-book-history-of-the-88072005.htmlRMF380MN–CARDING ENGINE AND DRAWING FRAME from E Baines' book History of the Cotton Manufacture, 1835

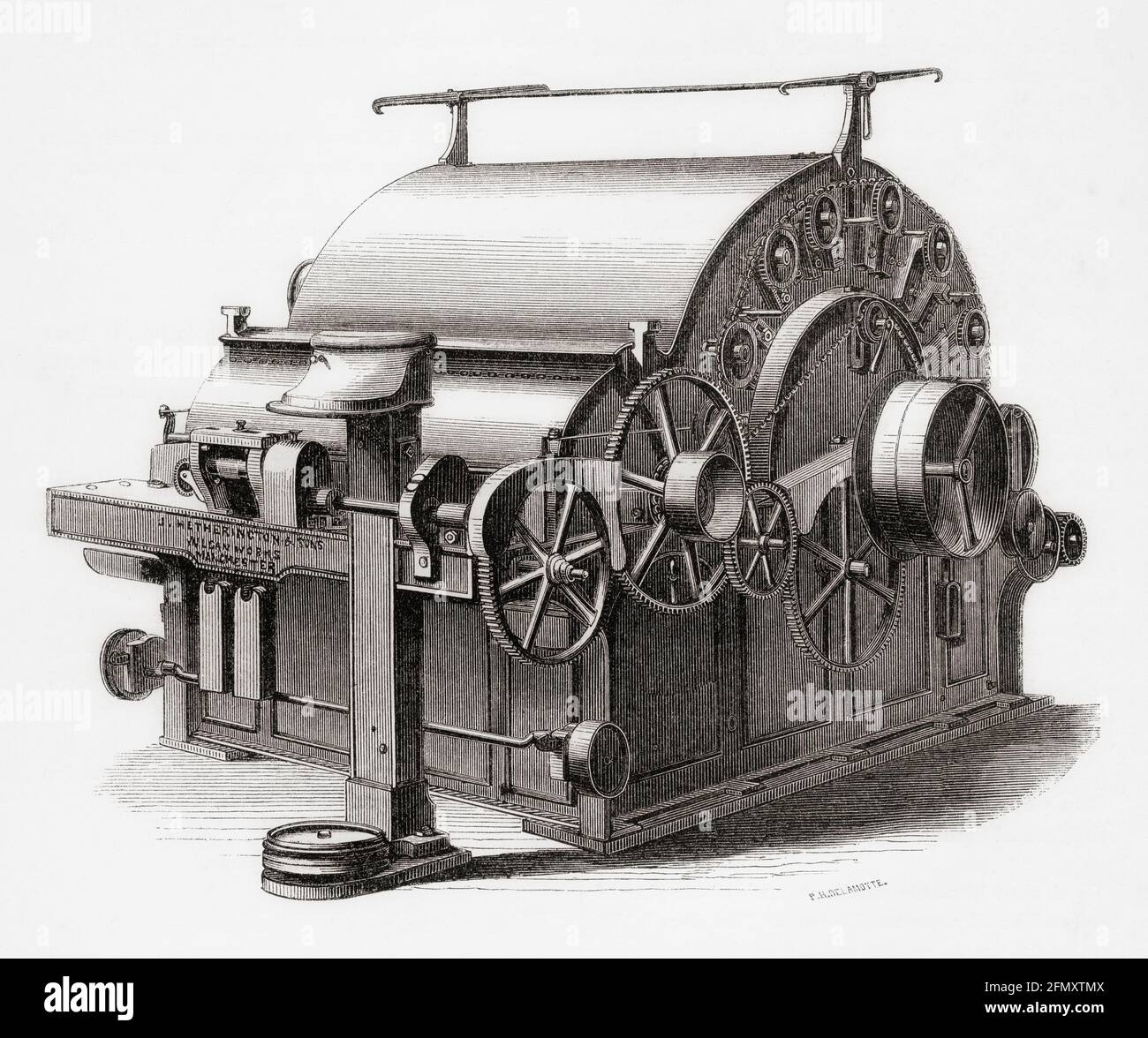

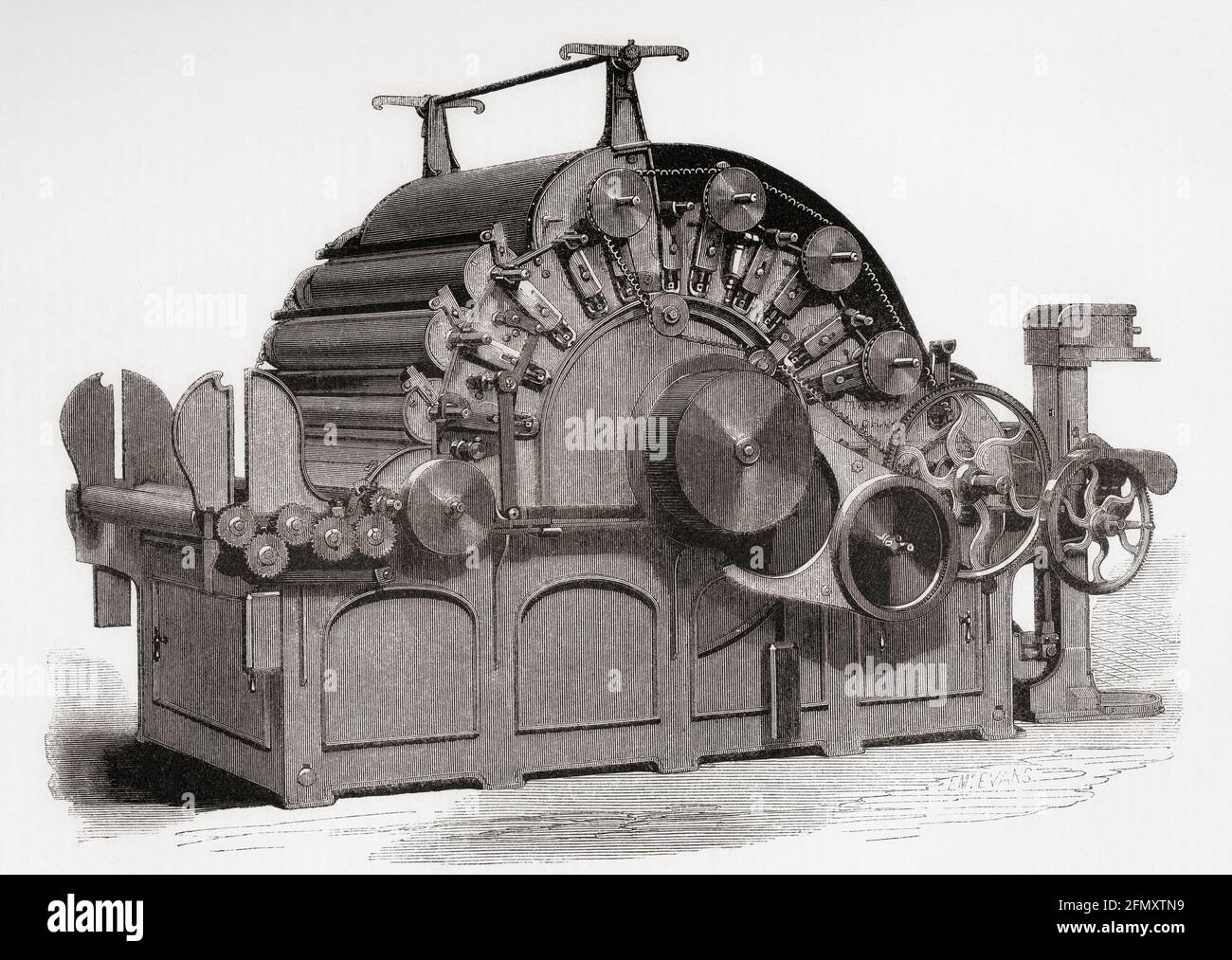

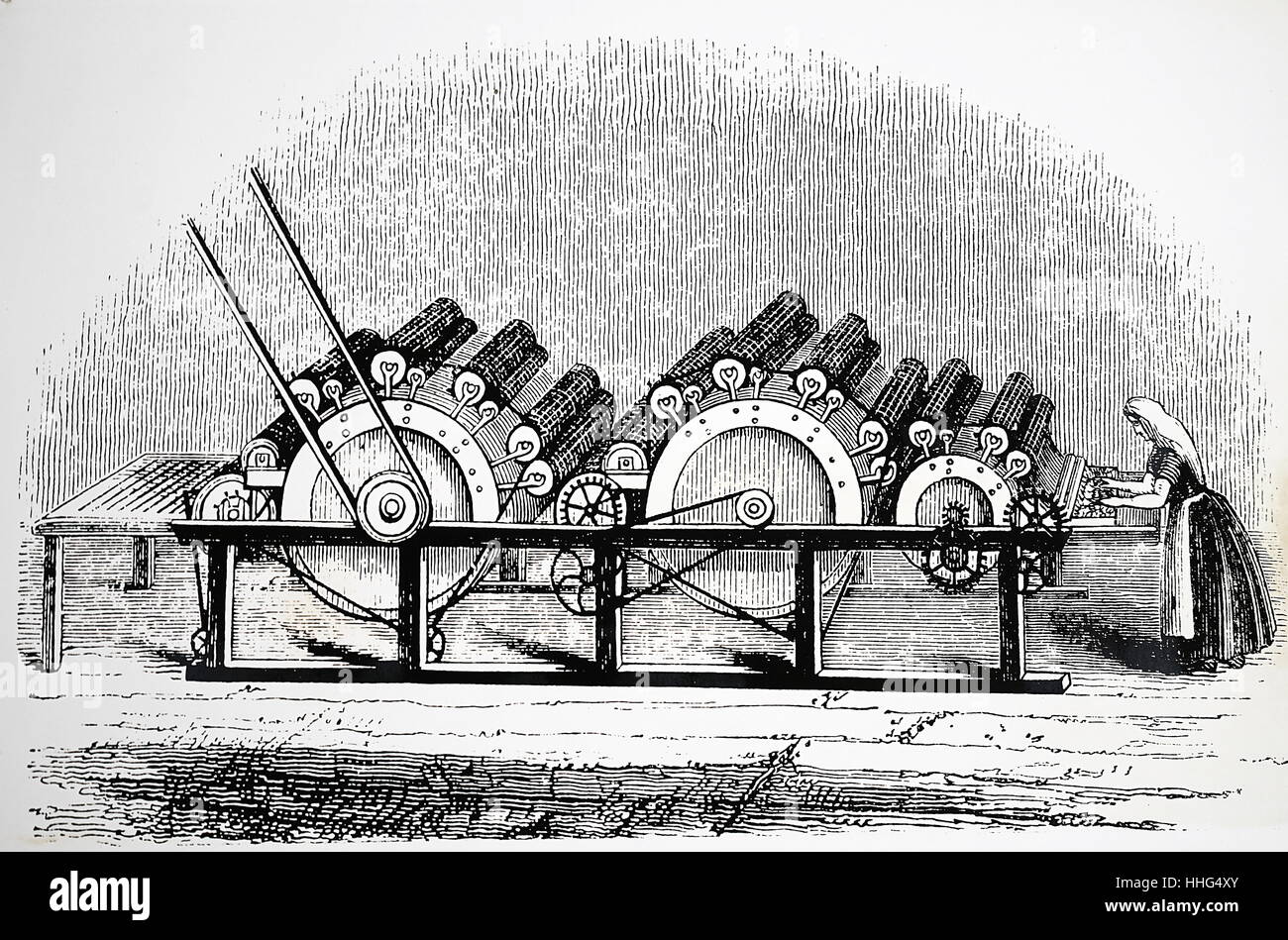

Carding engine. Carding is a mechanical process which disentangles, cleans and intermixes fibres. From A Concise History of The International Exhibition of 1862, published 1862. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-engine-carding-is-a-mechanical-process-which-disentangles-cleans-and-intermixes-fibres-from-a-concise-history-of-the-international-exhibition-of-1862-published-1862-image425932106.html

Carding engine. Carding is a mechanical process which disentangles, cleans and intermixes fibres. From A Concise History of The International Exhibition of 1862, published 1862. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-engine-carding-is-a-mechanical-process-which-disentangles-cleans-and-intermixes-fibres-from-a-concise-history-of-the-international-exhibition-of-1862-published-1862-image425932106.htmlRM2FMXTMX–Carding engine. Carding is a mechanical process which disentangles, cleans and intermixes fibres. From A Concise History of The International Exhibition of 1862, published 1862.

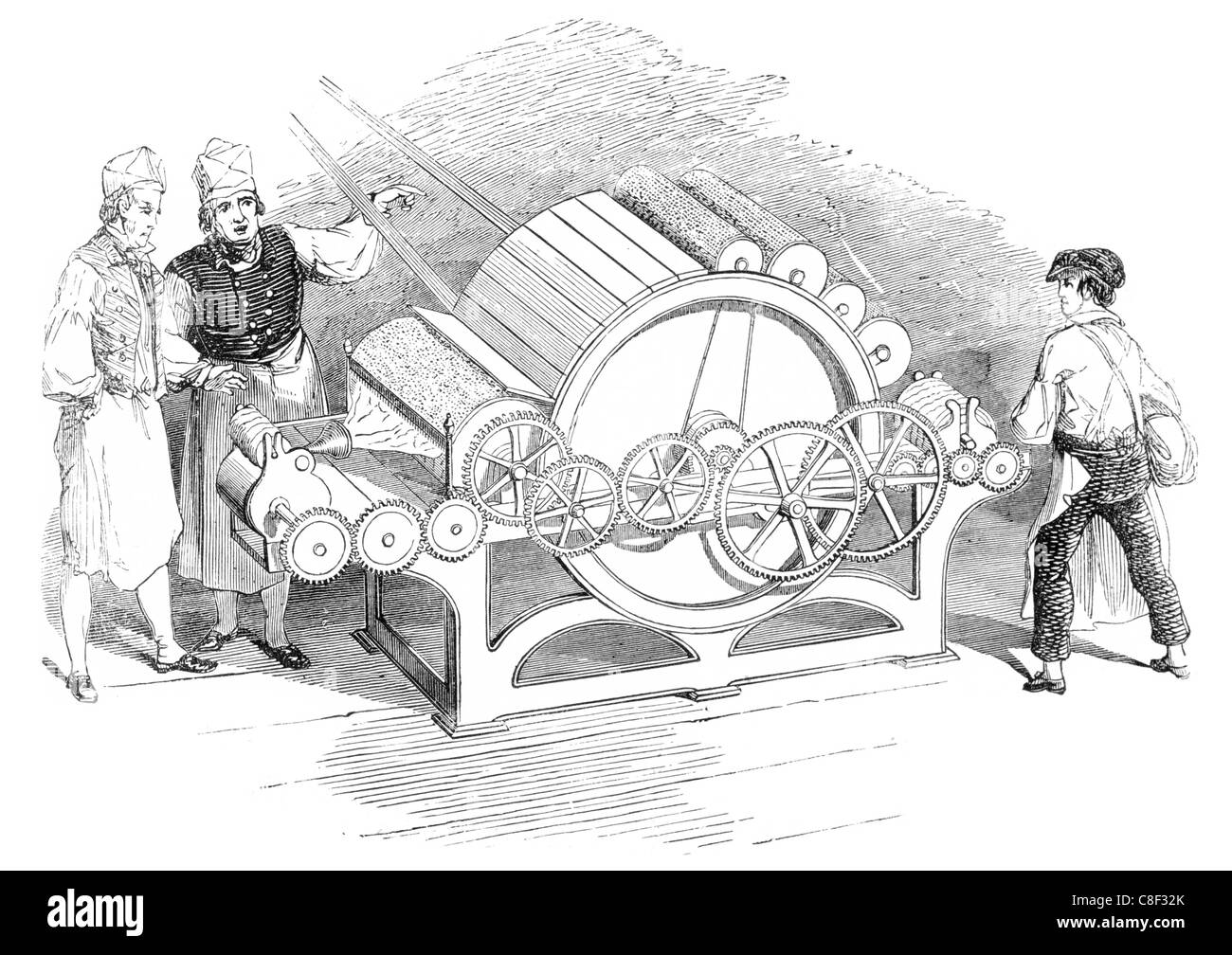

carding engine cotton machine Carding process fibre raw wool batting felt woollen worsted yarn clothing clothes cloth Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-carding-engine-cotton-machine-carding-process-fibre-raw-wool-batting-39669691.html

carding engine cotton machine Carding process fibre raw wool batting felt woollen worsted yarn clothing clothes cloth Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-carding-engine-cotton-machine-carding-process-fibre-raw-wool-batting-39669691.htmlRFC8F32K–carding engine cotton machine Carding process fibre raw wool batting felt woollen worsted yarn clothing clothes cloth

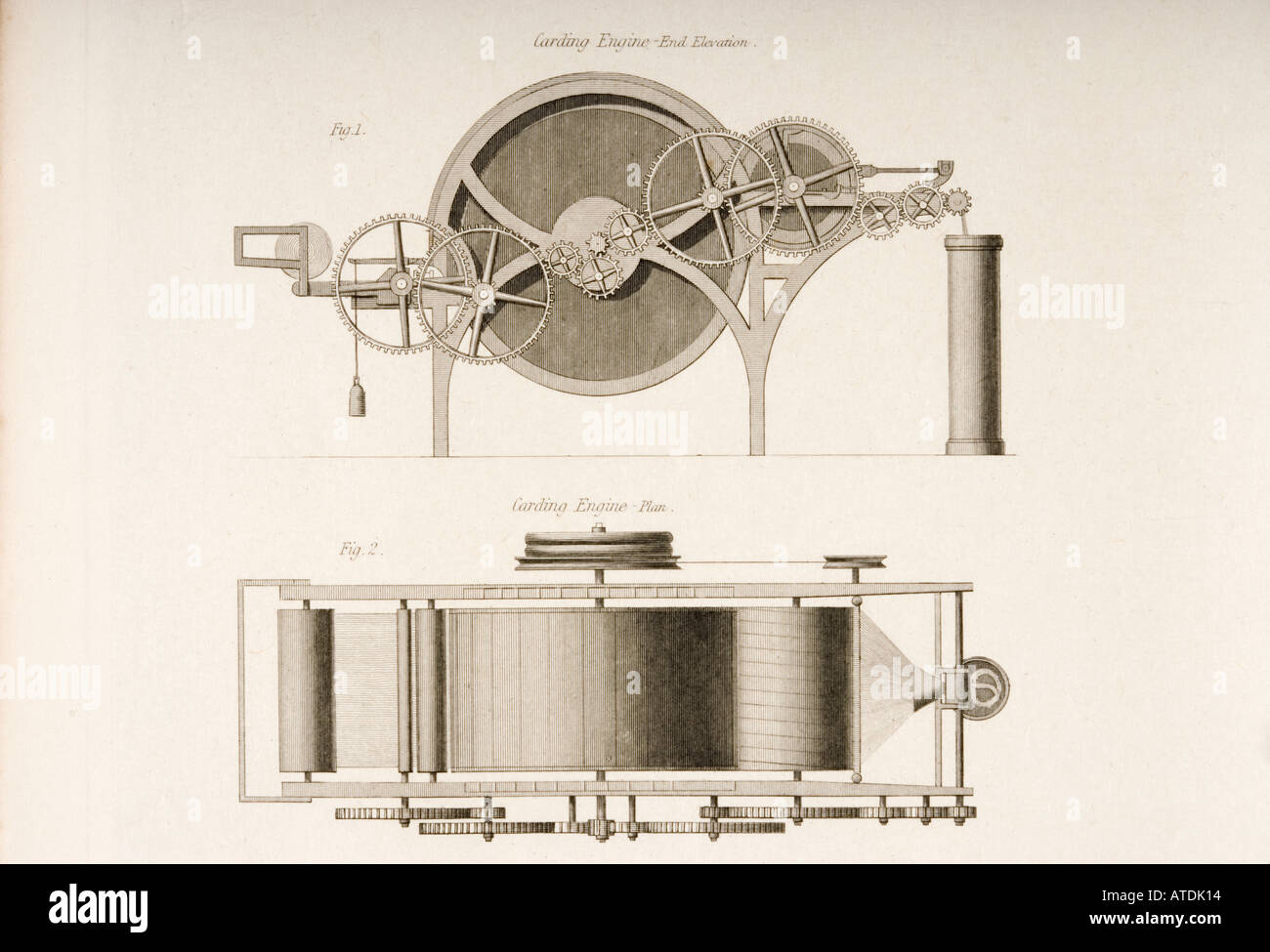

Carding Engine, end election top and plan at bottom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-engine-end-election-top-and-plan-at-bottom-image5316371.html

Carding Engine, end election top and plan at bottom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-engine-end-election-top-and-plan-at-bottom-image5316371.htmlRMATDK14–Carding Engine, end election top and plan at bottom

