Quick filters:

Machine factory 1800s Stock Photos and Images

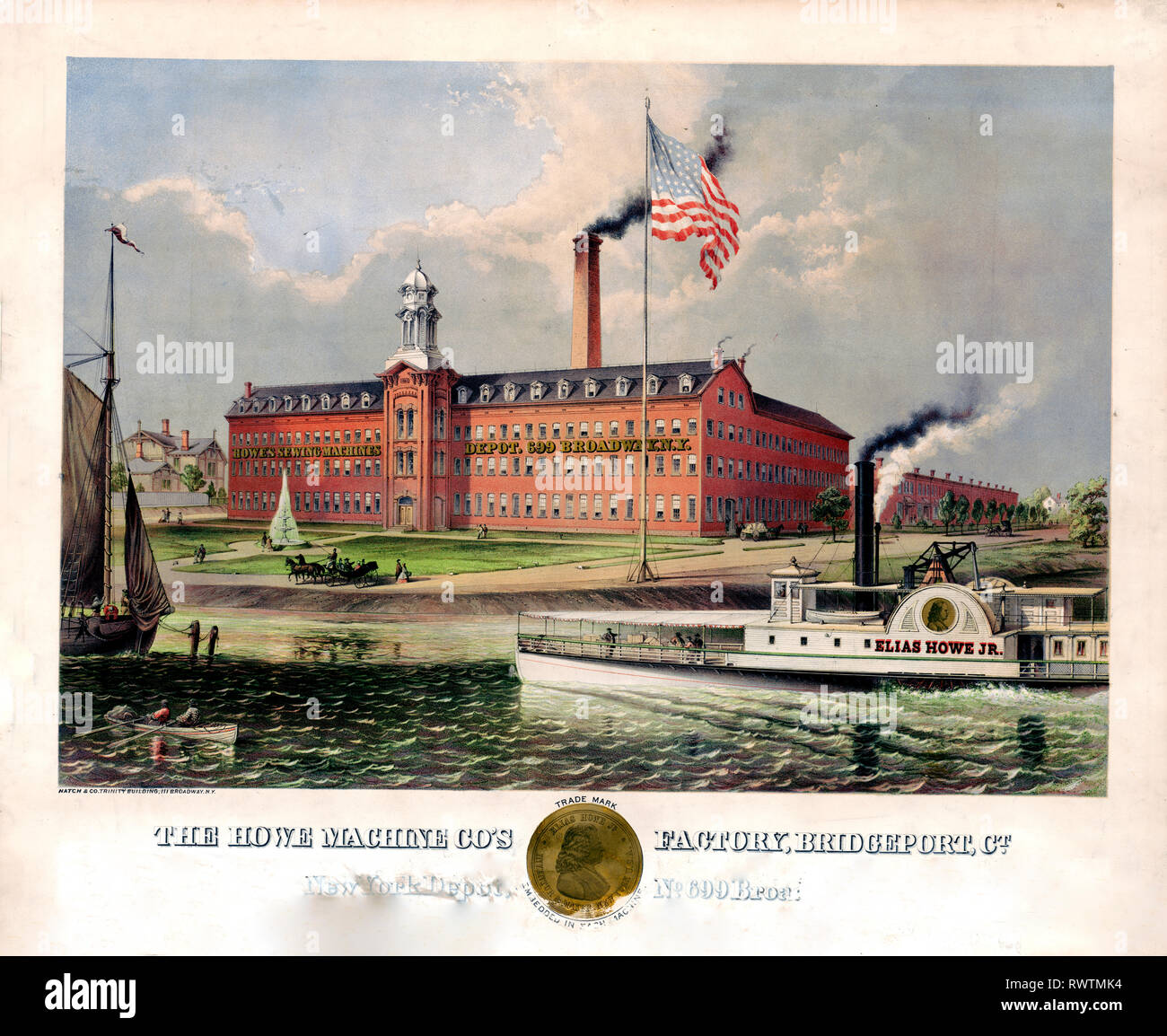

The Howe machine co's factory, Bridgeport, Co. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-howe-machine-cos-factory-bridgeport-co-image239644248.html

The Howe machine co's factory, Bridgeport, Co. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-howe-machine-cos-factory-bridgeport-co-image239644248.htmlRMRWTMK4–The Howe machine co's factory, Bridgeport, Co.

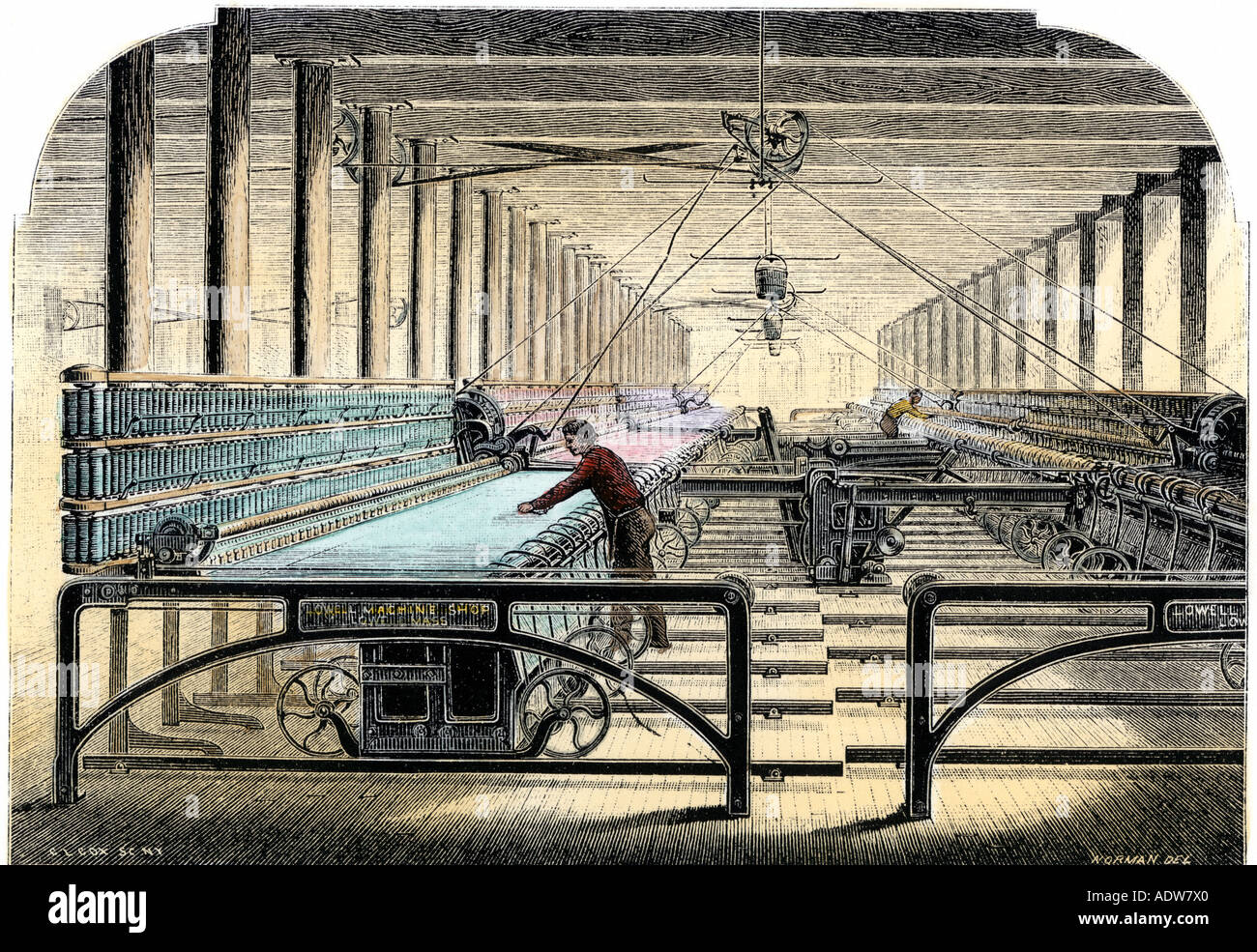

Mill worker tending mule-spinners an industrial textile machine 1800s. Hand-colored woodcut Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/mill-worker-tending-mule-spinners-an-industrial-textile-machine-1800s-image7712479.html

Mill worker tending mule-spinners an industrial textile machine 1800s. Hand-colored woodcut Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/mill-worker-tending-mule-spinners-an-industrial-textile-machine-1800s-image7712479.htmlRMADW7X0–Mill worker tending mule-spinners an industrial textile machine 1800s. Hand-colored woodcut

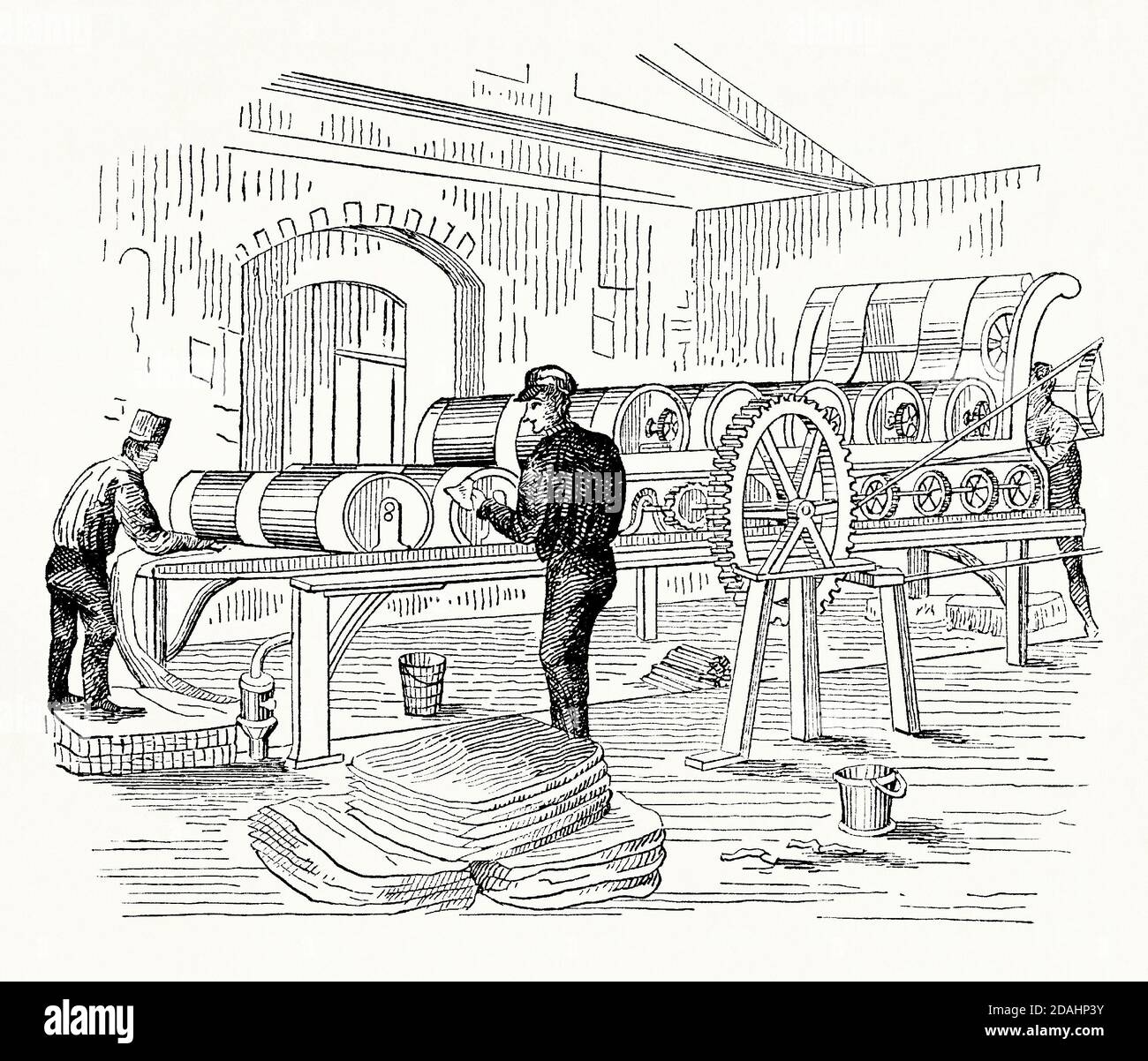

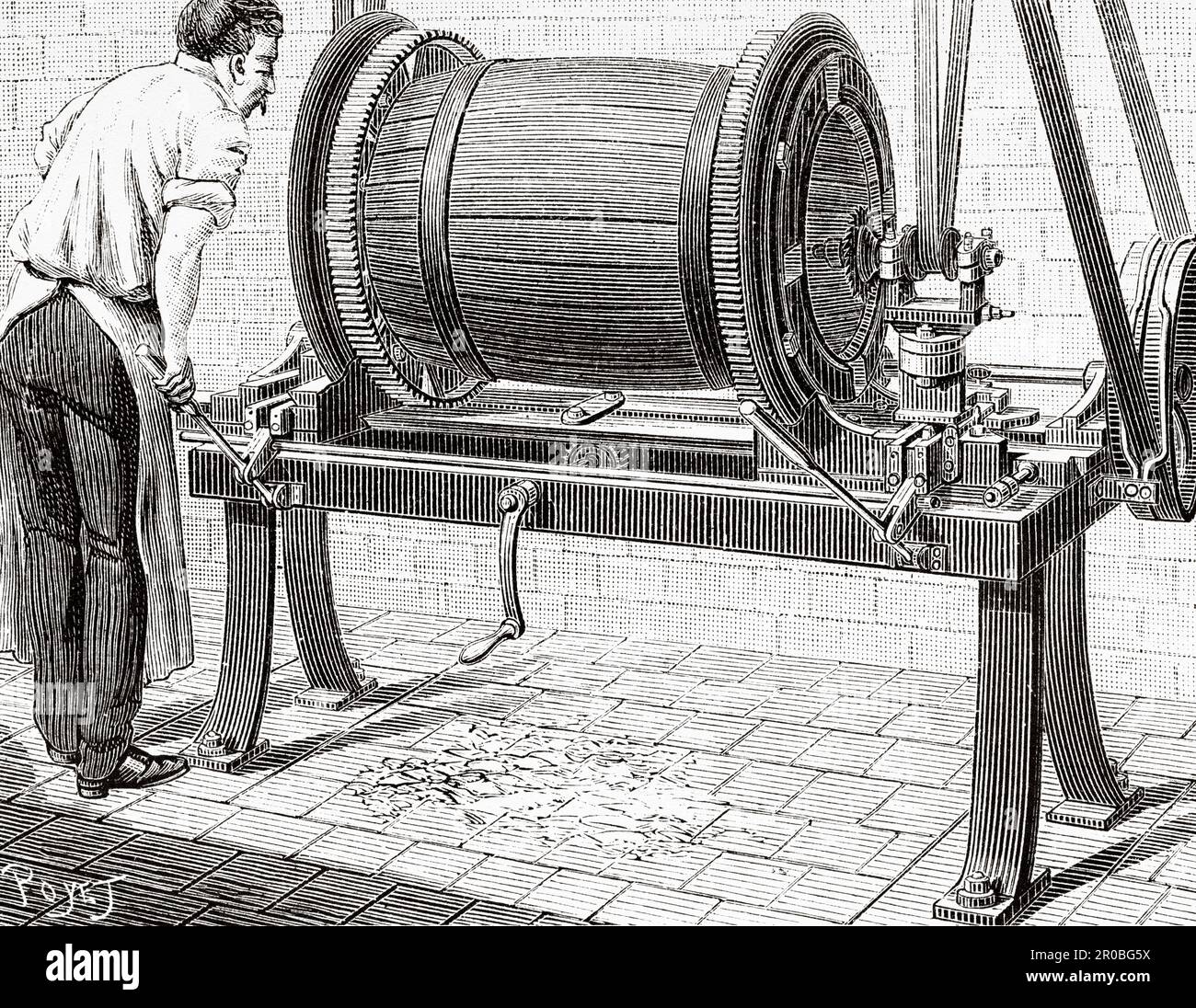

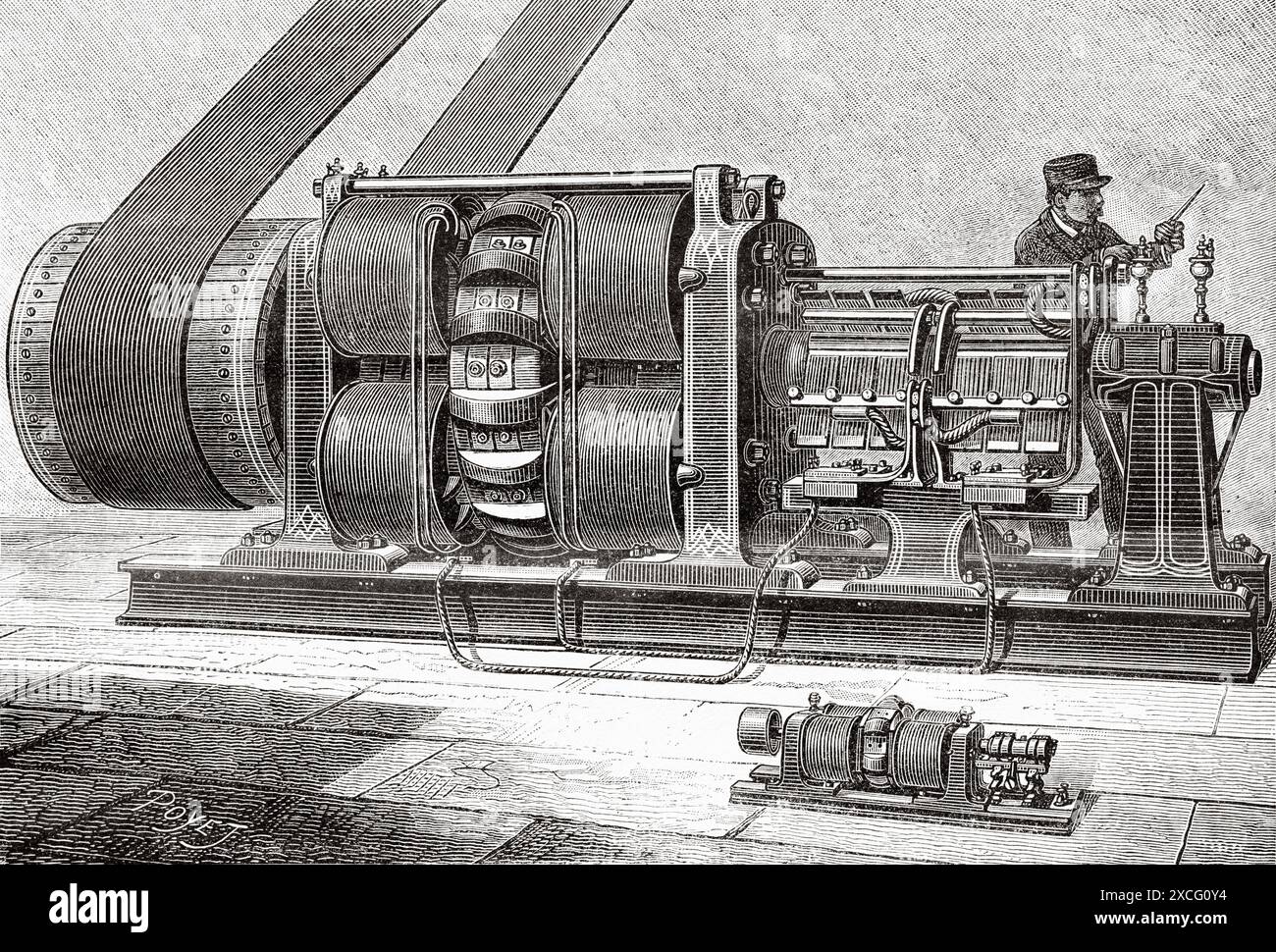

An old engraving showing dash wheels used in the washing of fabric and clothing in a factory or mill the early 1800s. It is from a Victorian mechanical engineering book of the 1880s. These large wheels were large hollow and divided into four compartments, into which bundles of cloth and water were placed. Dirt and impurities were washed out of the cloth as the rapidly revolving drums threw their load backwards and forwards. From the 1820s dash wheels were gradually replaced by the industrial washing machine. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-showing-dash-wheels-used-in-the-washing-of-fabric-and-clothing-in-a-factory-or-mill-the-early-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-these-large-wheels-were-large-hollow-and-divided-into-four-compartments-into-which-bundles-of-cloth-and-water-were-placed-dirt-and-impurities-were-washed-out-of-the-cloth-as-the-rapidly-revolving-drums-threw-their-load-backwards-and-forwards-from-the-1820s-dash-wheels-were-gradually-replaced-by-the-industrial-washing-machine-image384283124.html

An old engraving showing dash wheels used in the washing of fabric and clothing in a factory or mill the early 1800s. It is from a Victorian mechanical engineering book of the 1880s. These large wheels were large hollow and divided into four compartments, into which bundles of cloth and water were placed. Dirt and impurities were washed out of the cloth as the rapidly revolving drums threw their load backwards and forwards. From the 1820s dash wheels were gradually replaced by the industrial washing machine. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-showing-dash-wheels-used-in-the-washing-of-fabric-and-clothing-in-a-factory-or-mill-the-early-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-these-large-wheels-were-large-hollow-and-divided-into-four-compartments-into-which-bundles-of-cloth-and-water-were-placed-dirt-and-impurities-were-washed-out-of-the-cloth-as-the-rapidly-revolving-drums-threw-their-load-backwards-and-forwards-from-the-1820s-dash-wheels-were-gradually-replaced-by-the-industrial-washing-machine-image384283124.htmlRM2D95H18–An old engraving showing dash wheels used in the washing of fabric and clothing in a factory or mill the early 1800s. It is from a Victorian mechanical engineering book of the 1880s. These large wheels were large hollow and divided into four compartments, into which bundles of cloth and water were placed. Dirt and impurities were washed out of the cloth as the rapidly revolving drums threw their load backwards and forwards. From the 1820s dash wheels were gradually replaced by the industrial washing machine.

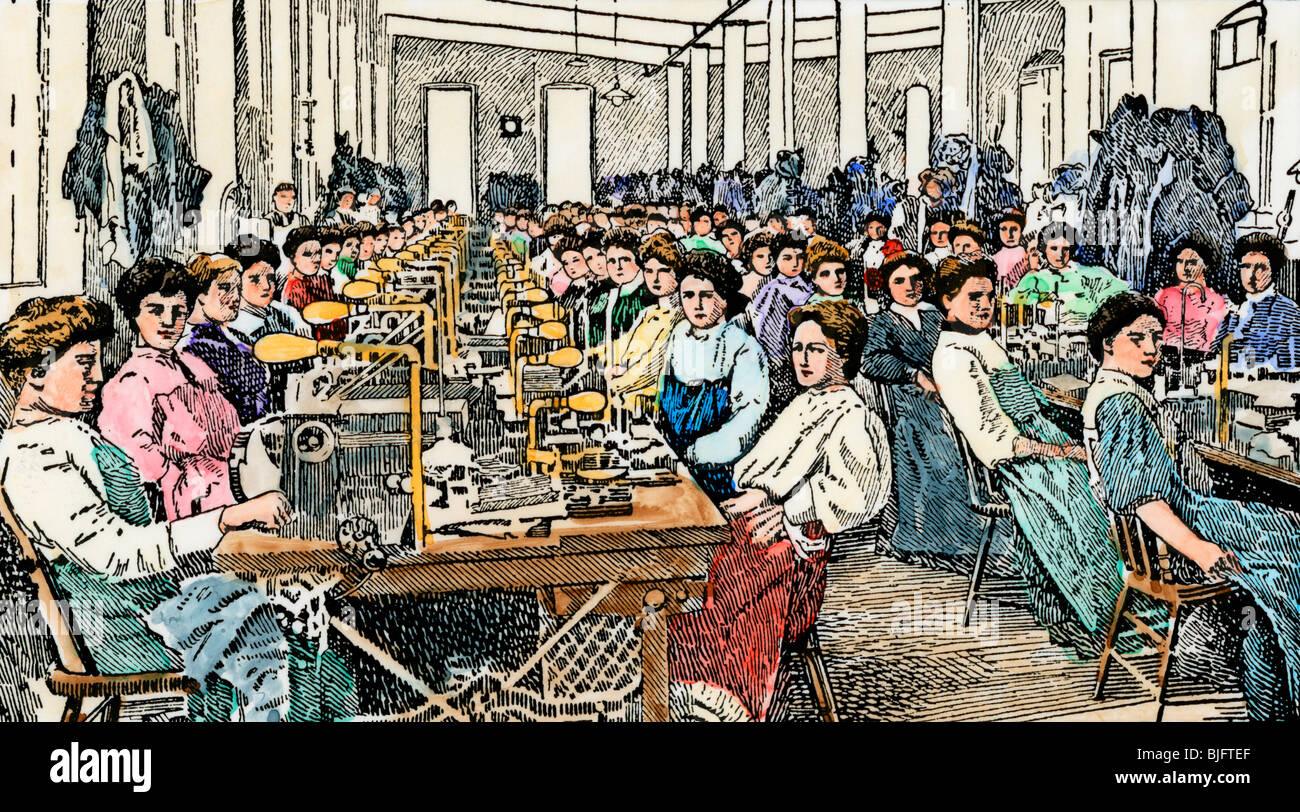

Workers at their machines in a knitting mill, 1800s. Hand-colored woodcut Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-workers-at-their-machines-in-a-knitting-mill-1800s-hand-colored-woodcut-28622679.html

Workers at their machines in a knitting mill, 1800s. Hand-colored woodcut Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-workers-at-their-machines-in-a-knitting-mill-1800s-hand-colored-woodcut-28622679.htmlRMBJFTEF–Workers at their machines in a knitting mill, 1800s. Hand-colored woodcut

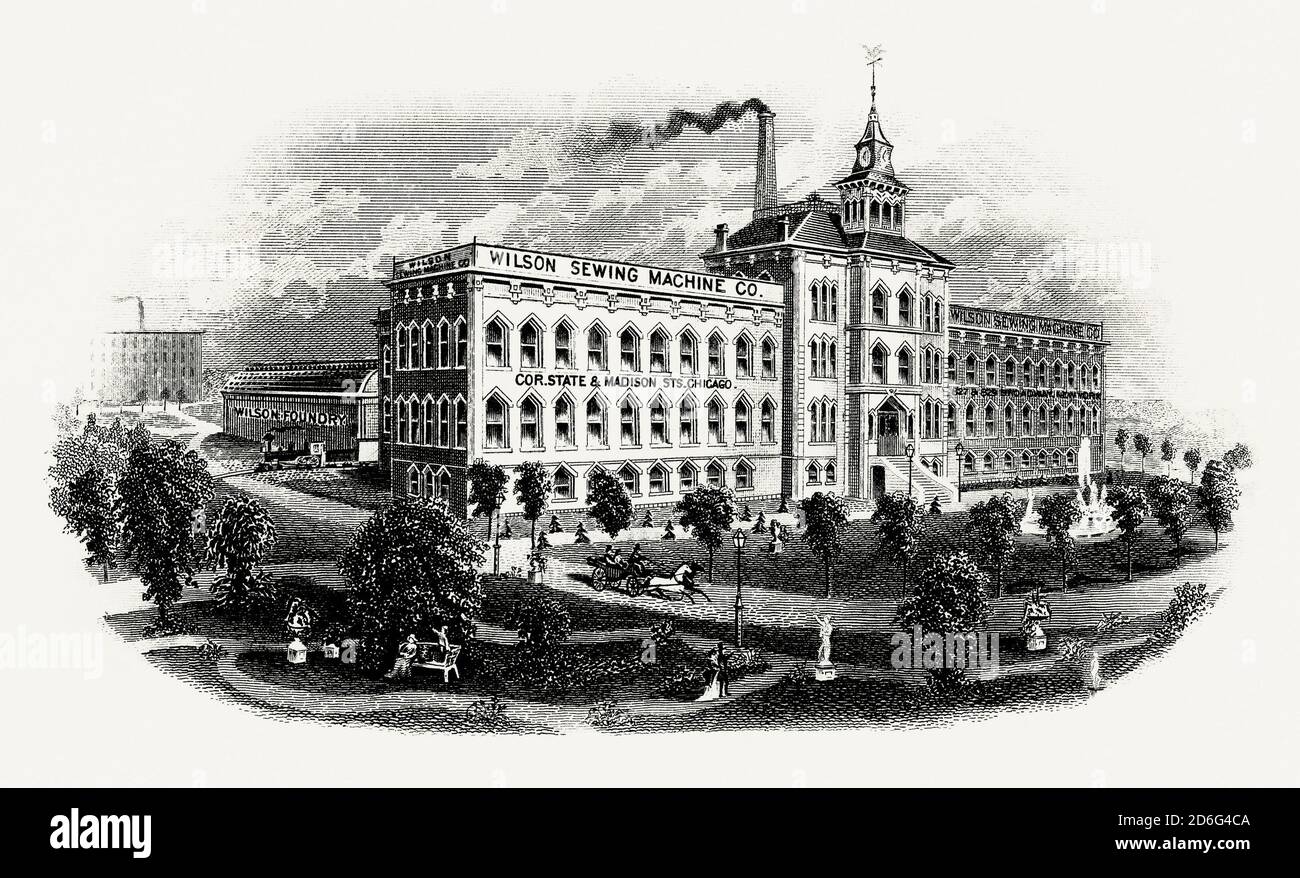

An old engraving of The W G Wilson Company sewing machine factory, Chicago, Illinois, USA. It is from a Victorian mechanical engineering book of the 1880s. The company was originally based in Cleveland but moved their operations to Chicago in 1875. Machines could be delivered, free of charge, at any railroad depot in the USA. At the Centennial Exposition of 1876 Wilson received the Grand Prize Medal and Diploma. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-the-w-g-wilson-company-sewing-machine-factory-chicago-illinois-usa-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-the-company-was-originally-based-in-cleveland-but-moved-their-operations-to-chicago-in-1875-machines-could-be-delivered-free-of-charge-at-any-railroad-depot-in-the-usa-at-the-centennial-exposition-of-1876-wilson-received-the-grand-prize-medal-and-diploma-image382670746.html

An old engraving of The W G Wilson Company sewing machine factory, Chicago, Illinois, USA. It is from a Victorian mechanical engineering book of the 1880s. The company was originally based in Cleveland but moved their operations to Chicago in 1875. Machines could be delivered, free of charge, at any railroad depot in the USA. At the Centennial Exposition of 1876 Wilson received the Grand Prize Medal and Diploma. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-the-w-g-wilson-company-sewing-machine-factory-chicago-illinois-usa-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-the-company-was-originally-based-in-cleveland-but-moved-their-operations-to-chicago-in-1875-machines-could-be-delivered-free-of-charge-at-any-railroad-depot-in-the-usa-at-the-centennial-exposition-of-1876-wilson-received-the-grand-prize-medal-and-diploma-image382670746.htmlRM2D6G4CA–An old engraving of The W G Wilson Company sewing machine factory, Chicago, Illinois, USA. It is from a Victorian mechanical engineering book of the 1880s. The company was originally based in Cleveland but moved their operations to Chicago in 1875. Machines could be delivered, free of charge, at any railroad depot in the USA. At the Centennial Exposition of 1876 Wilson received the Grand Prize Medal and Diploma.

