Quick filters:

Power loom weaving Stock Photos and Images

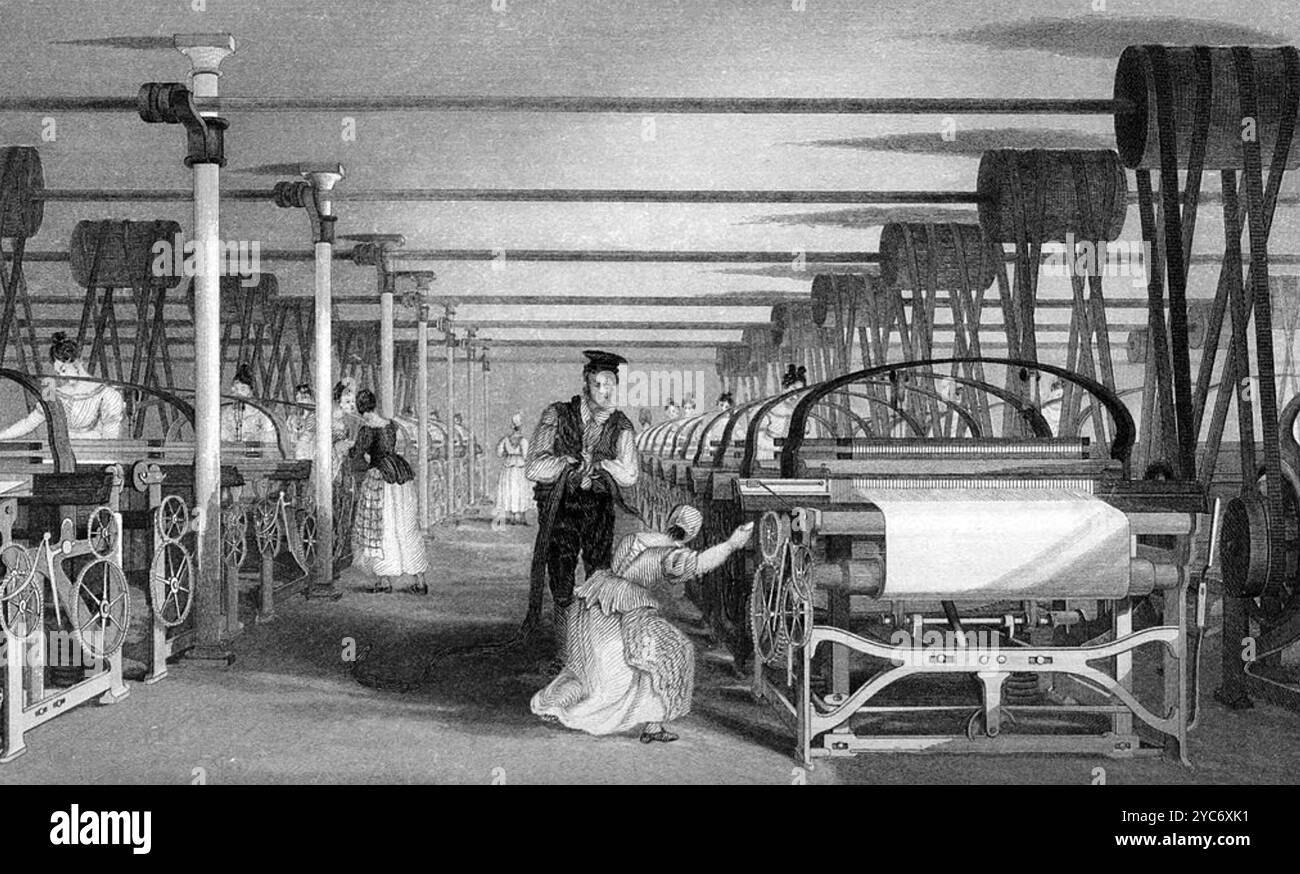

Interior of cotton mill: power loom weaving. Man and woman tend machine. Date: 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-interior-of-cotton-mill-power-loom-weaving-man-and-woman-tend-machine-105279634.html