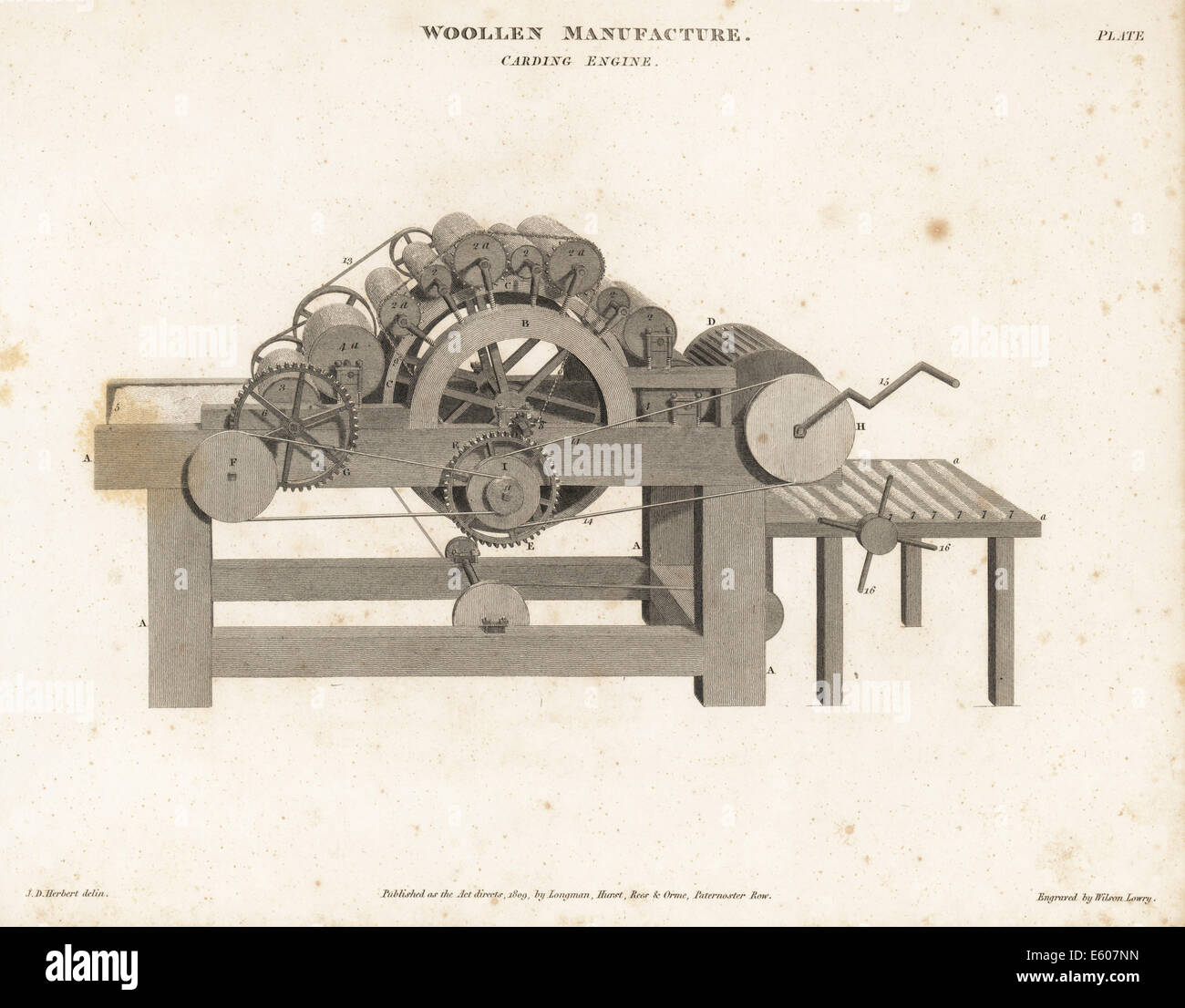

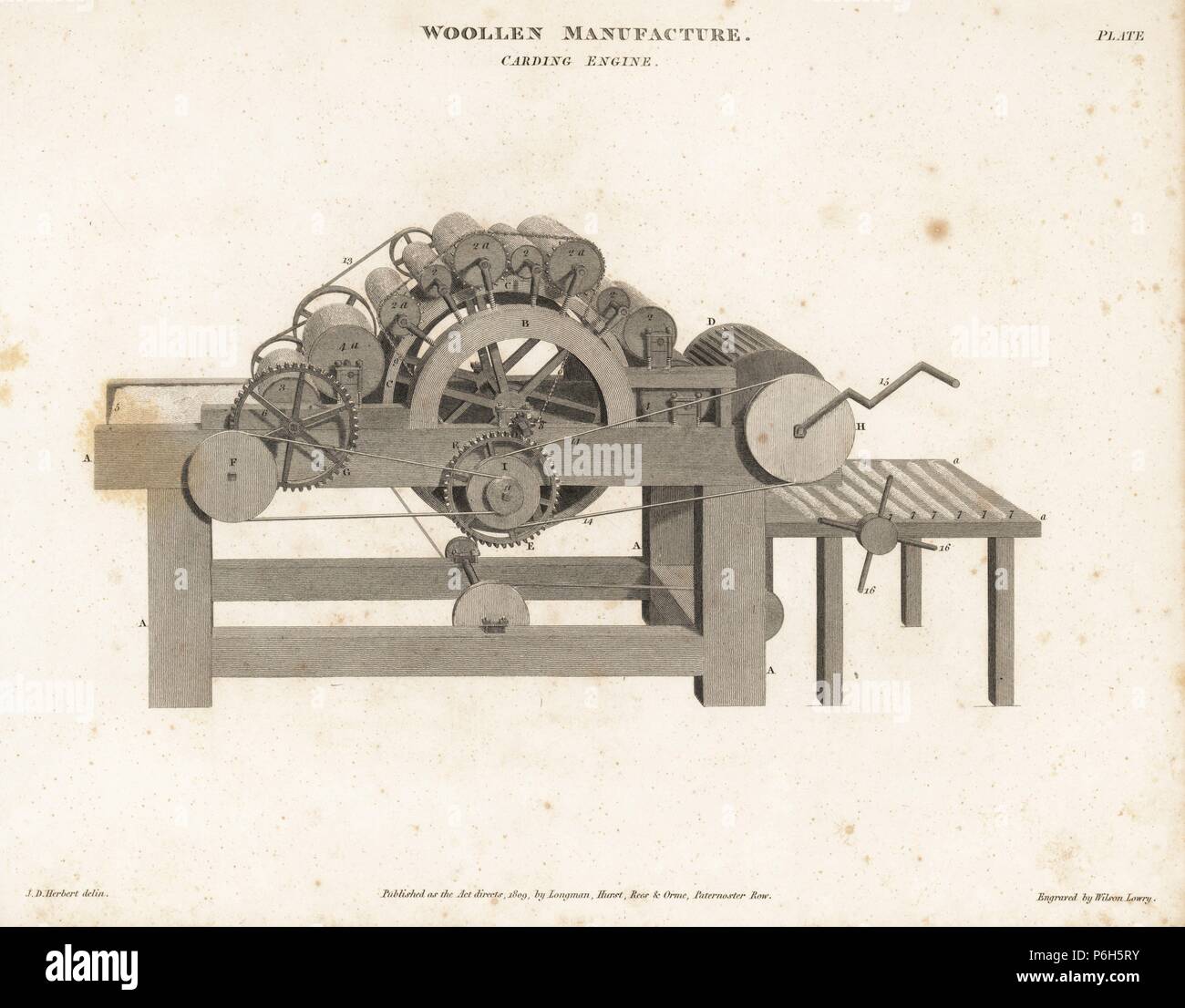

Carding engine used for wool manufacture, 18th century. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-carding-engine-used-for-wool-manufacture-18th-century-72535505.html

Carding engine used for wool manufacture, 18th century. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-carding-engine-used-for-wool-manufacture-18th-century-72535505.htmlRME607NN–Carding engine used for wool manufacture, 18th century.

A breaker carding machine used in the cotton and textile industry. Carding is a technique used to disentangle, clean, and mix fibres such as cotton or wool. From A Concise History of The International Exhibition of 1862, published 1862. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/a-breaker-carding-machine-used-in-the-cotton-and-textile-industry-carding-is-a-technique-used-to-disentangle-clean-and-mix-fibres-such-as-cotton-or-wool-from-a-concise-history-of-the-international-exhibition-of-1862-published-1862-image425932117.html

A breaker carding machine used in the cotton and textile industry. Carding is a technique used to disentangle, clean, and mix fibres such as cotton or wool. From A Concise History of The International Exhibition of 1862, published 1862. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/a-breaker-carding-machine-used-in-the-cotton-and-textile-industry-carding-is-a-technique-used-to-disentangle-clean-and-mix-fibres-such-as-cotton-or-wool-from-a-concise-history-of-the-international-exhibition-of-1862-published-1862-image425932117.htmlRM2FMXTN9–A breaker carding machine used in the cotton and textile industry. Carding is a technique used to disentangle, clean, and mix fibres such as cotton or wool. From A Concise History of The International Exhibition of 1862, published 1862.

Carding engine used for wool manufacture, 18th century. Copperplate engraving by Wilson Lowry from Abraham Rees' 'Cyclopedia or Universal Dictionary,' London, 1809. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-engine-used-for-wool-manufacture-18th-century-copperplate-engraving-by-wilson-lowry-from-abraham-rees-cyclopedia-or-universal-dictionary-london-1809-image210590127.html

Carding engine used for wool manufacture, 18th century. Copperplate engraving by Wilson Lowry from Abraham Rees' 'Cyclopedia or Universal Dictionary,' London, 1809. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-engine-used-for-wool-manufacture-18th-century-copperplate-engraving-by-wilson-lowry-from-abraham-rees-cyclopedia-or-universal-dictionary-london-1809-image210590127.htmlRMP6H5RY–Carding engine used for wool manufacture, 18th century. Copperplate engraving by Wilson Lowry from Abraham Rees' 'Cyclopedia or Universal Dictionary,' London, 1809.

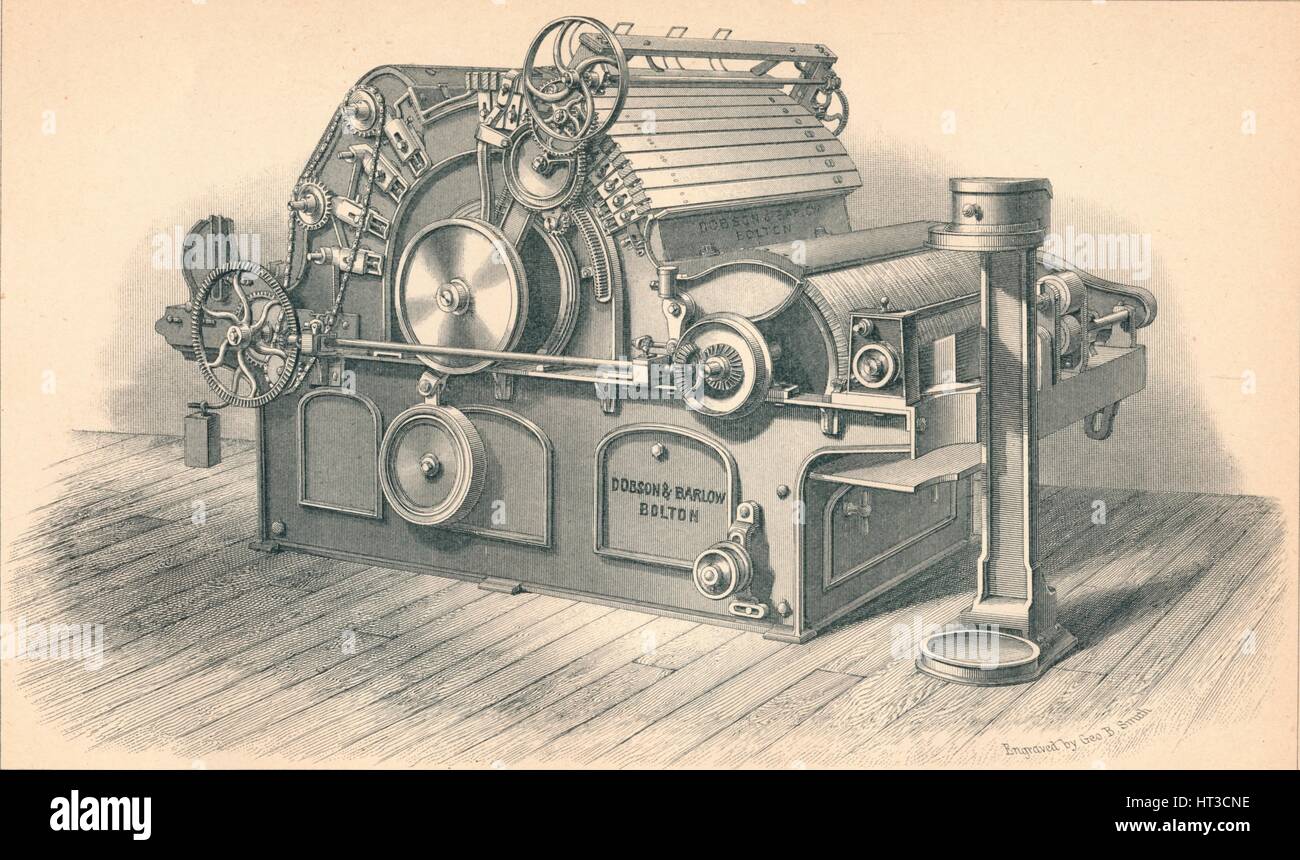

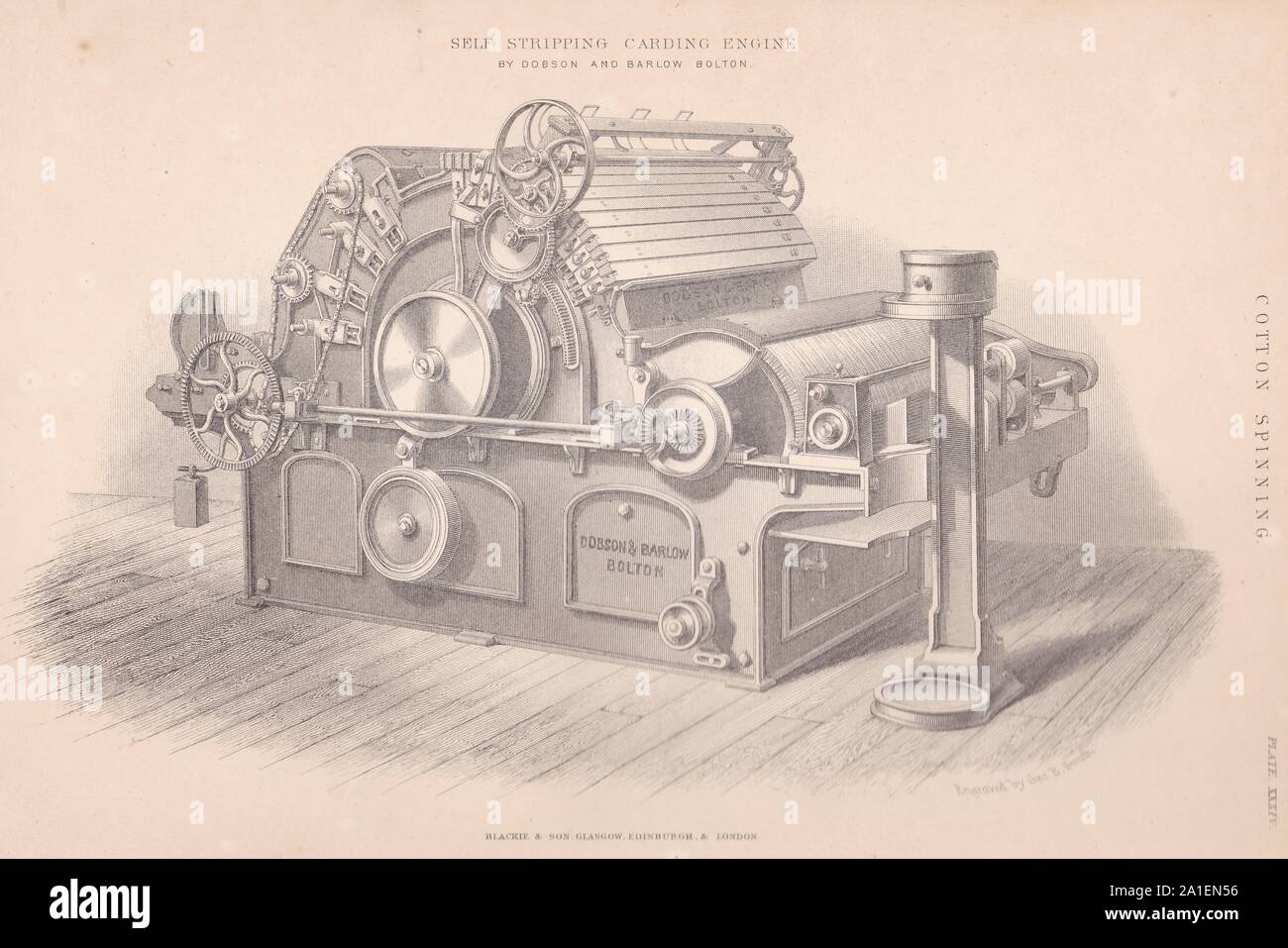

Self Stripping Carding Engine, by Dobson and Barlow Bolton', 1874. Artist: GB Smith. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/self-stripping-carding-engine-by-dobson-and-barlow-bolton-1874-artist-gb-smith-image262791510.html

Self Stripping Carding Engine, by Dobson and Barlow Bolton', 1874. Artist: GB Smith. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/self-stripping-carding-engine-by-dobson-and-barlow-bolton-1874-artist-gb-smith-image262791510.htmlRMW7F572–Self Stripping Carding Engine, by Dobson and Barlow Bolton', 1874. Artist: GB Smith.

Self Stripping Carding Engine, by Dobson and Barlow Bolton', 1874. Artist: GB Smith. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-self-stripping-carding-engine-by-dobson-and-barlow-bolton-1874-artist-135300186.html

Self Stripping Carding Engine, by Dobson and Barlow Bolton', 1874. Artist: GB Smith. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-self-stripping-carding-engine-by-dobson-and-barlow-bolton-1874-artist-135300186.htmlRMHT3CNE–Self Stripping Carding Engine, by Dobson and Barlow Bolton', 1874. Artist: GB Smith.