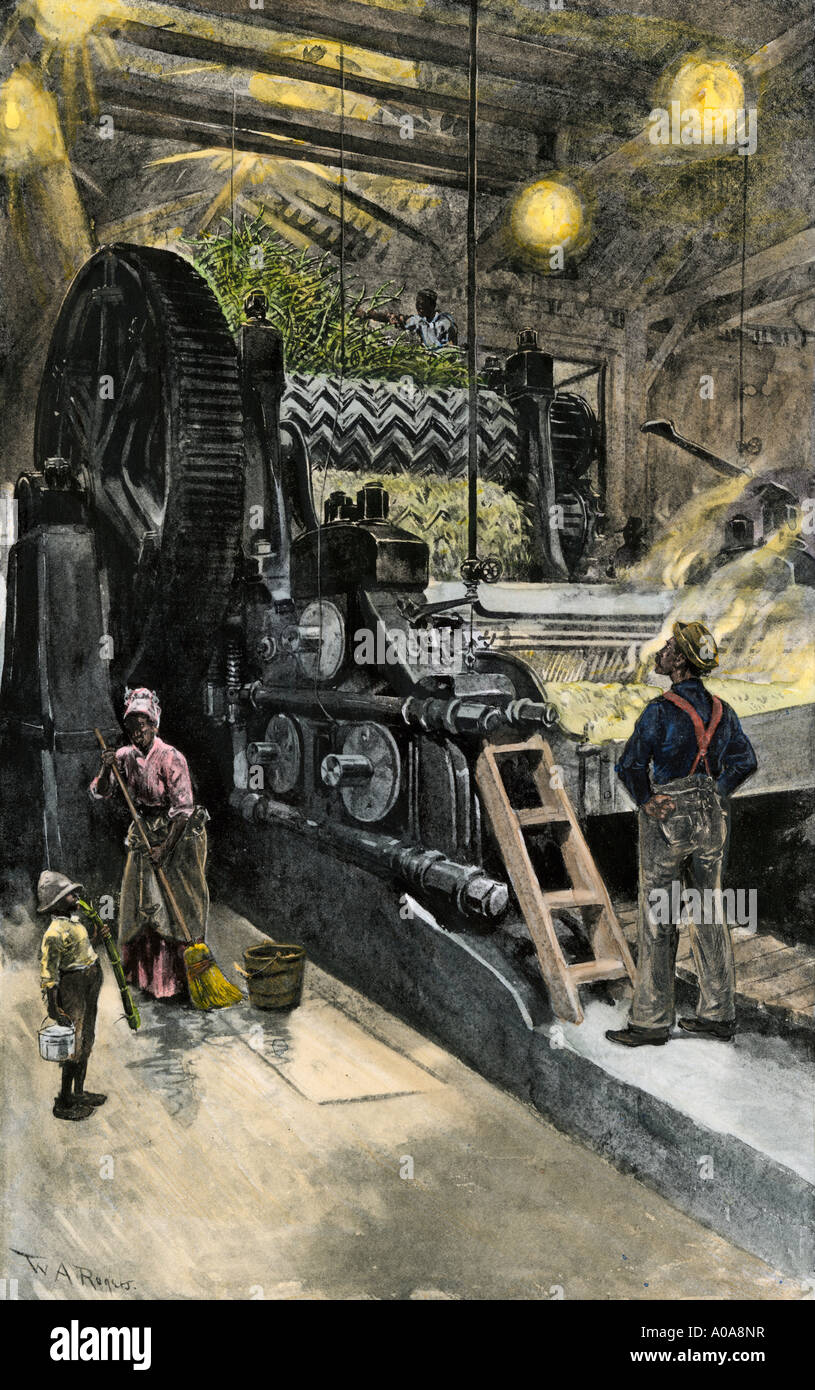

African American workers operating a cane crushing machine in a sugar house at Bayou Teche Louisiana 1900. Hand-colored halftone of an illustration Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/african-american-workers-operating-a-cane-crushing-machine-in-a-sugar-image9931522.html

African American workers operating a cane crushing machine in a sugar house at Bayou Teche Louisiana 1900. Hand-colored halftone of an illustration Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/african-american-workers-operating-a-cane-crushing-machine-in-a-sugar-image9931522.htmlRMA0A8NR–African American workers operating a cane crushing machine in a sugar house at Bayou Teche Louisiana 1900. Hand-colored halftone of an illustration

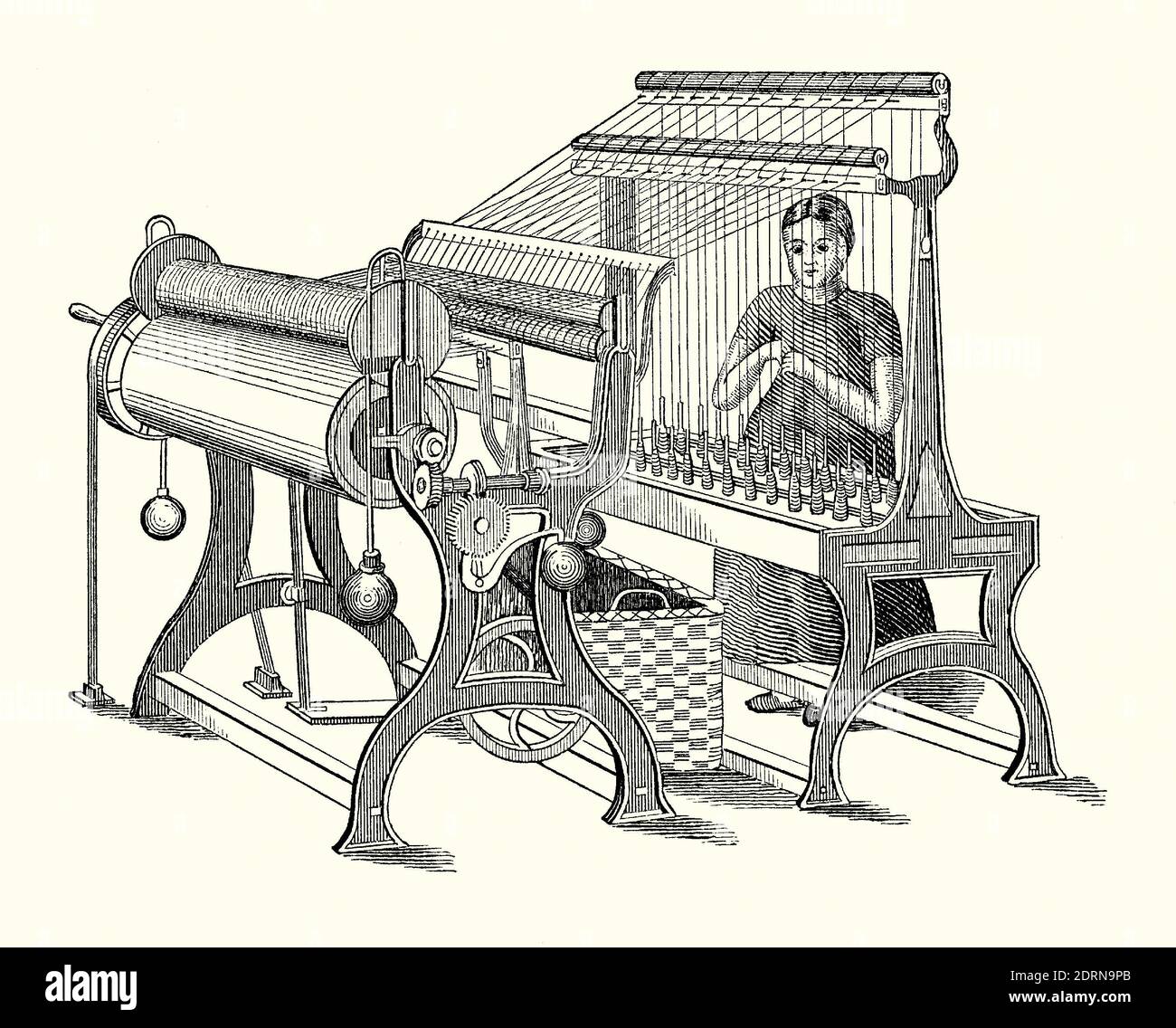

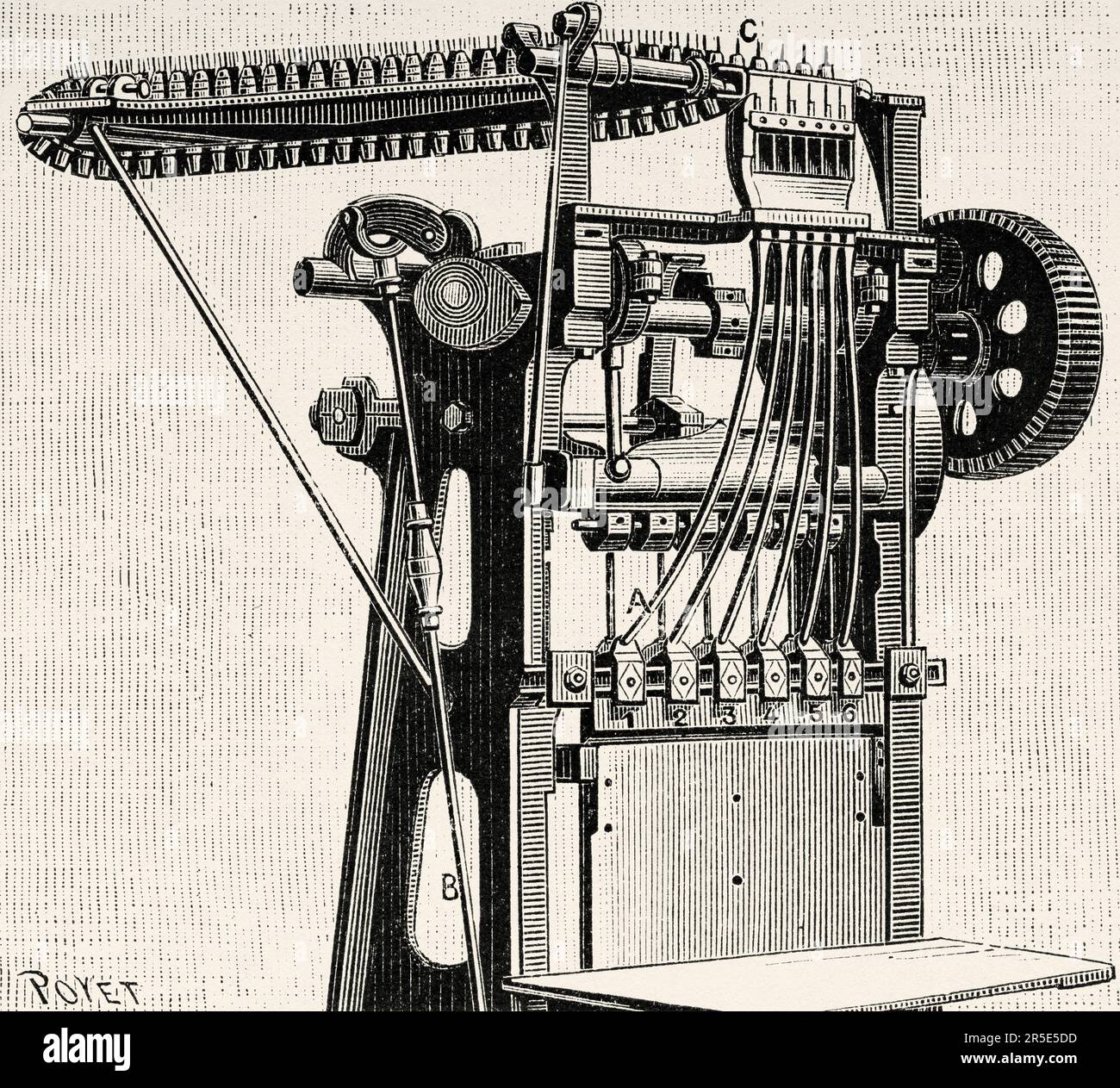

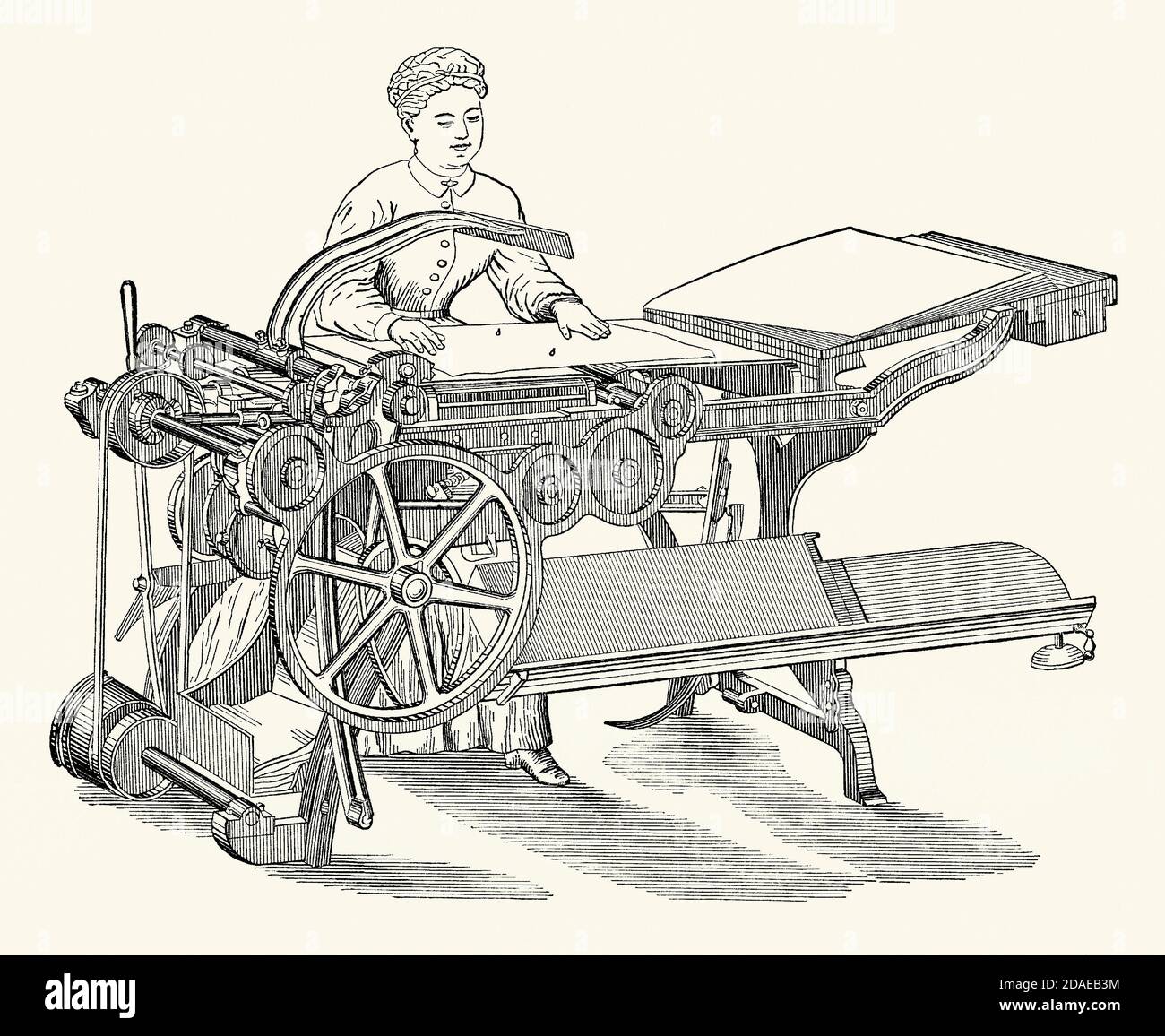

An old engraving of a woman working at a yarn spooler machine in a textile mill the 1800s. It is from a Victorian mechanical engineering book of the 1880s. This powered machine is designed to speedily wrap the fibre onto spools, bobbins or shuttles. Cotton, linen or wool yarn is held on rollers (right) and fed down through the ‘eyes’ to the spindles which are rotated from gears below them. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-woman-working-at-a-yarn-spooler-machine-in-a-textile-mill-the-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-this-powered-machine-is-designed-to-speedily-wrap-the-fibre-onto-spools-bobbins-or-shuttles-cotton-linen-or-wool-yarn-is-held-on-rollers-right-and-fed-down-through-the-eyes-to-the-spindles-which-are-rotated-from-gears-below-them-image393233859.html

An old engraving of a woman working at a yarn spooler machine in a textile mill the 1800s. It is from a Victorian mechanical engineering book of the 1880s. This powered machine is designed to speedily wrap the fibre onto spools, bobbins or shuttles. Cotton, linen or wool yarn is held on rollers (right) and fed down through the ‘eyes’ to the spindles which are rotated from gears below them. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-woman-working-at-a-yarn-spooler-machine-in-a-textile-mill-the-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-this-powered-machine-is-designed-to-speedily-wrap-the-fibre-onto-spools-bobbins-or-shuttles-cotton-linen-or-wool-yarn-is-held-on-rollers-right-and-fed-down-through-the-eyes-to-the-spindles-which-are-rotated-from-gears-below-them-image393233859.htmlRM2DRN9PB–An old engraving of a woman working at a yarn spooler machine in a textile mill the 1800s. It is from a Victorian mechanical engineering book of the 1880s. This powered machine is designed to speedily wrap the fibre onto spools, bobbins or shuttles. Cotton, linen or wool yarn is held on rollers (right) and fed down through the ‘eyes’ to the spindles which are rotated from gears below them.

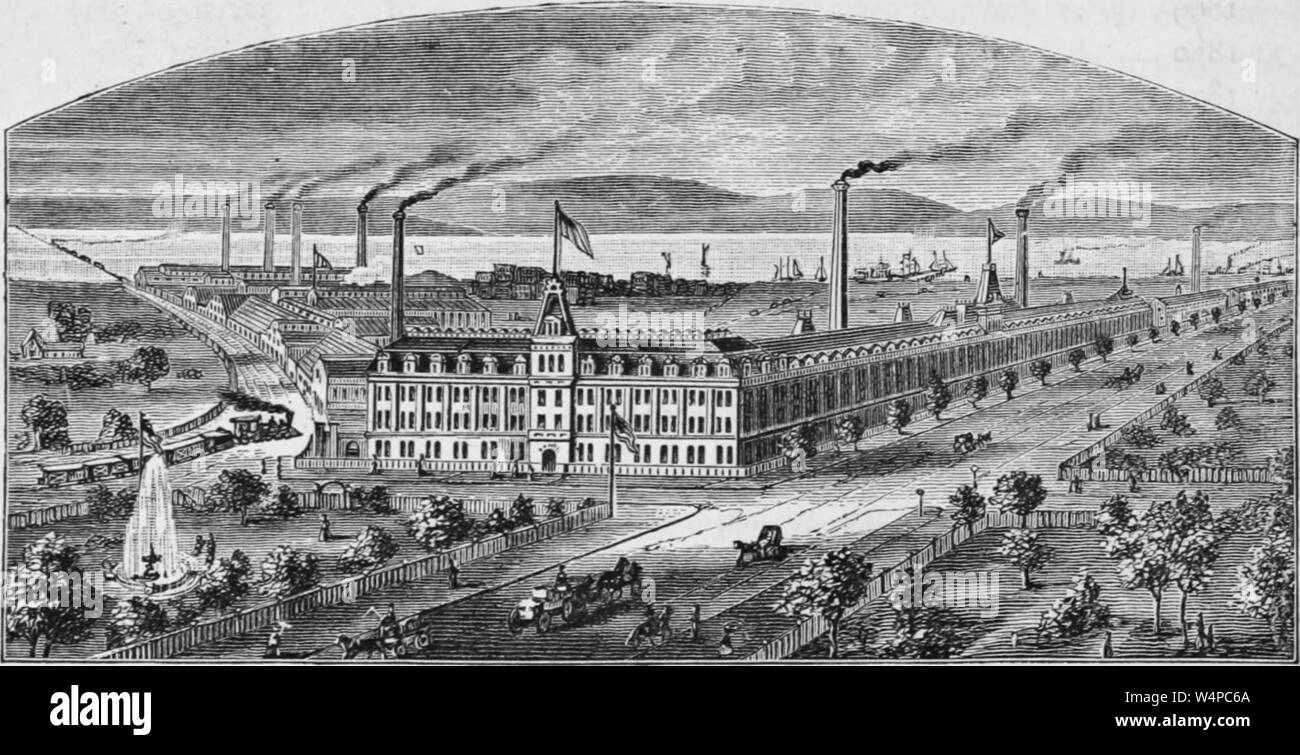

Engraving of the Singer Sewing Machine Company factory, Elizabethport, New Jersey, from the book 'Industrial history of the United States' by Albert Sidney Bolles, 1878. Courtesy Internet Archive. () Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-the-singer-sewing-machine-company-factory-elizabethport-new-jersey-from-the-book-industrial-history-of-the-united-states-by-albert-sidney-bolles-1878-courtesy-internet-archive-image261106674.html

Engraving of the Singer Sewing Machine Company factory, Elizabethport, New Jersey, from the book 'Industrial history of the United States' by Albert Sidney Bolles, 1878. Courtesy Internet Archive. () Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-the-singer-sewing-machine-company-factory-elizabethport-new-jersey-from-the-book-industrial-history-of-the-united-states-by-albert-sidney-bolles-1878-courtesy-internet-archive-image261106674.htmlRMW4PC6A–Engraving of the Singer Sewing Machine Company factory, Elizabethport, New Jersey, from the book 'Industrial history of the United States' by Albert Sidney Bolles, 1878. Courtesy Internet Archive. ()

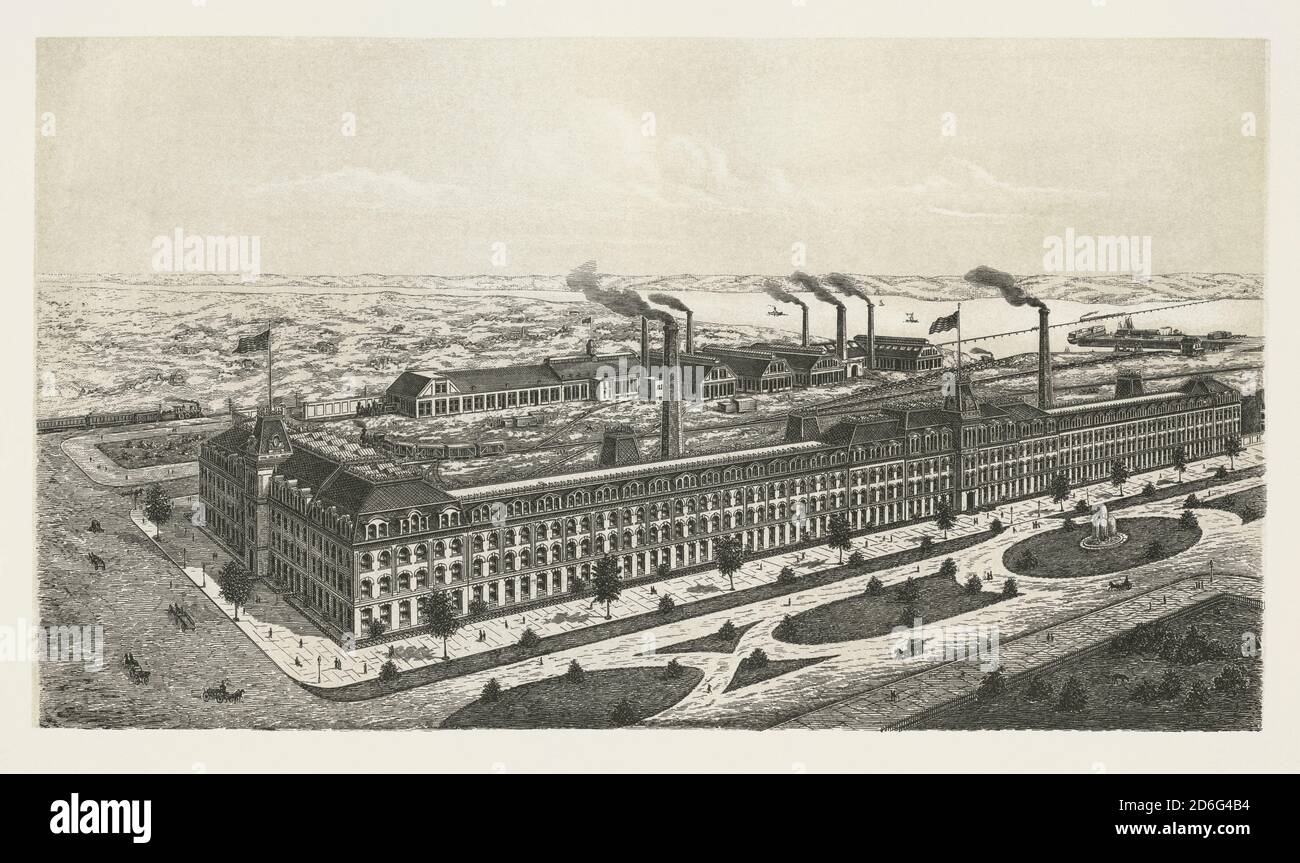

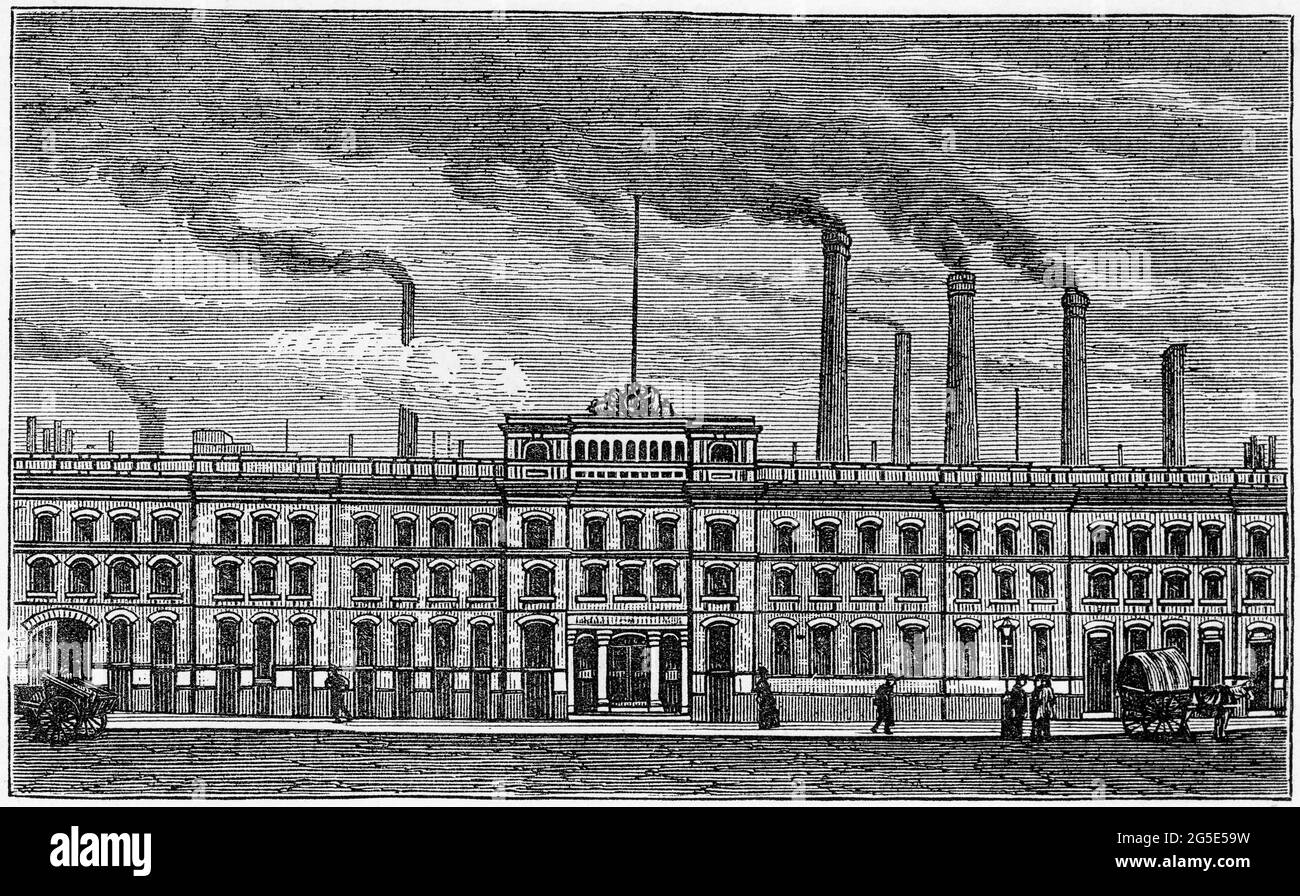

An old engraving of the Singer sewing machine factory, Elizabeth, New Jersey, USA. It is from a Victorian mechanical engineering book of the 1880s. The Singer Corporation is an American manufacturer of consumer sewing machines, first established as I M Singer & Co in 1851 by Isaac M Singer and New York lawyer Edward C Clark. It was renamed Singer Manufacturing Company in 1865, then the Singer Company in 1963. Its first large factory was built in 1863 in New Jersey but it is now based in La Vergne, Tennessee, near Nashville. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-the-singer-sewing-machine-factory-elizabeth-new-jersey-usa-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-the-singer-corporation-is-an-american-manufacturer-of-consumer-sewing-machines-first-established-as-i-m-singer-co-in-1851-by-isaac-m-singer-and-new-york-lawyer-edward-c-clark-it-was-renamed-singer-manufacturing-company-in-1865-then-the-singer-company-in-1963-its-first-large-factory-was-built-in-1863-in-new-jersey-but-it-is-now-based-in-la-vergne-tennessee-near-nashville-image382670712.html

An old engraving of the Singer sewing machine factory, Elizabeth, New Jersey, USA. It is from a Victorian mechanical engineering book of the 1880s. The Singer Corporation is an American manufacturer of consumer sewing machines, first established as I M Singer & Co in 1851 by Isaac M Singer and New York lawyer Edward C Clark. It was renamed Singer Manufacturing Company in 1865, then the Singer Company in 1963. Its first large factory was built in 1863 in New Jersey but it is now based in La Vergne, Tennessee, near Nashville. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-the-singer-sewing-machine-factory-elizabeth-new-jersey-usa-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-the-singer-corporation-is-an-american-manufacturer-of-consumer-sewing-machines-first-established-as-i-m-singer-co-in-1851-by-isaac-m-singer-and-new-york-lawyer-edward-c-clark-it-was-renamed-singer-manufacturing-company-in-1865-then-the-singer-company-in-1963-its-first-large-factory-was-built-in-1863-in-new-jersey-but-it-is-now-based-in-la-vergne-tennessee-near-nashville-image382670712.htmlRM2D6G4B4–An old engraving of the Singer sewing machine factory, Elizabeth, New Jersey, USA. It is from a Victorian mechanical engineering book of the 1880s. The Singer Corporation is an American manufacturer of consumer sewing machines, first established as I M Singer & Co in 1851 by Isaac M Singer and New York lawyer Edward C Clark. It was renamed Singer Manufacturing Company in 1865, then the Singer Company in 1963. Its first large factory was built in 1863 in New Jersey but it is now based in La Vergne, Tennessee, near Nashville.

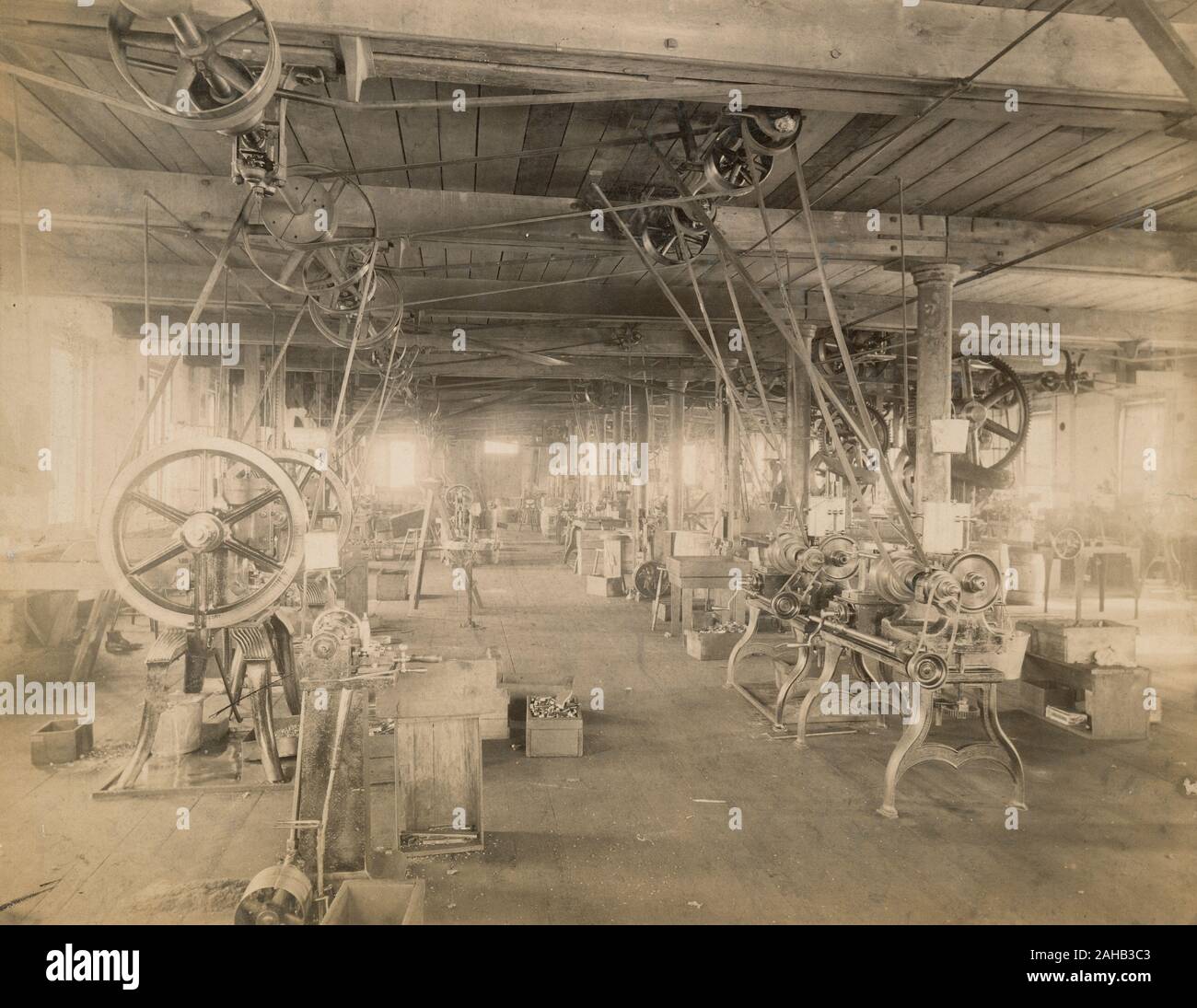

Antique c1890 photograph, machine room at the Crandall, Stone & Co. carriage hardware factory in Binghamton, New York. SOURCE: ORIGINAL PHOTOGRAPH Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/antique-c1890-photograph-machine-room-at-the-crandall-stone-co-carriage-hardware-factory-in-binghamton-new-york-source-original-photograph-image337690307.html

Antique c1890 photograph, machine room at the Crandall, Stone & Co. carriage hardware factory in Binghamton, New York. SOURCE: ORIGINAL PHOTOGRAPH Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/antique-c1890-photograph-machine-room-at-the-crandall-stone-co-carriage-hardware-factory-in-binghamton-new-york-source-original-photograph-image337690307.htmlRM2AHB3C3–Antique c1890 photograph, machine room at the Crandall, Stone & Co. carriage hardware factory in Binghamton, New York. SOURCE: ORIGINAL PHOTOGRAPH

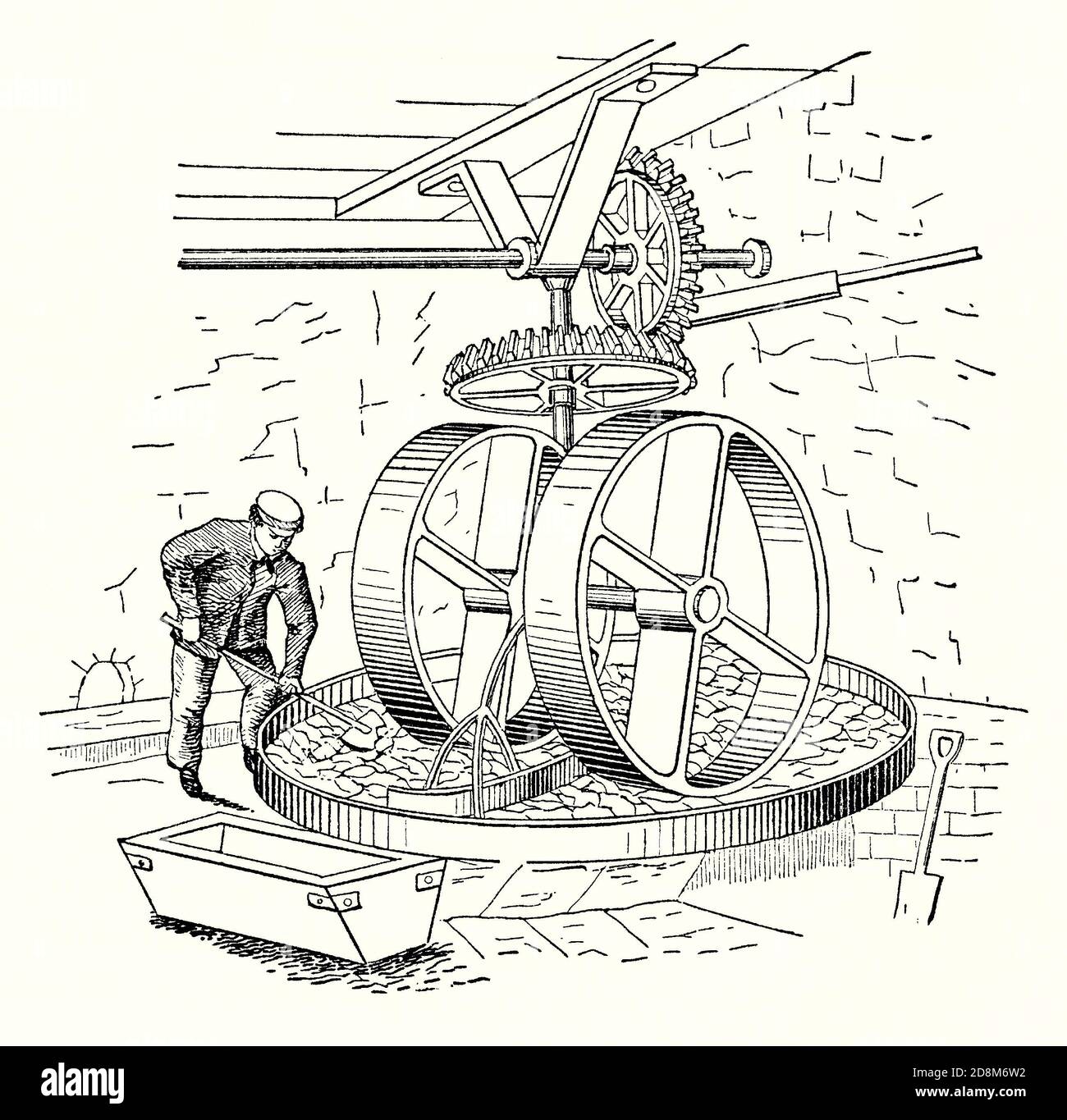

An old engraving of a clay mill in the 1800s. It is from a Victorian mechanical engineering book of the 1880s. The illustration shows the clay being worked by a belt-driven system with cogs and gears. A clay mill, pugmill or pug mill is the machinery in which clay (or other materials) are mixed into a plastic state. Industrial applications include mixing for pottery, bricks and cement. Some mills were driven by horses. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-clay-mill-in-the-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-the-illustration-shows-the-clay-being-worked-by-a-belt-driven-system-with-cogs-and-gears-a-clay-mill-pugmill-or-pug-mill-is-the-machinery-in-which-clay-or-other-materials-are-mixed-into-a-plastic-state-industrial-applications-include-mixing-for-pottery-bricks-and-cement-some-mills-were-driven-by-horses-image383989790.html

An old engraving of a clay mill in the 1800s. It is from a Victorian mechanical engineering book of the 1880s. The illustration shows the clay being worked by a belt-driven system with cogs and gears. A clay mill, pugmill or pug mill is the machinery in which clay (or other materials) are mixed into a plastic state. Industrial applications include mixing for pottery, bricks and cement. Some mills were driven by horses. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-clay-mill-in-the-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-the-illustration-shows-the-clay-being-worked-by-a-belt-driven-system-with-cogs-and-gears-a-clay-mill-pugmill-or-pug-mill-is-the-machinery-in-which-clay-or-other-materials-are-mixed-into-a-plastic-state-industrial-applications-include-mixing-for-pottery-bricks-and-cement-some-mills-were-driven-by-horses-image383989790.htmlRM2D8M6W2–An old engraving of a clay mill in the 1800s. It is from a Victorian mechanical engineering book of the 1880s. The illustration shows the clay being worked by a belt-driven system with cogs and gears. A clay mill, pugmill or pug mill is the machinery in which clay (or other materials) are mixed into a plastic state. Industrial applications include mixing for pottery, bricks and cement. Some mills were driven by horses.