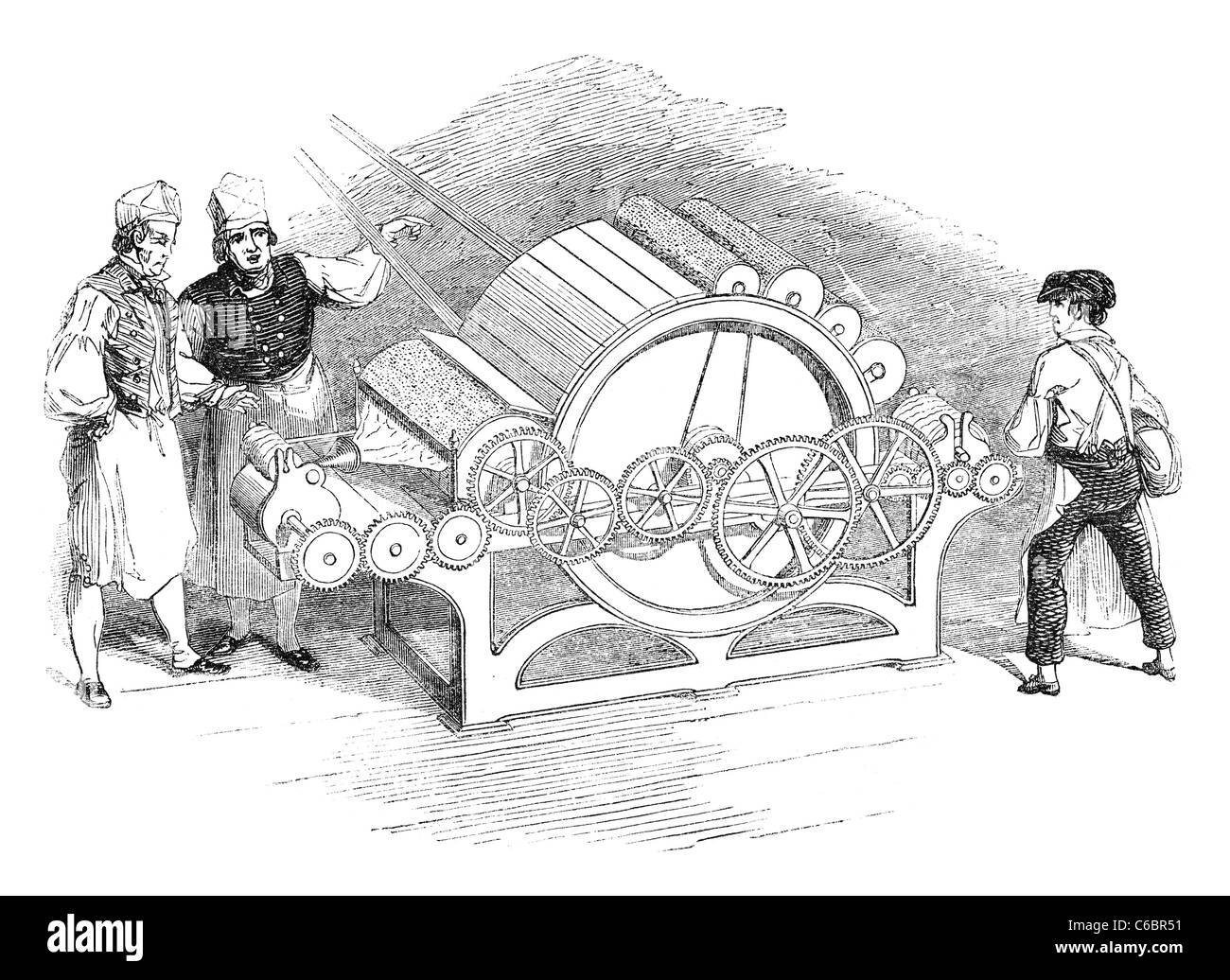

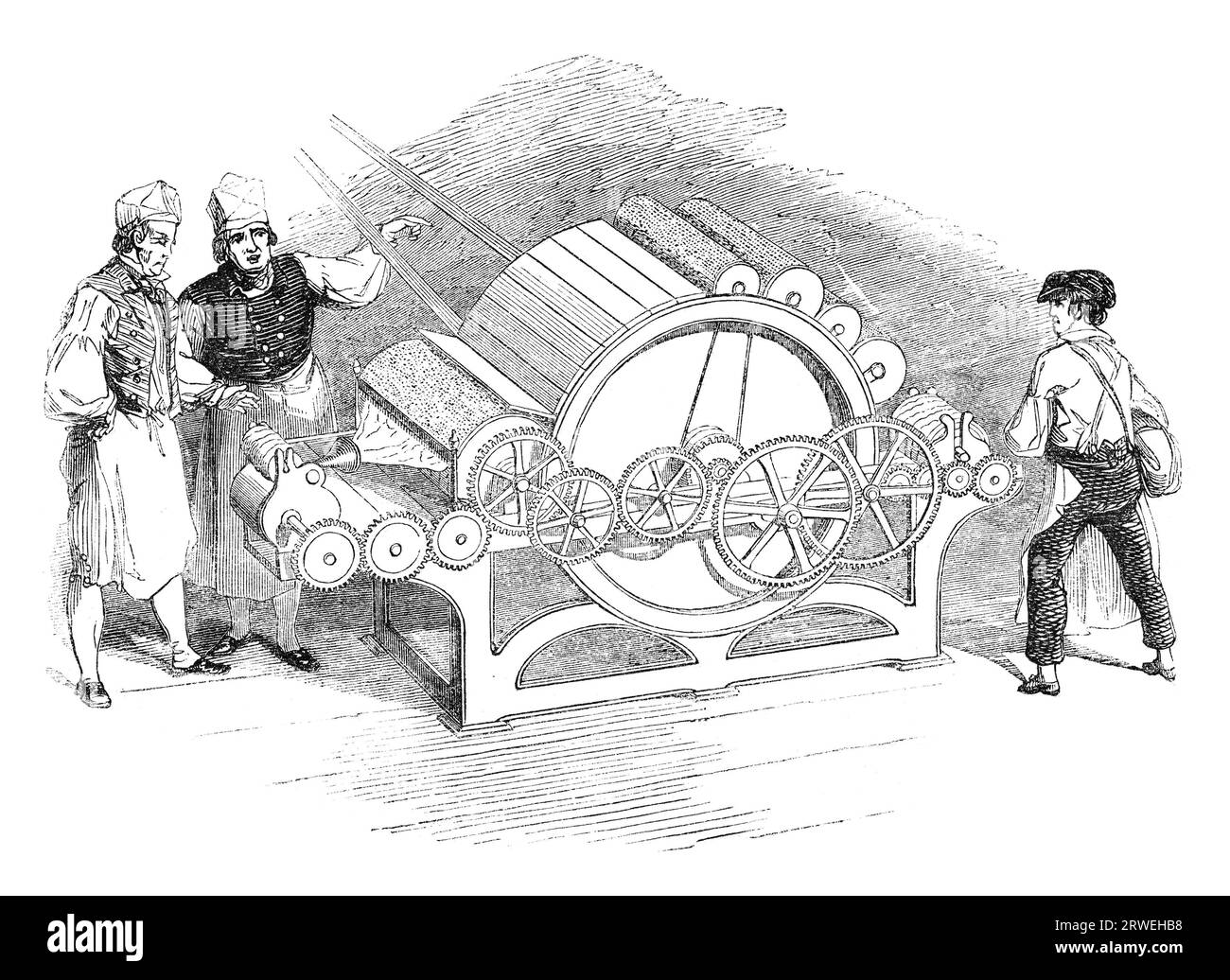

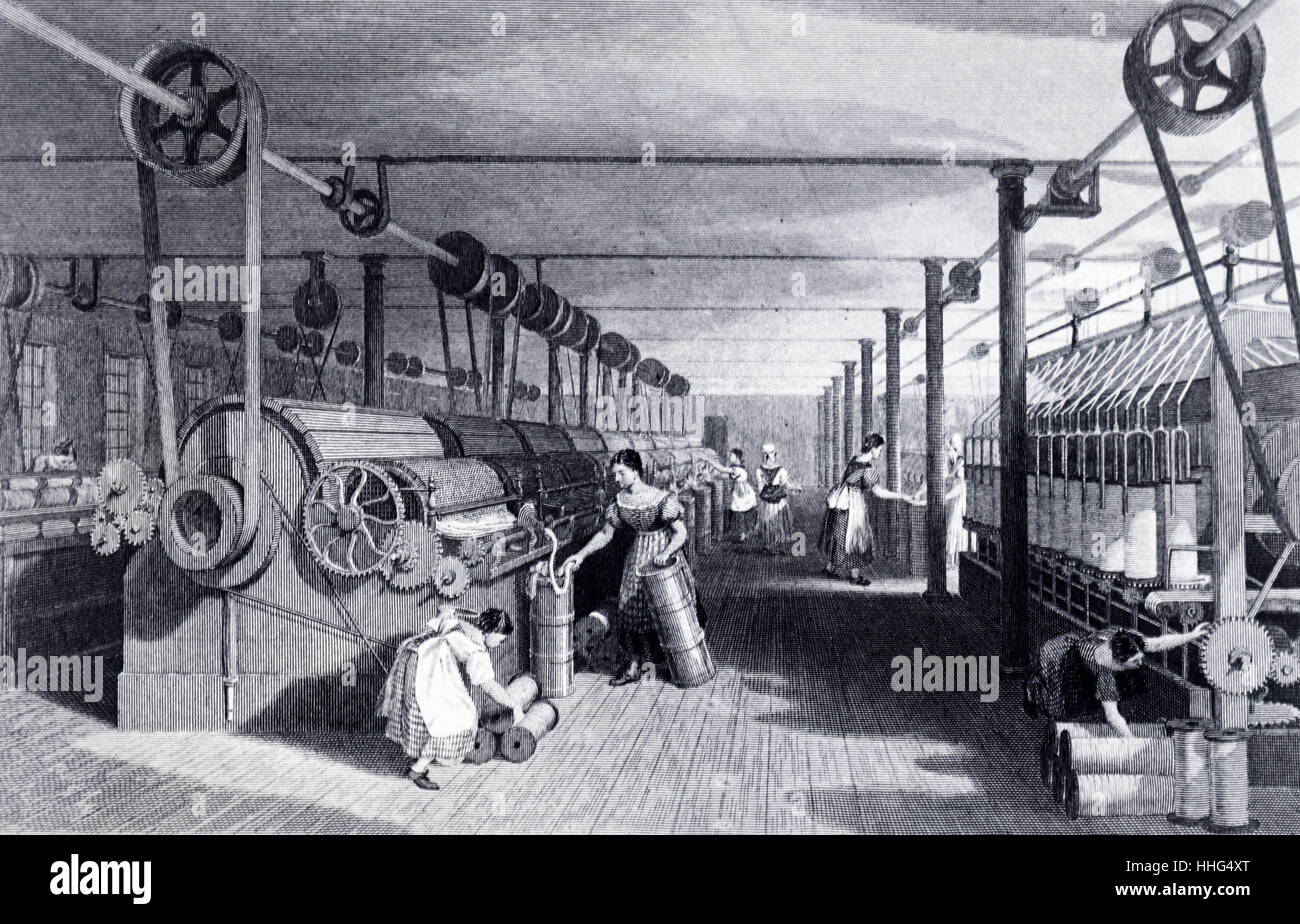

A Day at a Cotton Factory in Manchester: Carding-engine and factory operatives. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-a-day-at-a-cotton-factory-in-manchester-carding-engine-and-factory-38368317.html

A Day at a Cotton Factory in Manchester: Carding-engine and factory operatives. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-a-day-at-a-cotton-factory-in-manchester-carding-engine-and-factory-38368317.htmlRMC6BR51–A Day at a Cotton Factory in Manchester: Carding-engine and factory operatives.

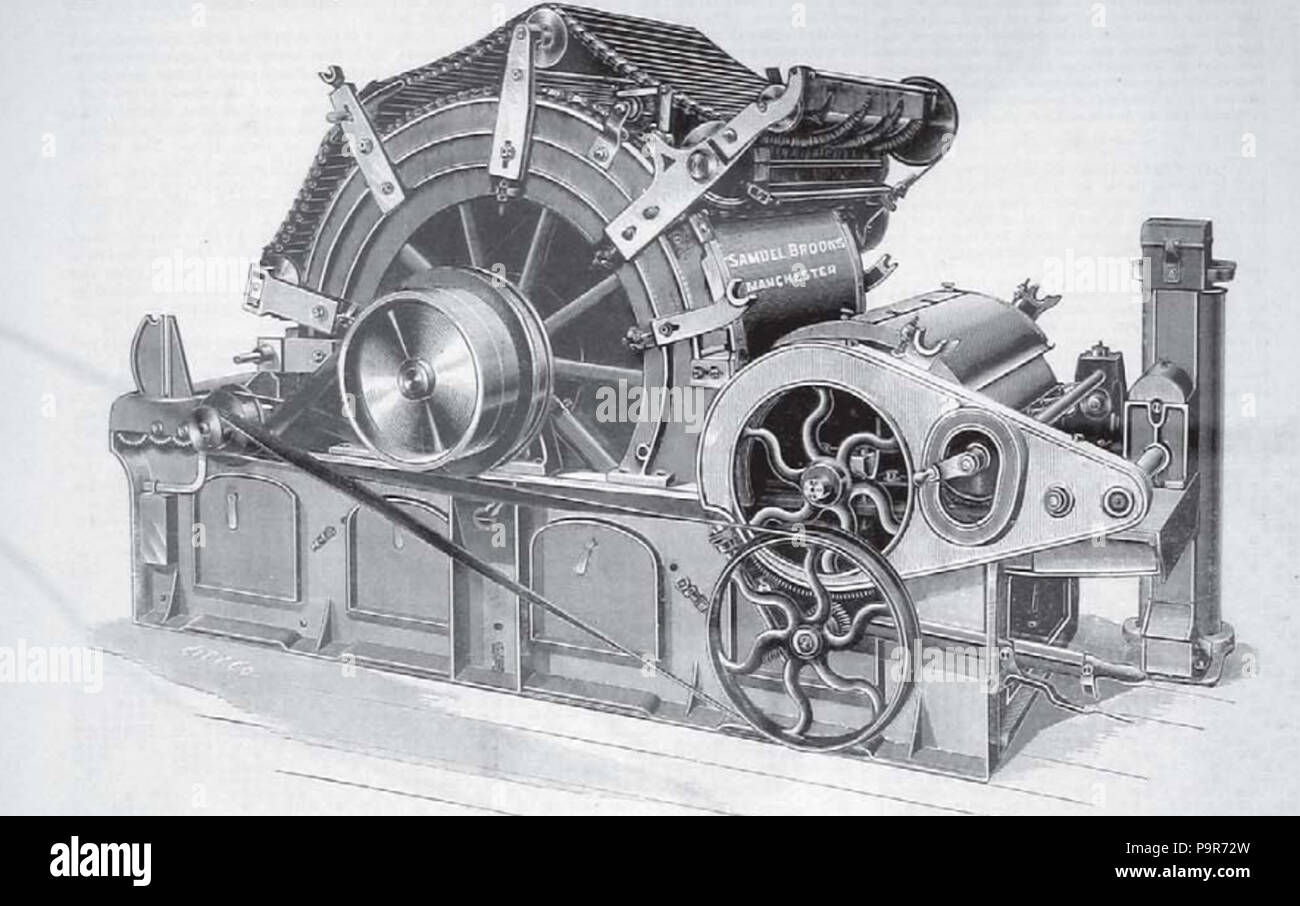

252 Brooks and Doxey Carding Engine TM142 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/252-brooks-and-doxey-carding-engine-tm142-image212566785.html

252 Brooks and Doxey Carding Engine TM142 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/252-brooks-and-doxey-carding-engine-tm142-image212566785.htmlRMP9R72W–252 Brooks and Doxey Carding Engine TM142

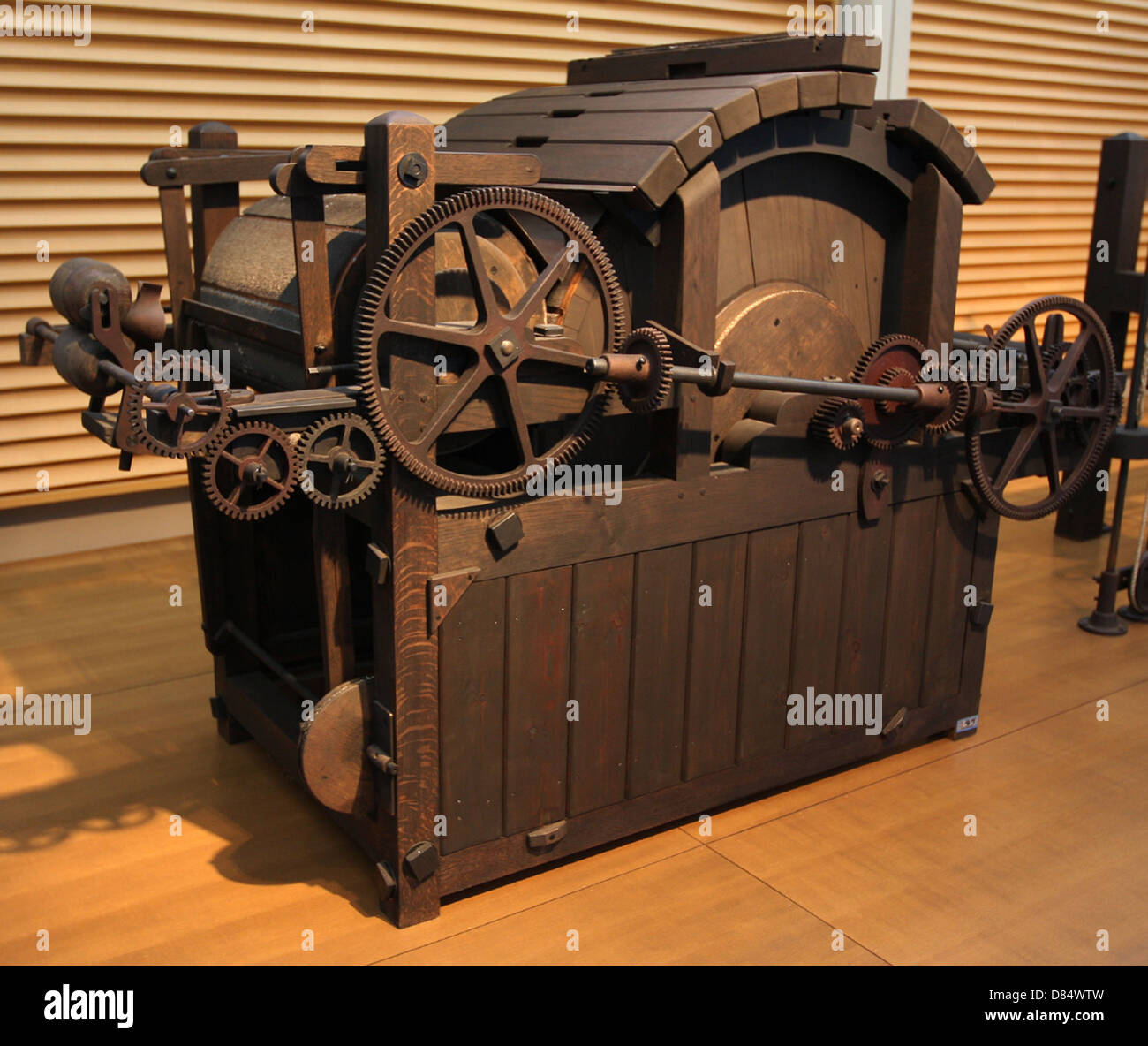

1775 Arkwright Carding Engine (replica). Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-1775-arkwright-carding-engine-replica-56656457.html

1775 Arkwright Carding Engine (replica). Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-1775-arkwright-carding-engine-replica-56656457.htmlRMD84WTW–1775 Arkwright Carding Engine (replica).

Book plate of Self Stripping Carding Engine by Dodson and Barlow, Bolton. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/book-plate-of-self-stripping-carding-engine-by-dodson-and-barlow-bolton-image327935586.html

Book plate of Self Stripping Carding Engine by Dodson and Barlow, Bolton. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/book-plate-of-self-stripping-carding-engine-by-dodson-and-barlow-bolton-image327935586.htmlRF2A1EN56–Book plate of Self Stripping Carding Engine by Dodson and Barlow, Bolton.

![The International Exhibition - cotton manufacture: machinery of Platt Brothers, Oldham, 1862. Fig. 1 the Macarthy Gin; Fig. 4. the Carding-engine...The purpose of [the gin] is to separate the cotton fibre from its seed, pieces of the pod, sheath, or any other matter...The cotton...requires now to be still further cleaned, and the fibres combed and separated to the greatest minuteness. This is done by passing the fleece through a series of machines called carding-engines...They are called carding-engines because they operate by means of cards'. From "Illustrated London News", 1862. Stock Photo The International Exhibition - cotton manufacture: machinery of Platt Brothers, Oldham, 1862. Fig. 1 the Macarthy Gin; Fig. 4. the Carding-engine...The purpose of [the gin] is to separate the cotton fibre from its seed, pieces of the pod, sheath, or any other matter...The cotton...requires now to be still further cleaned, and the fibres combed and separated to the greatest minuteness. This is done by passing the fleece through a series of machines called carding-engines...They are called carding-engines because they operate by means of cards'. From "Illustrated London News", 1862. Stock Photo](https://c8.alamy.com/comp/2WG0JJ0/the-international-exhibition-cotton-manufacture-machinery-of-platt-brothers-oldham-1862-fig-1-the-macarthy-gin-fig-4-the-carding-enginethe-purpose-of-the-gin-is-to-separate-the-cotton-fibre-from-its-seed-pieces-of-the-pod-sheath-or-any-other-matterthe-cottonrequires-now-to-be-still-further-cleaned-and-the-fibres-combed-and-separated-to-the-greatest-minuteness-this-is-done-by-passing-the-fleece-through-a-series-of-machines-called-carding-enginesthey-are-called-carding-engines-because-they-operate-by-means-of-cards-from-quotillustrated-london-newsquot-1862-2WG0JJ0.jpg) The International Exhibition - cotton manufacture: machinery of Platt Brothers, Oldham, 1862. Fig. 1 the Macarthy Gin; Fig. 4. the Carding-engine...The purpose of [the gin] is to separate the cotton fibre from its seed, pieces of the pod, sheath, or any other matter...The cotton...requires now to be still further cleaned, and the fibres combed and separated to the greatest minuteness. This is done by passing the fleece through a series of machines called carding-engines...They are called carding-engines because they operate by means of cards'. From "Illustrated London News", 1862. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-international-exhibition-cotton-manufacture-machinery-of-platt-brothers-oldham-1862-fig-1-the-macarthy-gin-fig-4-the-carding-enginethe-purpose-of-the-gin-is-to-separate-the-cotton-fibre-from-its-seed-pieces-of-the-pod-sheath-or-any-other-matterthe-cottonrequires-now-to-be-still-further-cleaned-and-the-fibres-combed-and-separated-to-the-greatest-minuteness-this-is-done-by-passing-the-fleece-through-a-series-of-machines-called-carding-enginesthey-are-called-carding-engines-because-they-operate-by-means-of-cards-from-quotillustrated-london-newsquot-1862-image595001624.html

The International Exhibition - cotton manufacture: machinery of Platt Brothers, Oldham, 1862. Fig. 1 the Macarthy Gin; Fig. 4. the Carding-engine...The purpose of [the gin] is to separate the cotton fibre from its seed, pieces of the pod, sheath, or any other matter...The cotton...requires now to be still further cleaned, and the fibres combed and separated to the greatest minuteness. This is done by passing the fleece through a series of machines called carding-engines...They are called carding-engines because they operate by means of cards'. From "Illustrated London News", 1862. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-international-exhibition-cotton-manufacture-machinery-of-platt-brothers-oldham-1862-fig-1-the-macarthy-gin-fig-4-the-carding-enginethe-purpose-of-the-gin-is-to-separate-the-cotton-fibre-from-its-seed-pieces-of-the-pod-sheath-or-any-other-matterthe-cottonrequires-now-to-be-still-further-cleaned-and-the-fibres-combed-and-separated-to-the-greatest-minuteness-this-is-done-by-passing-the-fleece-through-a-series-of-machines-called-carding-enginesthey-are-called-carding-engines-because-they-operate-by-means-of-cards-from-quotillustrated-london-newsquot-1862-image595001624.htmlRM2WG0JJ0–The International Exhibition - cotton manufacture: machinery of Platt Brothers, Oldham, 1862. Fig. 1 the Macarthy Gin; Fig. 4. the Carding-engine...The purpose of [the gin] is to separate the cotton fibre from its seed, pieces of the pod, sheath, or any other matter...The cotton...requires now to be still further cleaned, and the fibres combed and separated to the greatest minuteness. This is done by passing the fleece through a series of machines called carding-engines...They are called carding-engines because they operate by means of cards'. From "Illustrated London News", 1862.

A Day at a Cotton Factory in Manchester: Carding-engine and factory operatives. Engraving from a british magazine printed in 1843 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/a-day-at-a-cotton-factory-in-manchester-carding-engine-and-factory-operatives-engraving-from-a-british-magazine-printed-in-1843-image566419148.html

A Day at a Cotton Factory in Manchester: Carding-engine and factory operatives. Engraving from a british magazine printed in 1843 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/a-day-at-a-cotton-factory-in-manchester-carding-engine-and-factory-operatives-engraving-from-a-british-magazine-printed-in-1843-image566419148.htmlRM2RWEHB8–A Day at a Cotton Factory in Manchester: Carding-engine and factory operatives. Engraving from a british magazine printed in 1843

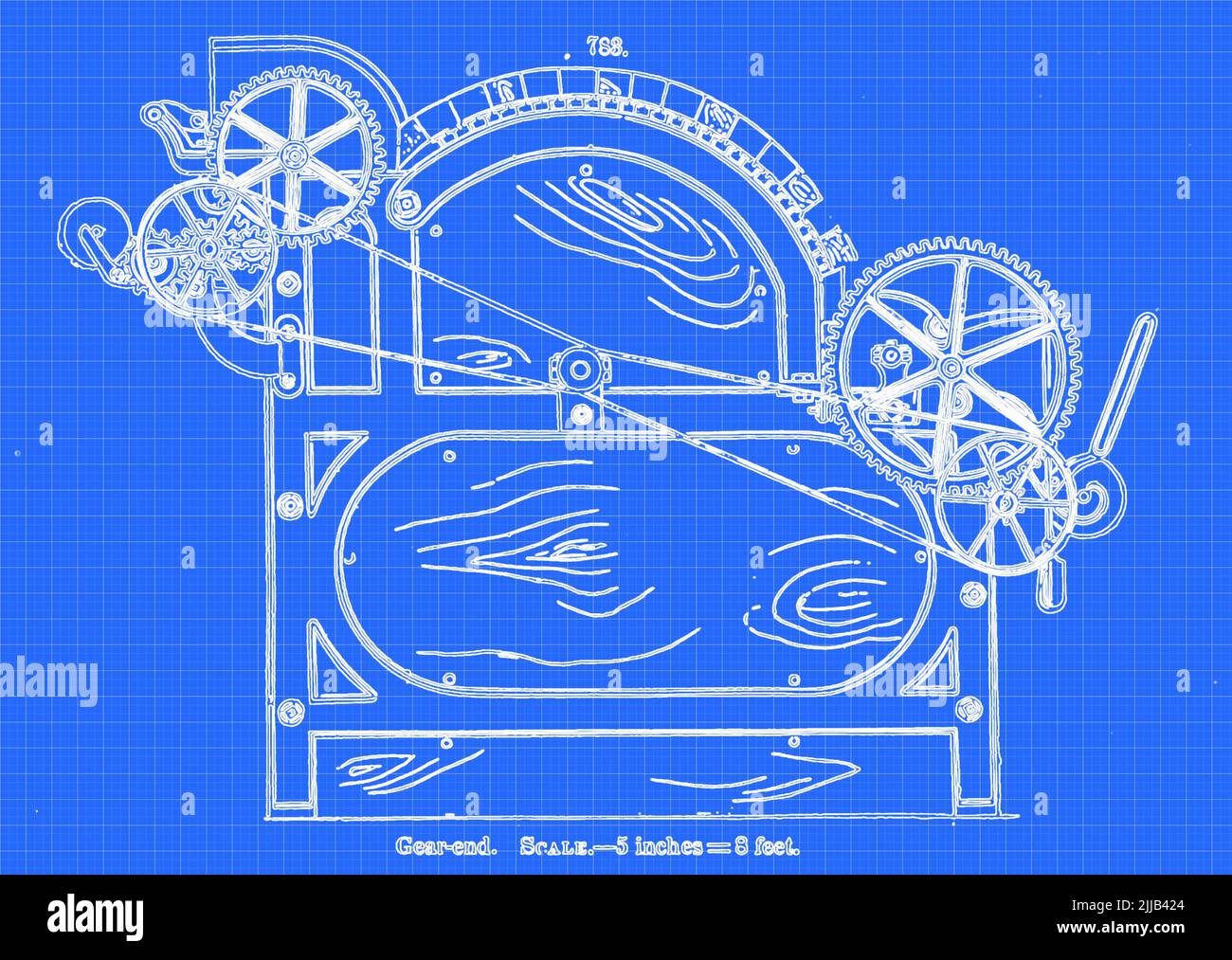

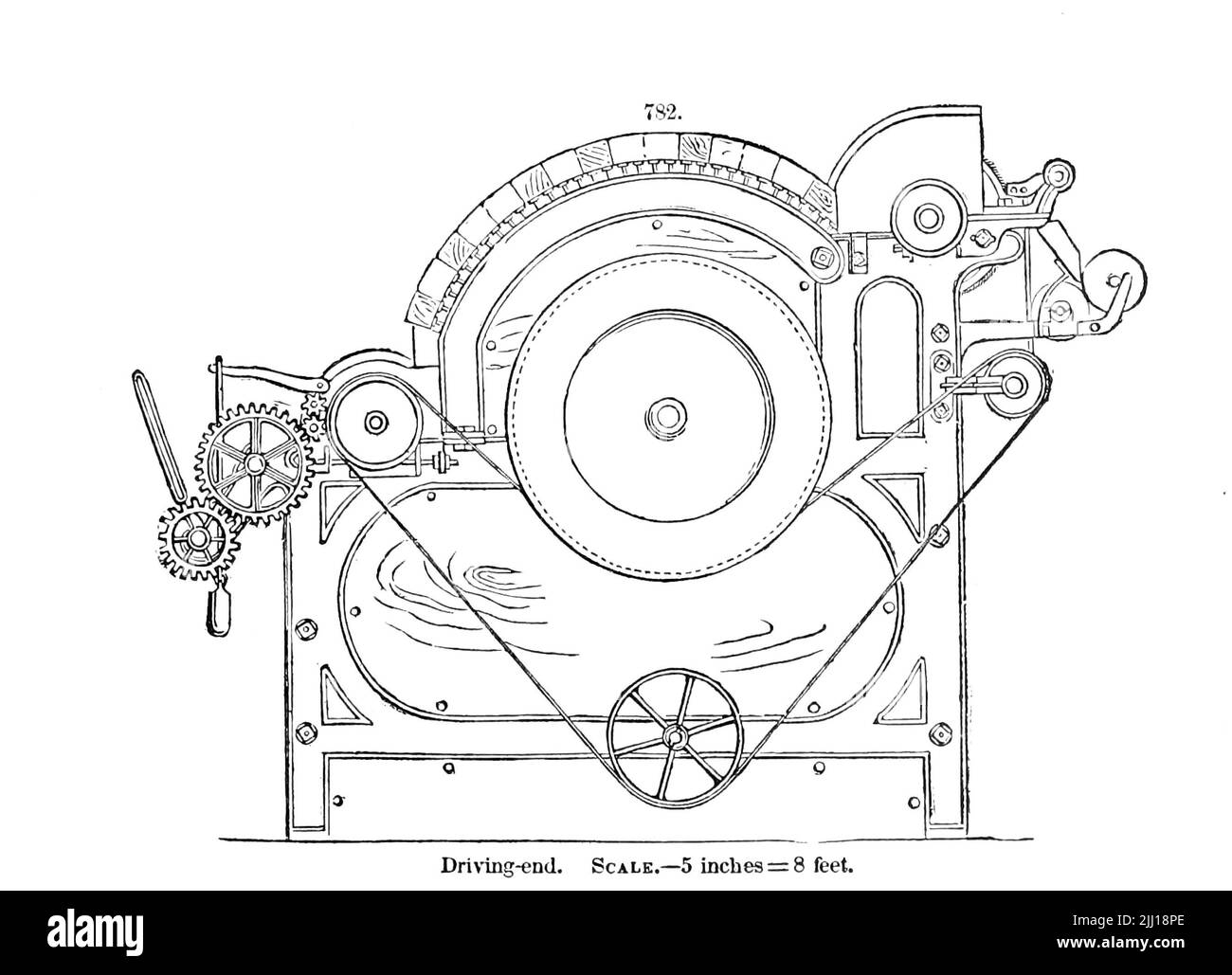

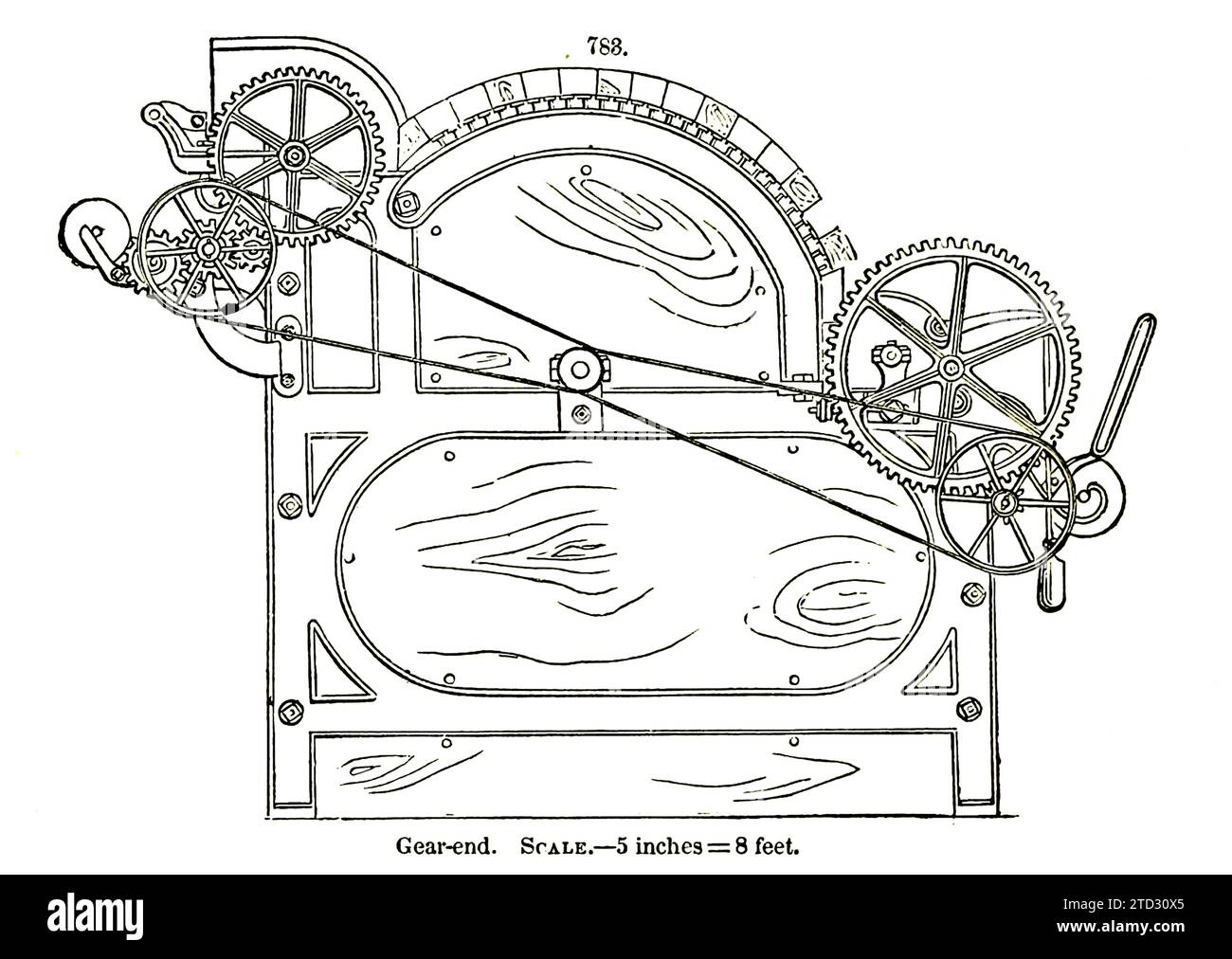

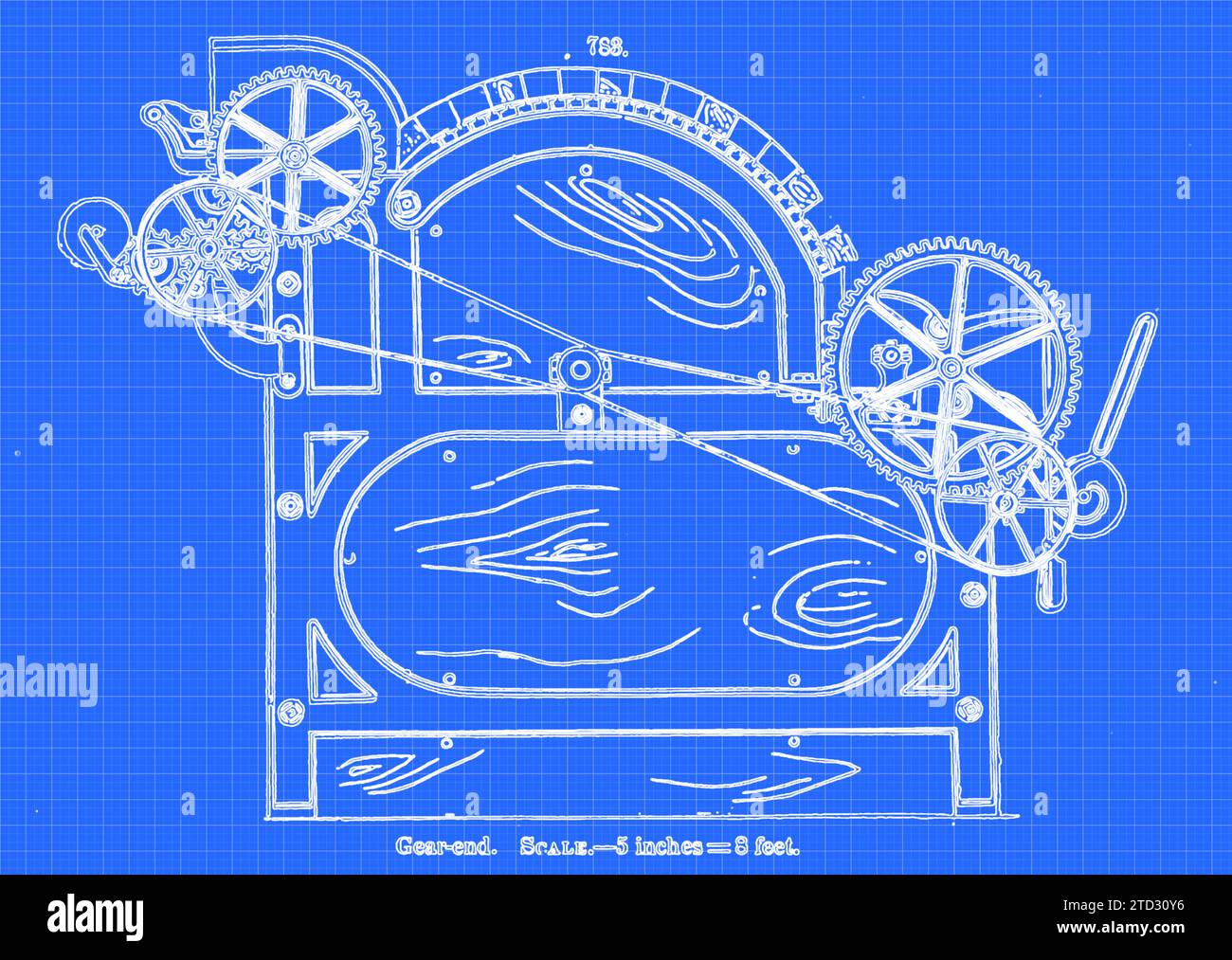

Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with 'card clothing', a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing from ' Appleton's dictionary of machines, mechanics, engine-work, and engineering ' Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-is-a-mechanical-process-that-disentangles-cleans-and-intermixes-fibres-to-produce-a-continuous-web-or-sliver-suitable-for-subsequent-processing-this-is-achieved-by-passing-the-fibres-between-differentially-moving-surfaces-covered-with-card-clothing-a-firm-flexible-material-embedded-with-metal-pins-it-breaks-up-locks-and-unorganised-clumps-of-fibre-and-then-aligns-the-individual-fibres-to-be-parallel-with-each-other-in-preparing-wool-fibre-for-spinning-carding-is-the-step-that-comes-after-teasing-from-appletons-dictionary-of-machines-mechanics-engine-work-and-engineering-image475988412.html

Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with 'card clothing', a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing from ' Appleton's dictionary of machines, mechanics, engine-work, and engineering ' Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-is-a-mechanical-process-that-disentangles-cleans-and-intermixes-fibres-to-produce-a-continuous-web-or-sliver-suitable-for-subsequent-processing-this-is-achieved-by-passing-the-fibres-between-differentially-moving-surfaces-covered-with-card-clothing-a-firm-flexible-material-embedded-with-metal-pins-it-breaks-up-locks-and-unorganised-clumps-of-fibre-and-then-aligns-the-individual-fibres-to-be-parallel-with-each-other-in-preparing-wool-fibre-for-spinning-carding-is-the-step-that-comes-after-teasing-from-appletons-dictionary-of-machines-mechanics-engine-work-and-engineering-image475988412.htmlRF2JJB424–Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with 'card clothing', a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing from ' Appleton's dictionary of machines, mechanics, engine-work, and engineering '

Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with 'card clothing', a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing from ' Appleton's dictionary of machines, mechanics, engine-work, and engineering ' Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-is-a-mechanical-process-that-disentangles-cleans-and-intermixes-fibres-to-produce-a-continuous-web-or-sliver-suitable-for-subsequent-processing-this-is-achieved-by-passing-the-fibres-between-differentially-moving-surfaces-covered-with-card-clothing-a-firm-flexible-material-embedded-with-metal-pins-it-breaks-up-locks-and-unorganised-clumps-of-fibre-and-then-aligns-the-individual-fibres-to-be-parallel-with-each-other-in-preparing-wool-fibre-for-spinning-carding-is-the-step-that-comes-after-teasing-from-appletons-dictionary-of-machines-mechanics-engine-work-and-engineering-image475772598.html

Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with 'card clothing', a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing from ' Appleton's dictionary of machines, mechanics, engine-work, and engineering ' Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-is-a-mechanical-process-that-disentangles-cleans-and-intermixes-fibres-to-produce-a-continuous-web-or-sliver-suitable-for-subsequent-processing-this-is-achieved-by-passing-the-fibres-between-differentially-moving-surfaces-covered-with-card-clothing-a-firm-flexible-material-embedded-with-metal-pins-it-breaks-up-locks-and-unorganised-clumps-of-fibre-and-then-aligns-the-individual-fibres-to-be-parallel-with-each-other-in-preparing-wool-fibre-for-spinning-carding-is-the-step-that-comes-after-teasing-from-appletons-dictionary-of-machines-mechanics-engine-work-and-engineering-image475772598.htmlRF2JJ18PE–Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with 'card clothing', a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing from ' Appleton's dictionary of machines, mechanics, engine-work, and engineering '

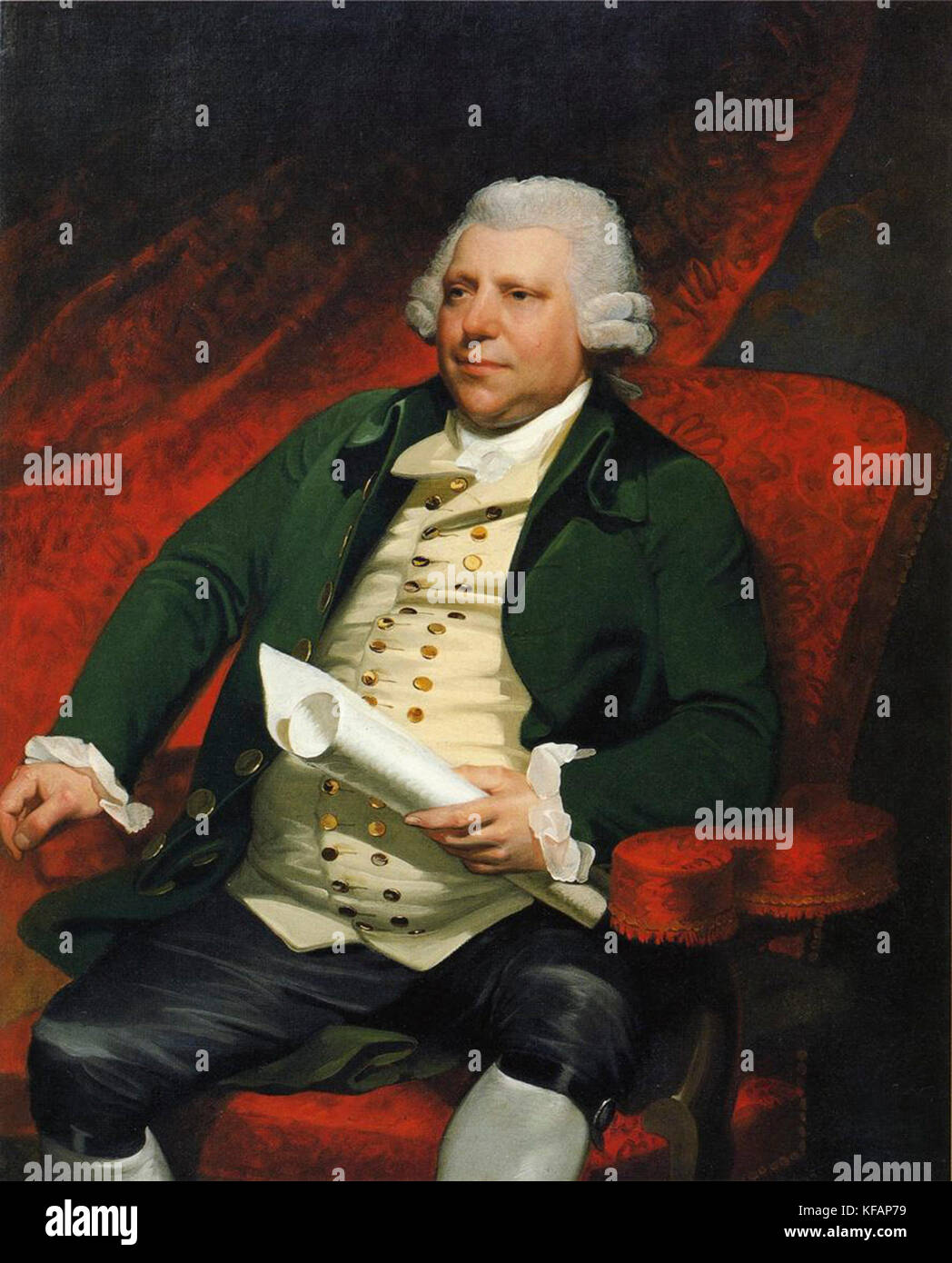

Sir Richard Arkwright, English inventor and a leading entrepreneur during the early Industrial Revolution. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-image-sir-richard-arkwright-english-inventor-and-a-leading-entrepreneur-164350125.html

Sir Richard Arkwright, English inventor and a leading entrepreneur during the early Industrial Revolution. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-image-sir-richard-arkwright-english-inventor-and-a-leading-entrepreneur-164350125.htmlRMKFAP79–Sir Richard Arkwright, English inventor and a leading entrepreneur during the early Industrial Revolution.

Sectional view of a carding engine: this machine brushed and separated the cotton fibres. Dated 1866 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-sectional-view-of-a-carding-engine-this-machine-brushed-and-separated-131276838.html

Sectional view of a carding engine: this machine brushed and separated the cotton fibres. Dated 1866 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-sectional-view-of-a-carding-engine-this-machine-brushed-and-separated-131276838.htmlRMHHG4XE–Sectional view of a carding engine: this machine brushed and separated the cotton fibres. Dated 1866

. A dictionary of arts, manufactures and mines : containing a clear exposition of their principles and practice. nvention of Lewis Paul of Northampton, but were greatly improvedand brought into nearly their present operative state by Sir Richard Arkwright. A 23 354 COTTON MANUFACTURE. carding engine consists of one or more cylinders, covered wilh card-leatlier (sometimescalled ^card cloth), and a set of plane surfaces similarly covered, made to work againsteach other, but so that their points do not come into absolute contact. Some cardsconsist entirely of cylinders, the central main cylinder Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/a-dictionary-of-arts-manufactures-and-mines-containing-a-clear-exposition-of-their-principles-and-practice-nvention-of-lewis-paul-of-northampton-but-were-greatly-improvedand-brought-into-nearly-their-present-operative-state-by-sir-richard-arkwright-a-23-354-cotton-manufacture-carding-engine-consists-of-one-or-more-cylinders-covered-wilh-card-leatlier-sometimescalled-card-cloth-and-a-set-of-plane-surfaces-similarly-covered-made-to-work-againsteach-other-but-so-that-their-points-do-not-come-into-absolute-contact-some-cardsconsist-entirely-of-cylinders-the-central-main-cylinder-image337045939.html

. A dictionary of arts, manufactures and mines : containing a clear exposition of their principles and practice. nvention of Lewis Paul of Northampton, but were greatly improvedand brought into nearly their present operative state by Sir Richard Arkwright. A 23 354 COTTON MANUFACTURE. carding engine consists of one or more cylinders, covered wilh card-leatlier (sometimescalled ^card cloth), and a set of plane surfaces similarly covered, made to work againsteach other, but so that their points do not come into absolute contact. Some cardsconsist entirely of cylinders, the central main cylinder Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/a-dictionary-of-arts-manufactures-and-mines-containing-a-clear-exposition-of-their-principles-and-practice-nvention-of-lewis-paul-of-northampton-but-were-greatly-improvedand-brought-into-nearly-their-present-operative-state-by-sir-richard-arkwright-a-23-354-cotton-manufacture-carding-engine-consists-of-one-or-more-cylinders-covered-wilh-card-leatlier-sometimescalled-card-cloth-and-a-set-of-plane-surfaces-similarly-covered-made-to-work-againsteach-other-but-so-that-their-points-do-not-come-into-absolute-contact-some-cardsconsist-entirely-of-cylinders-the-central-main-cylinder-image337045939.htmlRM2AG9NEY–. A dictionary of arts, manufactures and mines : containing a clear exposition of their principles and practice. nvention of Lewis Paul of Northampton, but were greatly improvedand brought into nearly their present operative state by Sir Richard Arkwright. A 23 354 COTTON MANUFACTURE. carding engine consists of one or more cylinders, covered wilh card-leatlier (sometimescalled ^card cloth), and a set of plane surfaces similarly covered, made to work againsteach other, but so that their points do not come into absolute contact. Some cardsconsist entirely of cylinders, the central main cylinder

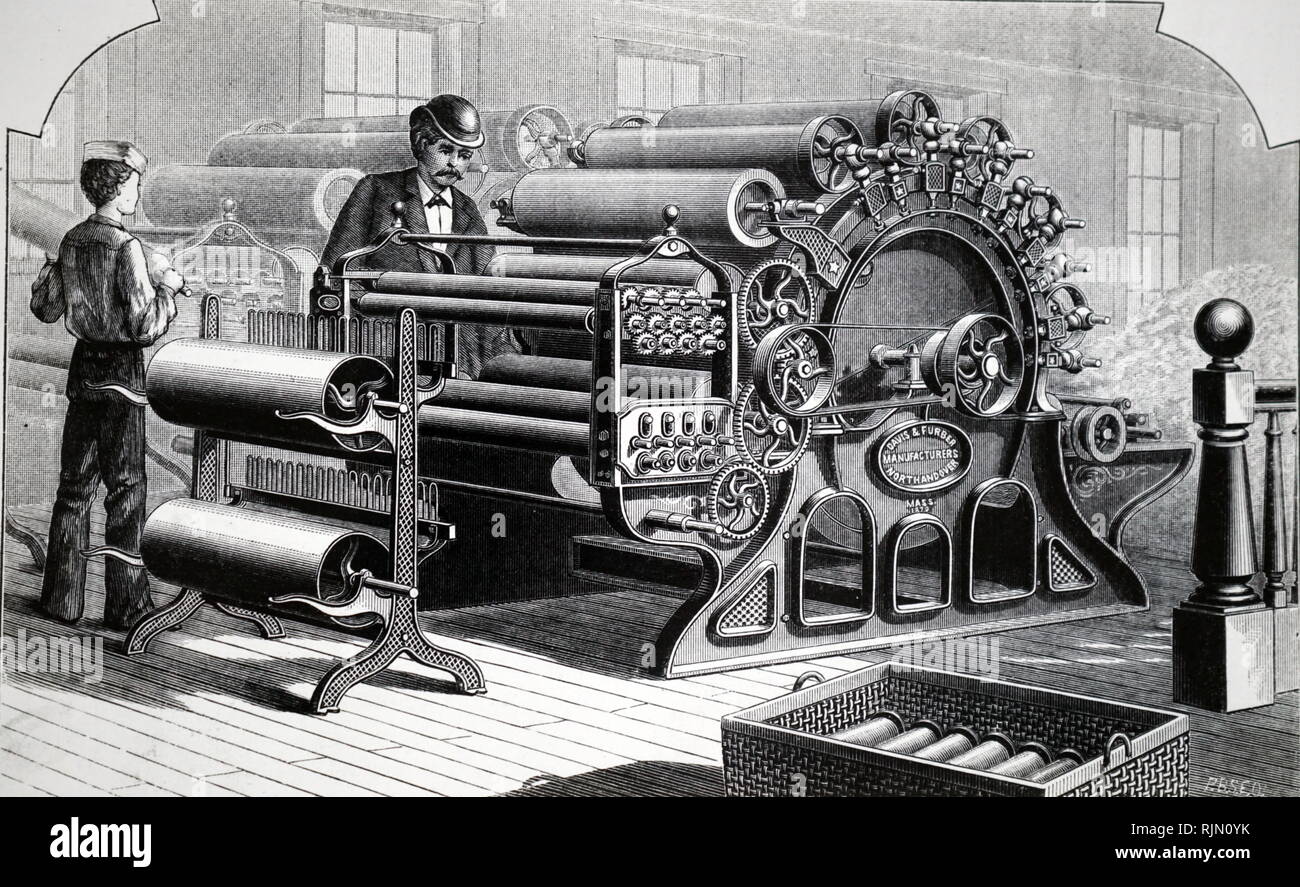

Illustration showing Wool carding engine by Davis & Furber, North Andover, Mass, USA 1880 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/illustration-showing-wool-carding-engine-by-davis-furber-north-andover-mass-usa-1880-image235260359.html