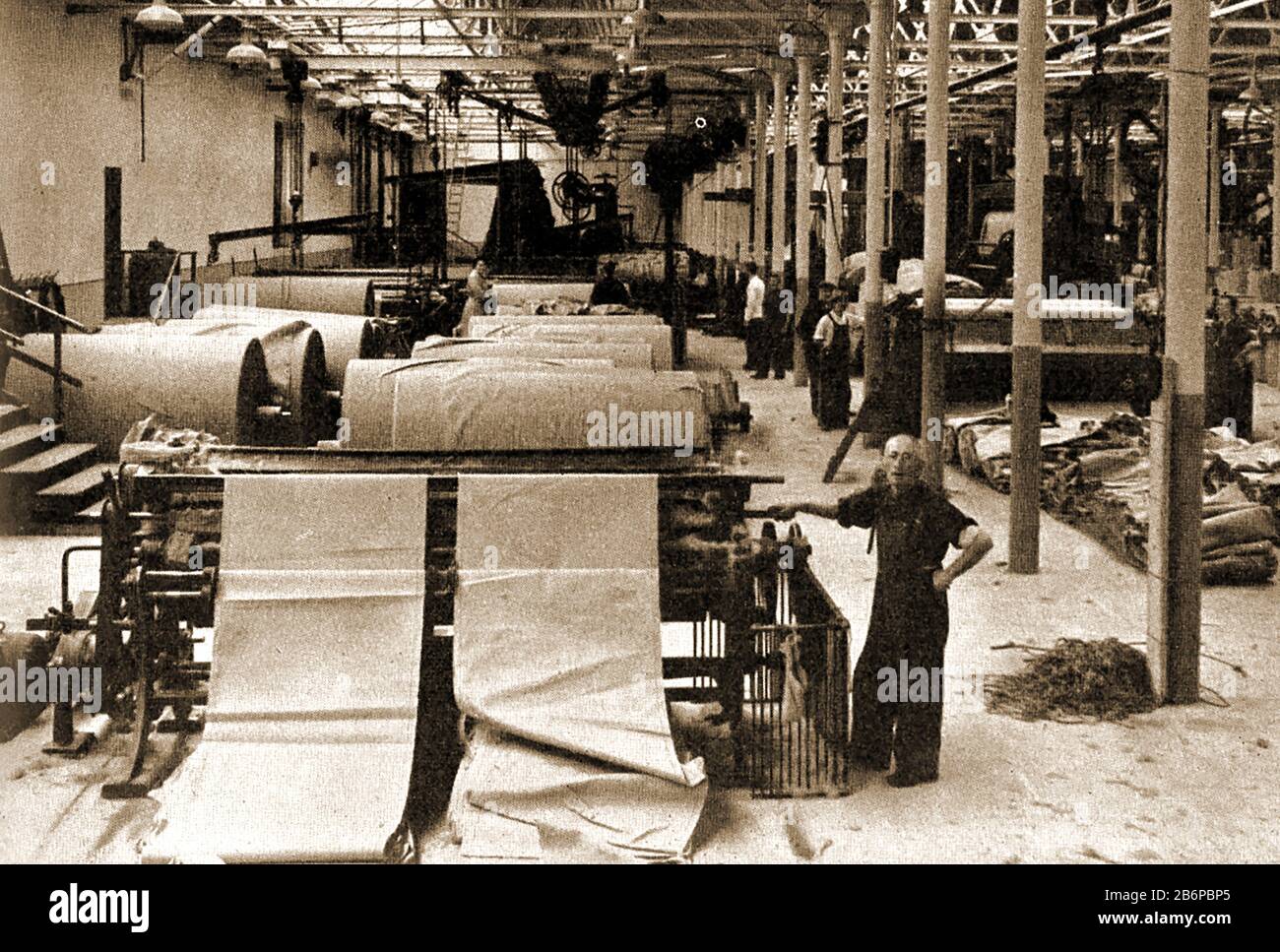

An early photograph showing a worker at a Jute factory in Dundee, Scotland putting sacking cloth through a cropping machine. Throughout the late 1800s, more than half of Dundee’s workforce worked in the textile sector, (mainly jute). Jute was cheap and hard wearing & was ideal for sacks, bags, sandbags, packing materials & even cart covers (like those used by wild west pioneers). During most of the time, a majority of females worked in the industry earning a wage men couldn't equal, Consequently men stayed at home as 'house-husbands' and were known locally as kettle bilers (kettle boilers). Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-early-photograph-showing-a-worker-at-a-jute-factory-in-dundee-scotland-putting-sacking-cloth-through-a-cropping-machine-throughout-the-late-1800s-more-than-half-of-dundees-workforce-worked-in-the-textile-sector-mainly-jute-jute-was-cheap-and-hard-wearing-was-ideal-for-sacks-bags-sandbags-packing-materials-even-cart-covers-like-those-used-by-wild-west-pioneers-during-most-of-the-time-a-majority-of-females-worked-in-the-industry-earning-a-wage-men-couldnt-equal-consequently-men-stayed-at-home-as-house-husbands-and-were-known-locally-as-kettle-bilers-kettle-boilers-image348387485.html

An early photograph showing a worker at a Jute factory in Dundee, Scotland putting sacking cloth through a cropping machine. Throughout the late 1800s, more than half of Dundee’s workforce worked in the textile sector, (mainly jute). Jute was cheap and hard wearing & was ideal for sacks, bags, sandbags, packing materials & even cart covers (like those used by wild west pioneers). During most of the time, a majority of females worked in the industry earning a wage men couldn't equal, Consequently men stayed at home as 'house-husbands' and were known locally as kettle bilers (kettle boilers). Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-early-photograph-showing-a-worker-at-a-jute-factory-in-dundee-scotland-putting-sacking-cloth-through-a-cropping-machine-throughout-the-late-1800s-more-than-half-of-dundees-workforce-worked-in-the-textile-sector-mainly-jute-jute-was-cheap-and-hard-wearing-was-ideal-for-sacks-bags-sandbags-packing-materials-even-cart-covers-like-those-used-by-wild-west-pioneers-during-most-of-the-time-a-majority-of-females-worked-in-the-industry-earning-a-wage-men-couldnt-equal-consequently-men-stayed-at-home-as-house-husbands-and-were-known-locally-as-kettle-bilers-kettle-boilers-image348387485.htmlRM2B6PBP5–An early photograph showing a worker at a Jute factory in Dundee, Scotland putting sacking cloth through a cropping machine. Throughout the late 1800s, more than half of Dundee’s workforce worked in the textile sector, (mainly jute). Jute was cheap and hard wearing & was ideal for sacks, bags, sandbags, packing materials & even cart covers (like those used by wild west pioneers). During most of the time, a majority of females worked in the industry earning a wage men couldn't equal, Consequently men stayed at home as 'house-husbands' and were known locally as kettle bilers (kettle boilers).

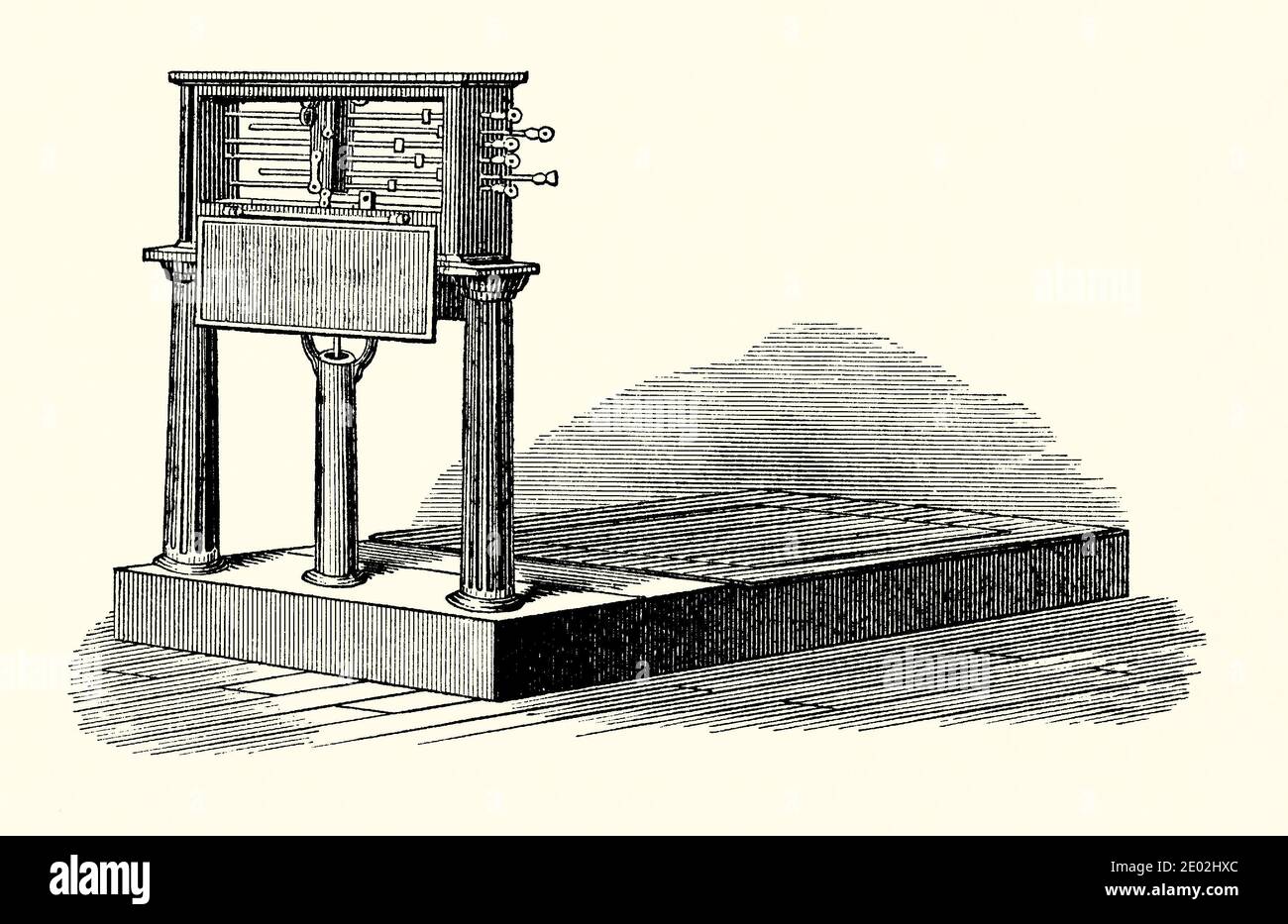

An old engraving of platform scales manufactured by E and T Fairbanks and Company in the 1800s. It is from a Victorian mechanical engineering book of the 1880s. These scales were useful to weigh loads in places like factories and warehouses. American Thaddeus Fairbanks (1796 –1886) was an American inventor. In 1824 he built an iron foundry in St Johnsbury, Vermont, USA with his brother Erastus. Fairbanks’s most famous invention, ‘The Fairbanks Scales’, a platform scale, capable of weighing of very large loads accurately. Fairbanks Scales continue to be made in St Johnsbury. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-platform-scales-manufactured-by-e-and-t-fairbanks-and-company-in-the-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-these-scales-were-useful-to-weigh-loads-in-places-like-factories-and-warehouses-american-thaddeus-fairbanks-1796-1886-was-an-american-inventor-in-1824-he-built-an-iron-foundry-in-st-johnsbury-vermont-usa-with-his-brother-erastus-fairbankss-most-famous-invention-the-fairbanks-scales-a-platform-scale-capable-of-weighing-of-very-large-loads-accurately-fairbanks-scales-continue-to-be-made-in-st-johnsbury-image395896436.html

An old engraving of platform scales manufactured by E and T Fairbanks and Company in the 1800s. It is from a Victorian mechanical engineering book of the 1880s. These scales were useful to weigh loads in places like factories and warehouses. American Thaddeus Fairbanks (1796 –1886) was an American inventor. In 1824 he built an iron foundry in St Johnsbury, Vermont, USA with his brother Erastus. Fairbanks’s most famous invention, ‘The Fairbanks Scales’, a platform scale, capable of weighing of very large loads accurately. Fairbanks Scales continue to be made in St Johnsbury. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-platform-scales-manufactured-by-e-and-t-fairbanks-and-company-in-the-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-these-scales-were-useful-to-weigh-loads-in-places-like-factories-and-warehouses-american-thaddeus-fairbanks-1796-1886-was-an-american-inventor-in-1824-he-built-an-iron-foundry-in-st-johnsbury-vermont-usa-with-his-brother-erastus-fairbankss-most-famous-invention-the-fairbanks-scales-a-platform-scale-capable-of-weighing-of-very-large-loads-accurately-fairbanks-scales-continue-to-be-made-in-st-johnsbury-image395896436.htmlRM2E02HXC–An old engraving of platform scales manufactured by E and T Fairbanks and Company in the 1800s. It is from a Victorian mechanical engineering book of the 1880s. These scales were useful to weigh loads in places like factories and warehouses. American Thaddeus Fairbanks (1796 –1886) was an American inventor. In 1824 he built an iron foundry in St Johnsbury, Vermont, USA with his brother Erastus. Fairbanks’s most famous invention, ‘The Fairbanks Scales’, a platform scale, capable of weighing of very large loads accurately. Fairbanks Scales continue to be made in St Johnsbury.

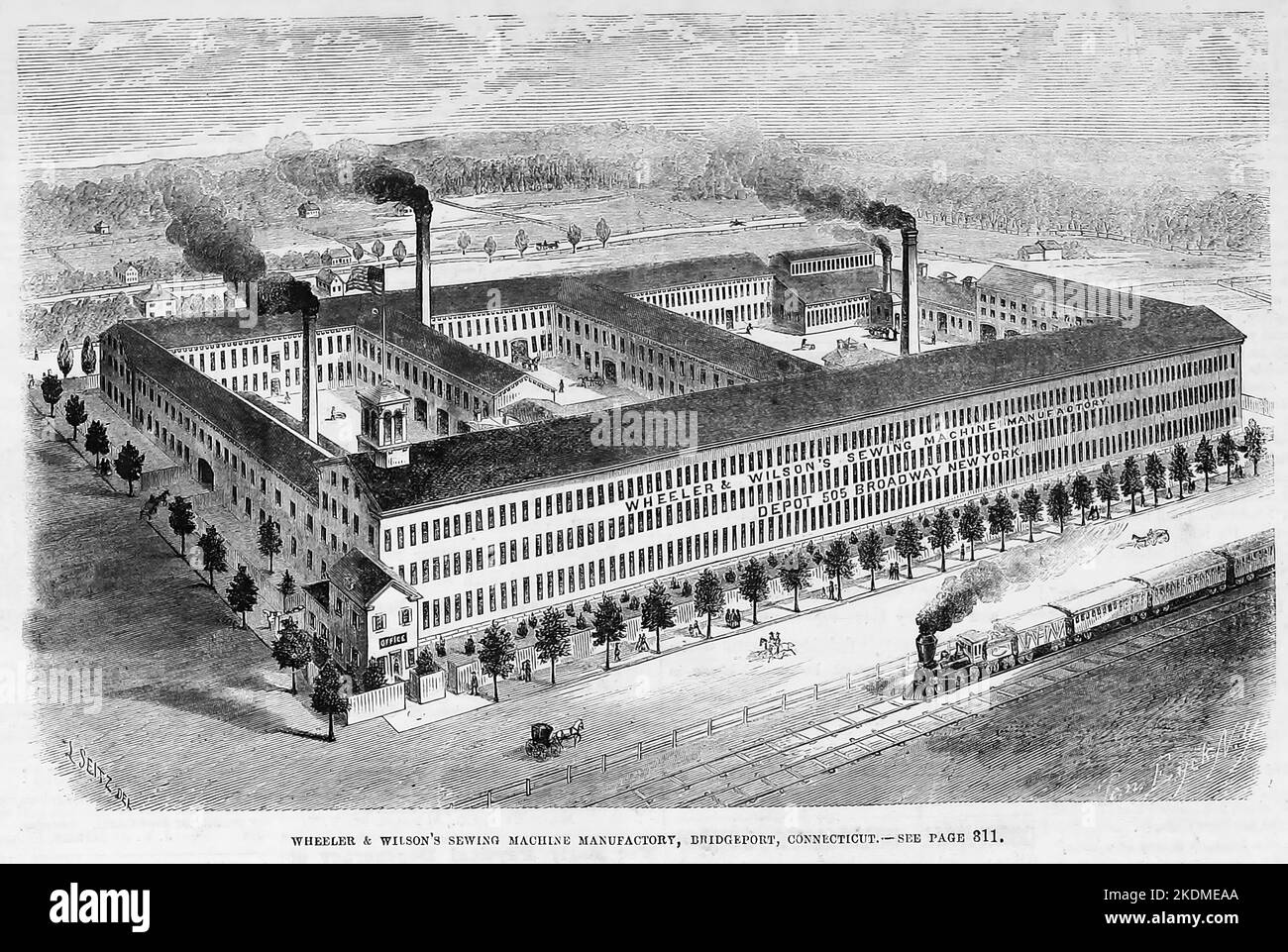

Wheeler and Wilson Sewing Machine Manufactory, Bridgeport, Connecticut. January 1863. 19th century American Civil War illustration from Frank Leslie's Illustrated Newspaper Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/wheeler-and-wilson-sewing-machine-manufactory-bridgeport-connecticut-january-1863-19th-century-american-civil-war-illustration-from-frank-leslies-illustrated-newspaper-image490331138.html

Wheeler and Wilson Sewing Machine Manufactory, Bridgeport, Connecticut. January 1863. 19th century American Civil War illustration from Frank Leslie's Illustrated Newspaper Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/wheeler-and-wilson-sewing-machine-manufactory-bridgeport-connecticut-january-1863-19th-century-american-civil-war-illustration-from-frank-leslies-illustrated-newspaper-image490331138.htmlRF2KDMEAA–Wheeler and Wilson Sewing Machine Manufactory, Bridgeport, Connecticut. January 1863. 19th century American Civil War illustration from Frank Leslie's Illustrated Newspaper

An old engraving of a cloth drying machine in a textile mill or factory. It is from a Victorian mechanical engineering book of the 1880s. The machinery in operation uses heated cylinders and rollers on which cotton or linen is run through. The process dries and irons the material. Similar machines are used to dry paper. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-cloth-drying-machine-in-a-textile-mill-or-factory-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-the-machinery-in-operation-uses-heated-cylinders-and-rollers-on-which-cotton-or-linen-is-run-through-the-process-dries-and-irons-the-material-similar-machines-are-used-to-dry-paper-image385165199.html

An old engraving of a cloth drying machine in a textile mill or factory. It is from a Victorian mechanical engineering book of the 1880s. The machinery in operation uses heated cylinders and rollers on which cotton or linen is run through. The process dries and irons the material. Similar machines are used to dry paper. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-cloth-drying-machine-in-a-textile-mill-or-factory-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-the-machinery-in-operation-uses-heated-cylinders-and-rollers-on-which-cotton-or-linen-is-run-through-the-process-dries-and-irons-the-material-similar-machines-are-used-to-dry-paper-image385165199.htmlRM2DAHP3Y–An old engraving of a cloth drying machine in a textile mill or factory. It is from a Victorian mechanical engineering book of the 1880s. The machinery in operation uses heated cylinders and rollers on which cotton or linen is run through. The process dries and irons the material. Similar machines are used to dry paper.

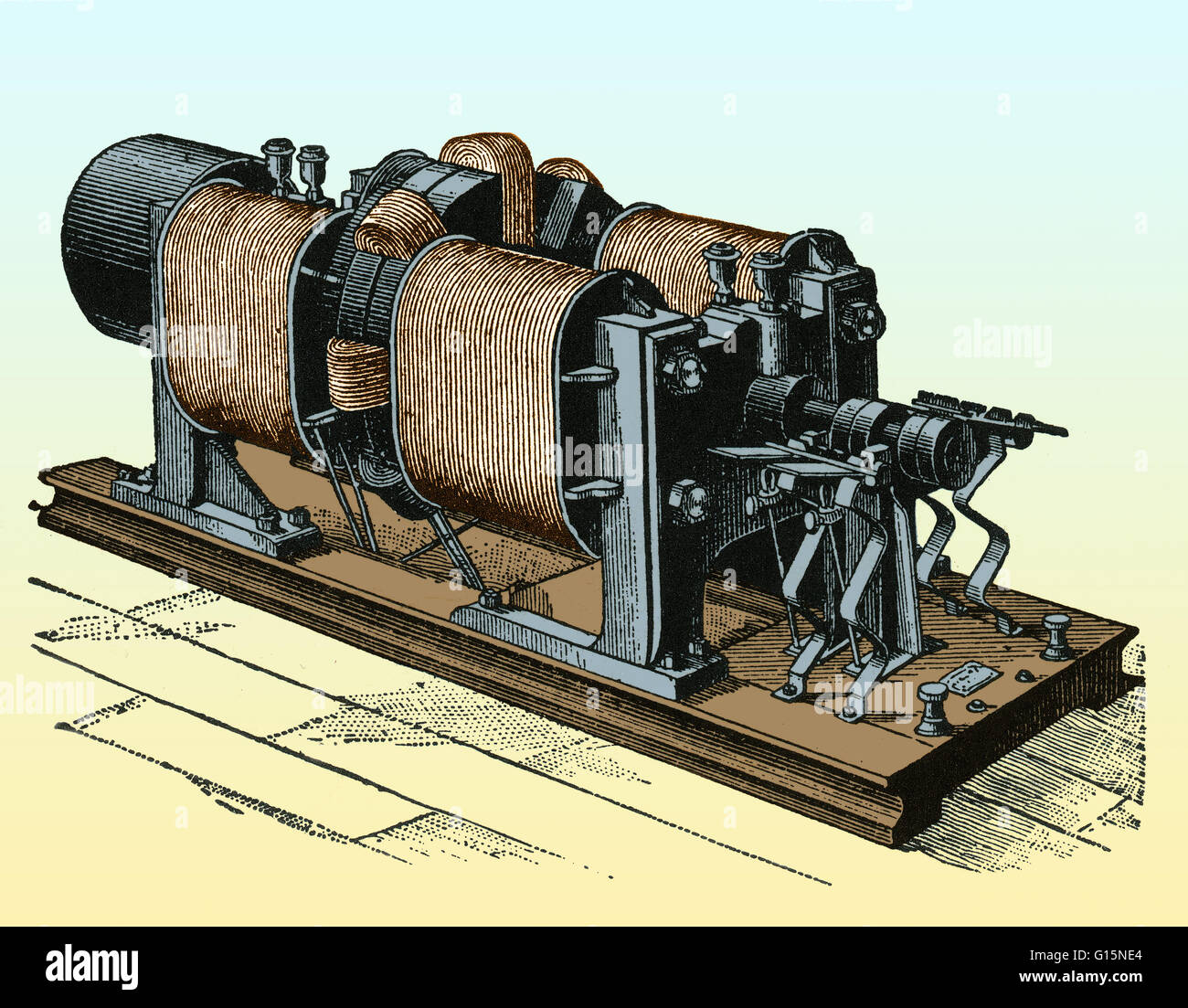

Dynamo Electric Machine. The Dynamo was the first electric generator capable of delivering power for industry. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-dynamo-electric-machine-the-dynamo-was-the-first-electric-generator-104003484.html

Dynamo Electric Machine. The Dynamo was the first electric generator capable of delivering power for industry. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-dynamo-electric-machine-the-dynamo-was-the-first-electric-generator-104003484.htmlRMG15NE4–Dynamo Electric Machine. The Dynamo was the first electric generator capable of delivering power for industry.

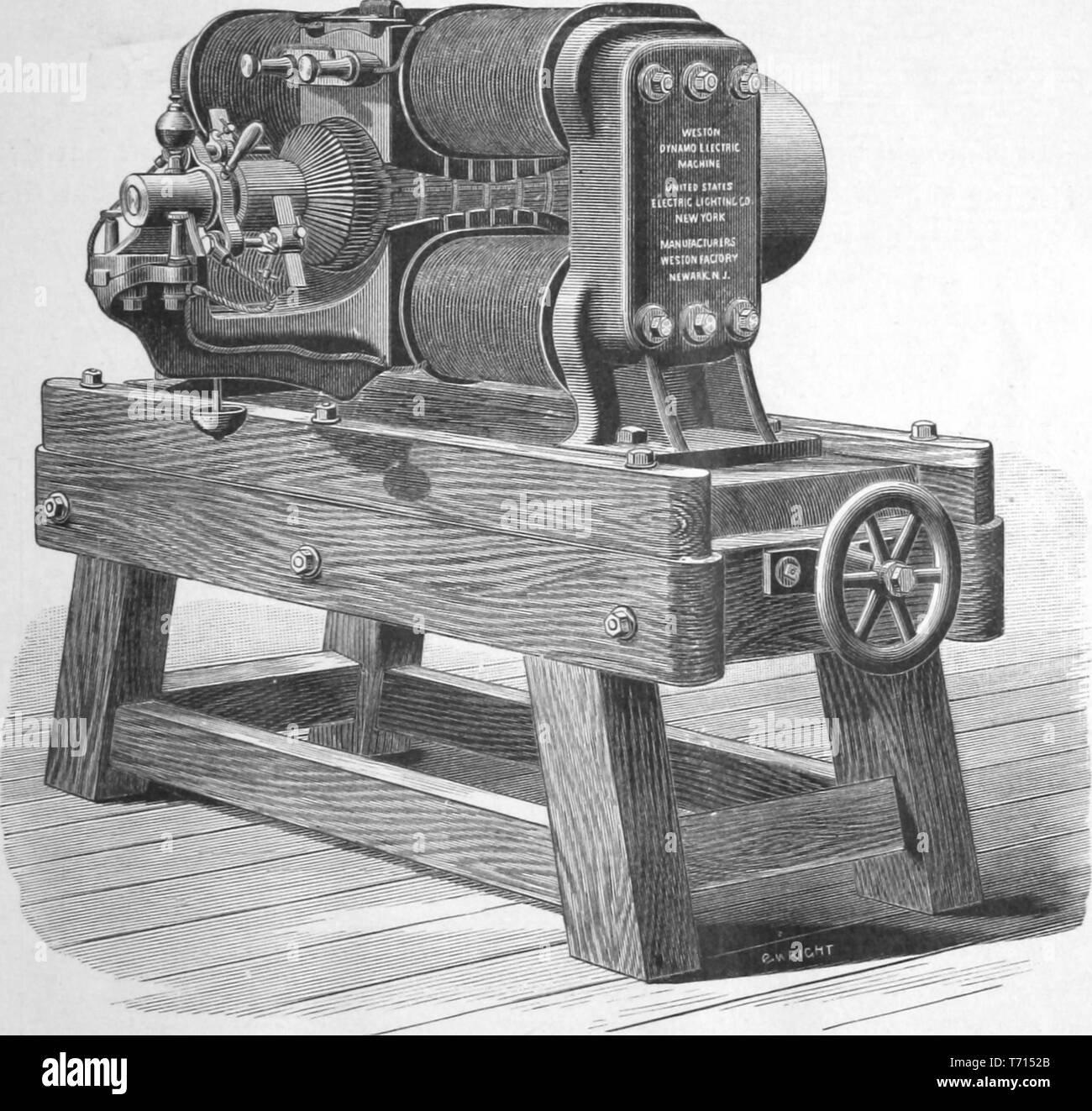

Drawing of the dynamoelectric machine on the adjustable base made by Weston factory Newark, from the book 'The Maxim Electric Light and Power Co.', 1882. Courtesy Internet Archive. () Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/drawing-of-the-dynamoelectric-machine-on-the-adjustable-base-made-by-weston-factory-newark-from-the-book-the-maxim-electric-light-and-power-co-1882-courtesy-internet-archive-image245273683.html

Drawing of the dynamoelectric machine on the adjustable base made by Weston factory Newark, from the book 'The Maxim Electric Light and Power Co.', 1882. Courtesy Internet Archive. () Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/drawing-of-the-dynamoelectric-machine-on-the-adjustable-base-made-by-weston-factory-newark-from-the-book-the-maxim-electric-light-and-power-co-1882-courtesy-internet-archive-image245273683.htmlRMT7152B–Drawing of the dynamoelectric machine on the adjustable base made by Weston factory Newark, from the book 'The Maxim Electric Light and Power Co.', 1882. Courtesy Internet Archive. ()

M Rapp rock slicing machine. Old 19th century engraved illustration from La Nature 1883 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/m-rapp-rock-slicing-machine-old-19th-century-engraved-illustration-from-la-nature-1883-image442909186.html

M Rapp rock slicing machine. Old 19th century engraved illustration from La Nature 1883 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/m-rapp-rock-slicing-machine-old-19th-century-engraved-illustration-from-la-nature-1883-image442909186.htmlRM2GMG756–M Rapp rock slicing machine. Old 19th century engraved illustration from La Nature 1883

Engraving of the Singer Sewing Machine Company factory, Elizabethport, New Jersey, from the book 'Industrial history of the United States' by Albert Sidney Bolles, 1878. Courtesy Internet Archive. Note: Image has been digitally colorized using a modern process. Colors may not be period-accurate. () Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-the-singer-sewing-machine-company-factory-elizabethport-new-jersey-from-the-book-industrial-history-of-the-united-states-by-albert-sidney-bolles-1878-courtesy-internet-archive-note-image-has-been-digitally-colorized-using-a-modern-process-colors-may-not-be-period-accurate-image349199585.html