Illustration showing Wool carding engine by Davis & Furber, North Andover, Mass, USA 1880 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/illustration-showing-wool-carding-engine-by-davis-furber-north-andover-mass-usa-1880-image235260359.htmlRMRJN0YK–Illustration showing Wool carding engine by Davis & Furber, North Andover, Mass, USA 1880

Carding machine, illustration. Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver s Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-machine-illustration-carding-is-a-mechanical-process-that-disentangles-cleans-and-intermixes-fibres-to-produce-a-continuous-web-or-sliver-s-image575999261.html

Carding machine, illustration. Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver s Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-machine-illustration-carding-is-a-mechanical-process-that-disentangles-cleans-and-intermixes-fibres-to-produce-a-continuous-web-or-sliver-s-image575999261.htmlRF2TD30X5–Carding machine, illustration. Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver s

Sir Richard Arkwright, 1732-1792, a leading entrepreneur during the early Industrial Revolution, Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-sir-richard-arkwright-1732-1792-a-leading-entrepreneur-during-the-91720755.html

Sir Richard Arkwright, 1732-1792, a leading entrepreneur during the early Industrial Revolution, Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-sir-richard-arkwright-1732-1792-a-leading-entrepreneur-during-the-91720755.htmlRMF966N7–Sir Richard Arkwright, 1732-1792, a leading entrepreneur during the early Industrial Revolution,

360 degree panoramic view of Carding roomhttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/360-degree-panoramic-view-of-carding-room-image219501022.html

360 degree panoramic view of Carding roomhttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/360-degree-panoramic-view-of-carding-room-image219501022.htmlRF360°PN33P6–Carding room

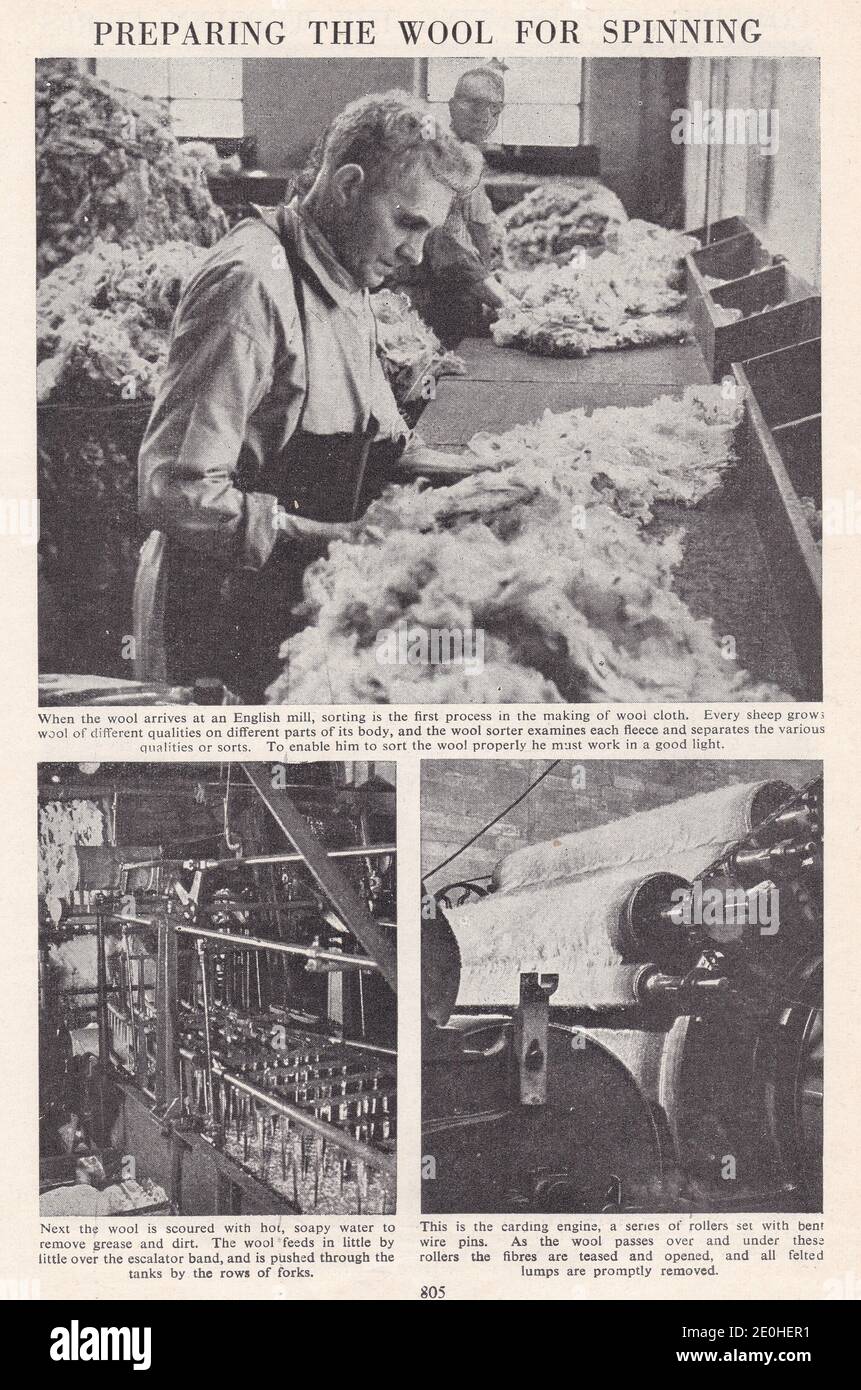

Vintage photos of the manufacturing of wool 1900s - Preparing the wool for spinning. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/vintage-photos-of-the-manufacturing-of-wool-1900s-preparing-the-wool-for-spinning-image396223269.html

Vintage photos of the manufacturing of wool 1900s - Preparing the wool for spinning. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/vintage-photos-of-the-manufacturing-of-wool-1900s-preparing-the-wool-for-spinning-image396223269.htmlRF2E0HER1–Vintage photos of the manufacturing of wool 1900s - Preparing the wool for spinning.

Elevator E. B. Ellington 388715 Embroidering frame and stand H. C. Ludwig 383.533 Engine. See Carding engine. Chemical engine Gas engine. Rotary engine. Steam engine. Envelope fastening W. H. Hubbard 383642 Eraser J. W. Osborne 3834E3 Eye bars blank for W. R. Webster 883509 Eye bars spreading the ends of W. R. Webster 383503 Eyeglasses. W. S. Wells 383604 Faucet filtering W. H. Sargent 883493 Feed cutter G. F. Schmid 383.494 Feeder automatic shelf W. M. Jewell (r) 10933 Fence machine Vandegrift & Maple 383.723 ence portable M. C. Margeson 383475 Fence wile P. C Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/elevator-e-b-ellington-388715-embroidering-frame-and-stand-h-c-ludwig-383533-engine-see-carding-engine-chemical-engine-gas-engine-rotary-engine-steam-engine-envelope-fastening-w-h-hubbard-383642-eraser-j-w-osborne-3834e3-eye-bars-blank-for-w-r-webster-883509-eye-bars-spreading-the-ends-of-w-r-webster-383503-eyeglasses-w-s-wells-383604-faucet-filtering-w-h-sargent-883493-feed-cutter-g-f-schmid-383494-feeder-automatic-shelf-w-m-jewell-r-10933-fence-machine-vandegrift-maple-383723-ence-portable-m-c-margeson-383475-fence-wile-p-c-image334331694.html

Elevator E. B. Ellington 388715 Embroidering frame and stand H. C. Ludwig 383.533 Engine. See Carding engine. Chemical engine Gas engine. Rotary engine. Steam engine. Envelope fastening W. H. Hubbard 383642 Eraser J. W. Osborne 3834E3 Eye bars blank for W. R. Webster 883509 Eye bars spreading the ends of W. R. Webster 383503 Eyeglasses. W. S. Wells 383604 Faucet filtering W. H. Sargent 883493 Feed cutter G. F. Schmid 383.494 Feeder automatic shelf W. M. Jewell (r) 10933 Fence machine Vandegrift & Maple 383.723 ence portable M. C. Margeson 383475 Fence wile P. C Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/elevator-e-b-ellington-388715-embroidering-frame-and-stand-h-c-ludwig-383533-engine-see-carding-engine-chemical-engine-gas-engine-rotary-engine-steam-engine-envelope-fastening-w-h-hubbard-383642-eraser-j-w-osborne-3834e3-eye-bars-blank-for-w-r-webster-883509-eye-bars-spreading-the-ends-of-w-r-webster-383503-eyeglasses-w-s-wells-383604-faucet-filtering-w-h-sargent-883493-feed-cutter-g-f-schmid-383494-feeder-automatic-shelf-w-m-jewell-r-10933-fence-machine-vandegrift-maple-383723-ence-portable-m-c-margeson-383475-fence-wile-p-c-image334331694.htmlRM2ABX3DJ–Elevator E. B. Ellington 388715 Embroidering frame and stand H. C. Ludwig 383.533 Engine. See Carding engine. Chemical engine Gas engine. Rotary engine. Steam engine. Envelope fastening W. H. Hubbard 383642 Eraser J. W. Osborne 3834E3 Eye bars blank for W. R. Webster 883509 Eye bars spreading the ends of W. R. Webster 383503 Eyeglasses. W. S. Wells 383604 Faucet filtering W. H. Sargent 883493 Feed cutter G. F. Schmid 383.494 Feeder automatic shelf W. M. Jewell (r) 10933 Fence machine Vandegrift & Maple 383.723 ence portable M. C. Margeson 383475 Fence wile P. C

Steel engraving, c. 1860, Sir Richard Arkwright, 1732-1792, a leading entrepreneur during the early Industrial Revolution Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-steel-engraving-c-1860-sir-richard-arkwright-1732-1792-a-leading-entrepreneur-72212090.html

Steel engraving, c. 1860, Sir Richard Arkwright, 1732-1792, a leading entrepreneur during the early Industrial Revolution Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-steel-engraving-c-1860-sir-richard-arkwright-1732-1792-a-leading-entrepreneur-72212090.htmlRME5DF76–Steel engraving, c. 1860, Sir Richard Arkwright, 1732-1792, a leading entrepreneur during the early Industrial Revolution

RME8DXW1–Engraved illustrations of Cotton Processing Equipment from Iconographic Encyclopedia of Science, Literature and Art, Circa 1851.

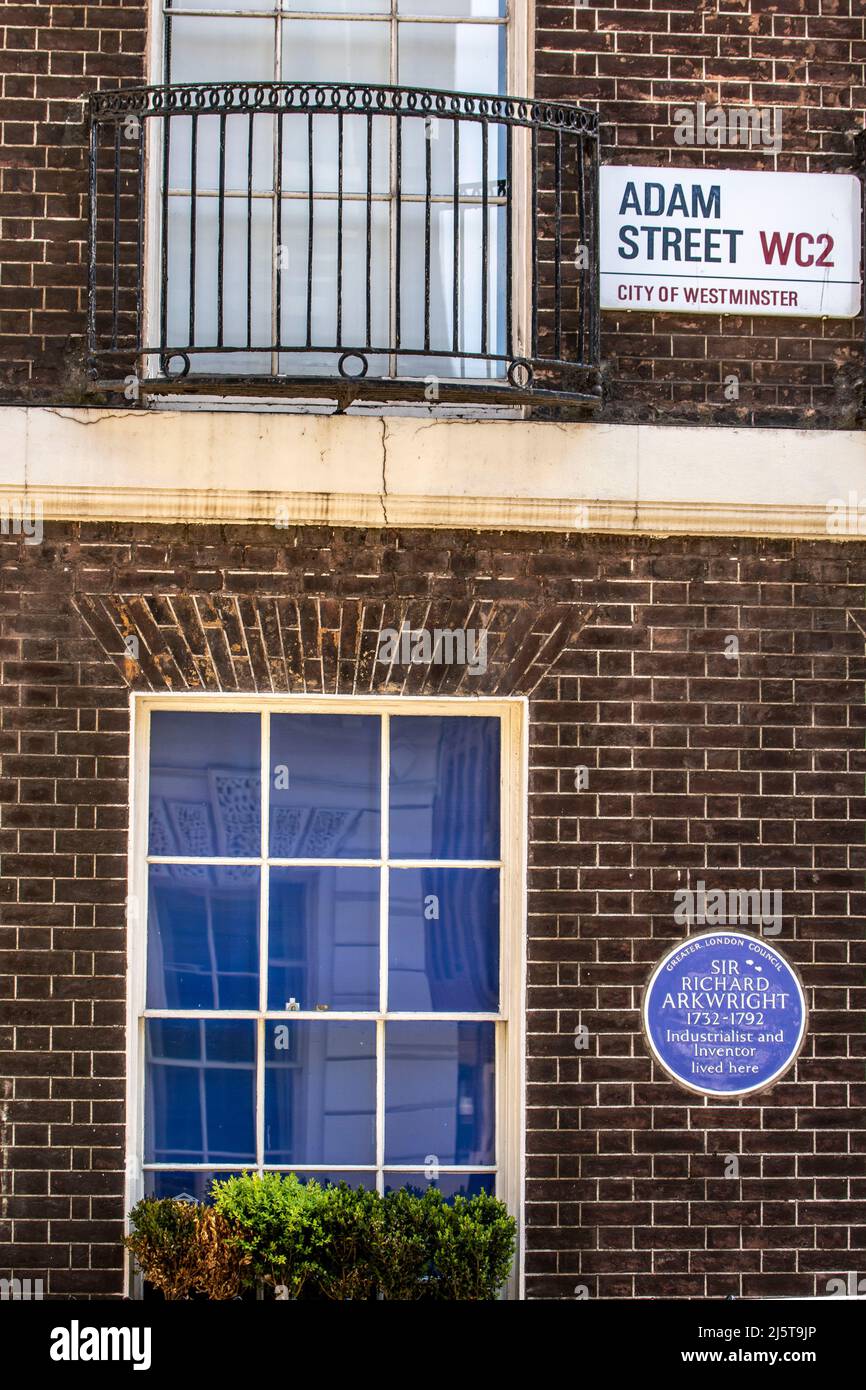

Blue plaque marking the occupancy by Arkwright in Adam Street, London Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/blue-plaque-marking-the-occupancy-by-arkwright-in-adam-street-london-image468287646.html

Blue plaque marking the occupancy by Arkwright in Adam Street, London Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/blue-plaque-marking-the-occupancy-by-arkwright-in-adam-street-london-image468287646.htmlRM2J5T9JP–Blue plaque marking the occupancy by Arkwright in Adam Street, London

The International Exhibition - cotton manufacture: machinery of Platt Brothers, Oldham, 1862. Fig. 3 the Lap-doubler; 'By this machine the slivers from the breaker carding-engine are formed into a fleece, and coiled into a lap to supply the finishing carding-machine'. Fig. 2. the Cotton-opener. From "Illustrated London News", 1862. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-international-exhibition-cotton-manufacture-machinery-of-platt-brothers-oldham-1862-fig-3-the-lap-doubler-by-this-machine-the-slivers-from-the-breaker-carding-engine-are-formed-into-a-fleece-and-coiled-into-a-lap-to-supply-the-finishing-carding-machine-fig-2-the-cotton-opener-from-quotillustrated-london-newsquot-1862-image595001628.html

The International Exhibition - cotton manufacture: machinery of Platt Brothers, Oldham, 1862. Fig. 3 the Lap-doubler; 'By this machine the slivers from the breaker carding-engine are formed into a fleece, and coiled into a lap to supply the finishing carding-machine'. Fig. 2. the Cotton-opener. From "Illustrated London News", 1862. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-international-exhibition-cotton-manufacture-machinery-of-platt-brothers-oldham-1862-fig-3-the-lap-doubler-by-this-machine-the-slivers-from-the-breaker-carding-engine-are-formed-into-a-fleece-and-coiled-into-a-lap-to-supply-the-finishing-carding-machine-fig-2-the-cotton-opener-from-quotillustrated-london-newsquot-1862-image595001628.htmlRM2WG0JJ4–The International Exhibition - cotton manufacture: machinery of Platt Brothers, Oldham, 1862. Fig. 3 the Lap-doubler; 'By this machine the slivers from the breaker carding-engine are formed into a fleece, and coiled into a lap to supply the finishing carding-machine'. Fig. 2. the Cotton-opener. From "Illustrated London News", 1862.

Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with 'card clothing', a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing from ' Appleton's dictionary of machines, mechanics, engine-work, and engineering ' Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-is-a-mechanical-process-that-disentangles-cleans-and-intermixes-fibres-to-produce-a-continuous-web-or-sliver-suitable-for-subsequent-processing-this-is-achieved-by-passing-the-fibres-between-differentially-moving-surfaces-covered-with-card-clothing-a-firm-flexible-material-embedded-with-metal-pins-it-breaks-up-locks-and-unorganised-clumps-of-fibre-and-then-aligns-the-individual-fibres-to-be-parallel-with-each-other-in-preparing-wool-fibre-for-spinning-carding-is-the-step-that-comes-after-teasing-from-appletons-dictionary-of-machines-mechanics-engine-work-and-engineering-image475772590.html

Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with 'card clothing', a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing from ' Appleton's dictionary of machines, mechanics, engine-work, and engineering ' Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-is-a-mechanical-process-that-disentangles-cleans-and-intermixes-fibres-to-produce-a-continuous-web-or-sliver-suitable-for-subsequent-processing-this-is-achieved-by-passing-the-fibres-between-differentially-moving-surfaces-covered-with-card-clothing-a-firm-flexible-material-embedded-with-metal-pins-it-breaks-up-locks-and-unorganised-clumps-of-fibre-and-then-aligns-the-individual-fibres-to-be-parallel-with-each-other-in-preparing-wool-fibre-for-spinning-carding-is-the-step-that-comes-after-teasing-from-appletons-dictionary-of-machines-mechanics-engine-work-and-engineering-image475772590.htmlRF2JJ18P6–Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with 'card clothing', a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing from ' Appleton's dictionary of machines, mechanics, engine-work, and engineering '

. Textile raw materials and their conversion into yarns : (the study of the raw materials and the technology of the spinning process) a text-book for textile, trade and higher technical schools, as also for self-instruction ; based upon the ordinary syllabus and curriculum of the Imperial and Royal Austrian weaving schools. which require to be further reducedto fibre after oiling (preceded if necessary by drying). Thiswork is done in the Garnet opener, a machine something likea carding engine, though more frequently by a thread opener(droussette), so called because it does excellent service in Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/textile-raw-materials-and-their-conversion-into-yarns-the-study-of-the-raw-materials-and-the-technology-of-the-spinning-process-a-text-book-for-textile-trade-and-higher-technical-schools-as-also-for-self-instruction-based-upon-the-ordinary-syllabus-and-curriculum-of-the-imperial-and-royal-austrian-weaving-schools-which-require-to-be-further-reducedto-fibre-after-oiling-preceded-if-necessary-by-drying-thiswork-is-done-in-the-garnet-opener-a-machine-something-likea-carding-engine-though-more-frequently-by-a-thread-openerdroussette-so-called-because-it-does-excellent-service-in-image336733613.html

. Textile raw materials and their conversion into yarns : (the study of the raw materials and the technology of the spinning process) a text-book for textile, trade and higher technical schools, as also for self-instruction ; based upon the ordinary syllabus and curriculum of the Imperial and Royal Austrian weaving schools. which require to be further reducedto fibre after oiling (preceded if necessary by drying). Thiswork is done in the Garnet opener, a machine something likea carding engine, though more frequently by a thread opener(droussette), so called because it does excellent service in Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/textile-raw-materials-and-their-conversion-into-yarns-the-study-of-the-raw-materials-and-the-technology-of-the-spinning-process-a-text-book-for-textile-trade-and-higher-technical-schools-as-also-for-self-instruction-based-upon-the-ordinary-syllabus-and-curriculum-of-the-imperial-and-royal-austrian-weaving-schools-which-require-to-be-further-reducedto-fibre-after-oiling-preceded-if-necessary-by-drying-thiswork-is-done-in-the-garnet-opener-a-machine-something-likea-carding-engine-though-more-frequently-by-a-thread-openerdroussette-so-called-because-it-does-excellent-service-in-image336733613.htmlRM2AFRF4D–. Textile raw materials and their conversion into yarns : (the study of the raw materials and the technology of the spinning process) a text-book for textile, trade and higher technical schools, as also for self-instruction ; based upon the ordinary syllabus and curriculum of the Imperial and Royal Austrian weaving schools. which require to be further reducedto fibre after oiling (preceded if necessary by drying). Thiswork is done in the Garnet opener, a machine something likea carding engine, though more frequently by a thread opener(droussette), so called because it does excellent service in

Illustration showing Wool carding engine by Davis & Furber, North Andover, Mass, USA 1880 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/illustration-showing-wool-carding-engine-by-davis-furber-north-andover-mass-usa-1880-image235260370.html

Illustration showing Wool carding engine by Davis & Furber, North Andover, Mass, USA 1880 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/illustration-showing-wool-carding-engine-by-davis-furber-north-andover-mass-usa-1880-image235260370.htmlRMRJN102–Illustration showing Wool carding engine by Davis & Furber, North Andover, Mass, USA 1880

Carding machine, illustration. Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver s Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-machine-illustration-carding-is-a-mechanical-process-that-disentangles-cleans-and-intermixes-fibres-to-produce-a-continuous-web-or-sliver-s-image575999290.html

Carding machine, illustration. Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver s Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/carding-machine-illustration-carding-is-a-mechanical-process-that-disentangles-cleans-and-intermixes-fibres-to-produce-a-continuous-web-or-sliver-s-image575999290.htmlRF2TD30Y6–Carding machine, illustration. Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver s

316 Lost Inventions. Interesting to Manufacturers. A Valuable Invention for Carding Wool. Pocket Cooking Stove. Improvement in Printing. A New Bridge. Water Wheels. Chrome. BROWN'S ANTI-CRANK ENGINE.Figure 1., scientific american, 1850-06-22 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/316-lost-inventions-interesting-to-manufacturers-a-valuable-invention-for-carding-wool-pocket-cooking-stove-improvement-in-printing-a-new-bridge-water-wheels-chrome-browns-anti-crank-enginefigure-1-scientific-american-1850-06-22-image334297382.html

316 Lost Inventions. Interesting to Manufacturers. A Valuable Invention for Carding Wool. Pocket Cooking Stove. Improvement in Printing. A New Bridge. Water Wheels. Chrome. BROWN'S ANTI-CRANK ENGINE.Figure 1., scientific american, 1850-06-22 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/316-lost-inventions-interesting-to-manufacturers-a-valuable-invention-for-carding-wool-pocket-cooking-stove-improvement-in-printing-a-new-bridge-water-wheels-chrome-browns-anti-crank-enginefigure-1-scientific-american-1850-06-22-image334297382.htmlRM2ABTFM6–316 Lost Inventions. Interesting to Manufacturers. A Valuable Invention for Carding Wool. Pocket Cooking Stove. Improvement in Printing. A New Bridge. Water Wheels. Chrome. BROWN'S ANTI-CRANK ENGINE.Figure 1., scientific american, 1850-06-22

RME8DX5E–Engraved illustrations of Wool Processing Equipment from Iconographic Encyclopedia of Science, Literature and Art, Circa 1851.

Blue plaque marking the occupancy by Arkwright in Adam Street, London Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/blue-plaque-marking-the-occupancy-by-arkwright-in-adam-street-london-image468287650.html

Blue plaque marking the occupancy by Arkwright in Adam Street, London Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/blue-plaque-marking-the-occupancy-by-arkwright-in-adam-street-london-image468287650.htmlRM2J5T9JX–Blue plaque marking the occupancy by Arkwright in Adam Street, London

RME8DTG8–Engraved illustrations of Weaving Equipment from Iconographic Encyclopedia of Science, Literature and Art, Circa 1851.

![The centenary mill engine, 1909. 'The Romance of Cotton: Cottage to Great Factory. We illustrate [one] of the many outward and visible signs of the great industry that is carried on at Messrs. Horrockses, Crewdson and Co.'s, a firm that can claim high place in the romance of cotton. In 1791 John Horrocks set aside his stone-mason's hammer and became a cotton-manufacturer, buying and carding the cotton himself. In ten years he had seven mills. Three years later, when he died, he was M.P. for Preston and had a fortune of £150,000'. From "Illustrated London News", 1909. Stock Photo The centenary mill engine, 1909. 'The Romance of Cotton: Cottage to Great Factory. We illustrate [one] of the many outward and visible signs of the great industry that is carried on at Messrs. Horrockses, Crewdson and Co.'s, a firm that can claim high place in the romance of cotton. In 1791 John Horrocks set aside his stone-mason's hammer and became a cotton-manufacturer, buying and carding the cotton himself. In ten years he had seven mills. Three years later, when he died, he was M.P. for Preston and had a fortune of £150,000'. From "Illustrated London News", 1909. Stock Photo](https://c8.alamy.com/comp/2XT30XT/the-centenary-mill-engine-1909-the-romance-of-cotton-cottage-to-great-factory-we-illustrate-one-of-the-many-outward-and-visible-signs-of-the-great-industry-that-is-carried-on-at-messrs-horrockses-crewdson-and-cos-a-firm-that-can-claim-high-place-in-the-romance-of-cotton-in-1791-john-horrocks-set-aside-his-stone-masons-hammer-and-became-a-cotton-manufacturer-buying-and-carding-the-cotton-himself-in-ten-years-he-had-seven-mills-three-years-later-when-he-died-he-was-mp-for-preston-and-had-a-fortune-of-xa3150000-from-quotillustrated-london-newsquot-1909-2XT30XT.jpg) The centenary mill engine, 1909. 'The Romance of Cotton: Cottage to Great Factory. We illustrate [one] of the many outward and visible signs of the great industry that is carried on at Messrs. Horrockses, Crewdson and Co.'s, a firm that can claim high place in the romance of cotton. In 1791 John Horrocks set aside his stone-mason's hammer and became a cotton-manufacturer, buying and carding the cotton himself. In ten years he had seven mills. Three years later, when he died, he was M.P. for Preston and had a fortune of £150,000'. From "Illustrated London News", 1909. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-centenary-mill-engine-1909-the-romance-of-cotton-cottage-to-great-factory-we-illustrate-one-of-the-many-outward-and-visible-signs-of-the-great-industry-that-is-carried-on-at-messrs-horrockses-crewdson-and-cos-a-firm-that-can-claim-high-place-in-the-romance-of-cotton-in-1791-john-horrocks-set-aside-his-stone-masons-hammer-and-became-a-cotton-manufacturer-buying-and-carding-the-cotton-himself-in-ten-years-he-had-seven-mills-three-years-later-when-he-died-he-was-mp-for-preston-and-had-a-fortune-of-xa3150000-from-quotillustrated-london-newsquot-1909-image617181232.html

The centenary mill engine, 1909. 'The Romance of Cotton: Cottage to Great Factory. We illustrate [one] of the many outward and visible signs of the great industry that is carried on at Messrs. Horrockses, Crewdson and Co.'s, a firm that can claim high place in the romance of cotton. In 1791 John Horrocks set aside his stone-mason's hammer and became a cotton-manufacturer, buying and carding the cotton himself. In ten years he had seven mills. Three years later, when he died, he was M.P. for Preston and had a fortune of £150,000'. From "Illustrated London News", 1909. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-centenary-mill-engine-1909-the-romance-of-cotton-cottage-to-great-factory-we-illustrate-one-of-the-many-outward-and-visible-signs-of-the-great-industry-that-is-carried-on-at-messrs-horrockses-crewdson-and-cos-a-firm-that-can-claim-high-place-in-the-romance-of-cotton-in-1791-john-horrocks-set-aside-his-stone-masons-hammer-and-became-a-cotton-manufacturer-buying-and-carding-the-cotton-himself-in-ten-years-he-had-seven-mills-three-years-later-when-he-died-he-was-mp-for-preston-and-had-a-fortune-of-xa3150000-from-quotillustrated-london-newsquot-1909-image617181232.htmlRM2XT30XT–The centenary mill engine, 1909. 'The Romance of Cotton: Cottage to Great Factory. We illustrate [one] of the many outward and visible signs of the great industry that is carried on at Messrs. Horrockses, Crewdson and Co.'s, a firm that can claim high place in the romance of cotton. In 1791 John Horrocks set aside his stone-mason's hammer and became a cotton-manufacturer, buying and carding the cotton himself. In ten years he had seven mills. Three years later, when he died, he was M.P. for Preston and had a fortune of £150,000'. From "Illustrated London News", 1909.

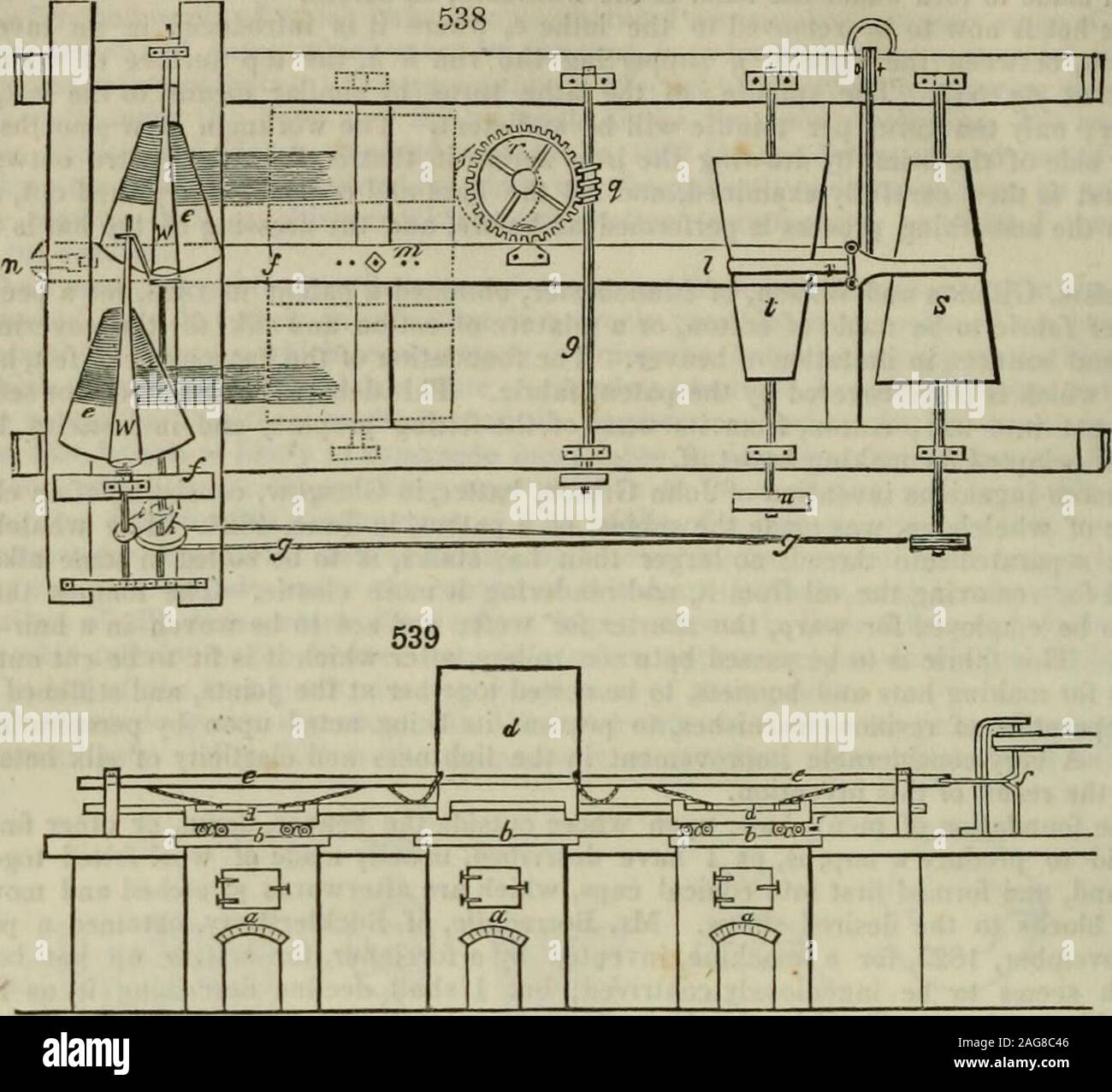

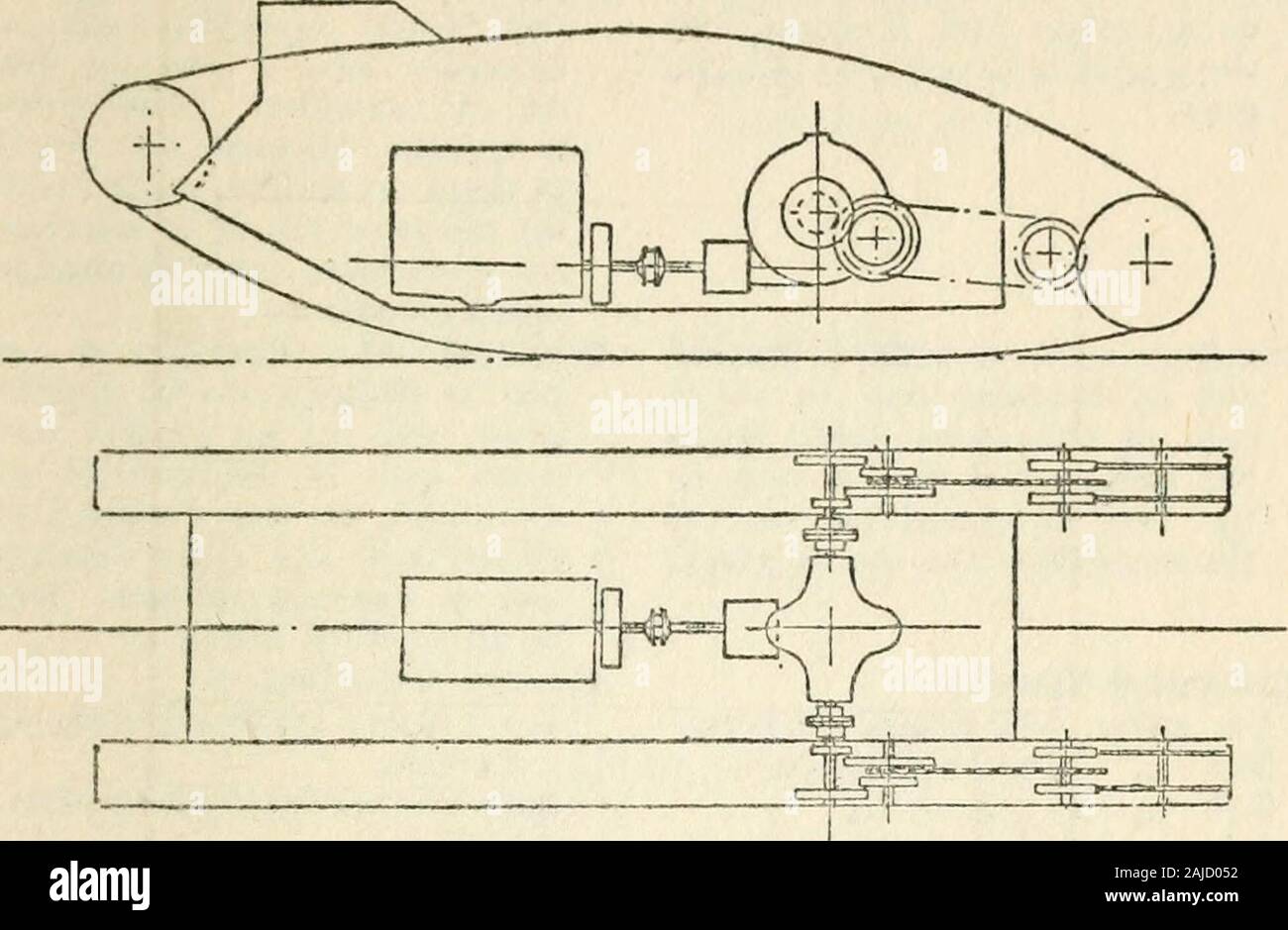

. A dictionary of arts, manufactures and mines : containing a clear exposition of their principles and practice. lliams, in September, 1826 ; butI fear it has never obtained a footing, nor even a fair trial in our manufactures, on ac-count of the hostility of the operatives to all labor-saving machines. Fig. 538 is a side view of the carding engine, with a horizontal or plan view of thelower part of the carding machine, showing the operative parts of the winding apparatus,as connected to the carding engine. The doffer cylinder is covered with fillets ofwire cards, such as are usually employed Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/a-dictionary-of-arts-manufactures-and-mines-containing-a-clear-exposition-of-their-principles-and-practice-lliams-in-september-1826-buti-fear-it-has-never-obtained-a-footing-nor-even-a-fair-trial-in-our-manufactures-on-ac-count-of-the-hostility-of-the-operatives-to-all-labor-saving-machines-fig-538-is-a-side-view-of-the-carding-engine-with-a-horizontal-or-plan-view-of-thelower-part-of-the-carding-machine-showing-the-operative-parts-of-the-winding-apparatusas-connected-to-the-carding-engine-the-doffer-cylinder-is-covered-with-fillets-ofwire-cards-such-as-are-usually-employed-image337016630.html

. A dictionary of arts, manufactures and mines : containing a clear exposition of their principles and practice. lliams, in September, 1826 ; butI fear it has never obtained a footing, nor even a fair trial in our manufactures, on ac-count of the hostility of the operatives to all labor-saving machines. Fig. 538 is a side view of the carding engine, with a horizontal or plan view of thelower part of the carding machine, showing the operative parts of the winding apparatus,as connected to the carding engine. The doffer cylinder is covered with fillets ofwire cards, such as are usually employed Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/a-dictionary-of-arts-manufactures-and-mines-containing-a-clear-exposition-of-their-principles-and-practice-lliams-in-september-1826-buti-fear-it-has-never-obtained-a-footing-nor-even-a-fair-trial-in-our-manufactures-on-ac-count-of-the-hostility-of-the-operatives-to-all-labor-saving-machines-fig-538-is-a-side-view-of-the-carding-engine-with-a-horizontal-or-plan-view-of-thelower-part-of-the-carding-machine-showing-the-operative-parts-of-the-winding-apparatusas-connected-to-the-carding-engine-the-doffer-cylinder-is-covered-with-fillets-ofwire-cards-such-as-are-usually-employed-image337016630.htmlRM2AG8C46–. A dictionary of arts, manufactures and mines : containing a clear exposition of their principles and practice. lliams, in September, 1826 ; butI fear it has never obtained a footing, nor even a fair trial in our manufactures, on ac-count of the hostility of the operatives to all labor-saving machines. Fig. 538 is a side view of the carding engine, with a horizontal or plan view of thelower part of the carding machine, showing the operative parts of the winding apparatus,as connected to the carding engine. The doffer cylinder is covered with fillets ofwire cards, such as are usually employed

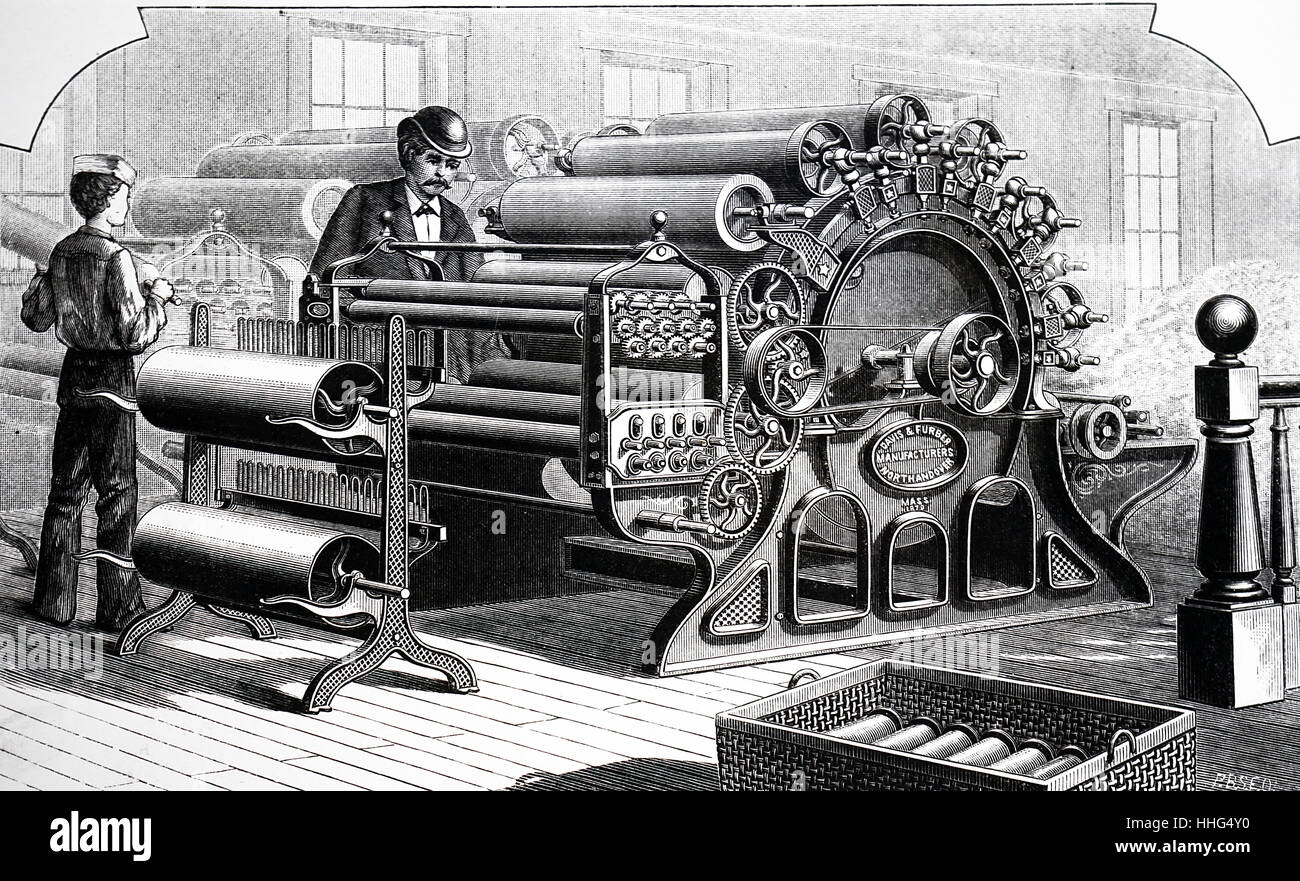

Wool carding engine by Davis & Furber, North Andover, Mass, USA. New York 1880. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-wool-carding-engine-by-davis-furber-north-andover-mass-usa-new-york-131276852.html

Wool carding engine by Davis & Furber, North Andover, Mass, USA. New York 1880. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-wool-carding-engine-by-davis-furber-north-andover-mass-usa-new-york-131276852.htmlRMHHG4Y0–Wool carding engine by Davis & Furber, North Andover, Mass, USA. New York 1880.