Engraving of the Singer Sewing Machine Company factory, Elizabethport, New Jersey, from the book 'Industrial history of the United States' by Albert Sidney Bolles, 1878. Courtesy Internet Archive. Note: Image has been digitally colorized using a modern process. Colors may not be period-accurate. () Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-the-singer-sewing-machine-company-factory-elizabethport-new-jersey-from-the-book-industrial-history-of-the-united-states-by-albert-sidney-bolles-1878-courtesy-internet-archive-note-image-has-been-digitally-colorized-using-a-modern-process-colors-may-not-be-period-accurate-image349199585.htmlRM2B83BHN–Engraving of the Singer Sewing Machine Company factory, Elizabethport, New Jersey, from the book 'Industrial history of the United States' by Albert Sidney Bolles, 1878. Courtesy Internet Archive. Note: Image has been digitally colorized using a modern process. Colors may not be period-accurate. ()

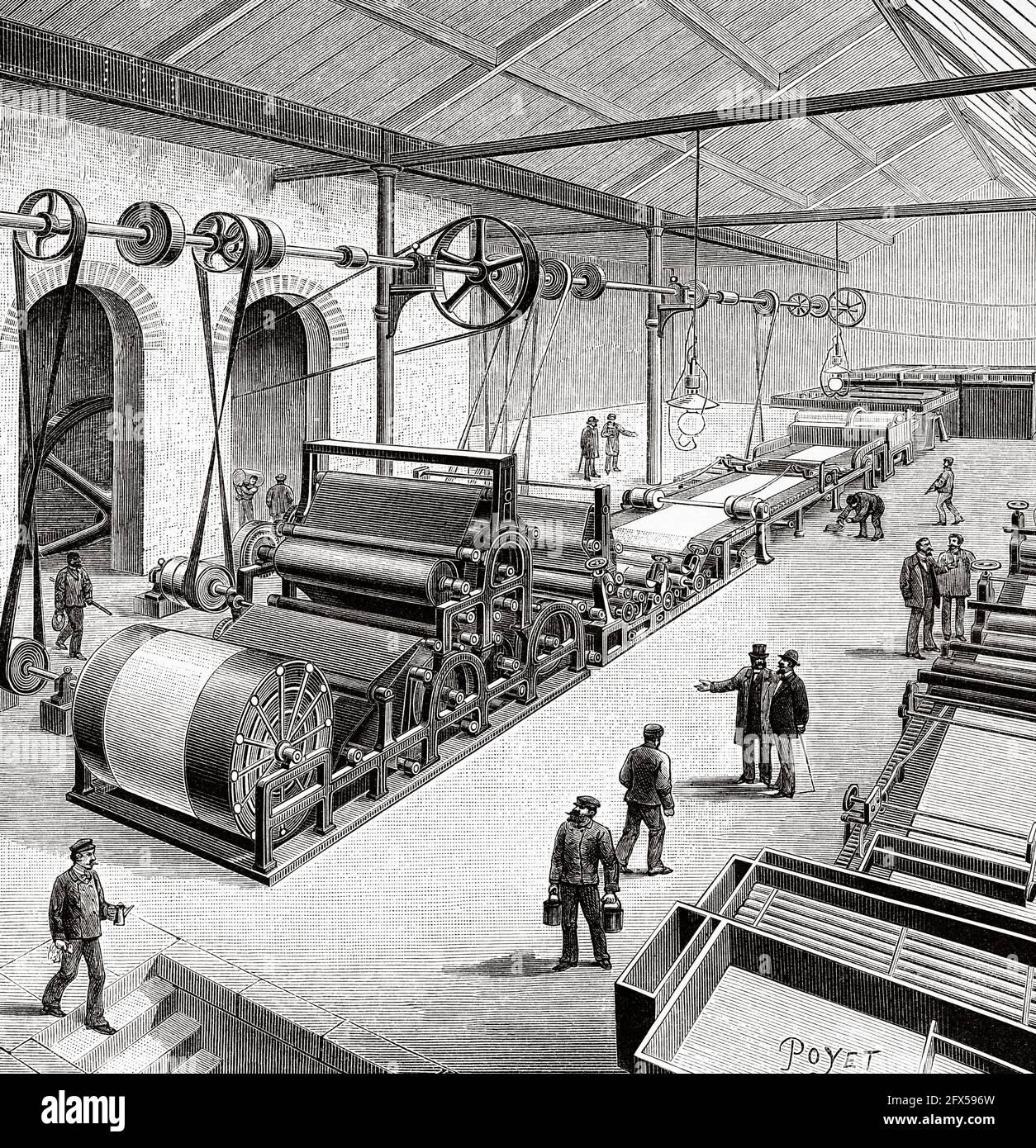

Continuous paper machine for making cigarette paper designed by Burot. Old 19th century engraved illustration from La Nature 1893 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/continuous-paper-machine-for-making-cigarette-paper-designed-by-burot-old-19th-century-engraved-illustration-from-la-nature-1893-image429146897.html

Continuous paper machine for making cigarette paper designed by Burot. Old 19th century engraved illustration from La Nature 1893 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/continuous-paper-machine-for-making-cigarette-paper-designed-by-burot-old-19th-century-engraved-illustration-from-la-nature-1893-image429146897.htmlRM2FX596W–Continuous paper machine for making cigarette paper designed by Burot. Old 19th century engraved illustration from La Nature 1893

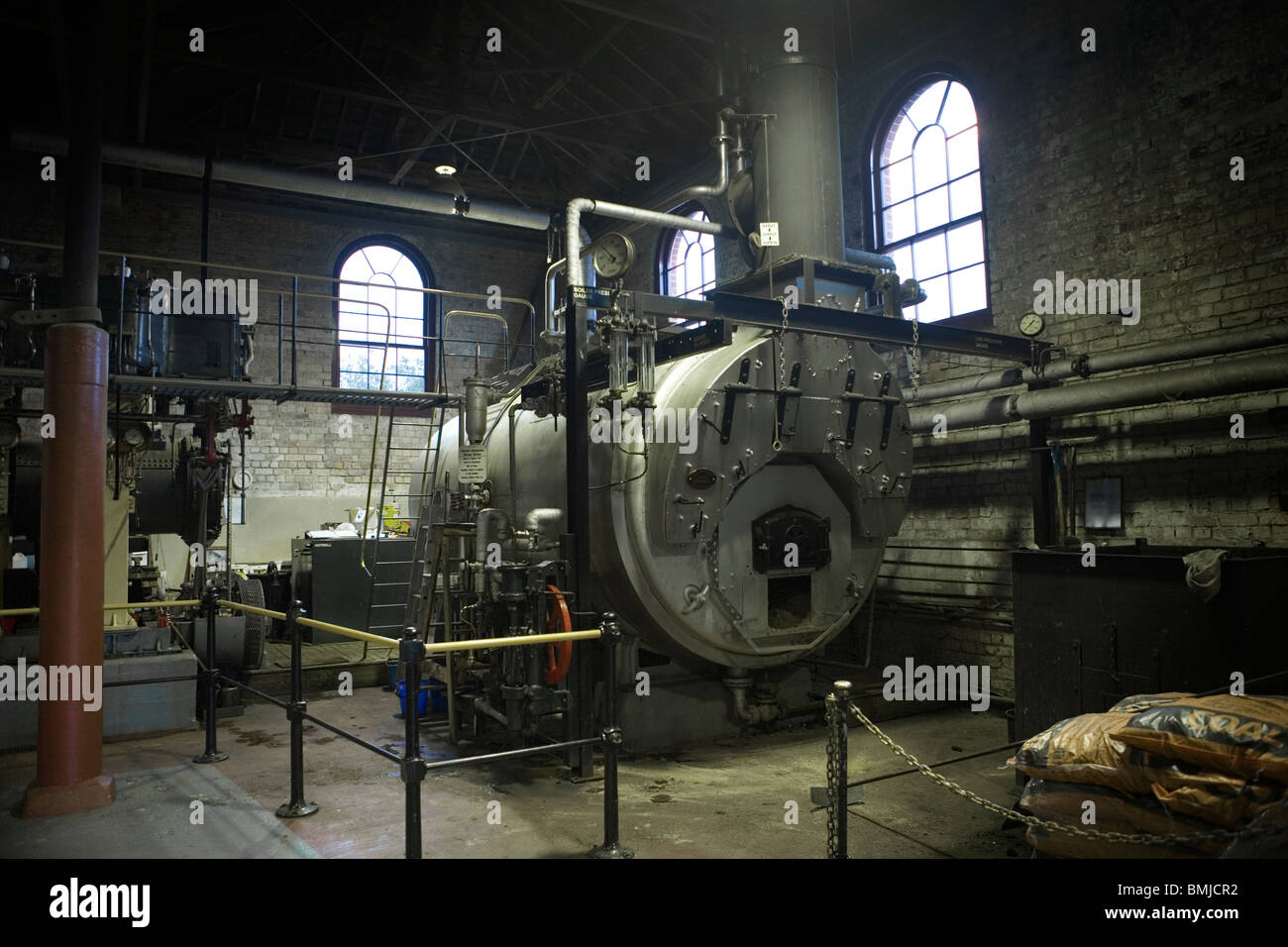

A nineteenth (XIX) century (1800s) heat machine room with a big coal boiler, Auckland, New Zealand Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-a-nineteenth-xix-century-1800s-heat-machine-room-with-a-big-coal-boiler-29908678.html

A nineteenth (XIX) century (1800s) heat machine room with a big coal boiler, Auckland, New Zealand Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-a-nineteenth-xix-century-1800s-heat-machine-room-with-a-big-coal-boiler-29908678.htmlRMBMJCR2–A nineteenth (XIX) century (1800s) heat machine room with a big coal boiler, Auckland, New Zealand

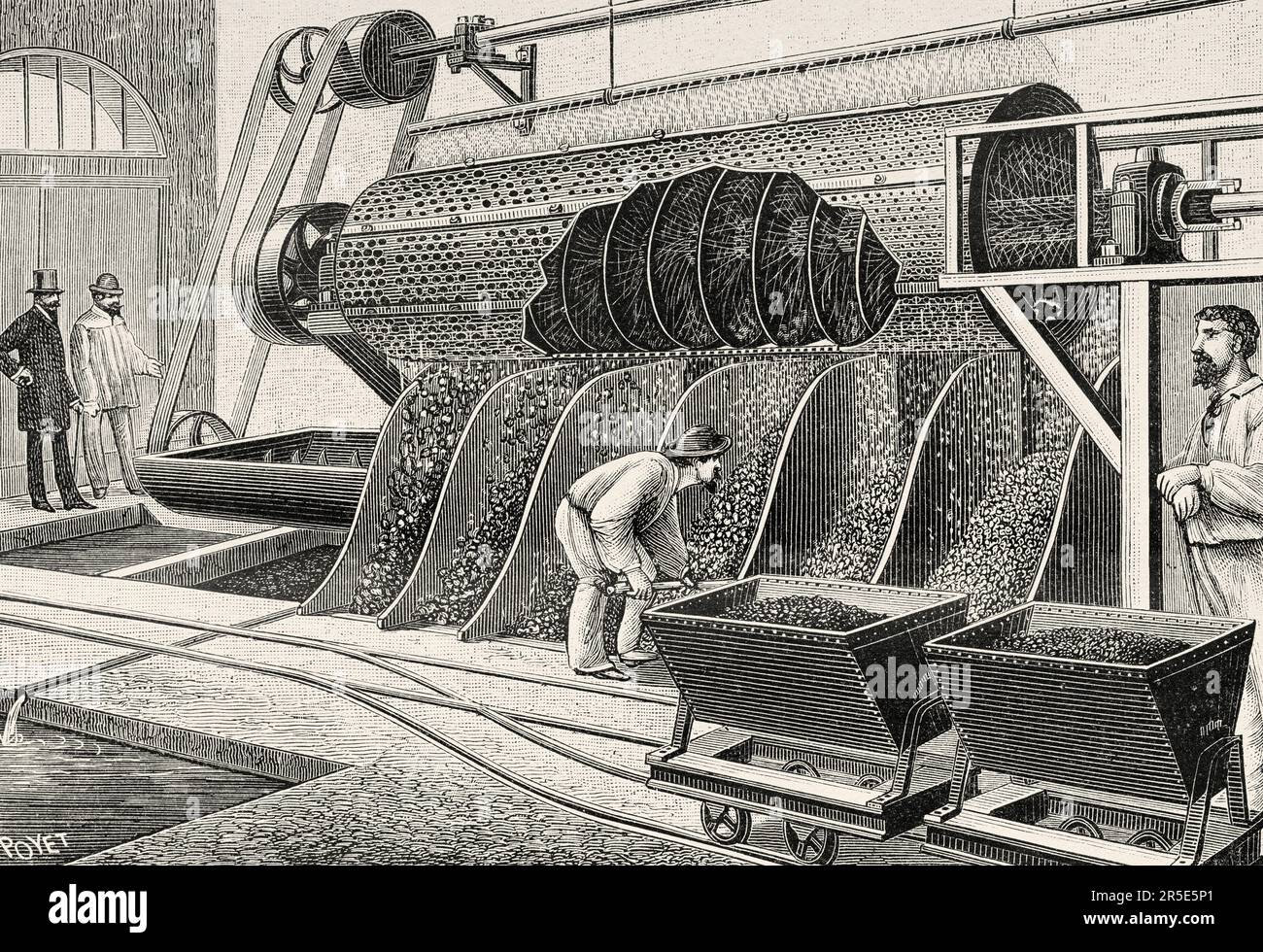

Machine to classify stones according to their size. Old 19th century engraving from La Nature 1887 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/machine-to-classify-stones-according-to-their-size-old-19th-century-engraving-from-la-nature-1887-image554116921.html

Machine to classify stones according to their size. Old 19th century engraving from La Nature 1887 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/machine-to-classify-stones-according-to-their-size-old-19th-century-engraving-from-la-nature-1887-image554116921.htmlRM2R5E5P1–Machine to classify stones according to their size. Old 19th century engraving from La Nature 1887

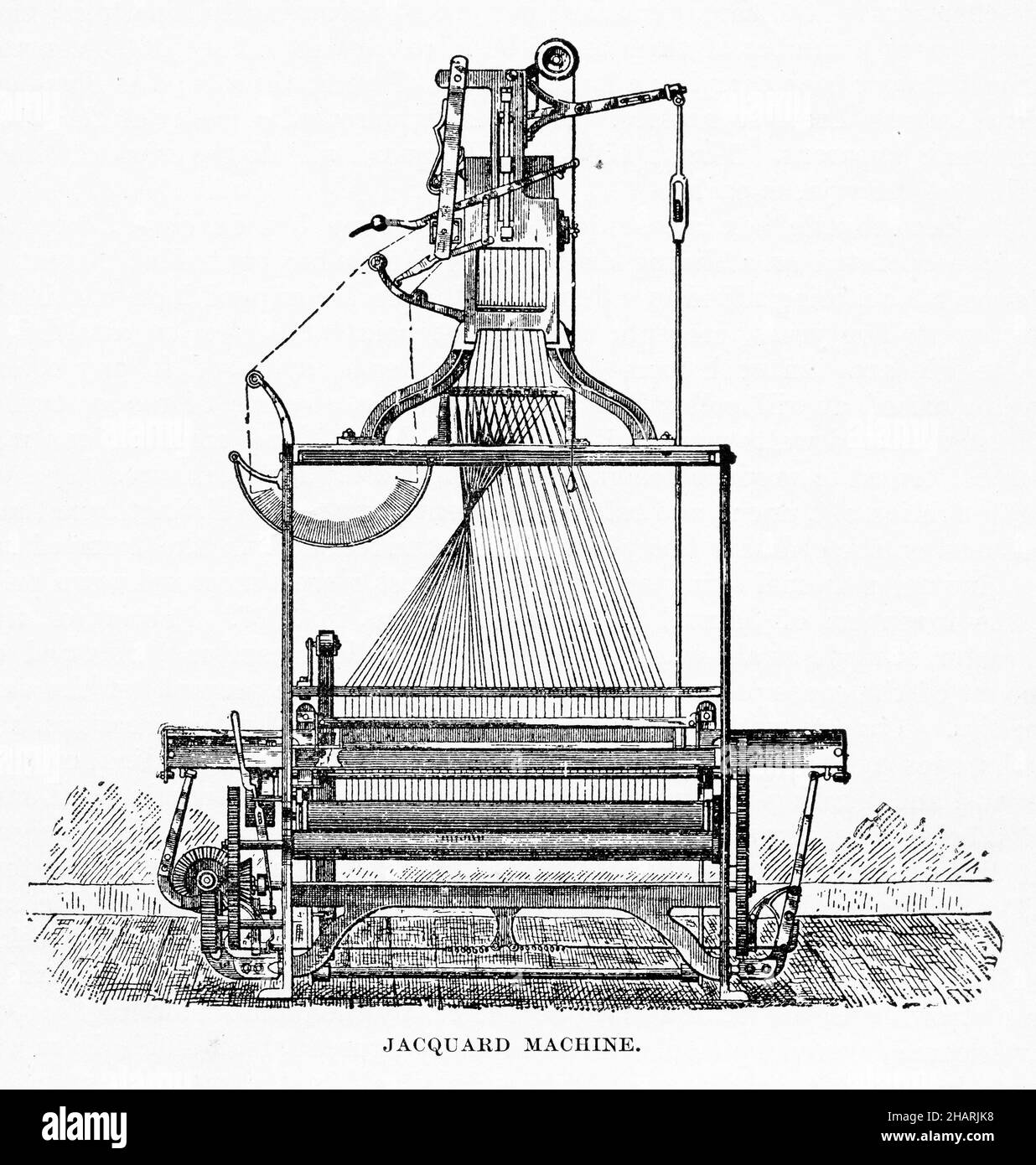

Engraving of a jacquard machine for adding brocade, damask and matelassé to fabric Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-a-jacquard-machine-for-adding-brocade-damask-and-matelass-to-fabric-image454135676.html

Engraving of a jacquard machine for adding brocade, damask and matelassé to fabric Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-a-jacquard-machine-for-adding-brocade-damask-and-matelass-to-fabric-image454135676.htmlRM2HARJK8–Engraving of a jacquard machine for adding brocade, damask and matelassé to fabric

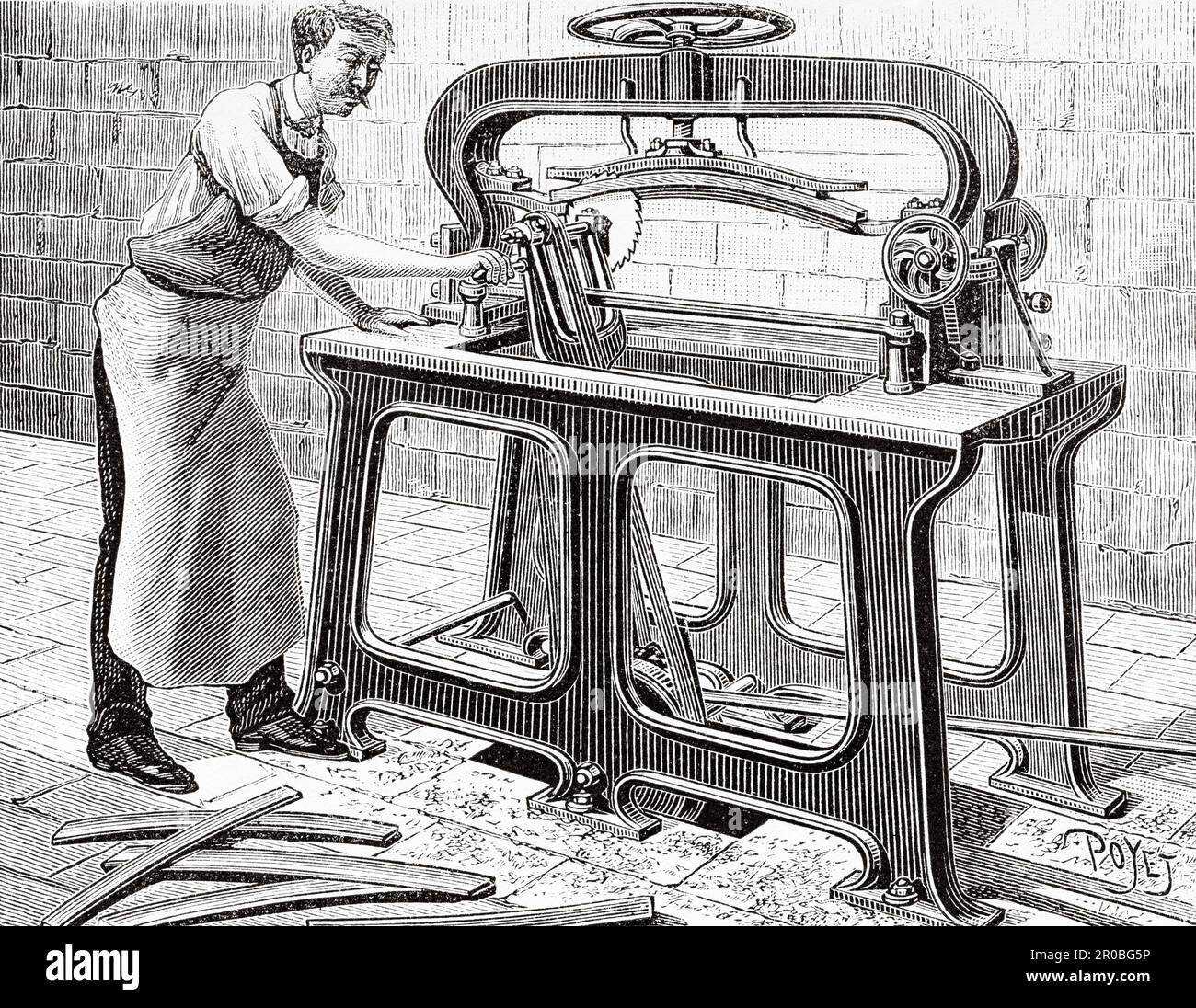

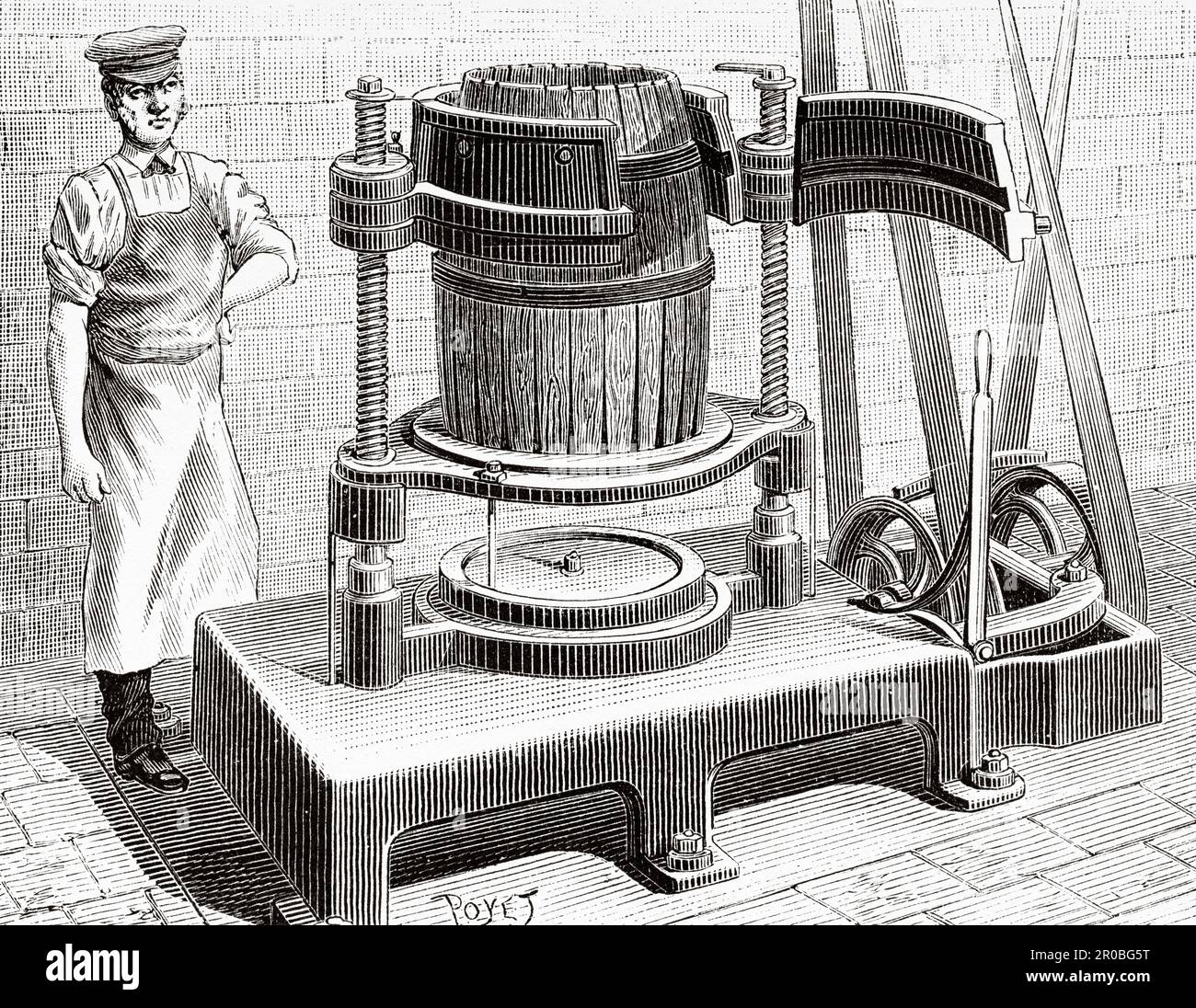

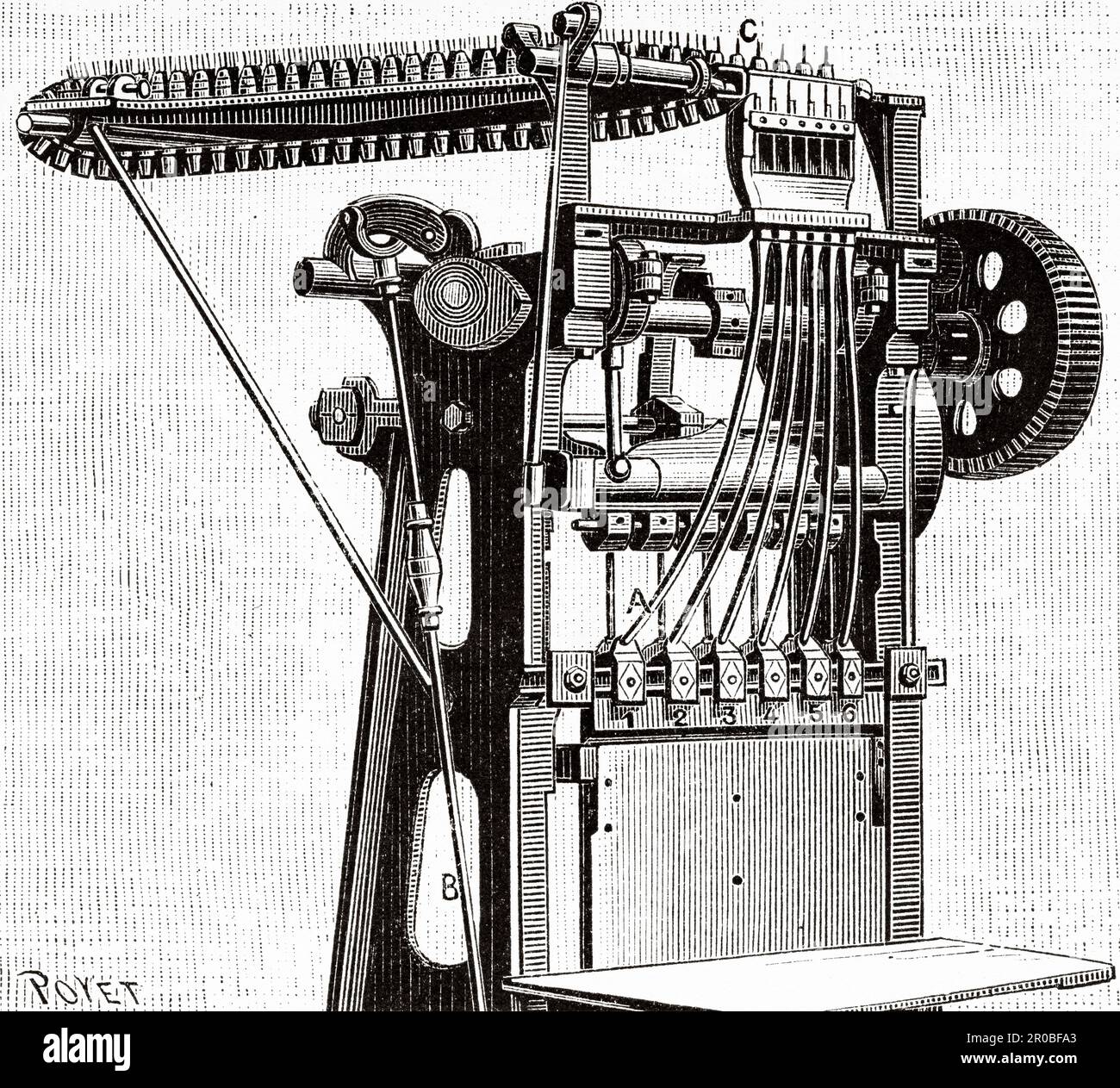

Wood cutting machine. Old 19th century engraving from La Nature 1887 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/wood-cutting-machine-old-19th-century-engraving-from-la-nature-1887-image550985954.html

Wood cutting machine. Old 19th century engraving from La Nature 1887 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/wood-cutting-machine-old-19th-century-engraving-from-la-nature-1887-image550985954.htmlRM2R0BG5P–Wood cutting machine. Old 19th century engraving from La Nature 1887

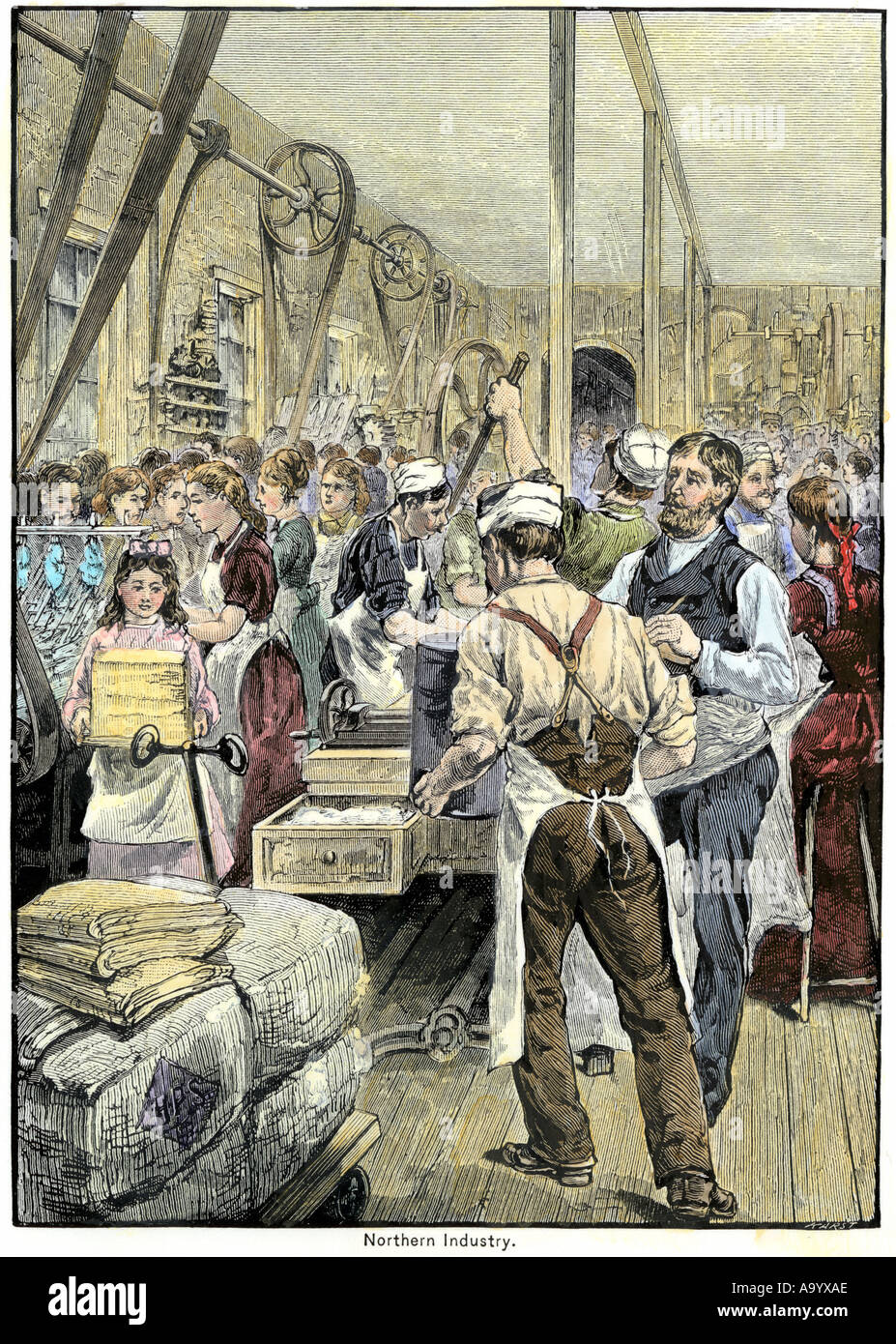

Textile workers in a northern mill in the US 1800s. Hand-colored woodcut Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/textile-workers-in-a-northern-mill-in-the-us-1800s-hand-colored-woodcut-image4071085.html

Textile workers in a northern mill in the US 1800s. Hand-colored woodcut Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/textile-workers-in-a-northern-mill-in-the-us-1800s-hand-colored-woodcut-image4071085.htmlRMA9YXAE–Textile workers in a northern mill in the US 1800s. Hand-colored woodcut