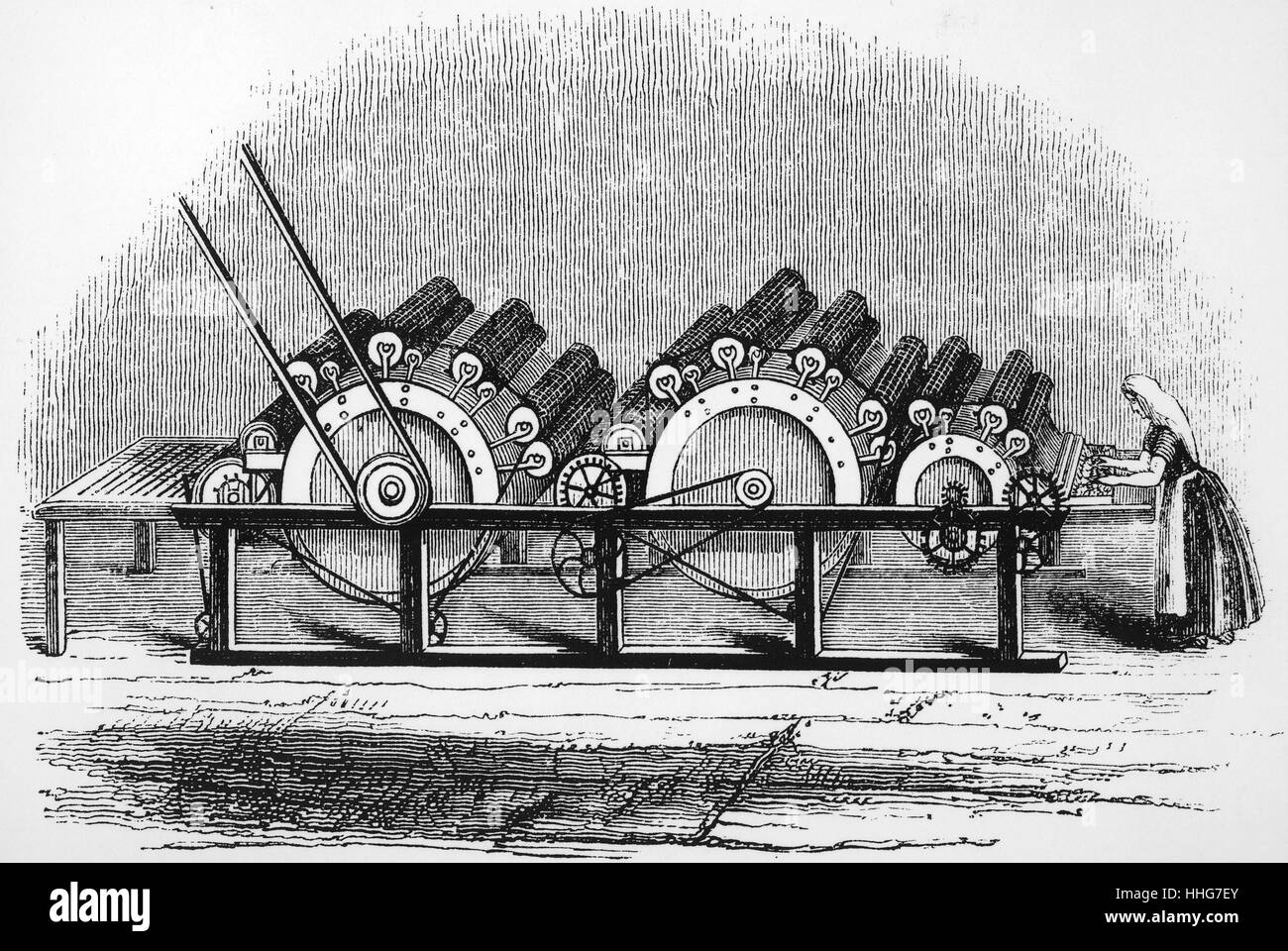

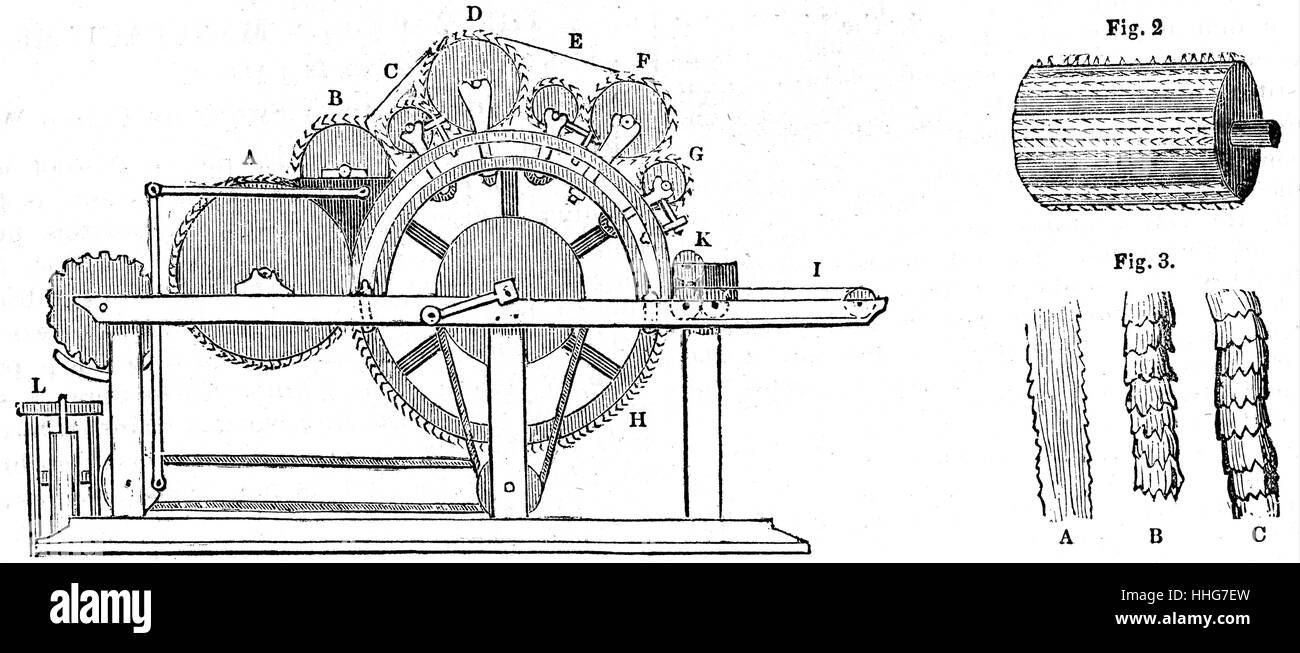

Illustration depicting a carding engine. Carding is the process that disentangles; cleans; and intermixes the woollen fibres. Dated 19th Century Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-illustration-depicting-a-carding-engine-carding-is-the-process-that-131278867.html

Illustration depicting a carding engine. Carding is the process that disentangles; cleans; and intermixes the woollen fibres. Dated 19th Century Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-illustration-depicting-a-carding-engine-carding-is-the-process-that-131278867.htmlRMHHG7EY–Illustration depicting a carding engine. Carding is the process that disentangles; cleans; and intermixes the woollen fibres. Dated 19th Century

Illustration depicting a carding engine. Carding is the process that disentangles; cleans; and intermixes the woollen fibres. Dated 19th Century Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-illustration-depicting-a-carding-engine-carding-is-the-process-that-131278865.html

Illustration depicting a carding engine. Carding is the process that disentangles; cleans; and intermixes the woollen fibres. Dated 19th Century Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-illustration-depicting-a-carding-engine-carding-is-the-process-that-131278865.htmlRMHHG7EW–Illustration depicting a carding engine. Carding is the process that disentangles; cleans; and intermixes the woollen fibres. Dated 19th Century

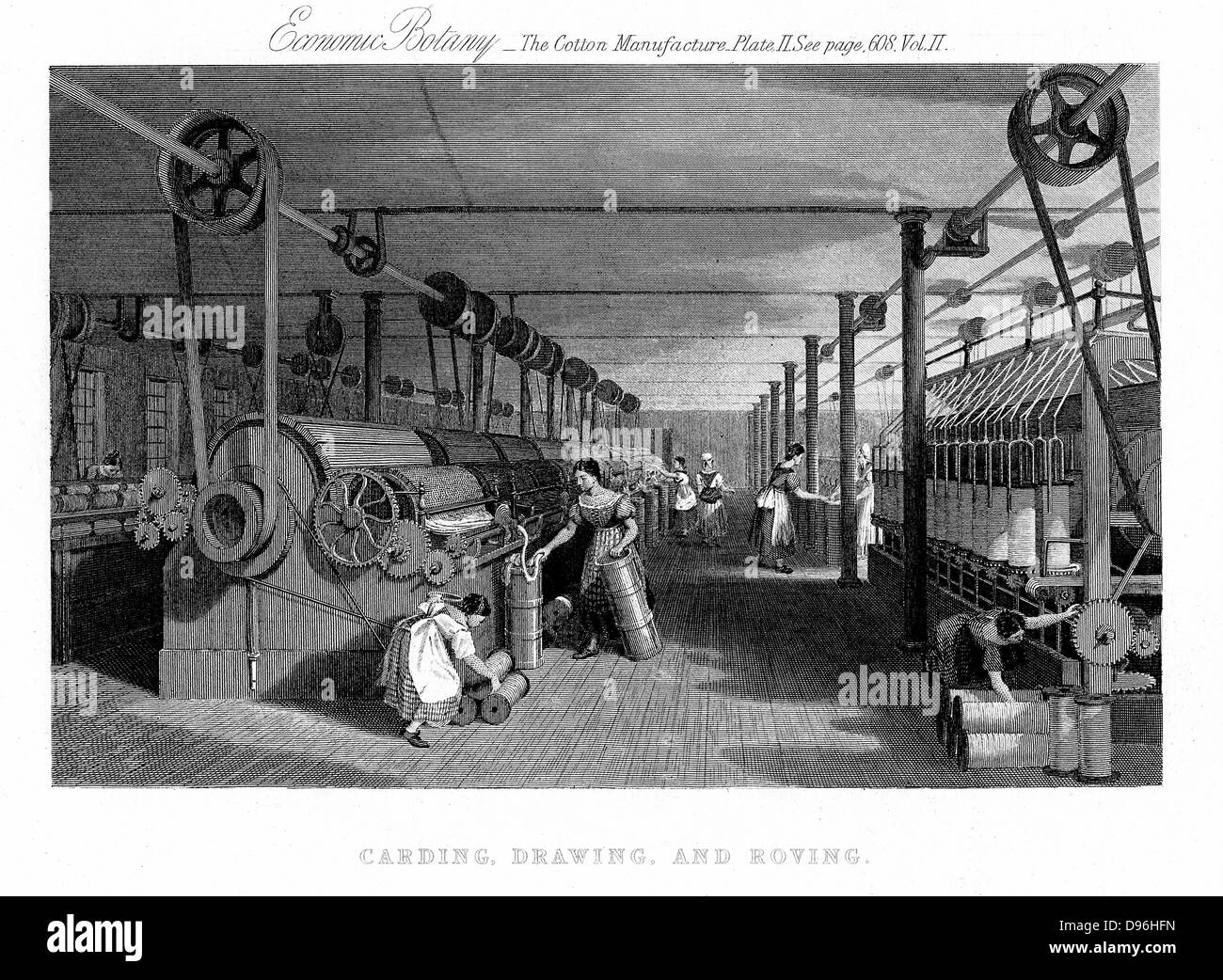

Carding, drawing and roving cotton. Carding engine (left) delivers cotton in a single sliver. Factory operated by shafts & belting. Could be powered by water or steam. Engraving c1830. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-carding-drawing-and-roving-cotton-carding-engine-left-delivers-cotton-57308489.html

Carding, drawing and roving cotton. Carding engine (left) delivers cotton in a single sliver. Factory operated by shafts & belting. Could be powered by water or steam. Engraving c1830. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-carding-drawing-and-roving-cotton-carding-engine-left-delivers-cotton-57308489.htmlRMD96HFN–Carding, drawing and roving cotton. Carding engine (left) delivers cotton in a single sliver. Factory operated by shafts & belting. Could be powered by water or steam. Engraving c1830.

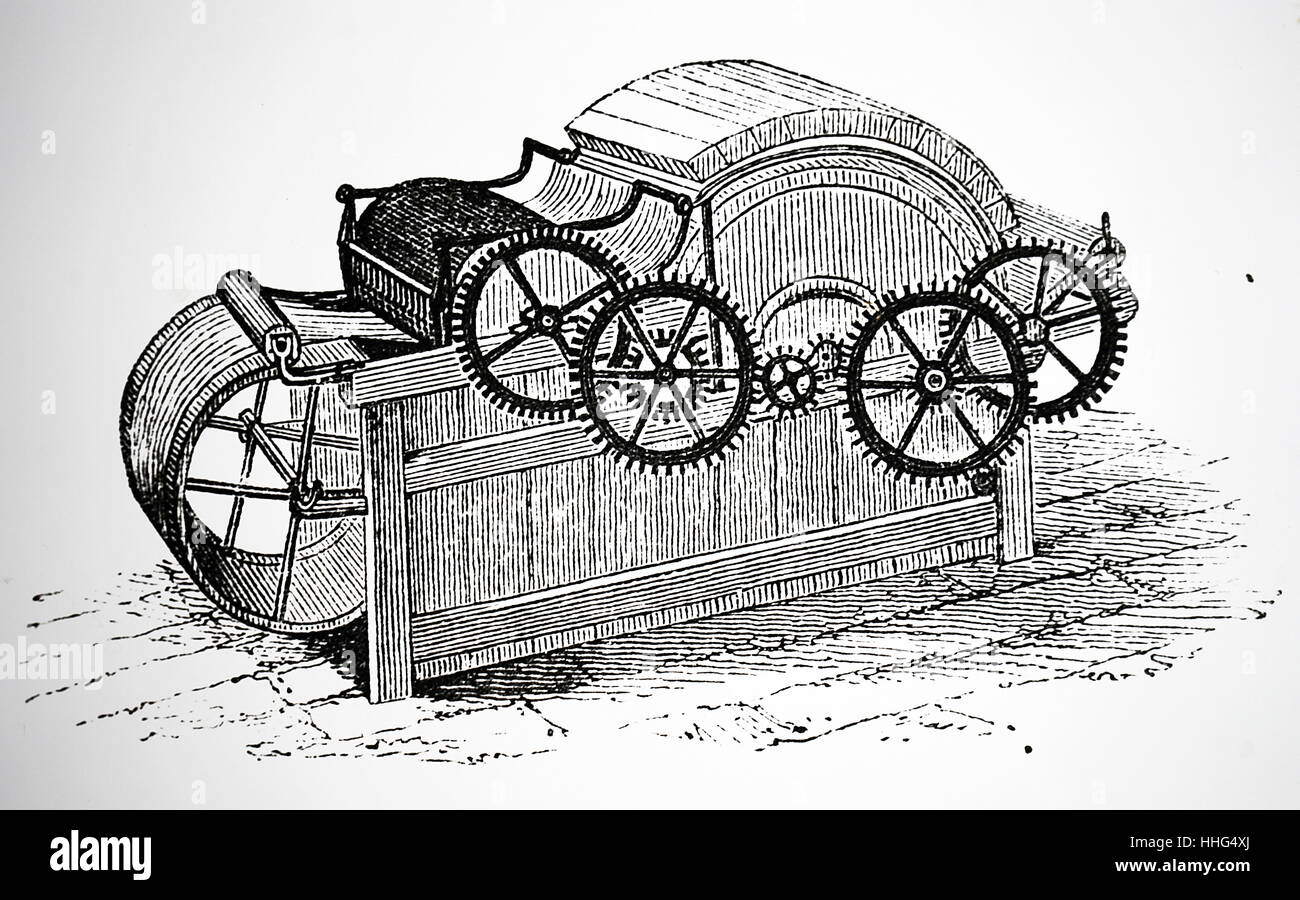

Carding engine incorporating an early improvement which brought off carded cotton in a continuous sliver. This is a breaker-card, the first of two machines cotton was put through for fine spinning, and had coarser teeth than the second machine - the finishing-card. Dated 1845. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-carding-engine-incorporating-an-early-improvement-which-brought-off-131276842.html

Carding engine incorporating an early improvement which brought off carded cotton in a continuous sliver. This is a breaker-card, the first of two machines cotton was put through for fine spinning, and had coarser teeth than the second machine - the finishing-card. Dated 1845. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-carding-engine-incorporating-an-early-improvement-which-brought-off-131276842.htmlRMHHG4XJ–Carding engine incorporating an early improvement which brought off carded cotton in a continuous sliver. This is a breaker-card, the first of two machines cotton was put through for fine spinning, and had coarser teeth than the second machine - the finishing-card. Dated 1845.

Blue plaque marking the occupancy by Arkwright in Adam Street, London Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/blue-plaque-marking-the-occupancy-by-arkwright-in-adam-street-london-image468287648.html

Blue plaque marking the occupancy by Arkwright in Adam Street, London Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/blue-plaque-marking-the-occupancy-by-arkwright-in-adam-street-london-image468287648.htmlRM2J5T9JT–Blue plaque marking the occupancy by Arkwright in Adam Street, London

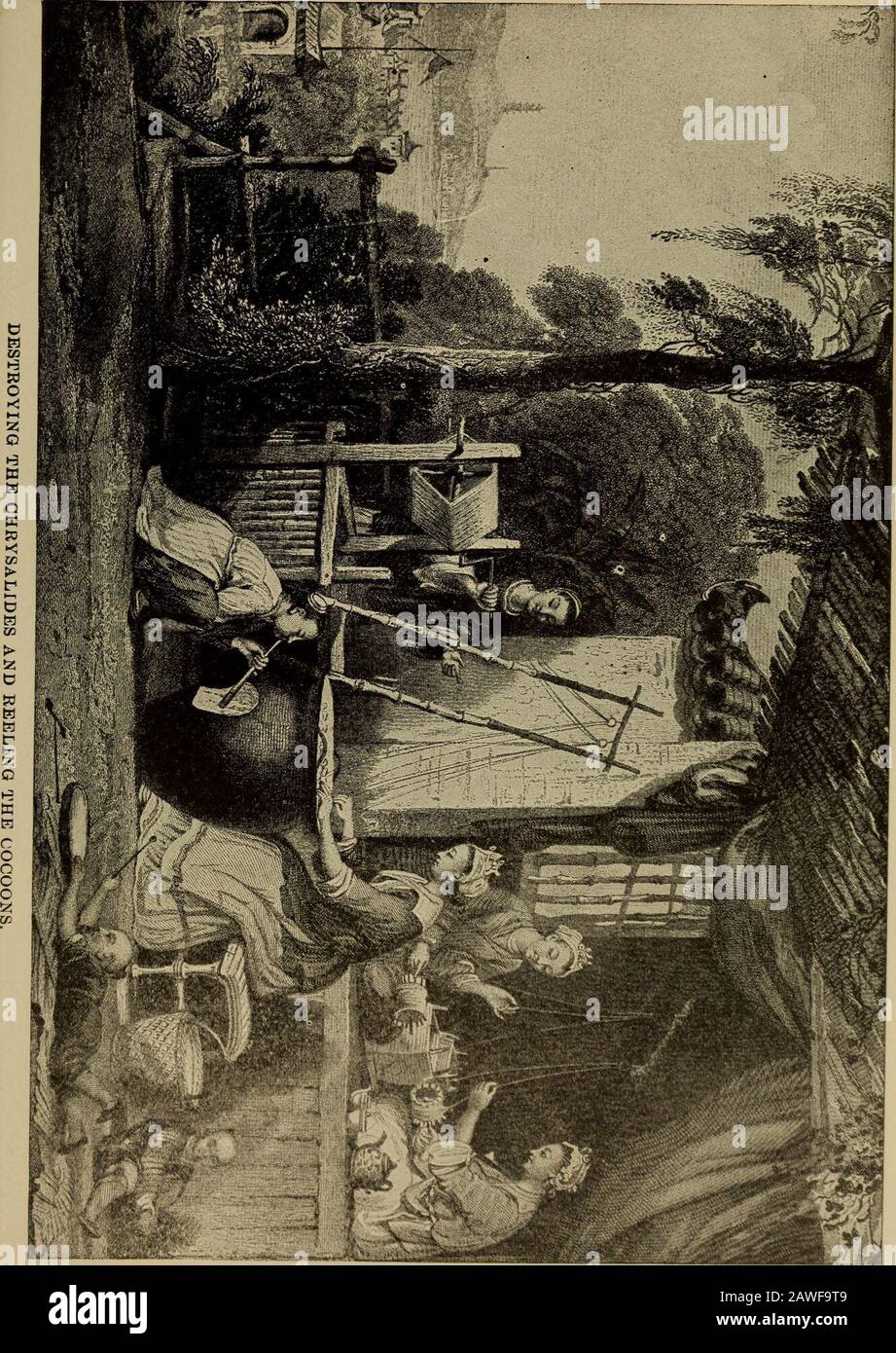

The fireside university of modern invention, discovery, industry and art for home circle study and entertainment . nt jealous of the possession ofthese machines? Yes, None were exportable, nor could a spinner, or oneacquainted with the throstle, mules, or carding engine emigrate,even to America. All out-going baggage and mail was searchedfor models and plans, and a model was actually seized in a trunkat a custom house. Nevertheless, the secret reached America atan early date. Now there are vast Cotton mills, both in Chinaand Mexico. The actual secrecy of all the trades is, even to-day,a matter Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-fireside-university-of-modern-invention-discovery-industry-and-art-for-home-circle-study-and-entertainment-nt-jealous-of-the-possession-ofthese-machines-yes-none-were-exportable-nor-could-a-spinner-or-oneacquainted-with-the-throstle-mules-or-carding-engine-emigrateeven-to-america-all-out-going-baggage-and-mail-was-searchedfor-models-and-plans-and-a-model-was-actually-seized-in-a-trunkat-a-custom-house-nevertheless-the-secret-reached-america-atan-early-date-now-there-are-vast-cotton-mills-both-in-chinaand-mexico-the-actual-secrecy-of-all-the-trades-is-even-to-daya-matter-image342700409.html

The fireside university of modern invention, discovery, industry and art for home circle study and entertainment . nt jealous of the possession ofthese machines? Yes, None were exportable, nor could a spinner, or oneacquainted with the throstle, mules, or carding engine emigrate,even to America. All out-going baggage and mail was searchedfor models and plans, and a model was actually seized in a trunkat a custom house. Nevertheless, the secret reached America atan early date. Now there are vast Cotton mills, both in Chinaand Mexico. The actual secrecy of all the trades is, even to-day,a matter Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-fireside-university-of-modern-invention-discovery-industry-and-art-for-home-circle-study-and-entertainment-nt-jealous-of-the-possession-ofthese-machines-yes-none-were-exportable-nor-could-a-spinner-or-oneacquainted-with-the-throstle-mules-or-carding-engine-emigrateeven-to-america-all-out-going-baggage-and-mail-was-searchedfor-models-and-plans-and-a-model-was-actually-seized-in-a-trunkat-a-custom-house-nevertheless-the-secret-reached-america-atan-early-date-now-there-are-vast-cotton-mills-both-in-chinaand-mexico-the-actual-secrecy-of-all-the-trades-is-even-to-daya-matter-image342700409.htmlRM2AWF9T9–The fireside university of modern invention, discovery, industry and art for home circle study and entertainment . nt jealous of the possession ofthese machines? Yes, None were exportable, nor could a spinner, or oneacquainted with the throstle, mules, or carding engine emigrate,even to America. All out-going baggage and mail was searchedfor models and plans, and a model was actually seized in a trunkat a custom house. Nevertheless, the secret reached America atan early date. Now there are vast Cotton mills, both in Chinaand Mexico. The actual secrecy of all the trades is, even to-day,a matter