Engraving of a young woman watching a cotton-making machine, circa 1880 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-a-young-woman-watching-a-cotton-making-machine-circa-1880-image537037881.html

Engraving of a young woman watching a cotton-making machine, circa 1880 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-a-young-woman-watching-a-cotton-making-machine-circa-1880-image537037881.htmlRM2P5M589–Engraving of a young woman watching a cotton-making machine, circa 1880

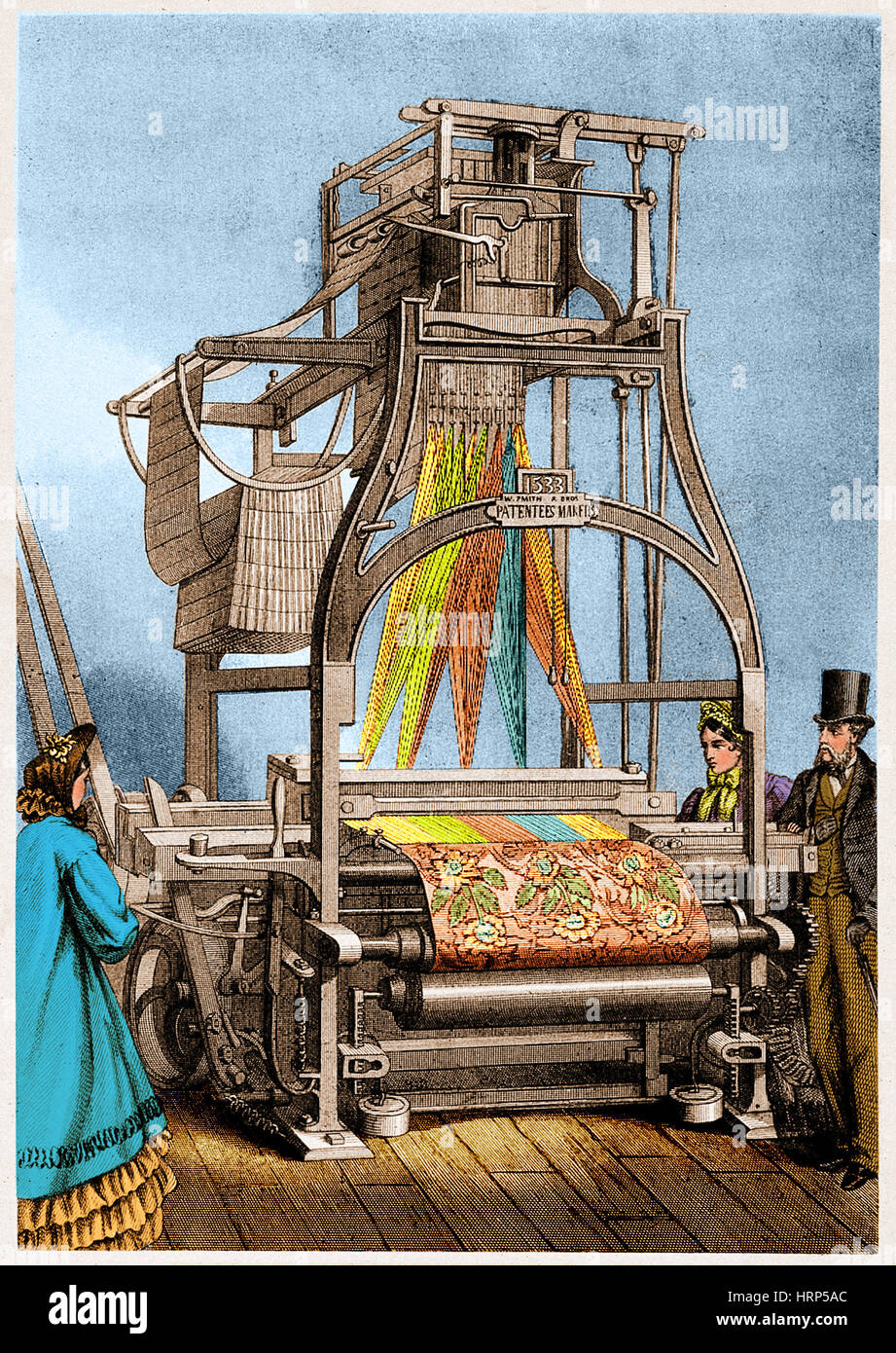

Woman worker using a mechanized Jacquard loom, 1880s. Hand-colored woodcut Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-woman-worker-using-a-mechanized-jacquard-loom-1880s-hand-colored-woodcut-28512473.html

Woman worker using a mechanized Jacquard loom, 1880s. Hand-colored woodcut Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-woman-worker-using-a-mechanized-jacquard-loom-1880s-hand-colored-woodcut-28512473.htmlRMBJARXH–Woman worker using a mechanized Jacquard loom, 1880s. Hand-colored woodcut

Ancient wooden machinery used in the 1800s in castles for various operations. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/ancient-wooden-machinery-used-in-the-1800s-in-castles-for-various-operations-image440212733.html

Ancient wooden machinery used in the 1800s in castles for various operations. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/ancient-wooden-machinery-used-in-the-1800s-in-castles-for-various-operations-image440212733.htmlRF2GG5BR9–Ancient wooden machinery used in the 1800s in castles for various operations.

A photograph of a mature Puerto Rican woman using a sewing machine in the Everglades Needlework Factory, she is using the machine to work a piece of floral patterned fabric, she wears a striped blouse and glasses, another work bench in the factory can be seen behind her, San Juan, Puerto Rico, 1864. From the New York Public Library. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-image-a-photograph-of-a-mature-puerto-rican-woman-using-a-sewing-machine-166777196.html

A photograph of a mature Puerto Rican woman using a sewing machine in the Everglades Needlework Factory, she is using the machine to work a piece of floral patterned fabric, she wears a striped blouse and glasses, another work bench in the factory can be seen behind her, San Juan, Puerto Rico, 1864. From the New York Public Library. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-image-a-photograph-of-a-mature-puerto-rican-woman-using-a-sewing-machine-166777196.htmlRMKK9A0C–A photograph of a mature Puerto Rican woman using a sewing machine in the Everglades Needlework Factory, she is using the machine to work a piece of floral patterned fabric, she wears a striped blouse and glasses, another work bench in the factory can be seen behind her, San Juan, Puerto Rico, 1864. From the New York Public Library.

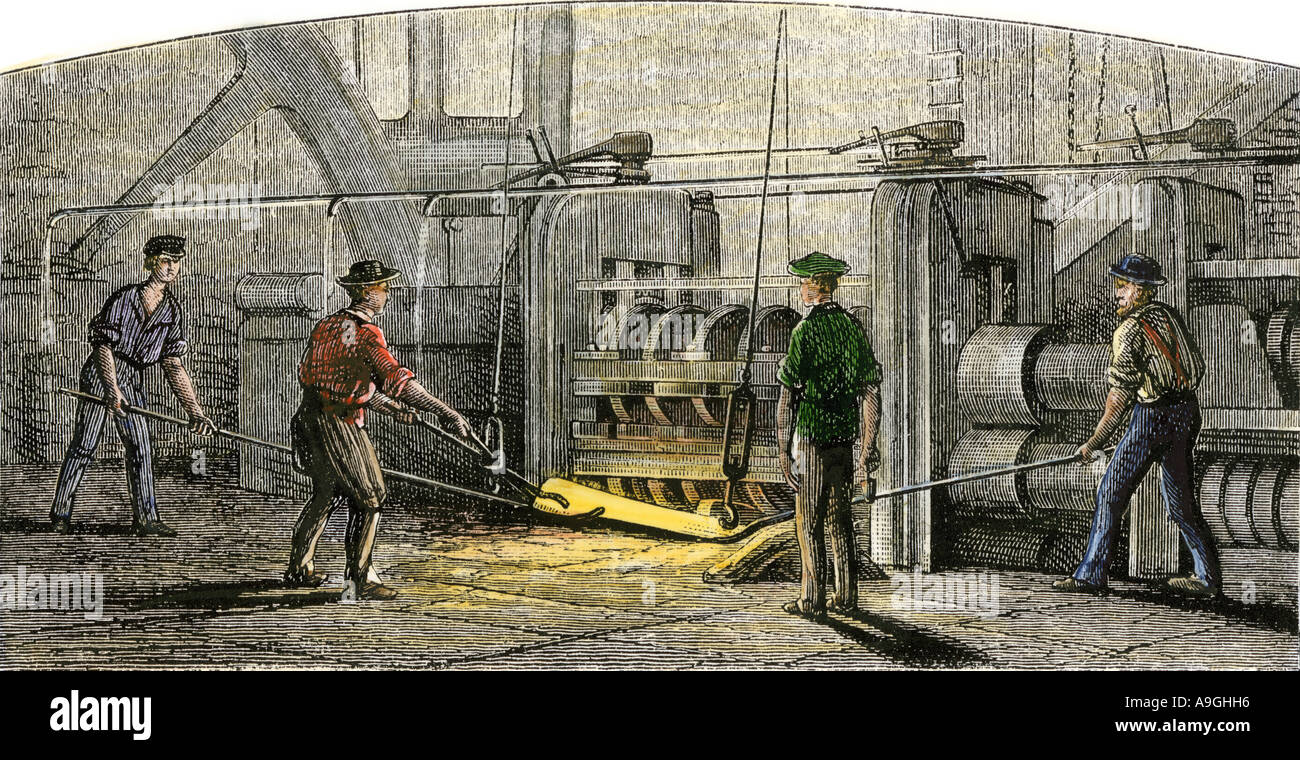

Vulcan Iron Works in Carondelet, Missouri in the mid 1800s. Hand-colored woodcut Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/vulcan-iron-works-in-carondelet-missouri-in-the-mid-1800s-hand-colored-image7063765.html

Vulcan Iron Works in Carondelet, Missouri in the mid 1800s. Hand-colored woodcut Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/vulcan-iron-works-in-carondelet-missouri-in-the-mid-1800s-hand-colored-image7063765.htmlRMA9GHH6–Vulcan Iron Works in Carondelet, Missouri in the mid 1800s. Hand-colored woodcut

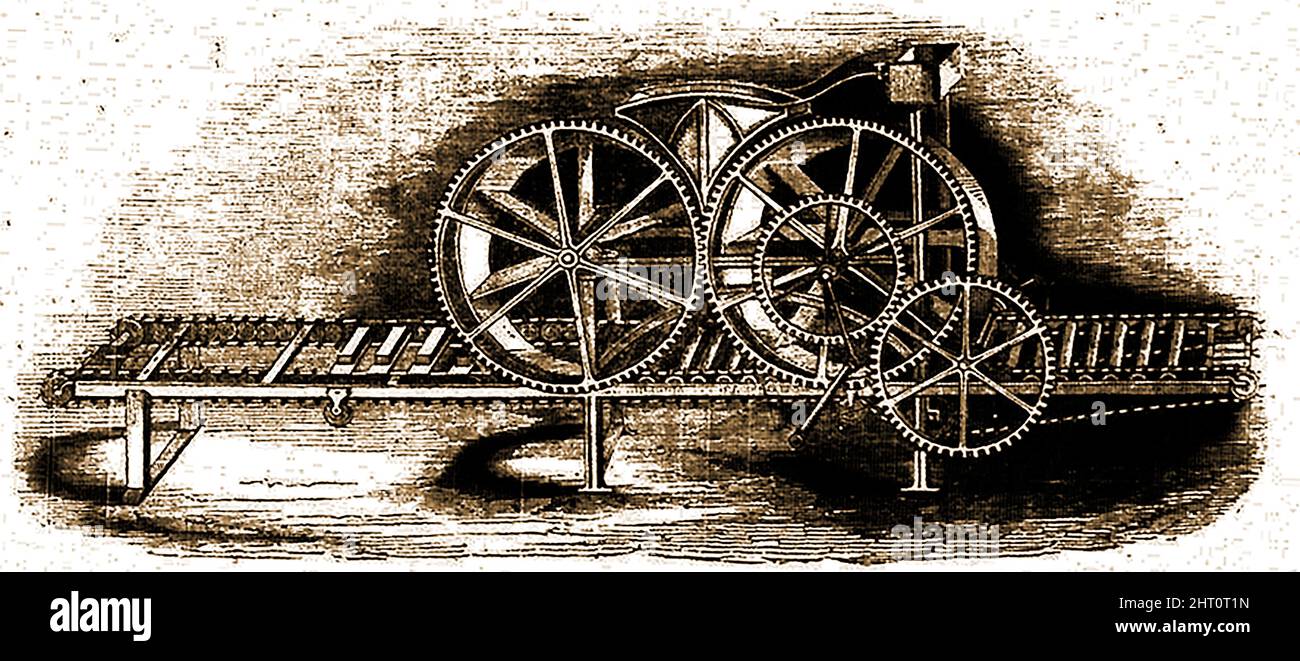

BRICK AND TILE-MAKING INDUSTRY - Automation - An early C1800s magazine illustration of a newly invented tile making machine Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/brick-and-tile-making-industry-automation-an-early-c1800s-magazine-illustration-of-a-newly-invented-tile-making-machine-image462240177.html

BRICK AND TILE-MAKING INDUSTRY - Automation - An early C1800s magazine illustration of a newly invented tile making machine Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/brick-and-tile-making-industry-automation-an-early-c1800s-magazine-illustration-of-a-newly-invented-tile-making-machine-image462240177.htmlRM2HT0T1N–BRICK AND TILE-MAKING INDUSTRY - Automation - An early C1800s magazine illustration of a newly invented tile making machine

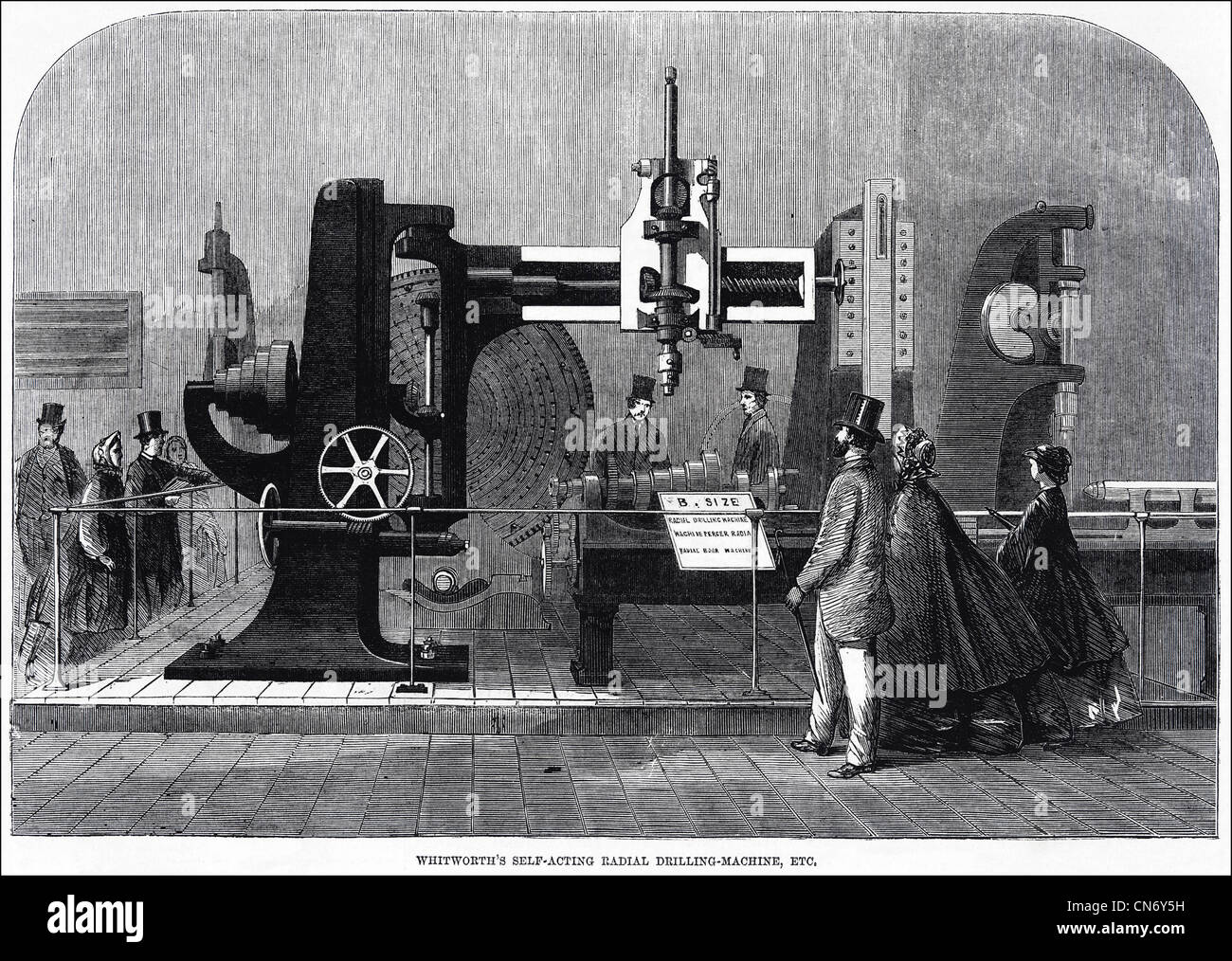

Whitworth's radial drilling machine exhibited at The International Exhibition South Kensington London, England. Victorian engraving dated 5th July 1862 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-whitworths-radial-drilling-machine-exhibited-at-the-international-47481549.html

Whitworth's radial drilling machine exhibited at The International Exhibition South Kensington London, England. Victorian engraving dated 5th July 1862 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-whitworths-radial-drilling-machine-exhibited-at-the-international-47481549.htmlRMCN6Y5H–Whitworth's radial drilling machine exhibited at The International Exhibition South Kensington London, England. Victorian engraving dated 5th July 1862

Vacuuming at the turn of the century 1800-1900. Before electricity became common in homes, the early vacuum cleaners were primitive dust machines. Here a recreated historical scene in a home where two women maneuver a hand driven vacuum cleaner. The younger woman creates vacuum and suction with a lever. The elderly woman uses it to clean the sofa. 1901 was the year of the first patent for an electrical vacuum cleaner. In Sweden Axel Wenner-Gren developed the invention and 1913 Lux factory began production of the first swedish electric one called Model 1, a machine of 14 kg. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/vacuuming-at-the-turn-of-the-century-1800-1900-before-electricity-became-common-in-homes-the-early-vacuum-cleaners-were-primitive-dust-machines-here-a-recreated-historical-scene-in-a-home-where-two-women-maneuver-a-hand-driven-vacuum-cleaner-the-younger-woman-creates-vacuum-and-suction-with-a-lever-the-elderly-woman-uses-it-to-clean-the-sofa-1901-was-the-year-of-the-first-patent-for-an-electrical-vacuum-cleaner-in-sweden-axel-wenner-gren-developed-the-invention-and-1913-lux-factory-began-production-of-the-first-swedish-electric-one-called-model-1-a-machine-of-14-kg-image264761721.html

Vacuuming at the turn of the century 1800-1900. Before electricity became common in homes, the early vacuum cleaners were primitive dust machines. Here a recreated historical scene in a home where two women maneuver a hand driven vacuum cleaner. The younger woman creates vacuum and suction with a lever. The elderly woman uses it to clean the sofa. 1901 was the year of the first patent for an electrical vacuum cleaner. In Sweden Axel Wenner-Gren developed the invention and 1913 Lux factory began production of the first swedish electric one called Model 1, a machine of 14 kg. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/vacuuming-at-the-turn-of-the-century-1800-1900-before-electricity-became-common-in-homes-the-early-vacuum-cleaners-were-primitive-dust-machines-here-a-recreated-historical-scene-in-a-home-where-two-women-maneuver-a-hand-driven-vacuum-cleaner-the-younger-woman-creates-vacuum-and-suction-with-a-lever-the-elderly-woman-uses-it-to-clean-the-sofa-1901-was-the-year-of-the-first-patent-for-an-electrical-vacuum-cleaner-in-sweden-axel-wenner-gren-developed-the-invention-and-1913-lux-factory-began-production-of-the-first-swedish-electric-one-called-model-1-a-machine-of-14-kg-image264761721.htmlRMWAMX7N–Vacuuming at the turn of the century 1800-1900. Before electricity became common in homes, the early vacuum cleaners were primitive dust machines. Here a recreated historical scene in a home where two women maneuver a hand driven vacuum cleaner. The younger woman creates vacuum and suction with a lever. The elderly woman uses it to clean the sofa. 1901 was the year of the first patent for an electrical vacuum cleaner. In Sweden Axel Wenner-Gren developed the invention and 1913 Lux factory began production of the first swedish electric one called Model 1, a machine of 14 kg.

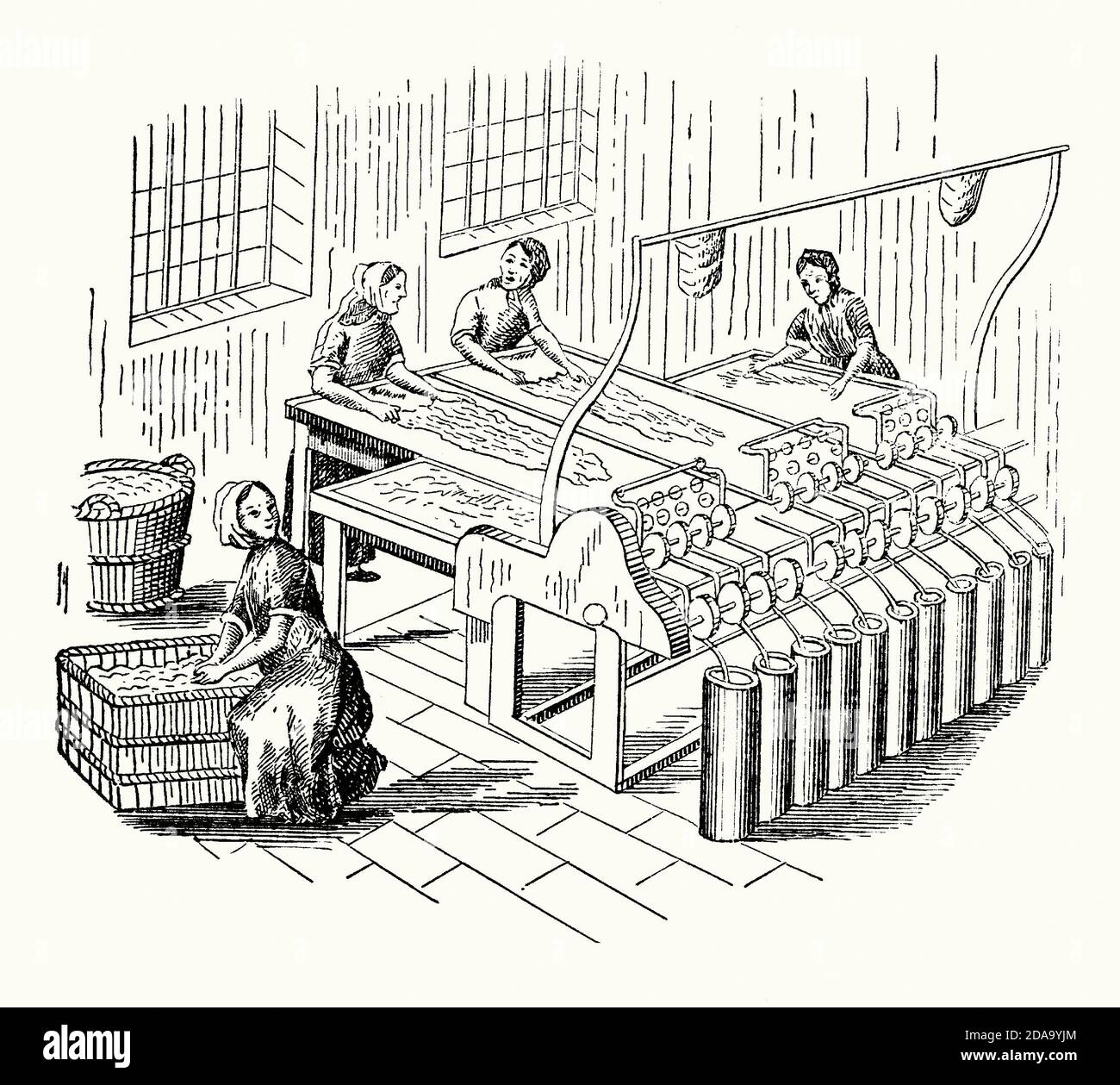

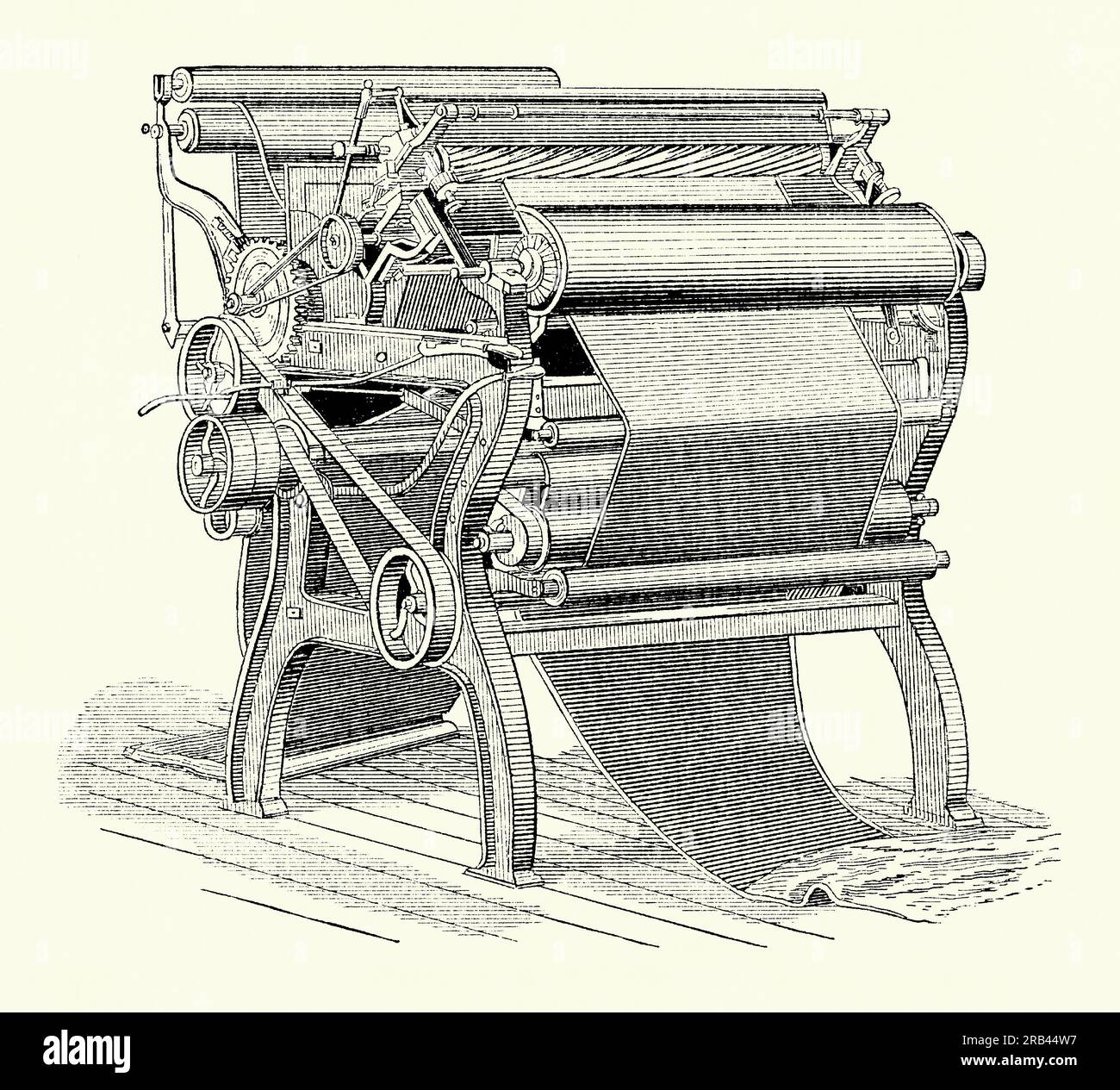

An old engraving of drawing out flax in a textile mill or factory. It is from a Victorian mechanical engineering book of the 1880s. The machinery in operation separates, cleans, and draws out the fibres, using toothed cylinders (breaking or heckling cylinders). The use of the cylinders and rollers can be performed repeatedly at the same machine (sometimes called ‘doubling’) until the fibres become uniform in thickness. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-drawing-out-flax-in-a-textile-mill-or-factory-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-the-machinery-in-operation-separates-cleans-and-draws-out-the-fibres-using-toothed-cylinders-breaking-or-heckling-cylinders-the-use-of-the-cylinders-and-rollers-can-be-performed-repeatedly-at-the-same-machine-sometimes-called-doubling-until-the-fibres-become-uniform-in-thickness-image384993916.html

An old engraving of drawing out flax in a textile mill or factory. It is from a Victorian mechanical engineering book of the 1880s. The machinery in operation separates, cleans, and draws out the fibres, using toothed cylinders (breaking or heckling cylinders). The use of the cylinders and rollers can be performed repeatedly at the same machine (sometimes called ‘doubling’) until the fibres become uniform in thickness. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-drawing-out-flax-in-a-textile-mill-or-factory-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-the-machinery-in-operation-separates-cleans-and-draws-out-the-fibres-using-toothed-cylinders-breaking-or-heckling-cylinders-the-use-of-the-cylinders-and-rollers-can-be-performed-repeatedly-at-the-same-machine-sometimes-called-doubling-until-the-fibres-become-uniform-in-thickness-image384993916.htmlRM2DA9YJM–An old engraving of drawing out flax in a textile mill or factory. It is from a Victorian mechanical engineering book of the 1880s. The machinery in operation separates, cleans, and draws out the fibres, using toothed cylinders (breaking or heckling cylinders). The use of the cylinders and rollers can be performed repeatedly at the same machine (sometimes called ‘doubling’) until the fibres become uniform in thickness.

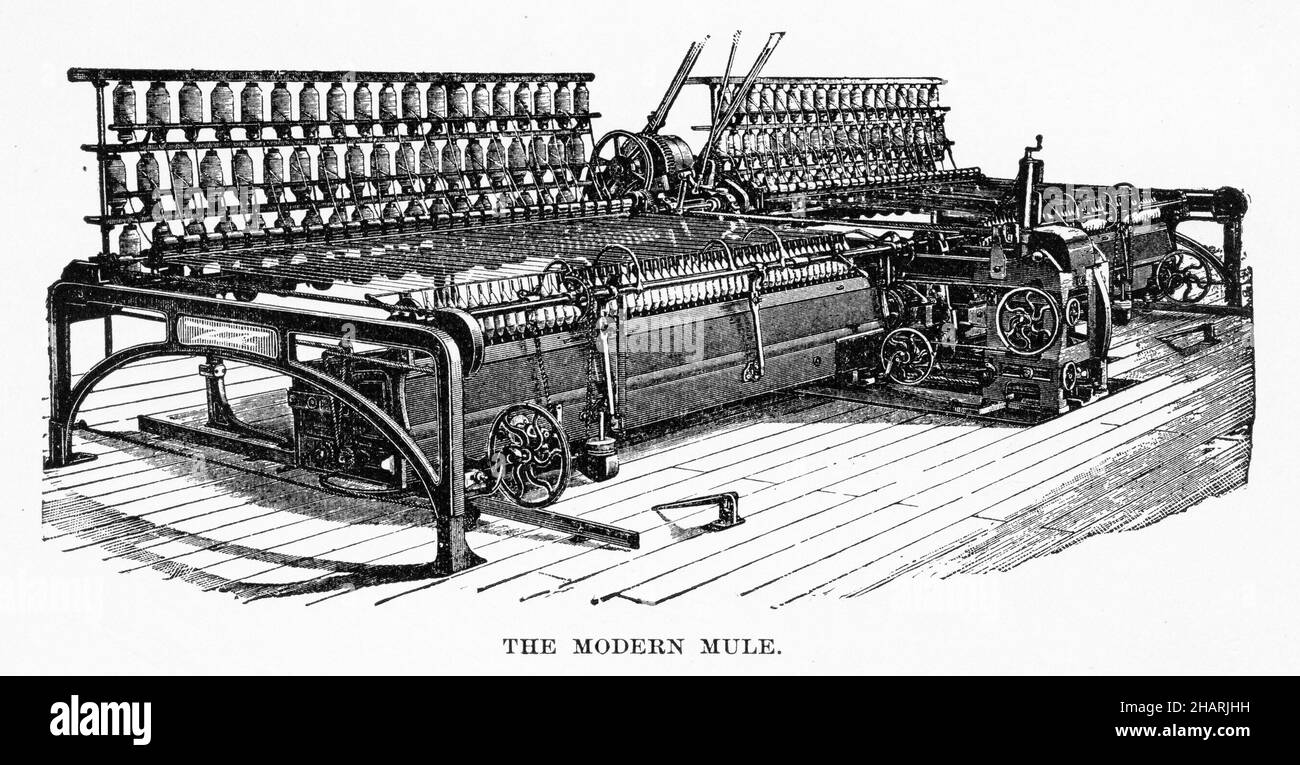

Engraving of 'the modern mule' a mechanised loom of the Industrial revolution Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-the-modern-mule-a-mechanised-loom-of-the-industrial-revolution-image454135629.html

Engraving of 'the modern mule' a mechanised loom of the Industrial revolution Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-the-modern-mule-a-mechanised-loom-of-the-industrial-revolution-image454135629.htmlRM2HARJHH–Engraving of 'the modern mule' a mechanised loom of the Industrial revolution

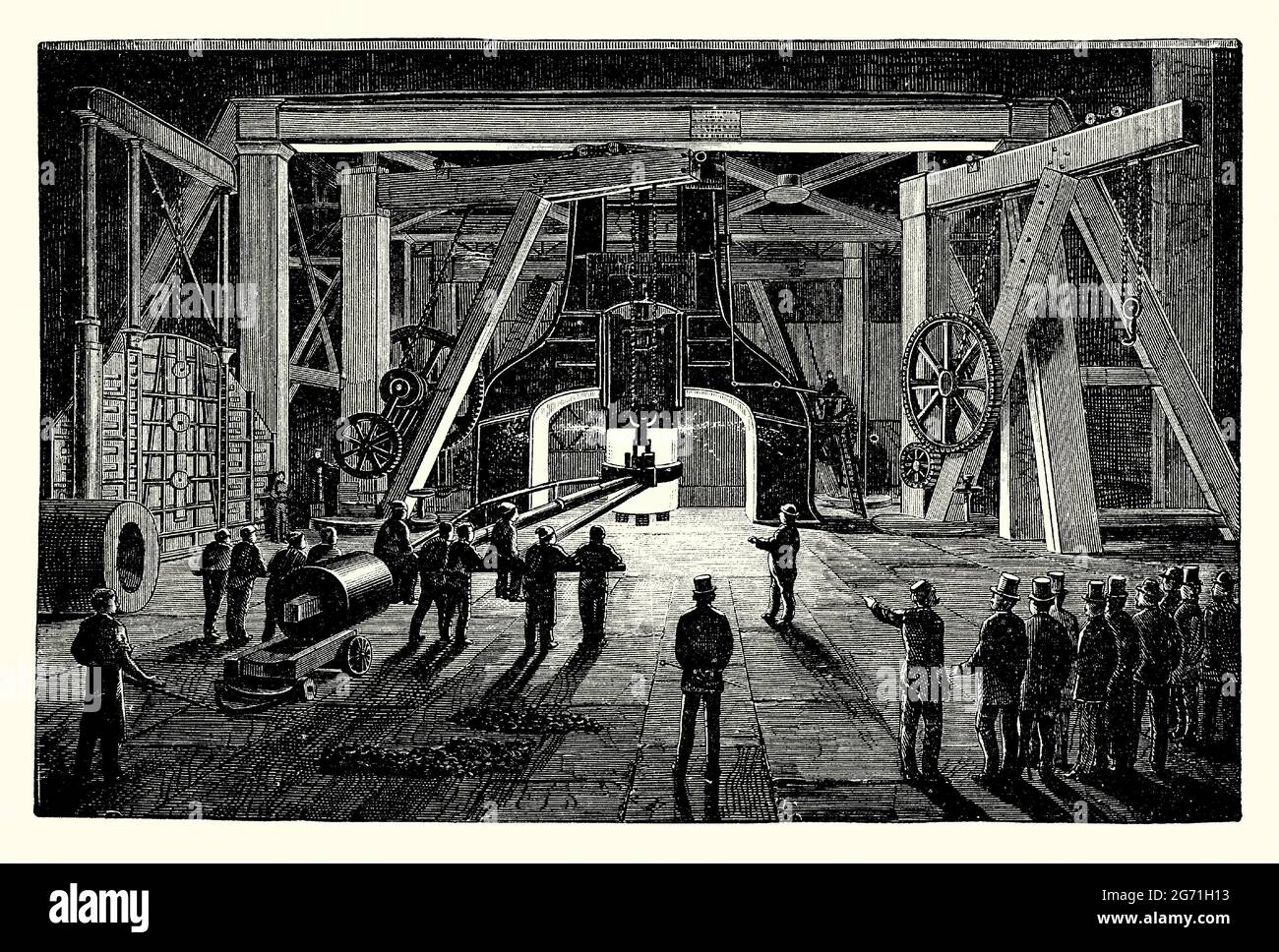

An old engraving of the Great Steam Hammer at the Woolwich Gun Factory, London, England, UK c. 1875. It is from a Victorian book of the 1890s on discoveries and inventions during the 1800s. The 35-ton hammer, built by Nasmyth and Co, was used to forge guns for the British Navy. A steam hammer, also called a drop hammer, is an industrial power hammer driven by steam that is used for tasks such as shaping forgings and driving piles. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-the-great-steam-hammer-at-the-woolwich-gun-factory-london-england-uk-c-1875-it-is-from-a-victorian-book-of-the-1890s-on-discoveries-and-inventions-during-the-1800s-the-35-ton-hammer-built-by-nasmyth-and-co-was-used-to-forge-guns-for-the-british-navy-a-steam-hammer-also-called-a-drop-hammer-is-an-industrial-power-hammer-driven-by-steam-that-is-used-for-tasks-such-as-shaping-forgings-and-driving-piles-image434597103.html

An old engraving of the Great Steam Hammer at the Woolwich Gun Factory, London, England, UK c. 1875. It is from a Victorian book of the 1890s on discoveries and inventions during the 1800s. The 35-ton hammer, built by Nasmyth and Co, was used to forge guns for the British Navy. A steam hammer, also called a drop hammer, is an industrial power hammer driven by steam that is used for tasks such as shaping forgings and driving piles. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-the-great-steam-hammer-at-the-woolwich-gun-factory-london-england-uk-c-1875-it-is-from-a-victorian-book-of-the-1890s-on-discoveries-and-inventions-during-the-1800s-the-35-ton-hammer-built-by-nasmyth-and-co-was-used-to-forge-guns-for-the-british-navy-a-steam-hammer-also-called-a-drop-hammer-is-an-industrial-power-hammer-driven-by-steam-that-is-used-for-tasks-such-as-shaping-forgings-and-driving-piles-image434597103.htmlRM2G71H13–An old engraving of the Great Steam Hammer at the Woolwich Gun Factory, London, England, UK c. 1875. It is from a Victorian book of the 1890s on discoveries and inventions during the 1800s. The 35-ton hammer, built by Nasmyth and Co, was used to forge guns for the British Navy. A steam hammer, also called a drop hammer, is an industrial power hammer driven by steam that is used for tasks such as shaping forgings and driving piles.

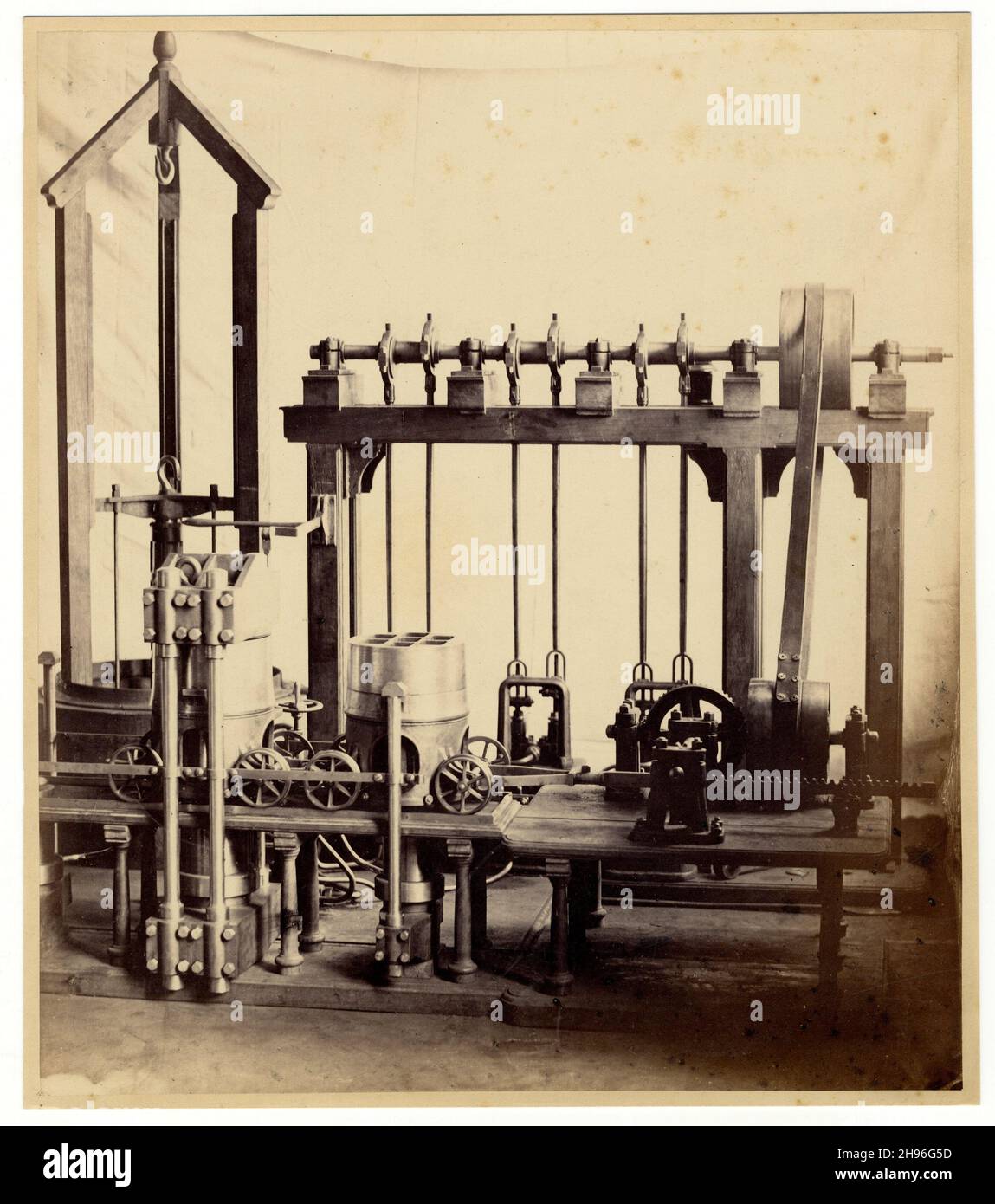

An industrial machine, circa 1865. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-industrial-machine-circa-1865-image453145881.html

An industrial machine, circa 1865. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-industrial-machine-circa-1865-image453145881.htmlRM2H96G5D–An industrial machine, circa 1865.

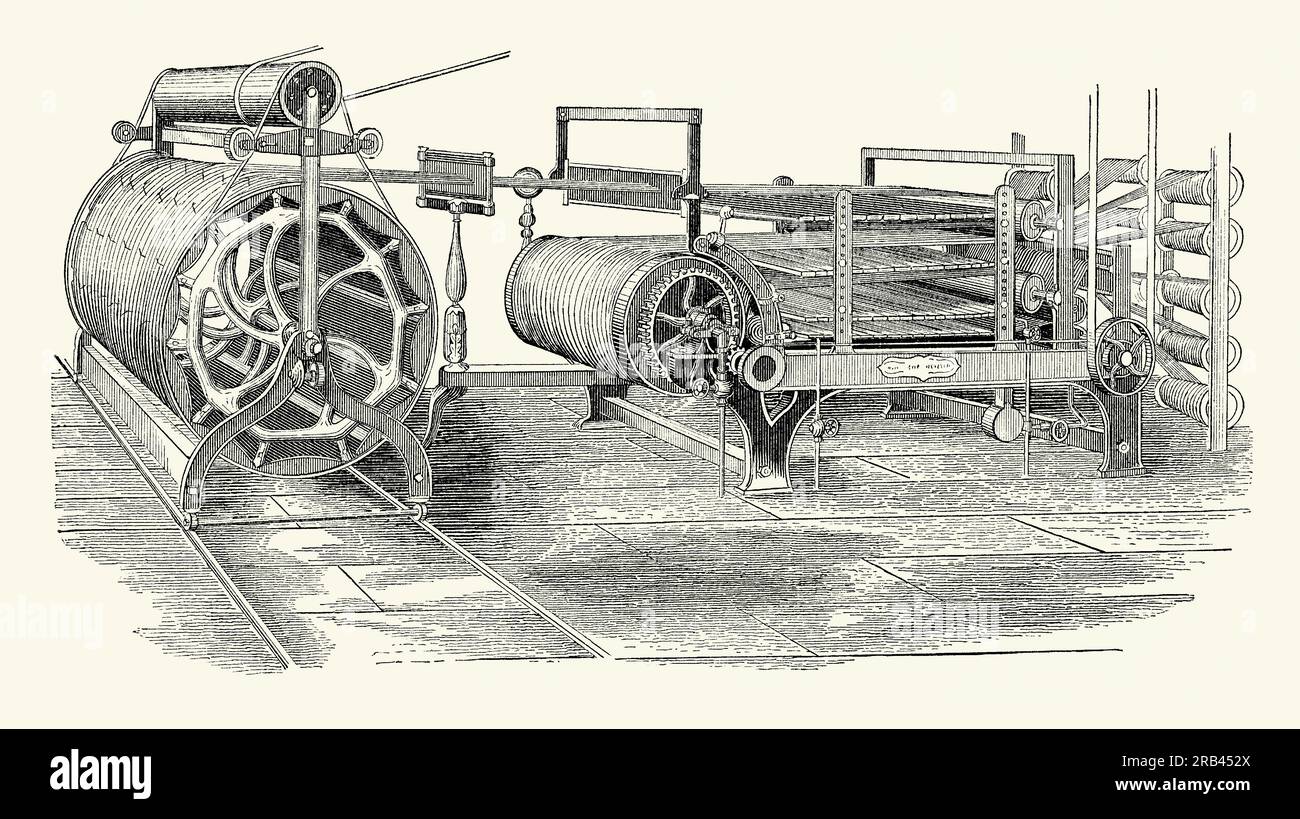

An old engraving of a yarn dresser and reel machine used in the textile mills of the 1800s. It is from a Victorian mechanical engineering book of the 1880s. This machine was used for sizing and polishing yarn. Using size (a starch for cotton) reduces the chances of threads fraying and breaking due to the friction of the weaving process. Belt-driven rollers deliver the yarn through a series of devices that ‘whip’ or brush it, removing unwanted strands and give it a polish. It then passes over steam pipes, then wound onto reels or bobbins (right), ready for weaving. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-yarn-dresser-and-reel-machine-used-in-the-textile-mills-of-the-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-this-machine-was-used-for-sizing-and-polishing-yarn-using-size-a-starch-for-cotton-reduces-the-chances-of-threads-fraying-and-breaking-due-to-the-friction-of-the-weaving-process-belt-driven-rollers-deliver-the-yarn-through-a-series-of-devices-that-whip-or-brush-it-removing-unwanted-strands-and-give-it-a-polish-it-then-passes-over-steam-pipes-then-wound-onto-reels-or-bobbins-right-ready-for-weaving-image557584802.html

An old engraving of a yarn dresser and reel machine used in the textile mills of the 1800s. It is from a Victorian mechanical engineering book of the 1880s. This machine was used for sizing and polishing yarn. Using size (a starch for cotton) reduces the chances of threads fraying and breaking due to the friction of the weaving process. Belt-driven rollers deliver the yarn through a series of devices that ‘whip’ or brush it, removing unwanted strands and give it a polish. It then passes over steam pipes, then wound onto reels or bobbins (right), ready for weaving. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-yarn-dresser-and-reel-machine-used-in-the-textile-mills-of-the-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-this-machine-was-used-for-sizing-and-polishing-yarn-using-size-a-starch-for-cotton-reduces-the-chances-of-threads-fraying-and-breaking-due-to-the-friction-of-the-weaving-process-belt-driven-rollers-deliver-the-yarn-through-a-series-of-devices-that-whip-or-brush-it-removing-unwanted-strands-and-give-it-a-polish-it-then-passes-over-steam-pipes-then-wound-onto-reels-or-bobbins-right-ready-for-weaving-image557584802.htmlRM2RB452X–An old engraving of a yarn dresser and reel machine used in the textile mills of the 1800s. It is from a Victorian mechanical engineering book of the 1880s. This machine was used for sizing and polishing yarn. Using size (a starch for cotton) reduces the chances of threads fraying and breaking due to the friction of the weaving process. Belt-driven rollers deliver the yarn through a series of devices that ‘whip’ or brush it, removing unwanted strands and give it a polish. It then passes over steam pipes, then wound onto reels or bobbins (right), ready for weaving.

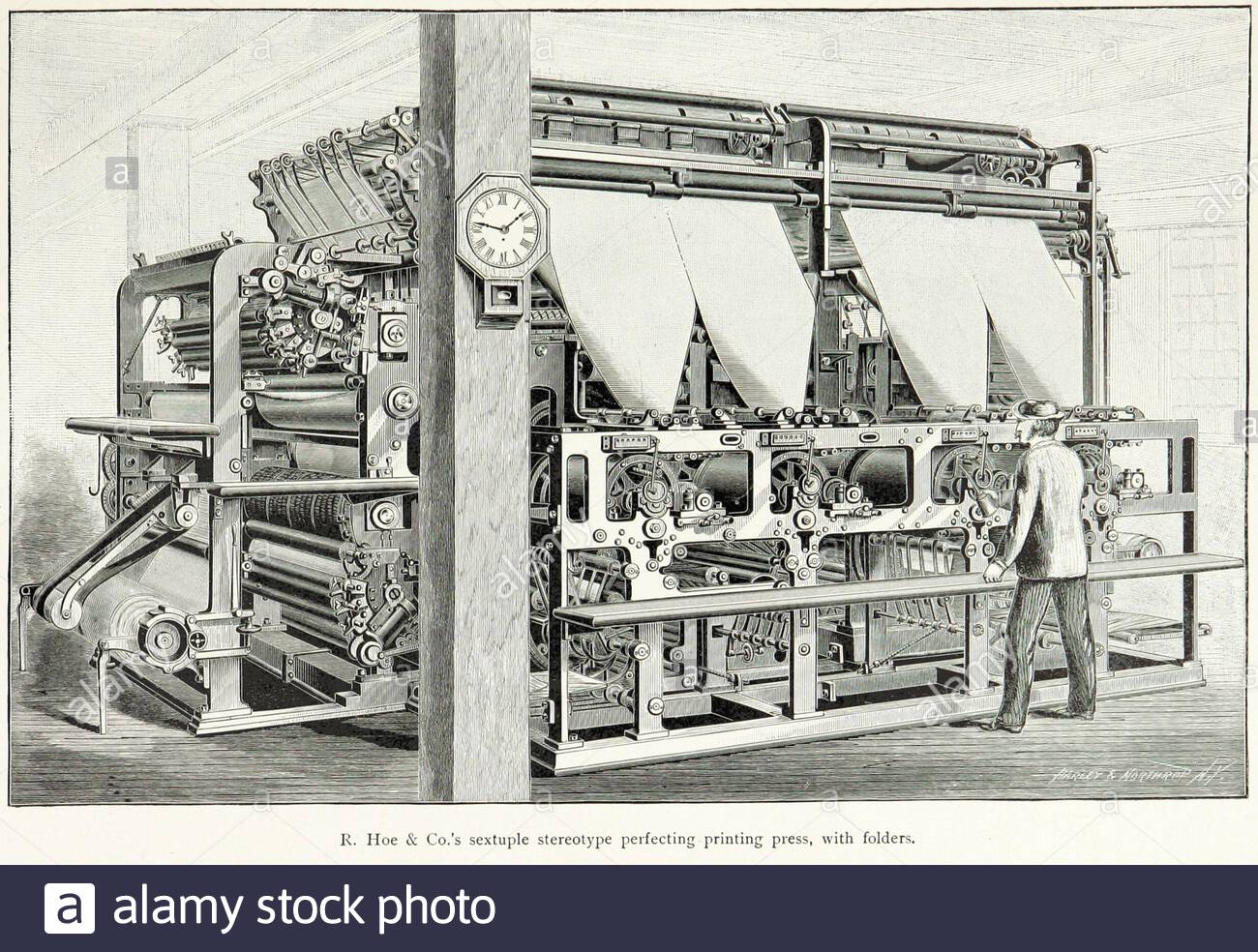

R. Hoe & Co.s sextuple stereotype perfecting printing press with folders, vintage illustration from 1894 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/r-hoe-cos-sextuple-stereotype-perfecting-printing-press-with-folders-vintage-illustration-from-1894-image396742981.html

R. Hoe & Co.s sextuple stereotype perfecting printing press with folders, vintage illustration from 1894 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/r-hoe-cos-sextuple-stereotype-perfecting-printing-press-with-folders-vintage-illustration-from-1894-image396742981.htmlRM2E1D5M5–R. Hoe & Co.s sextuple stereotype perfecting printing press with folders, vintage illustration from 1894

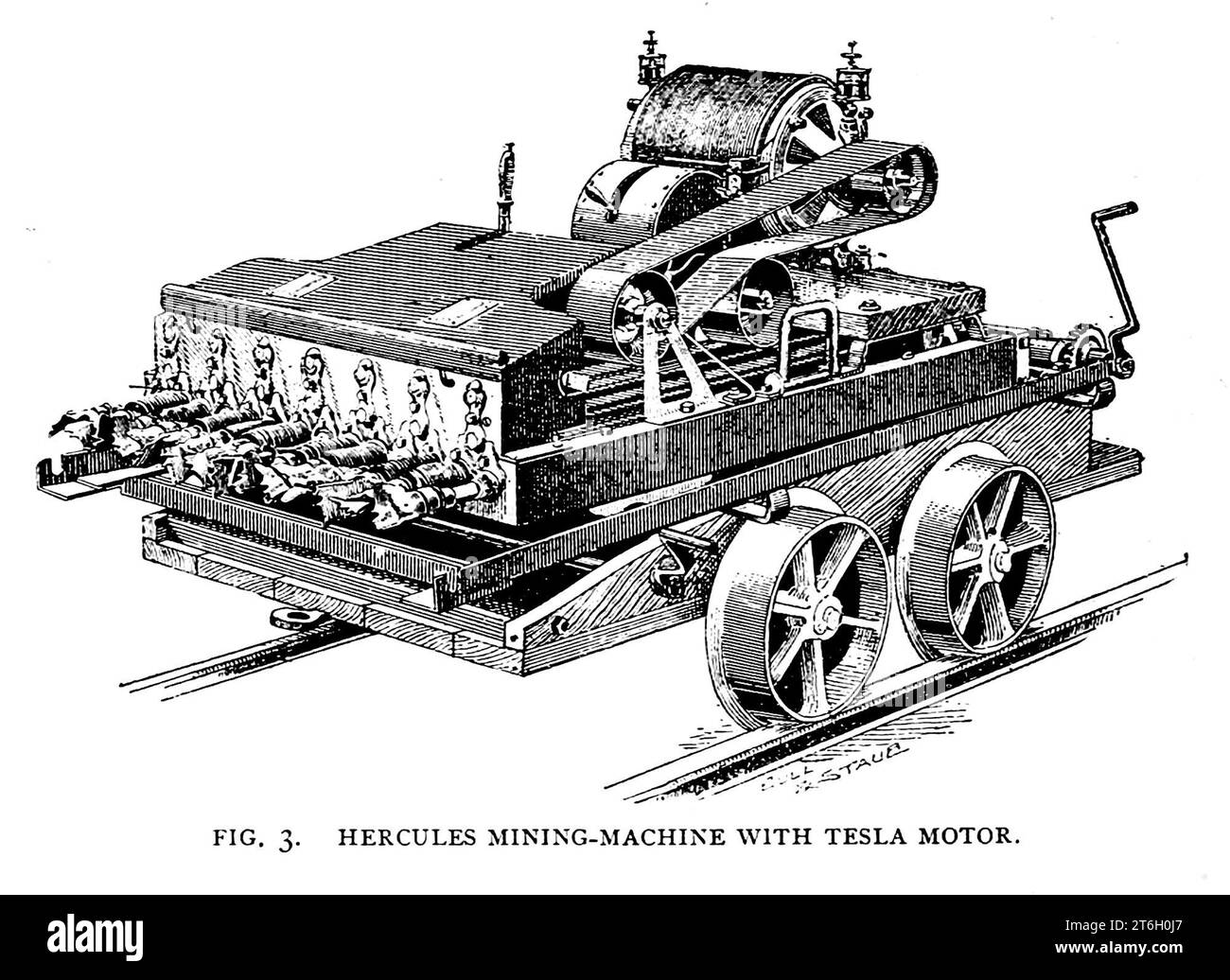

HERCULES MINING-MACHINE WITH TESLA MOTOR from the Article THE WONDERFUL EXPANSION IN THE USE OF ELECTRIC POWER. By Louis Bell from The Engineering Magazine DEVOTED TO INDUSTRIAL PROGRESS Volume XII October 1896 to March 1897 The Engineering Magazine Co Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/hercules-mining-machine-with-tesla-motor-from-the-article-the-wonderful-expansion-in-the-use-of-electric-power-by-louis-bell-from-the-engineering-magazine-devoted-to-industrial-progress-volume-xii-october-1896-to-march-1897-the-engineering-magazine-co-image572003775.html

HERCULES MINING-MACHINE WITH TESLA MOTOR from the Article THE WONDERFUL EXPANSION IN THE USE OF ELECTRIC POWER. By Louis Bell from The Engineering Magazine DEVOTED TO INDUSTRIAL PROGRESS Volume XII October 1896 to March 1897 The Engineering Magazine Co Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/hercules-mining-machine-with-tesla-motor-from-the-article-the-wonderful-expansion-in-the-use-of-electric-power-by-louis-bell-from-the-engineering-magazine-devoted-to-industrial-progress-volume-xii-october-1896-to-march-1897-the-engineering-magazine-co-image572003775.htmlRF2T6H0J7–HERCULES MINING-MACHINE WITH TESLA MOTOR from the Article THE WONDERFUL EXPANSION IN THE USE OF ELECTRIC POWER. By Louis Bell from The Engineering Magazine DEVOTED TO INDUSTRIAL PROGRESS Volume XII October 1896 to March 1897 The Engineering Magazine Co

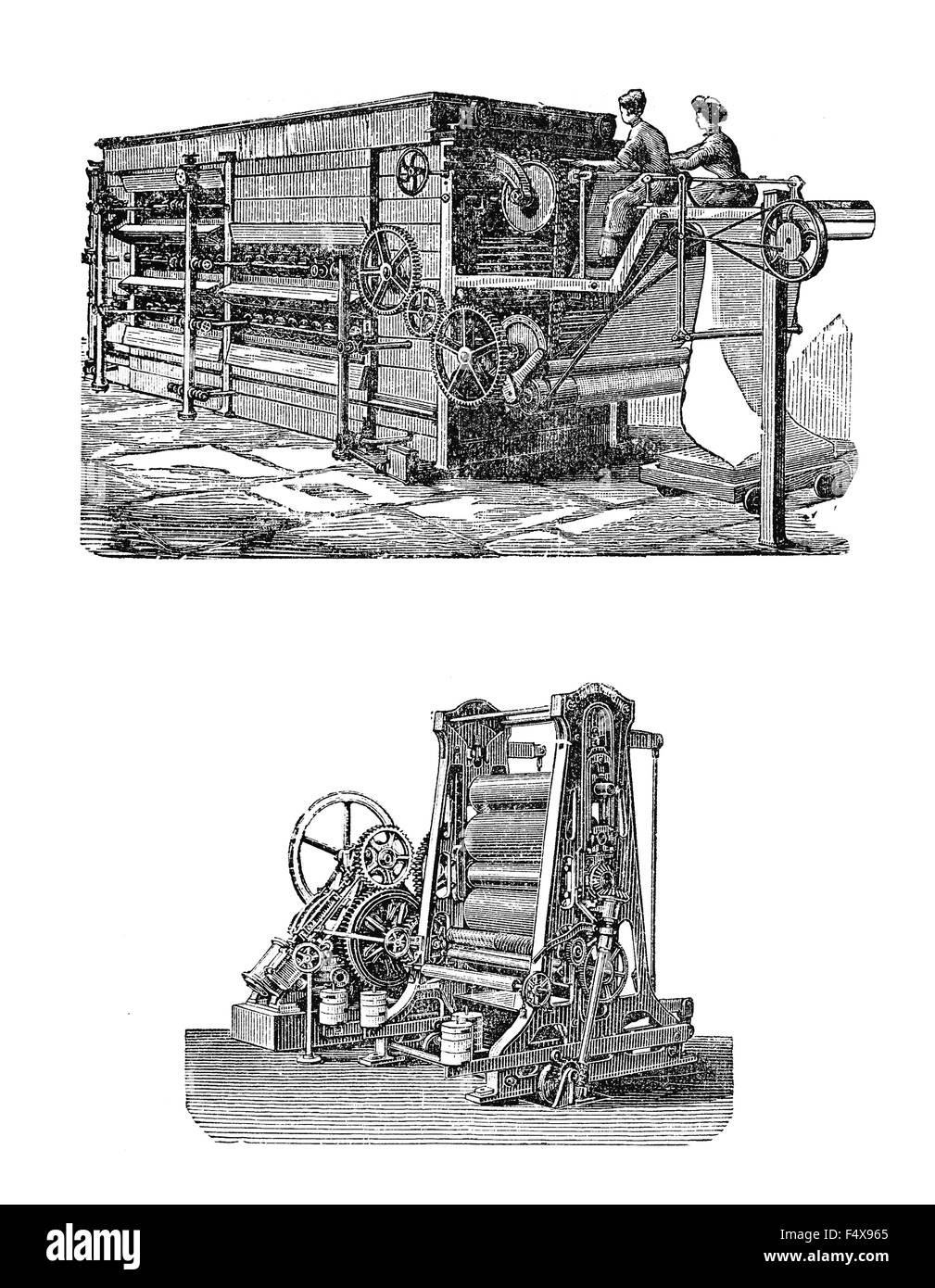

Steam stretch and calender dry machine for textile industry. Calender is a series of hard pressure rollers used to form or smooth a sheet of material such as fabric, also used for paper. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-steam-stretch-and-calender-dry-machine-for-textile-industry-calender-89088445.html

Steam stretch and calender dry machine for textile industry. Calender is a series of hard pressure rollers used to form or smooth a sheet of material such as fabric, also used for paper. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-steam-stretch-and-calender-dry-machine-for-textile-industry-calender-89088445.htmlRFF4X965–Steam stretch and calender dry machine for textile industry. Calender is a series of hard pressure rollers used to form or smooth a sheet of material such as fabric, also used for paper.

colored woolen threads on an old loom, Traditional Yarn in Canada. Close up Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/colored-woolen-threads-on-an-old-loom-traditional-yarn-in-canada-close-up-image333163998.html

colored woolen threads on an old loom, Traditional Yarn in Canada. Close up Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/colored-woolen-threads-on-an-old-loom-traditional-yarn-in-canada-close-up-image333163998.htmlRF2AA0X26–colored woolen threads on an old loom, Traditional Yarn in Canada. Close up

Wood barrel assembly machine. Old 19th century engraving from La Nature 1887 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/wood-barrel-assembly-machine-old-19th-century-engraving-from-la-nature-1887-image550985956.html

Wood barrel assembly machine. Old 19th century engraving from La Nature 1887 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/wood-barrel-assembly-machine-old-19th-century-engraving-from-la-nature-1887-image550985956.htmlRM2R0BG5T–Wood barrel assembly machine. Old 19th century engraving from La Nature 1887

Italy, Lombardy, Old Carding Wool Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/italy-lombardy-old-carding-wool-image608028382.html

Italy, Lombardy, Old Carding Wool Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/italy-lombardy-old-carding-wool-image608028382.htmlRM2X962BA–Italy, Lombardy, Old Carding Wool

Weighing cotton for export for the English market ; Bombay ; Mumbai ; Maharashtra ; India ; Asia ; old vintage 1800s engraving Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-weighing-cotton-for-export-for-the-english-market-bombay-mumbai-maharashtra-83597148.html

Weighing cotton for export for the English market ; Bombay ; Mumbai ; Maharashtra ; India ; Asia ; old vintage 1800s engraving Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-weighing-cotton-for-export-for-the-english-market-bombay-mumbai-maharashtra-83597148.htmlRMET050C–Weighing cotton for export for the English market ; Bombay ; Mumbai ; Maharashtra ; India ; Asia ; old vintage 1800s engraving

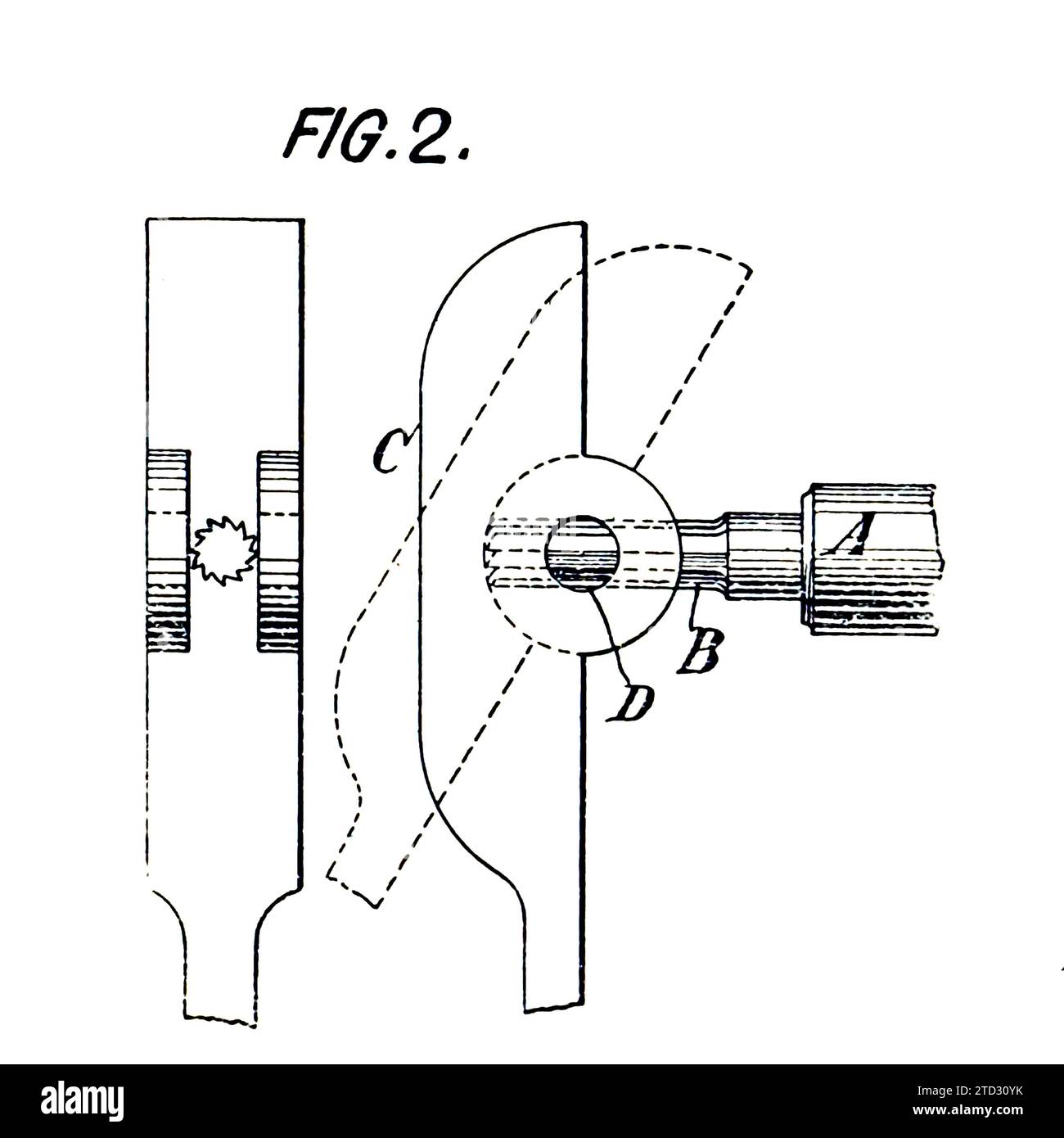

Illustration of a lathe. From 'Economy in Machine Shop Management' by James Brady from The Engineering Magazine, Volume VIII, 1895. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/illustration-of-a-lathe-from-economy-in-machine-shop-management-by-james-brady-from-the-engineering-magazine-volume-viii-1895-image575999303.html

Illustration of a lathe. From 'Economy in Machine Shop Management' by James Brady from The Engineering Magazine, Volume VIII, 1895. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/illustration-of-a-lathe-from-economy-in-machine-shop-management-by-james-brady-from-the-engineering-magazine-volume-viii-1895-image575999303.htmlRF2TD30YK–Illustration of a lathe. From 'Economy in Machine Shop Management' by James Brady from The Engineering Magazine, Volume VIII, 1895.