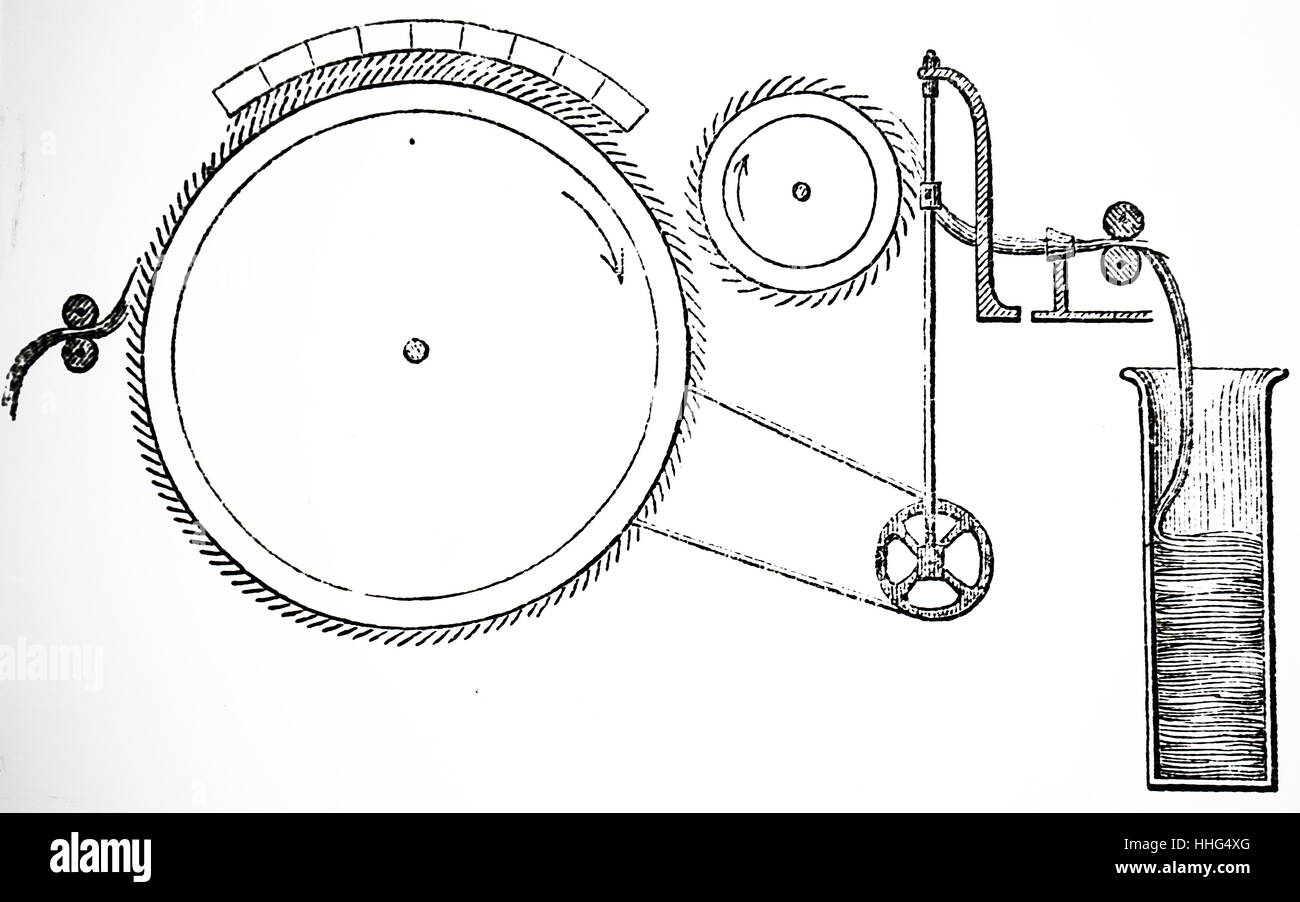

Principle of the carding engine: revolving drum covered with wire teeth, the top covered with concave frame with similar teeth. Cotton lap is fed through the rollers from left overnight drum. The fibres are now caught by second toothed cylinder and the sorted fibres are fed into can on right. Dated 1845 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-principle-of-the-carding-engine-revolving-drum-covered-with-wire-teeth-131276840.html

Principle of the carding engine: revolving drum covered with wire teeth, the top covered with concave frame with similar teeth. Cotton lap is fed through the rollers from left overnight drum. The fibres are now caught by second toothed cylinder and the sorted fibres are fed into can on right. Dated 1845 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-principle-of-the-carding-engine-revolving-drum-covered-with-wire-teeth-131276840.htmlRMHHG4XG–Principle of the carding engine: revolving drum covered with wire teeth, the top covered with concave frame with similar teeth. Cotton lap is fed through the rollers from left overnight drum. The fibres are now caught by second toothed cylinder and the sorted fibres are fed into can on right. Dated 1845

Detailed view of the Cotton Carding. Used to create a single - long strand of material, rather than clumps. machine. Dated 1851 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-detailed-view-of-the-cotton-carding-used-to-create-a-single-long-strand-131276851.html

Detailed view of the Cotton Carding. Used to create a single - long strand of material, rather than clumps. machine. Dated 1851 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-detailed-view-of-the-cotton-carding-used-to-create-a-single-long-strand-131276851.htmlRMHHG4XY–Detailed view of the Cotton Carding. Used to create a single - long strand of material, rather than clumps. machine. Dated 1851

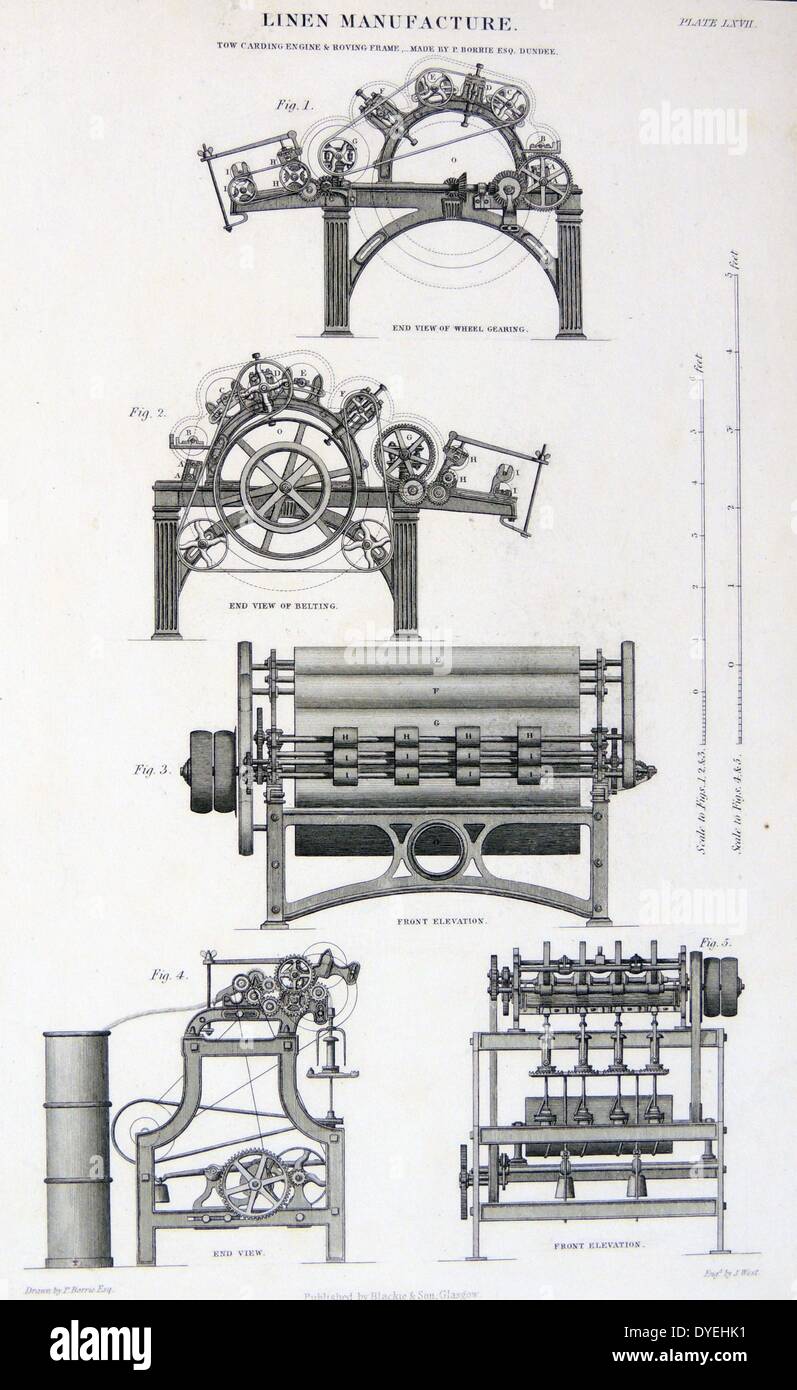

Linen manufacture: Carding engine and roving machine by P. Borrie of Dundee, Scotland. Engraving, Glasgow, 1888. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/linen-manufacture-carding-engine-and-roving-machine-by-p-borrie-of-image68548005.html

Linen manufacture: Carding engine and roving machine by P. Borrie of Dundee, Scotland. Engraving, Glasgow, 1888. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/linen-manufacture-carding-engine-and-roving-machine-by-p-borrie-of-image68548005.htmlRMDYEHK1–Linen manufacture: Carding engine and roving machine by P. Borrie of Dundee, Scotland. Engraving, Glasgow, 1888.

Carding, drawing and roving cotton. From a print published circa 1830. In this picture the carding engine (left) delivers the cotton in a single sliver. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-carding-drawing-and-roving-cotton-from-a-print-published-circa-1830-131276848.html

Carding, drawing and roving cotton. From a print published circa 1830. In this picture the carding engine (left) delivers the cotton in a single sliver. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-carding-drawing-and-roving-cotton-from-a-print-published-circa-1830-131276848.htmlRMHHG4XT–Carding, drawing and roving cotton. From a print published circa 1830. In this picture the carding engine (left) delivers the cotton in a single sliver.

Cotton carding machine, from James Wylde. London, dated 1865 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-cotton-carding-machine-from-james-wylde-london-dated-1865-131276853.html

Cotton carding machine, from James Wylde. London, dated 1865 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-cotton-carding-machine-from-james-wylde-london-dated-1865-131276853.htmlRMHHG4Y1–Cotton carding machine, from James Wylde. London, dated 1865

Three males are shown operating the Cotton Carding machine. Used to create a single - long strand of material, rather than clumps. machine. Dated 1851 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-three-males-are-shown-operating-the-cotton-carding-machine-used-to-131276850.html

Three males are shown operating the Cotton Carding machine. Used to create a single - long strand of material, rather than clumps. machine. Dated 1851 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-three-males-are-shown-operating-the-cotton-carding-machine-used-to-131276850.htmlRMHHG4XX–Three males are shown operating the Cotton Carding machine. Used to create a single - long strand of material, rather than clumps. machine. Dated 1851

Knight's American mechanical dictionary : a description of tools, instruments, machines, processes and engineering, history of inventions, general technological vocabulary ; and digest of mechanical appliances in science and the arts . Hat-Felrirtg Machine. dyeing and trimming.Hat-forming Ma-chine. Slivers of wool aretaken from the dofler of a carding-engine and wound Fig. 2431.. Hnt-Fonnins Machine. HAT-FULLING MACHINE. 1076 HAT-IKONING MACHINE. ill (litiereut directions upon a cone, whicli rpolvi.sami traverses or vibrates to and fro, by whieli iiiu-tioiis the lilaineuts of wool are crossed Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/knights-american-mechanical-dictionary-a-description-of-tools-instruments-machines-processes-and-engineering-history-of-inventions-general-technological-vocabulary-and-digest-of-mechanical-appliances-in-science-and-the-arts-hat-felrirtg-machine-dyeing-and-trimminghat-forming-ma-chine-slivers-of-wool-aretaken-from-the-dofler-of-a-carding-engine-and-wound-fig-2431-hnt-fonnins-machine-hat-fulling-machine-1076-hat-ikoning-machine-ill-litiereut-directions-upon-a-cone-whicli-rpolvisami-traverses-or-vibrates-to-and-fro-by-whieli-iiiu-tioiis-the-lilaineuts-of-wool-are-crossed-image340050828.html

Knight's American mechanical dictionary : a description of tools, instruments, machines, processes and engineering, history of inventions, general technological vocabulary ; and digest of mechanical appliances in science and the arts . Hat-Felrirtg Machine. dyeing and trimming.Hat-forming Ma-chine. Slivers of wool aretaken from the dofler of a carding-engine and wound Fig. 2431.. Hnt-Fonnins Machine. HAT-FULLING MACHINE. 1076 HAT-IKONING MACHINE. ill (litiereut directions upon a cone, whicli rpolvi.sami traverses or vibrates to and fro, by whieli iiiu-tioiis the lilaineuts of wool are crossed Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/knights-american-mechanical-dictionary-a-description-of-tools-instruments-machines-processes-and-engineering-history-of-inventions-general-technological-vocabulary-and-digest-of-mechanical-appliances-in-science-and-the-arts-hat-felrirtg-machine-dyeing-and-trimminghat-forming-ma-chine-slivers-of-wool-aretaken-from-the-dofler-of-a-carding-engine-and-wound-fig-2431-hnt-fonnins-machine-hat-fulling-machine-1076-hat-ikoning-machine-ill-litiereut-directions-upon-a-cone-whicli-rpolvisami-traverses-or-vibrates-to-and-fro-by-whieli-iiiu-tioiis-the-lilaineuts-of-wool-are-crossed-image340050828.htmlRM2AN6J8C–Knight's American mechanical dictionary : a description of tools, instruments, machines, processes and engineering, history of inventions, general technological vocabulary ; and digest of mechanical appliances in science and the arts . Hat-Felrirtg Machine. dyeing and trimming.Hat-forming Ma-chine. Slivers of wool aretaken from the dofler of a carding-engine and wound Fig. 2431.. Hnt-Fonnins Machine. HAT-FULLING MACHINE. 1076 HAT-IKONING MACHINE. ill (litiereut directions upon a cone, whicli rpolvi.sami traverses or vibrates to and fro, by whieli iiiu-tioiis the lilaineuts of wool are crossed

. Tops, a new American industry; a study in the development of the American worsted manufacture. The Arlington Mills ... 6 Appendix A. The Products of the Arlington Mills 115Appendix B. Columbus Sighting America: Jac- quard Design 121 Appendix C. The First Carding Engine built in America 126 Appendix D. Facts about the Property of the Arlington Mills ....... 130 Index 133 LIST OF ILLUSTRATIONS PageA Flock of Sheep, Franklin Park, Boston, Mass. Frontispiece Arlington Mills, Worsted Department . Facing 14 A Vermont Merino Ram . 20 Ground Plan of the Arlington Mills Property, Lawrence, Mass 31 Th Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/tops-a-new-american-industry-a-study-in-the-development-of-the-american-worsted-manufacture-the-arlington-mills-6-appendix-a-the-products-of-the-arlington-mills-115appendix-b-columbus-sighting-america-jac-quard-design-121-appendix-c-the-first-carding-engine-built-in-america-126-appendix-d-facts-about-the-property-of-the-arlington-mills-130-index-133-list-of-illustrations-pagea-flock-of-sheep-franklin-park-boston-mass-frontispiece-arlington-mills-worsted-department-facing-14-a-vermont-merino-ram-20-ground-plan-of-the-arlington-mills-property-lawrence-mass-31-th-image336688156.html

. Tops, a new American industry; a study in the development of the American worsted manufacture. The Arlington Mills ... 6 Appendix A. The Products of the Arlington Mills 115Appendix B. Columbus Sighting America: Jac- quard Design 121 Appendix C. The First Carding Engine built in America 126 Appendix D. Facts about the Property of the Arlington Mills ....... 130 Index 133 LIST OF ILLUSTRATIONS PageA Flock of Sheep, Franklin Park, Boston, Mass. Frontispiece Arlington Mills, Worsted Department . Facing 14 A Vermont Merino Ram . 20 Ground Plan of the Arlington Mills Property, Lawrence, Mass 31 Th Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/tops-a-new-american-industry-a-study-in-the-development-of-the-american-worsted-manufacture-the-arlington-mills-6-appendix-a-the-products-of-the-arlington-mills-115appendix-b-columbus-sighting-america-jac-quard-design-121-appendix-c-the-first-carding-engine-built-in-america-126-appendix-d-facts-about-the-property-of-the-arlington-mills-130-index-133-list-of-illustrations-pagea-flock-of-sheep-franklin-park-boston-mass-frontispiece-arlington-mills-worsted-department-facing-14-a-vermont-merino-ram-20-ground-plan-of-the-arlington-mills-property-lawrence-mass-31-th-image336688156.htmlRM2AFND50–. Tops, a new American industry; a study in the development of the American worsted manufacture. The Arlington Mills ... 6 Appendix A. The Products of the Arlington Mills 115Appendix B. Columbus Sighting America: Jac- quard Design 121 Appendix C. The First Carding Engine built in America 126 Appendix D. Facts about the Property of the Arlington Mills ....... 130 Index 133 LIST OF ILLUSTRATIONS PageA Flock of Sheep, Franklin Park, Boston, Mass. Frontispiece Arlington Mills, Worsted Department . Facing 14 A Vermont Merino Ram . 20 Ground Plan of the Arlington Mills Property, Lawrence, Mass 31 Th

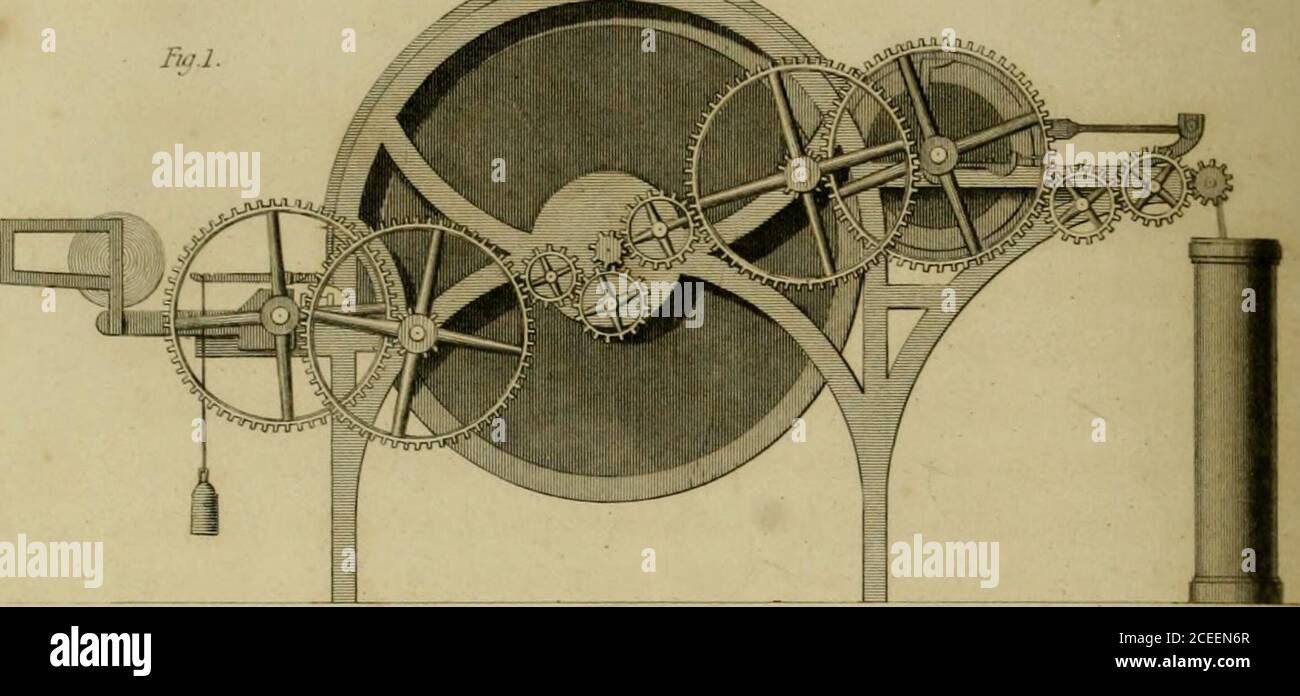

. History of the cotton manufacture in Great Britain : with a notice of its early history in the East, and in all the quarters of the globe : a description of the great mechanical inventions, which have caused its unexampled extension in Britain, and a view of the present state of the manufacture and the condition of the classes engaged in its several departments. Carding Engine Plan. Dramno Frame. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/history-of-the-cotton-manufacture-in-great-britain-with-a-notice-of-its-early-history-in-the-east-and-in-all-the-quarters-of-the-globe-a-description-of-the-great-mechanical-inventions-which-have-caused-its-unexampled-extension-in-britain-and-a-view-of-the-present-state-of-the-manufacture-and-the-condition-of-the-classes-engaged-in-its-several-departments-carding-engine-plan-dramno-frame-image370346895.html

. History of the cotton manufacture in Great Britain : with a notice of its early history in the East, and in all the quarters of the globe : a description of the great mechanical inventions, which have caused its unexampled extension in Britain, and a view of the present state of the manufacture and the condition of the classes engaged in its several departments. Carding Engine Plan. Dramno Frame. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/history-of-the-cotton-manufacture-in-great-britain-with-a-notice-of-its-early-history-in-the-east-and-in-all-the-quarters-of-the-globe-a-description-of-the-great-mechanical-inventions-which-have-caused-its-unexampled-extension-in-britain-and-a-view-of-the-present-state-of-the-manufacture-and-the-condition-of-the-classes-engaged-in-its-several-departments-carding-engine-plan-dramno-frame-image370346895.htmlRM2CEEN6R–. History of the cotton manufacture in Great Britain : with a notice of its early history in the East, and in all the quarters of the globe : a description of the great mechanical inventions, which have caused its unexampled extension in Britain, and a view of the present state of the manufacture and the condition of the classes engaged in its several departments. Carding Engine Plan. Dramno Frame.

. Cassier's magazine . FIG. 12. HALL & KAY DUST EXTRACTOR ON CARDING ENGINE DUST EXTRACTION IN COTTON MILLS 59i. FIG. 13. DUST EXTRACTORS OVER TWO LINES OF CARDING MACHINES the operator to open the exhaustwhen commencing to strip the cardand to close it immediately the workis finished. The receiver in this in-stallation covers the back and frontportions of the stripping brush, as shown in Fig. 15. Any shutter inthe series may be opened to allow ofinterchange of air for ordinary ven-tilation. This condition is also ad-missible in the event of the card cyl-inders being reground by means of Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/cassiers-magazine-fig-12-hall-kay-dust-extractor-on-carding-engine-dust-extraction-in-cotton-mills-59i-fig-13-dust-extractors-over-two-lines-of-carding-machines-the-operator-to-open-the-exhaustwhen-commencing-to-strip-the-cardand-to-close-it-immediately-the-workis-finished-the-receiver-in-this-in-stallation-covers-the-back-and-frontportions-of-the-stripping-brush-as-shown-in-fig-15-any-shutter-inthe-series-may-be-opened-to-allow-ofinterchange-of-air-for-ordinary-ven-tilation-this-condition-is-also-ad-missible-in-the-event-of-the-card-cyl-inders-being-reground-by-means-of-image372520230.html

. Cassier's magazine . FIG. 12. HALL & KAY DUST EXTRACTOR ON CARDING ENGINE DUST EXTRACTION IN COTTON MILLS 59i. FIG. 13. DUST EXTRACTORS OVER TWO LINES OF CARDING MACHINES the operator to open the exhaustwhen commencing to strip the cardand to close it immediately the workis finished. The receiver in this in-stallation covers the back and frontportions of the stripping brush, as shown in Fig. 15. Any shutter inthe series may be opened to allow ofinterchange of air for ordinary ven-tilation. This condition is also ad-missible in the event of the card cyl-inders being reground by means of Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/cassiers-magazine-fig-12-hall-kay-dust-extractor-on-carding-engine-dust-extraction-in-cotton-mills-59i-fig-13-dust-extractors-over-two-lines-of-carding-machines-the-operator-to-open-the-exhaustwhen-commencing-to-strip-the-cardand-to-close-it-immediately-the-workis-finished-the-receiver-in-this-in-stallation-covers-the-back-and-frontportions-of-the-stripping-brush-as-shown-in-fig-15-any-shutter-inthe-series-may-be-opened-to-allow-ofinterchange-of-air-for-ordinary-ven-tilation-this-condition-is-also-ad-missible-in-the-event-of-the-card-cyl-inders-being-reground-by-means-of-image372520230.htmlRM2CJ1N9X–. Cassier's magazine . FIG. 12. HALL & KAY DUST EXTRACTOR ON CARDING ENGINE DUST EXTRACTION IN COTTON MILLS 59i. FIG. 13. DUST EXTRACTORS OVER TWO LINES OF CARDING MACHINES the operator to open the exhaustwhen commencing to strip the cardand to close it immediately the workis finished. The receiver in this in-stallation covers the back and frontportions of the stripping brush, as shown in Fig. 15. Any shutter inthe series may be opened to allow ofinterchange of air for ordinary ven-tilation. This condition is also ad-missible in the event of the card cyl-inders being reground by means of