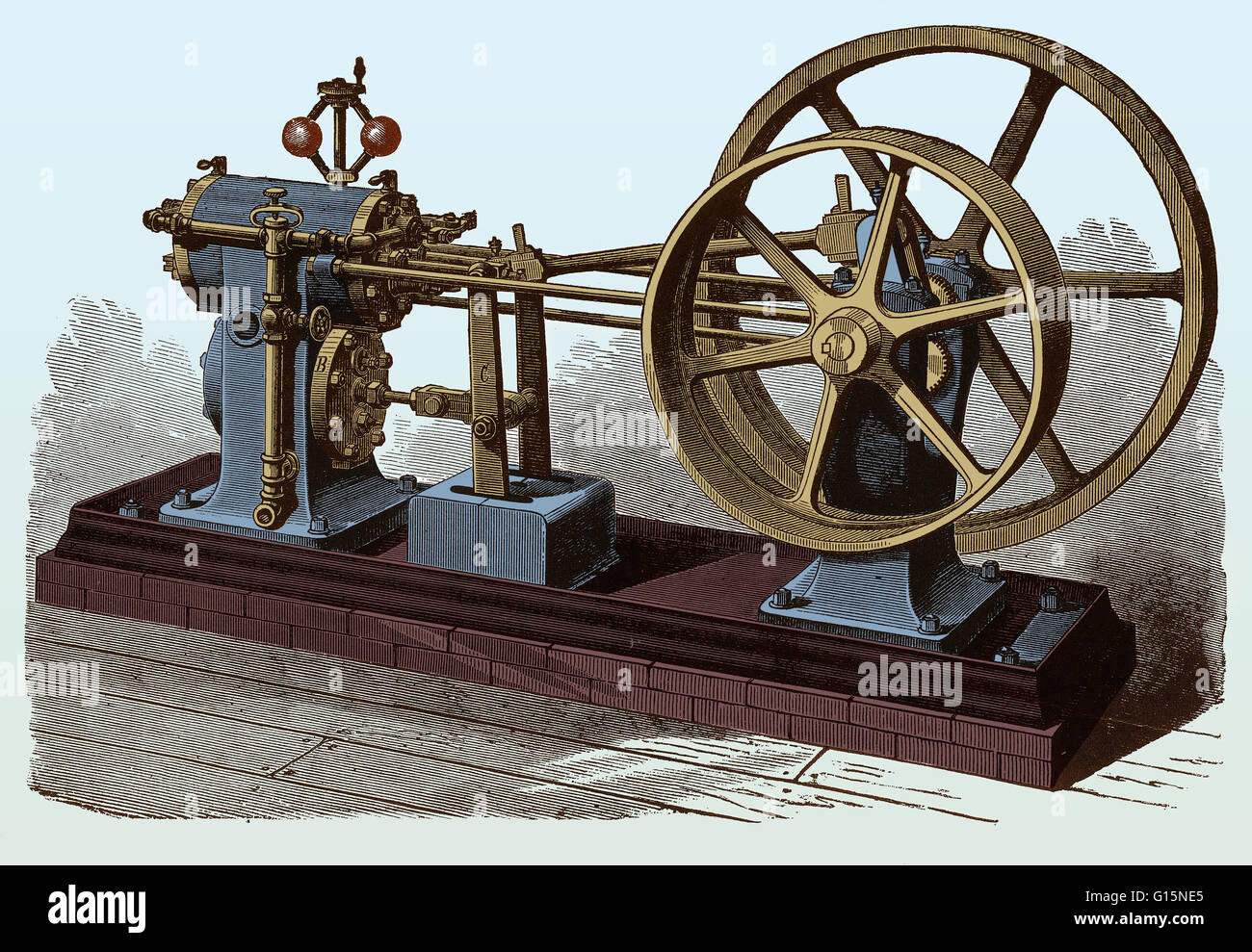

An illustration of the Brayton Hydrocarbon Engine, created by the American mechanical engineer George Brayton (1830 - 1892). Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-an-illustration-of-the-brayton-hydrocarbon-engine-created-by-the-american-104003485.html

An illustration of the Brayton Hydrocarbon Engine, created by the American mechanical engineer George Brayton (1830 - 1892). Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-an-illustration-of-the-brayton-hydrocarbon-engine-created-by-the-american-104003485.htmlRMG15NE5–An illustration of the Brayton Hydrocarbon Engine, created by the American mechanical engineer George Brayton (1830 - 1892).

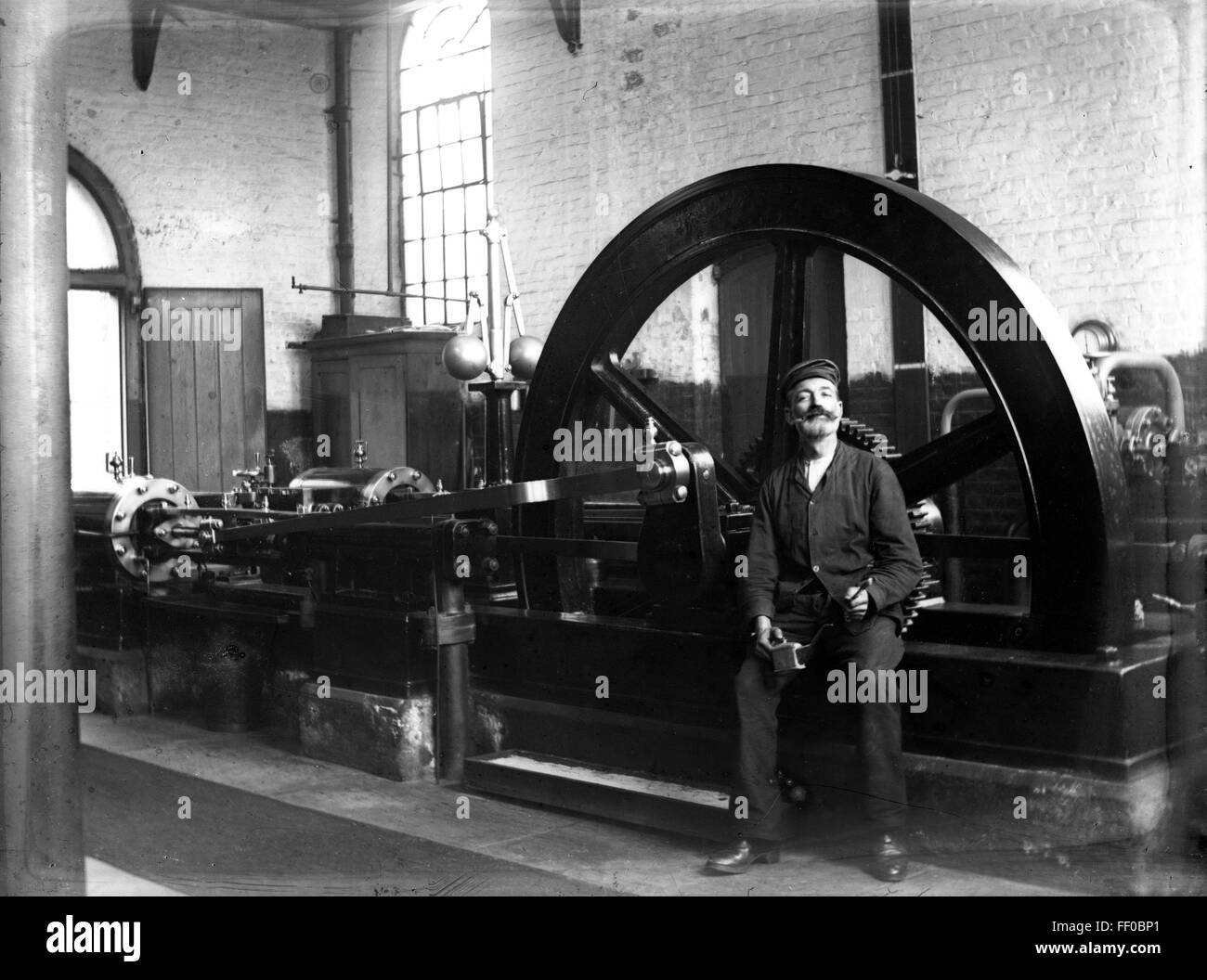

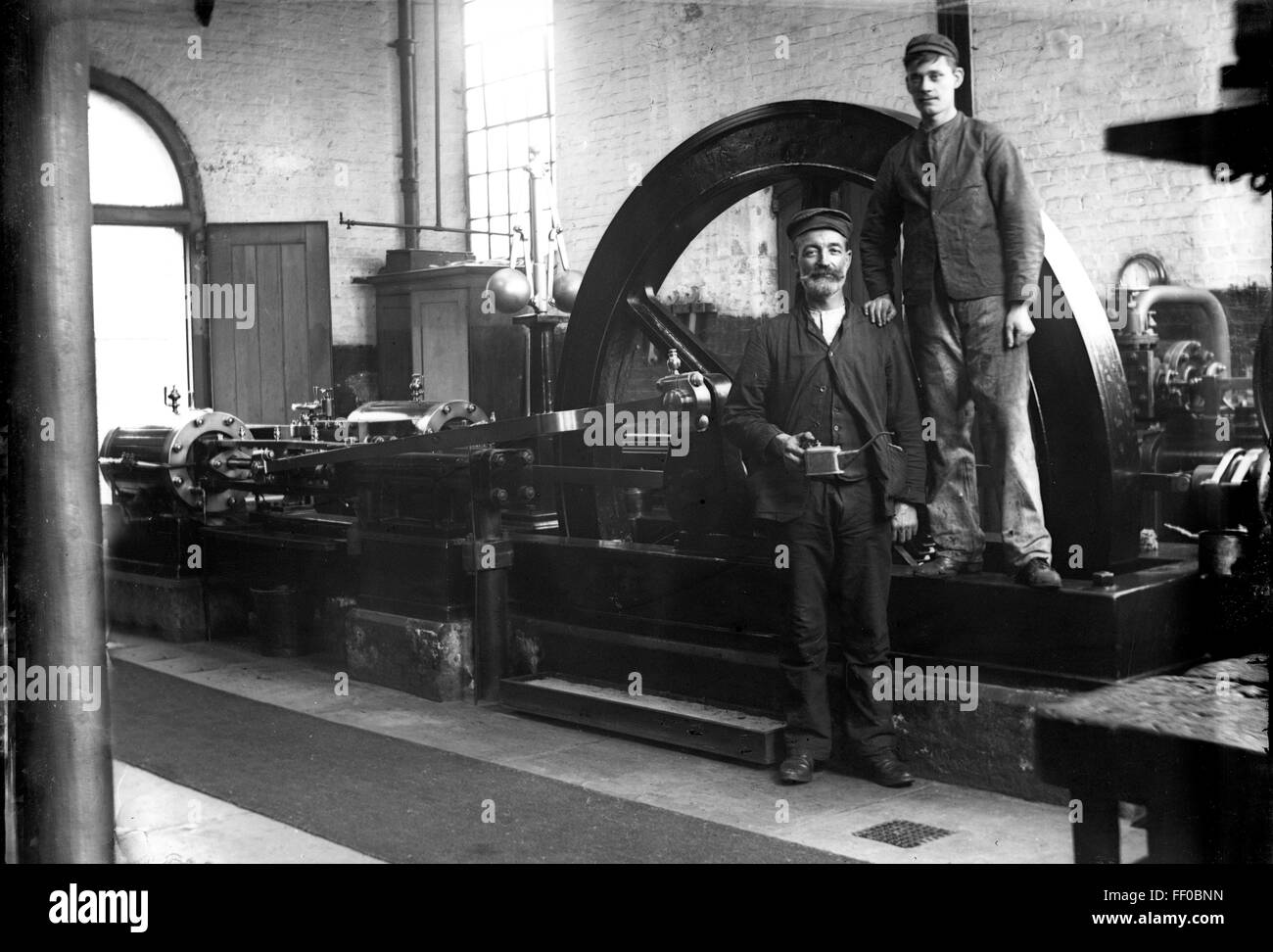

Victorian steam engine pump and engineer mechanic workman 1898 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-victorian-steam-engine-pump-and-engineer-mechanic-workman-1898-95280921.html

Victorian steam engine pump and engineer mechanic workman 1898 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-victorian-steam-engine-pump-and-engineer-mechanic-workman-1898-95280921.htmlRMFF0BP1–Victorian steam engine pump and engineer mechanic workman 1898

Power looms inside the Boott Cotton Mills at Lowell National Historical Park Massachusetts. Photograph Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/power-looms-inside-the-boott-cotton-mills-at-lowell-national-historical-image6548572.html

Power looms inside the Boott Cotton Mills at Lowell National Historical Park Massachusetts. Photograph Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/power-looms-inside-the-boott-cotton-mills-at-lowell-national-historical-image6548572.htmlRMA64NWD–Power looms inside the Boott Cotton Mills at Lowell National Historical Park Massachusetts. Photograph

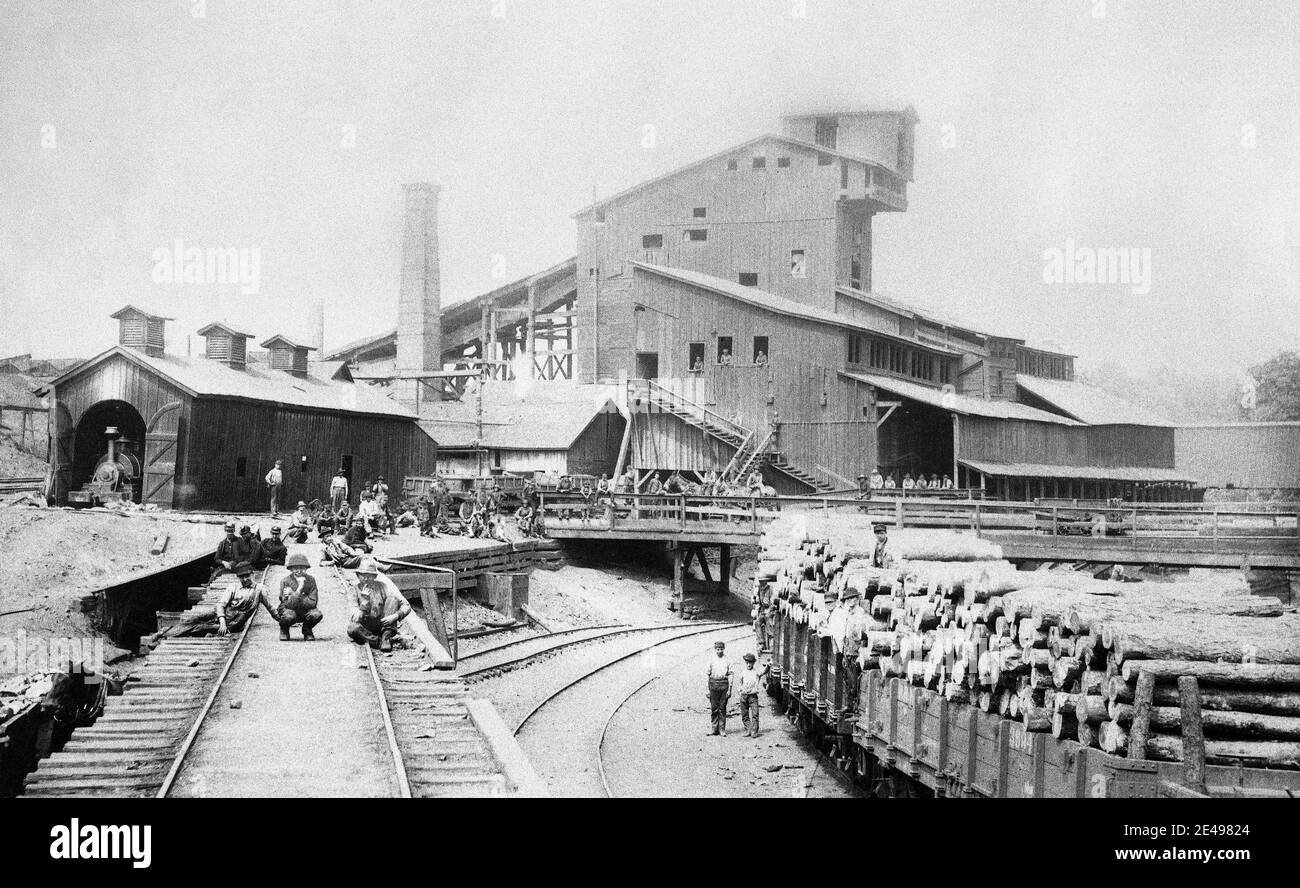

This is an unknown Anthracite coal breaker in Nanticoke Pennsylvania. Late 1800s. Nanticoke is a town in the anthracite coal regions of North Eastern Pennsylvania, USA. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/this-is-an-unknown-anthracite-coal-breaker-in-nanticoke-pennsylvania-late-1800s-nanticoke-is-a-town-in-the-anthracite-coal-regions-of-north-eastern-pennsylvania-usa-image398500988.html

This is an unknown Anthracite coal breaker in Nanticoke Pennsylvania. Late 1800s. Nanticoke is a town in the anthracite coal regions of North Eastern Pennsylvania, USA. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/this-is-an-unknown-anthracite-coal-breaker-in-nanticoke-pennsylvania-late-1800s-nanticoke-is-a-town-in-the-anthracite-coal-regions-of-north-eastern-pennsylvania-usa-image398500988.htmlRM2E49824–This is an unknown Anthracite coal breaker in Nanticoke Pennsylvania. Late 1800s. Nanticoke is a town in the anthracite coal regions of North Eastern Pennsylvania, USA.

The Old Furniture Factory, Art Music and Community Center, 6 West Loudoun Street, Round Hill, Virginia Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-the-old-furniture-factory-art-music-and-community-center-6-west-loudoun-113662809.html

The Old Furniture Factory, Art Music and Community Center, 6 West Loudoun Street, Round Hill, Virginia Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-the-old-furniture-factory-art-music-and-community-center-6-west-loudoun-113662809.htmlRMGGWP21–The Old Furniture Factory, Art Music and Community Center, 6 West Loudoun Street, Round Hill, Virginia

South Carolina Cotton Museum in Bishopville SC USA Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/south-carolina-cotton-museum-in-bishopville-sc-usa-image2557302.html

South Carolina Cotton Museum in Bishopville SC USA Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/south-carolina-cotton-museum-in-bishopville-sc-usa-image2557302.htmlRMAET577–South Carolina Cotton Museum in Bishopville SC USA

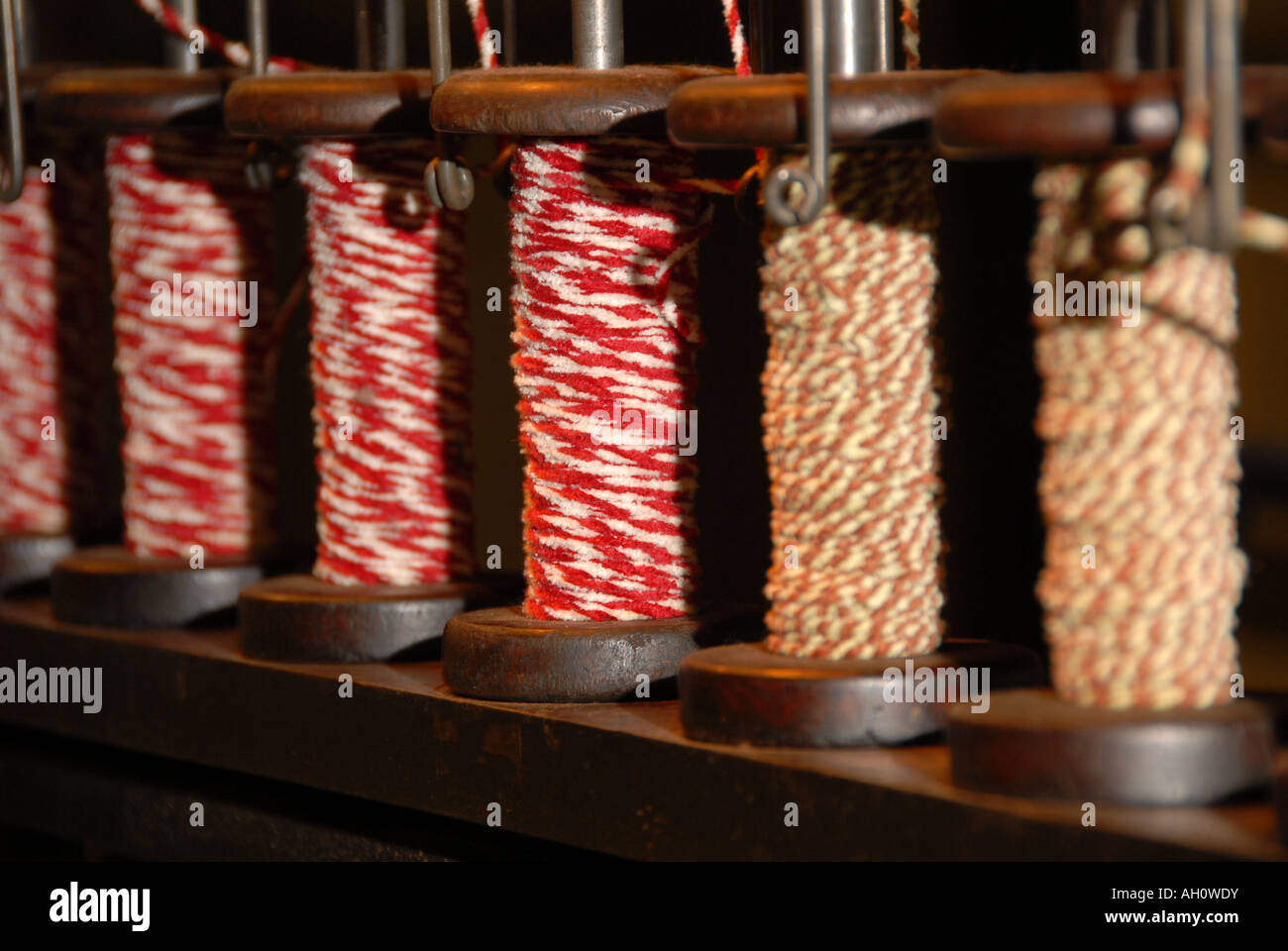

Spindles with yarn ready for use in Lowell weaving millls Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-spindles-with-yarn-ready-for-use-in-lowell-weaving-millls-14321270.html

Spindles with yarn ready for use in Lowell weaving millls Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-spindles-with-yarn-ready-for-use-in-lowell-weaving-millls-14321270.htmlRMAH0WDY–Spindles with yarn ready for use in Lowell weaving millls

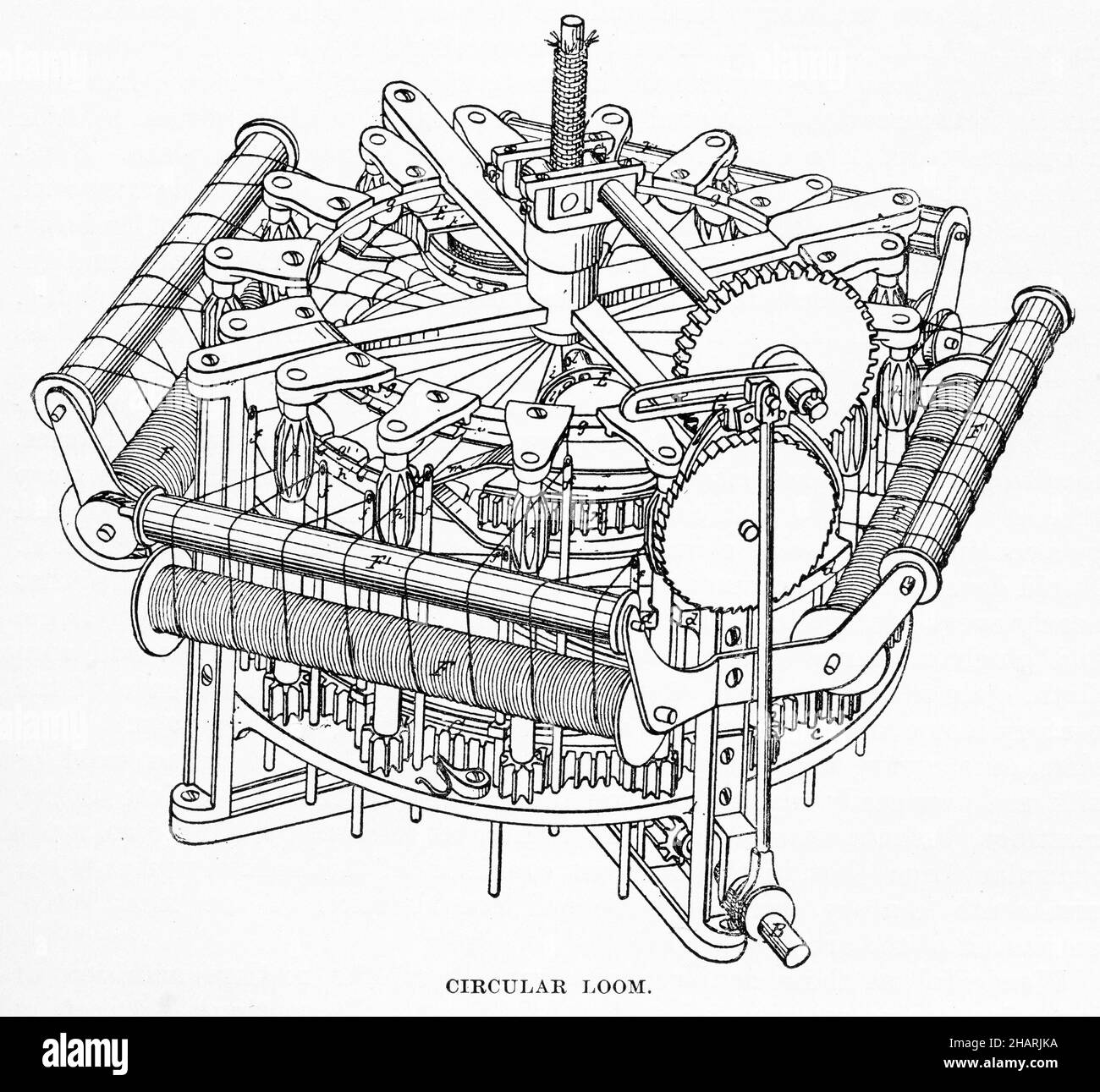

Engraving of a circular loom; used for putting an embroidered edge on fabric Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-a-circular-loom-used-for-putting-an-embroidered-edge-on-fabric-image454135678.html

Engraving of a circular loom; used for putting an embroidered edge on fabric Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-a-circular-loom-used-for-putting-an-embroidered-edge-on-fabric-image454135678.htmlRM2HARJKA–Engraving of a circular loom; used for putting an embroidered edge on fabric

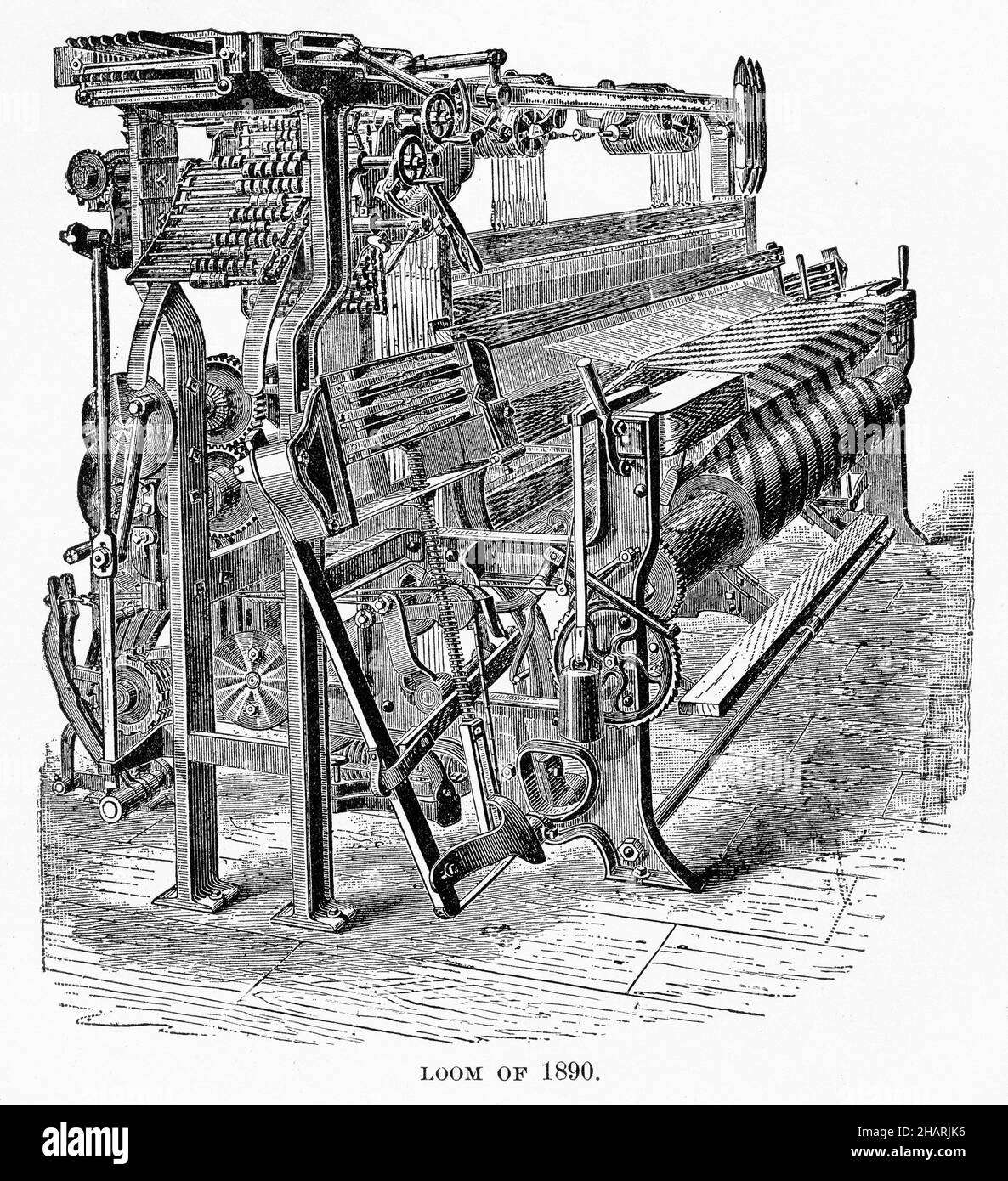

Engraving of a loom from 1890 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-a-loom-from-1890-image454135674.html

Engraving of a loom from 1890 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-a-loom-from-1890-image454135674.htmlRM2HARJK6–Engraving of a loom from 1890

An old engraving of a warp beaming machine (warper) used in the textile mills of the 1800s. It is from a Victorian mechanical engineering book of the 1880s. This device prepares the warp through ‘warping’. This process consists in placing reels – cotton or silk threads – in a creel (centre). This holds the cross-wound, rotating bobbins. The threads are pulled through guides and then inserted into the comb of the winding machine and attached to the warp beam. The rotating warp beam unwinds thread from the bobbins onto the warp beam, collected and wound up side by side. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-warp-beaming-machine-warper-used-in-the-textile-mills-of-the-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-this-device-prepares-the-warp-through-warping-this-process-consists-in-placing-reels-cotton-or-silk-threads-in-a-creel-centre-this-holds-the-cross-wound-rotating-bobbins-the-threads-are-pulled-through-guides-and-then-inserted-into-the-comb-of-the-winding-machine-and-attached-to-the-warp-beam-the-rotating-warp-beam-unwinds-thread-from-the-bobbins-onto-the-warp-beam-collected-and-wound-up-side-by-side-image557584743.html

An old engraving of a warp beaming machine (warper) used in the textile mills of the 1800s. It is from a Victorian mechanical engineering book of the 1880s. This device prepares the warp through ‘warping’. This process consists in placing reels – cotton or silk threads – in a creel (centre). This holds the cross-wound, rotating bobbins. The threads are pulled through guides and then inserted into the comb of the winding machine and attached to the warp beam. The rotating warp beam unwinds thread from the bobbins onto the warp beam, collected and wound up side by side. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-warp-beaming-machine-warper-used-in-the-textile-mills-of-the-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-this-device-prepares-the-warp-through-warping-this-process-consists-in-placing-reels-cotton-or-silk-threads-in-a-creel-centre-this-holds-the-cross-wound-rotating-bobbins-the-threads-are-pulled-through-guides-and-then-inserted-into-the-comb-of-the-winding-machine-and-attached-to-the-warp-beam-the-rotating-warp-beam-unwinds-thread-from-the-bobbins-onto-the-warp-beam-collected-and-wound-up-side-by-side-image557584743.htmlRM2RB450R–An old engraving of a warp beaming machine (warper) used in the textile mills of the 1800s. It is from a Victorian mechanical engineering book of the 1880s. This device prepares the warp through ‘warping’. This process consists in placing reels – cotton or silk threads – in a creel (centre). This holds the cross-wound, rotating bobbins. The threads are pulled through guides and then inserted into the comb of the winding machine and attached to the warp beam. The rotating warp beam unwinds thread from the bobbins onto the warp beam, collected and wound up side by side.

Engraving of women repairing lace curtains, circa 1880 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-women-repairing-lace-curtains-circa-1880-image537037984.html

Engraving of women repairing lace curtains, circa 1880 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-women-repairing-lace-curtains-circa-1880-image537037984.htmlRM2P5M5C0–Engraving of women repairing lace curtains, circa 1880

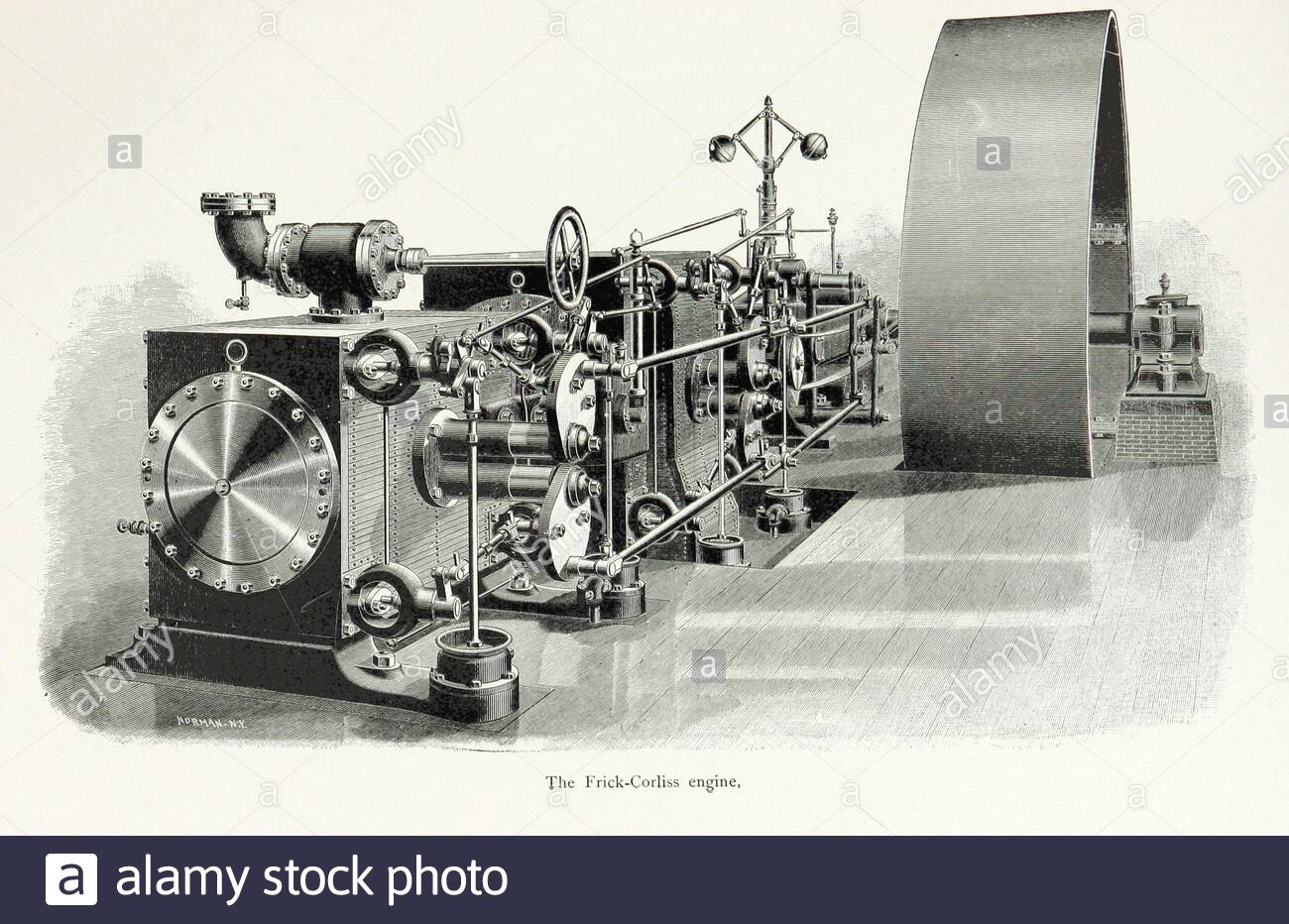

Frick Corliss steam engine, vintage illustration from 1894 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/frick-corliss-steam-engine-vintage-illustration-from-1894-image396742984.html

Frick Corliss steam engine, vintage illustration from 1894 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/frick-corliss-steam-engine-vintage-illustration-from-1894-image396742984.htmlRM2E1D5M8–Frick Corliss steam engine, vintage illustration from 1894

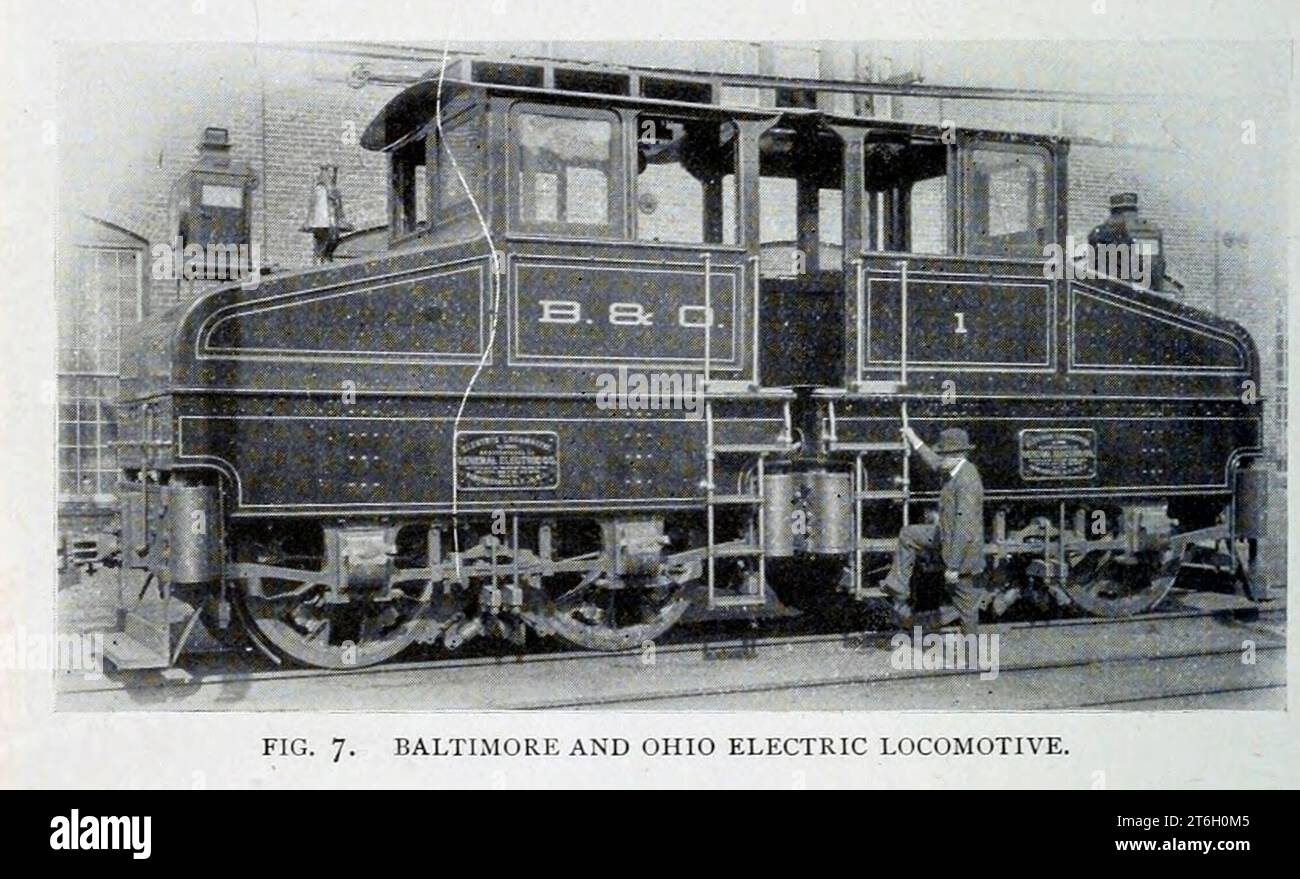

BALTIMORE AND OHIO ELECTRIC LOCOMOTIVE. from the Article THE WONDERFUL EXPANSION IN THE USE OF ELECTRIC POWER. By Louis Bell from The Engineering Magazine DEVOTED TO INDUSTRIAL PROGRESS Volume XII October 1896 to March 1897 The Engineering Magazine Co Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/baltimore-and-ohio-electric-locomotive-from-the-article-the-wonderful-expansion-in-the-use-of-electric-power-by-louis-bell-from-the-engineering-magazine-devoted-to-industrial-progress-volume-xii-october-1896-to-march-1897-the-engineering-magazine-co-image572003829.html

BALTIMORE AND OHIO ELECTRIC LOCOMOTIVE. from the Article THE WONDERFUL EXPANSION IN THE USE OF ELECTRIC POWER. By Louis Bell from The Engineering Magazine DEVOTED TO INDUSTRIAL PROGRESS Volume XII October 1896 to March 1897 The Engineering Magazine Co Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/baltimore-and-ohio-electric-locomotive-from-the-article-the-wonderful-expansion-in-the-use-of-electric-power-by-louis-bell-from-the-engineering-magazine-devoted-to-industrial-progress-volume-xii-october-1896-to-march-1897-the-engineering-magazine-co-image572003829.htmlRF2T6H0M5–BALTIMORE AND OHIO ELECTRIC LOCOMOTIVE. from the Article THE WONDERFUL EXPANSION IN THE USE OF ELECTRIC POWER. By Louis Bell from The Engineering Magazine DEVOTED TO INDUSTRIAL PROGRESS Volume XII October 1896 to March 1897 The Engineering Magazine Co

Thomas Edison Multipolar Dynamo, vintage illustration from 1894 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/thomas-edison-multipolar-dynamo-vintage-illustration-from-1894-image396995129.html

Thomas Edison Multipolar Dynamo, vintage illustration from 1894 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/thomas-edison-multipolar-dynamo-vintage-illustration-from-1894-image396995129.htmlRM2E1TK9D–Thomas Edison Multipolar Dynamo, vintage illustration from 1894

Machine for turning and beveling the bottoms of barrels. Old 19th century engraving from La Nature 1887 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/machine-for-turning-and-beveling-the-bottoms-of-barrels-old-19th-century-engraving-from-la-nature-1887-image550985960.html

Machine for turning and beveling the bottoms of barrels. Old 19th century engraving from La Nature 1887 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/machine-for-turning-and-beveling-the-bottoms-of-barrels-old-19th-century-engraving-from-la-nature-1887-image550985960.htmlRM2R0BG60–Machine for turning and beveling the bottoms of barrels. Old 19th century engraving from La Nature 1887

Italy, Lombardy, Old Carding Wool Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/italy-lombardy-old-carding-wool-image608028399.html

Italy, Lombardy, Old Carding Wool Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/italy-lombardy-old-carding-wool-image608028399.htmlRM2X962BY–Italy, Lombardy, Old Carding Wool

Spools of colored thread that were used in a woolen mill 1800's and early 1900's. colored woolen threads on an old loom, Traditional Yarn in Canada. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/spools-of-colored-thread-that-were-used-in-a-woolen-mill-1800s-and-early-1900s-colored-woolen-threads-on-an-old-loom-traditional-yarn-in-canada-image333164033.html

Spools of colored thread that were used in a woolen mill 1800's and early 1900's. colored woolen threads on an old loom, Traditional Yarn in Canada. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/spools-of-colored-thread-that-were-used-in-a-woolen-mill-1800s-and-early-1900s-colored-woolen-threads-on-an-old-loom-traditional-yarn-in-canada-image333164033.htmlRF2AA0X3D–Spools of colored thread that were used in a woolen mill 1800's and early 1900's. colored woolen threads on an old loom, Traditional Yarn in Canada.

Illustration of a lathe. From 'Economy in Machine Shop Management' by James Brady from The Engineering Magazine, Volume VIII, 1895. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/illustration-of-a-lathe-from-economy-in-machine-shop-management-by-james-brady-from-the-engineering-magazine-volume-viii-1895-image575999308.html

Illustration of a lathe. From 'Economy in Machine Shop Management' by James Brady from The Engineering Magazine, Volume VIII, 1895. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/illustration-of-a-lathe-from-economy-in-machine-shop-management-by-james-brady-from-the-engineering-magazine-volume-viii-1895-image575999308.htmlRF2TD30YT–Illustration of a lathe. From 'Economy in Machine Shop Management' by James Brady from The Engineering Magazine, Volume VIII, 1895.

Bigelow Stationary Engine, as seen at the Centennial Exposition of 1876. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-bigelow-stationary-engine-as-seen-at-the-centennial-exposition-of-104003483.html

Bigelow Stationary Engine, as seen at the Centennial Exposition of 1876. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-bigelow-stationary-engine-as-seen-at-the-centennial-exposition-of-104003483.htmlRMG15NE3–Bigelow Stationary Engine, as seen at the Centennial Exposition of 1876.

Victorian steam engine pump and engineer mechanic workman 1898 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-victorian-steam-engine-pump-and-engineer-mechanic-workman-1898-95280913.html

Victorian steam engine pump and engineer mechanic workman 1898 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-victorian-steam-engine-pump-and-engineer-mechanic-workman-1898-95280913.htmlRMFF0BNN–Victorian steam engine pump and engineer mechanic workman 1898

Bobbins with machine-spun thread on a loom, Boott Cotton Mills, Lowell, Massachusetts. Photograph Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-bobbins-with-machine-spun-thread-on-a-loom-boott-cotton-mills-lowell-20445851.html

Bobbins with machine-spun thread on a loom, Boott Cotton Mills, Lowell, Massachusetts. Photograph Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-bobbins-with-machine-spun-thread-on-a-loom-boott-cotton-mills-lowell-20445851.htmlRMB57ATY–Bobbins with machine-spun thread on a loom, Boott Cotton Mills, Lowell, Massachusetts. Photograph

The Old Furniture Factory, Art Music and Community Center, 6 West Loudoun Street, Round Hill, Virginia Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-the-old-furniture-factory-art-music-and-community-center-6-west-loudoun-113662796.html

The Old Furniture Factory, Art Music and Community Center, 6 West Loudoun Street, Round Hill, Virginia Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-the-old-furniture-factory-art-music-and-community-center-6-west-loudoun-113662796.htmlRMGGWP1G–The Old Furniture Factory, Art Music and Community Center, 6 West Loudoun Street, Round Hill, Virginia

South Carolina Cotton Museum in Bishopville SC USA Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/south-carolina-cotton-museum-in-bishopville-sc-usa-image2557257.html

South Carolina Cotton Museum in Bishopville SC USA Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/south-carolina-cotton-museum-in-bishopville-sc-usa-image2557257.htmlRMAET54A–South Carolina Cotton Museum in Bishopville SC USA

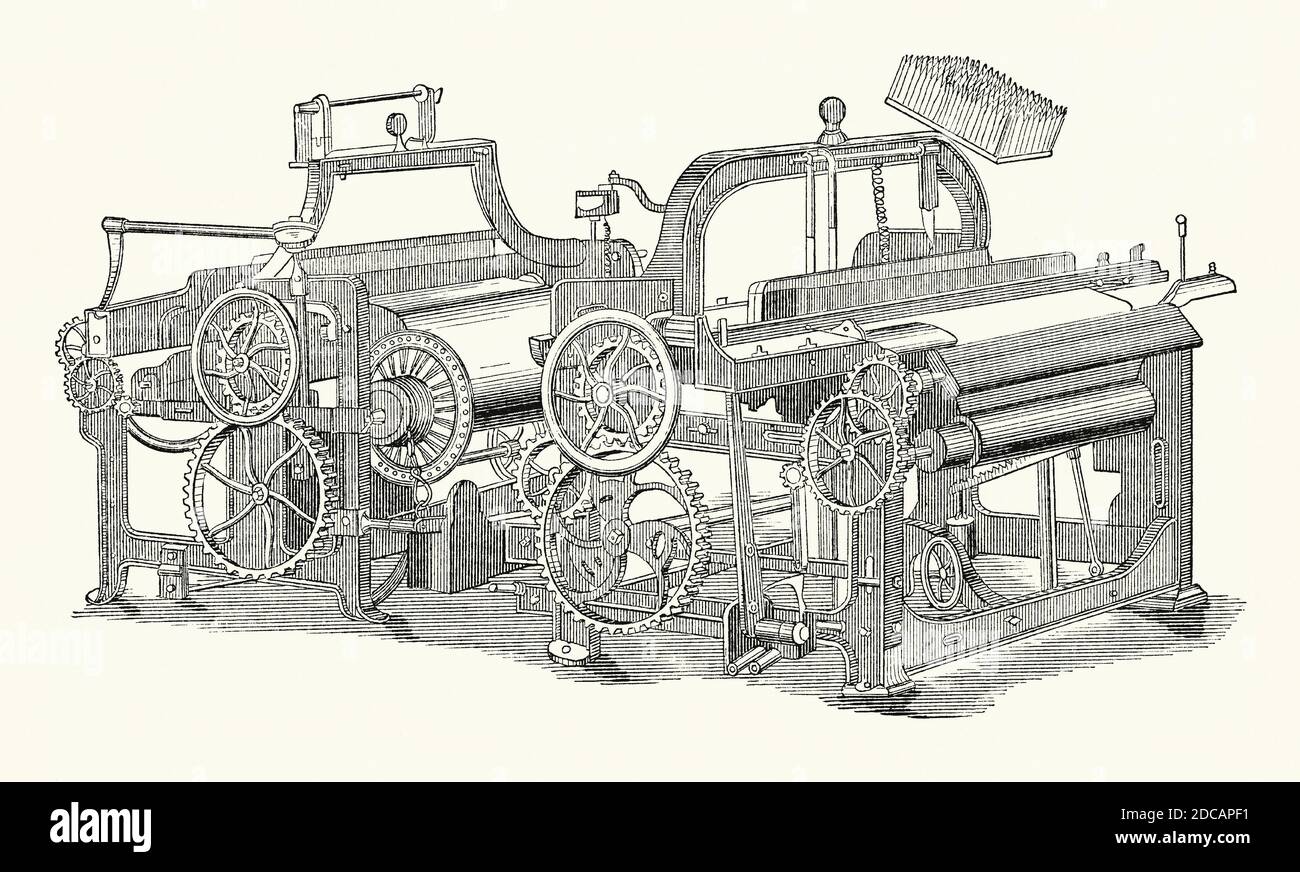

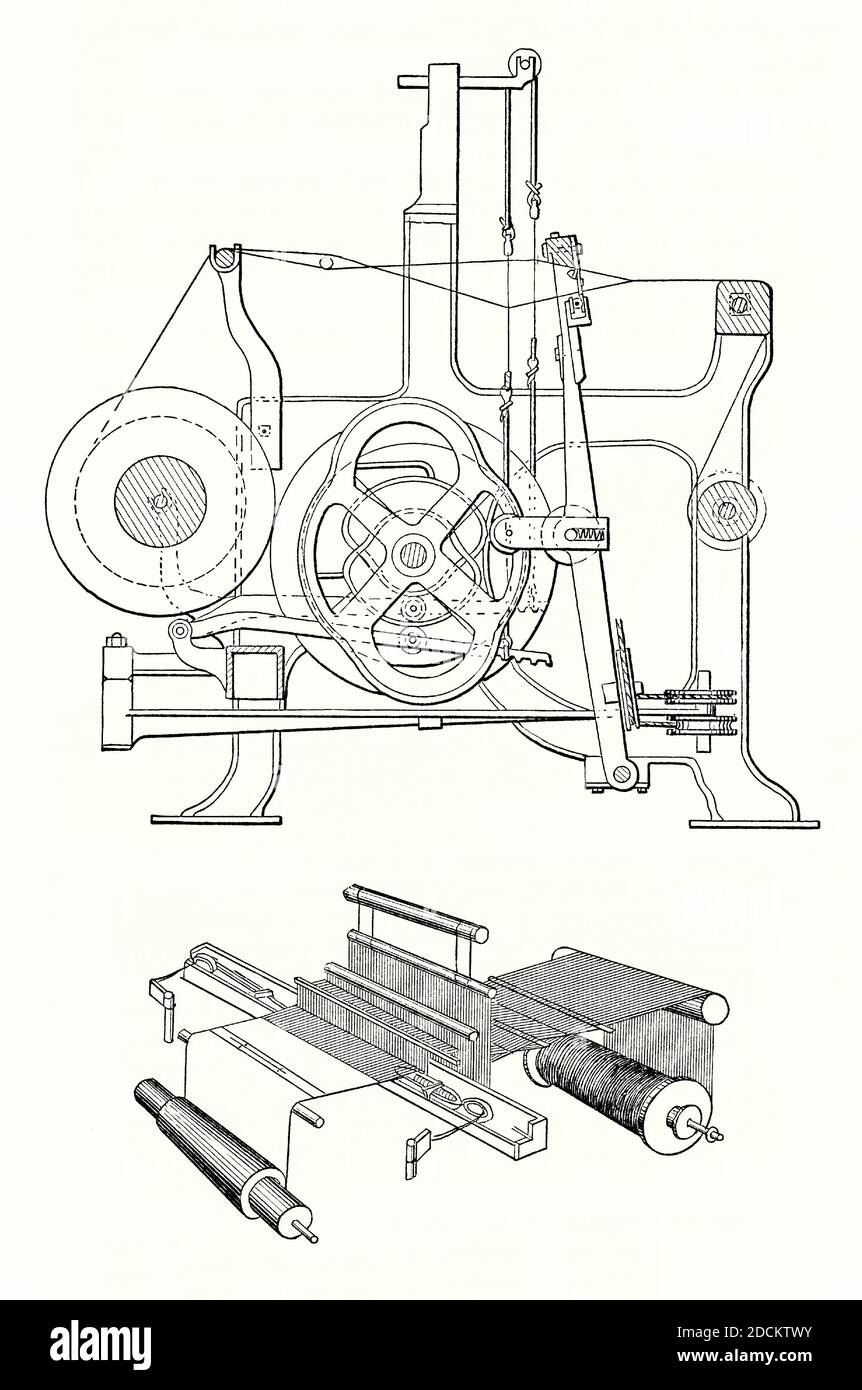

An old engraving of a warping mill (left), a winding machine (centre) and a power loom (right) used in producing cotton in the 1800s. It is from a Victorian mechanical engineering book of the 1880s. A loom is a device used to weave cloth. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. Englishman Edmund Cartwright built and patented a power loom in 1785, and it was this that was adopted by cotton industry. Water and/or steam provided the power needed to run the looms, usually by belt drives to the individual looms. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-warping-mill-left-a-winding-machine-centre-and-a-power-loom-right-used-in-producing-cotton-in-the-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-a-loom-is-a-device-used-to-weave-cloth-the-basic-purpose-of-any-loom-is-to-hold-the-warp-threads-under-tension-to-facilitate-the-interweaving-of-the-weft-threads-englishman-edmund-cartwright-built-and-patented-a-power-loom-in-1785-and-it-was-this-that-was-adopted-by-cotton-industry-water-andor-steam-provided-the-power-needed-to-run-the-looms-usually-by-belt-drives-to-the-individual-looms-image559321655.html

An old engraving of a warping mill (left), a winding machine (centre) and a power loom (right) used in producing cotton in the 1800s. It is from a Victorian mechanical engineering book of the 1880s. A loom is a device used to weave cloth. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. Englishman Edmund Cartwright built and patented a power loom in 1785, and it was this that was adopted by cotton industry. Water and/or steam provided the power needed to run the looms, usually by belt drives to the individual looms. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-warping-mill-left-a-winding-machine-centre-and-a-power-loom-right-used-in-producing-cotton-in-the-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-a-loom-is-a-device-used-to-weave-cloth-the-basic-purpose-of-any-loom-is-to-hold-the-warp-threads-under-tension-to-facilitate-the-interweaving-of-the-weft-threads-englishman-edmund-cartwright-built-and-patented-a-power-loom-in-1785-and-it-was-this-that-was-adopted-by-cotton-industry-water-andor-steam-provided-the-power-needed-to-run-the-looms-usually-by-belt-drives-to-the-individual-looms-image559321655.htmlRM2RDY8DB–An old engraving of a warping mill (left), a winding machine (centre) and a power loom (right) used in producing cotton in the 1800s. It is from a Victorian mechanical engineering book of the 1880s. A loom is a device used to weave cloth. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. Englishman Edmund Cartwright built and patented a power loom in 1785, and it was this that was adopted by cotton industry. Water and/or steam provided the power needed to run the looms, usually by belt drives to the individual looms.

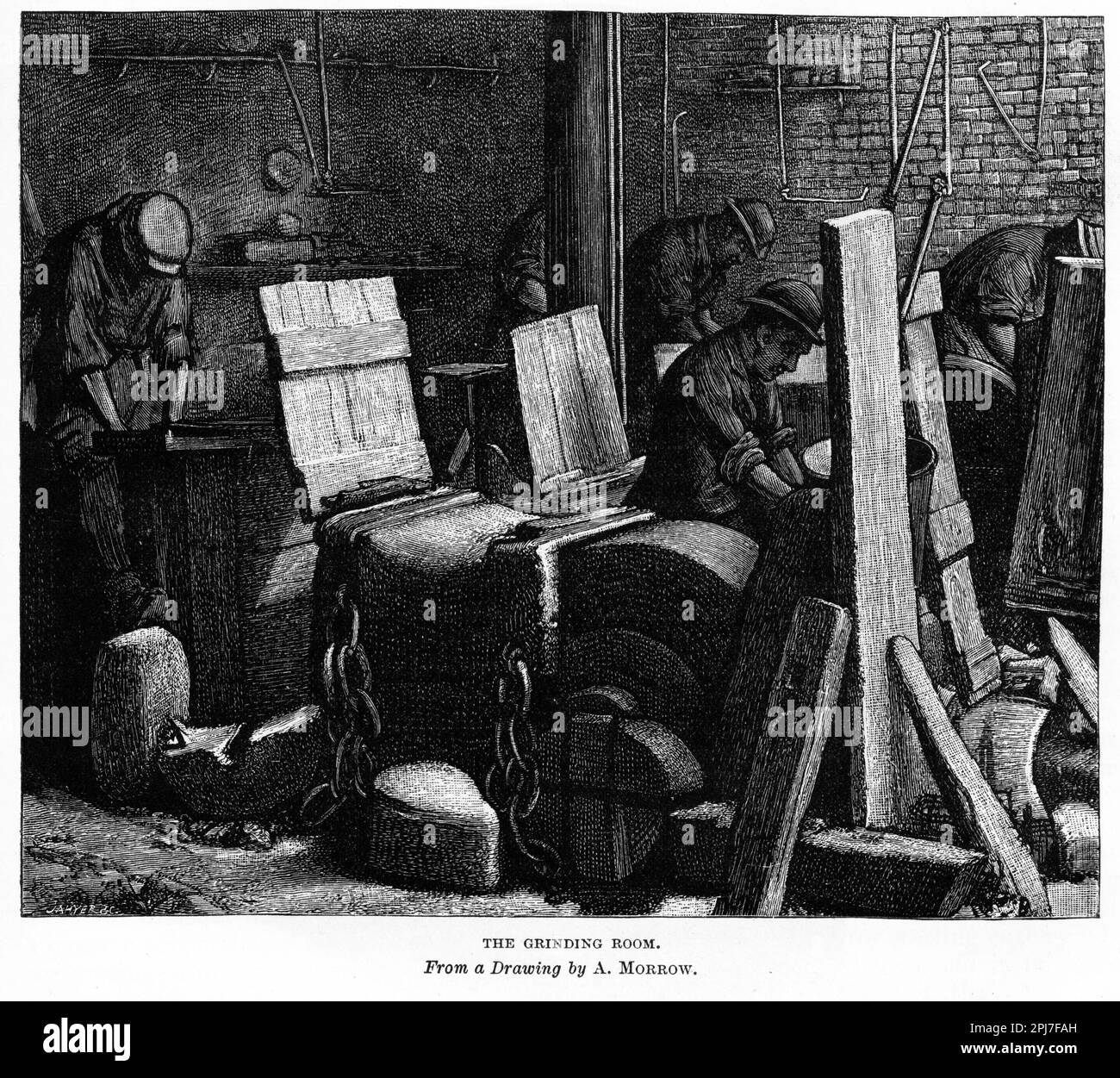

Engraving of men working in the grinding room , circa 1880 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-men-working-in-the-grinding-room-circa-1880-image544750937.html

Engraving of men working in the grinding room , circa 1880 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-men-working-in-the-grinding-room-circa-1880-image544750937.htmlRM2PJ7FAH–Engraving of men working in the grinding room , circa 1880

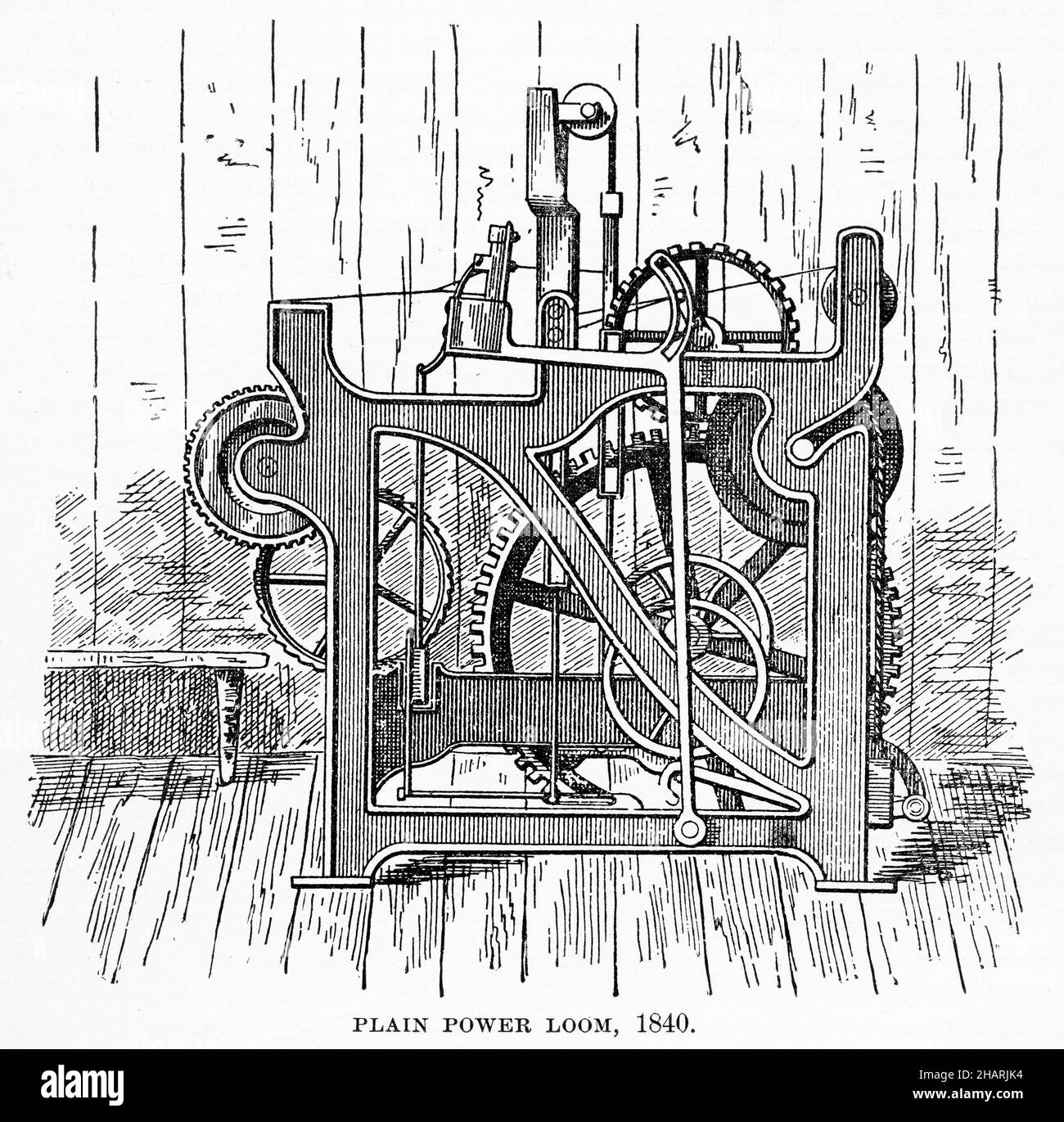

Engraving of a plain power loom from 1840 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-a-plain-power-loom-from-1840-image454135672.html

Engraving of a plain power loom from 1840 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-of-a-plain-power-loom-from-1840-image454135672.htmlRM2HARJK4–Engraving of a plain power loom from 1840