Interior of cotton mill: power loom weaving. Man and woman tend machine. Date: 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-interior-of-cotton-mill-power-loom-weaving-man-and-woman-tend-machine-105279634.htmlRMG37W6X–Interior of cotton mill: power loom weaving. Man and woman tend machine. Date: 1835

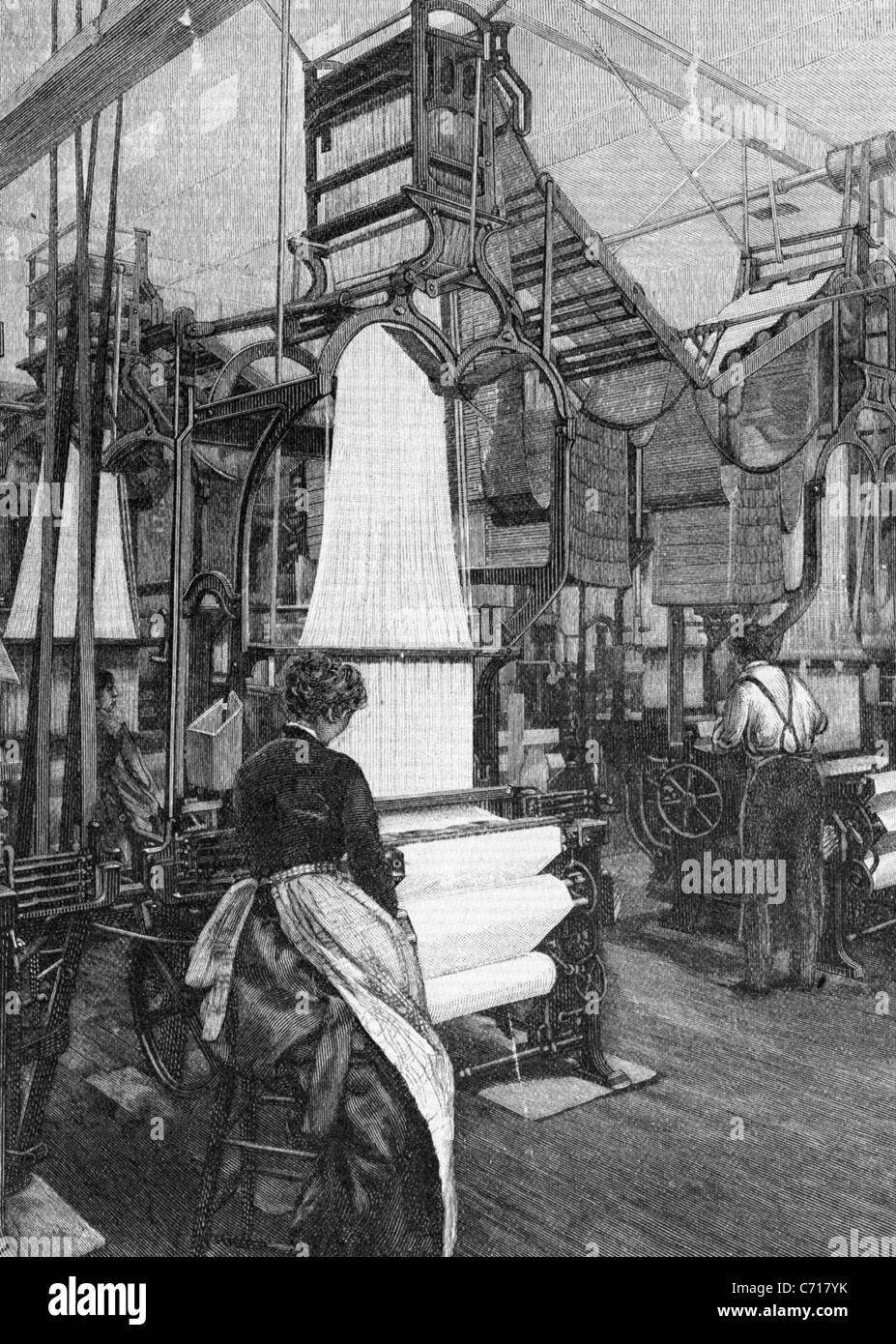

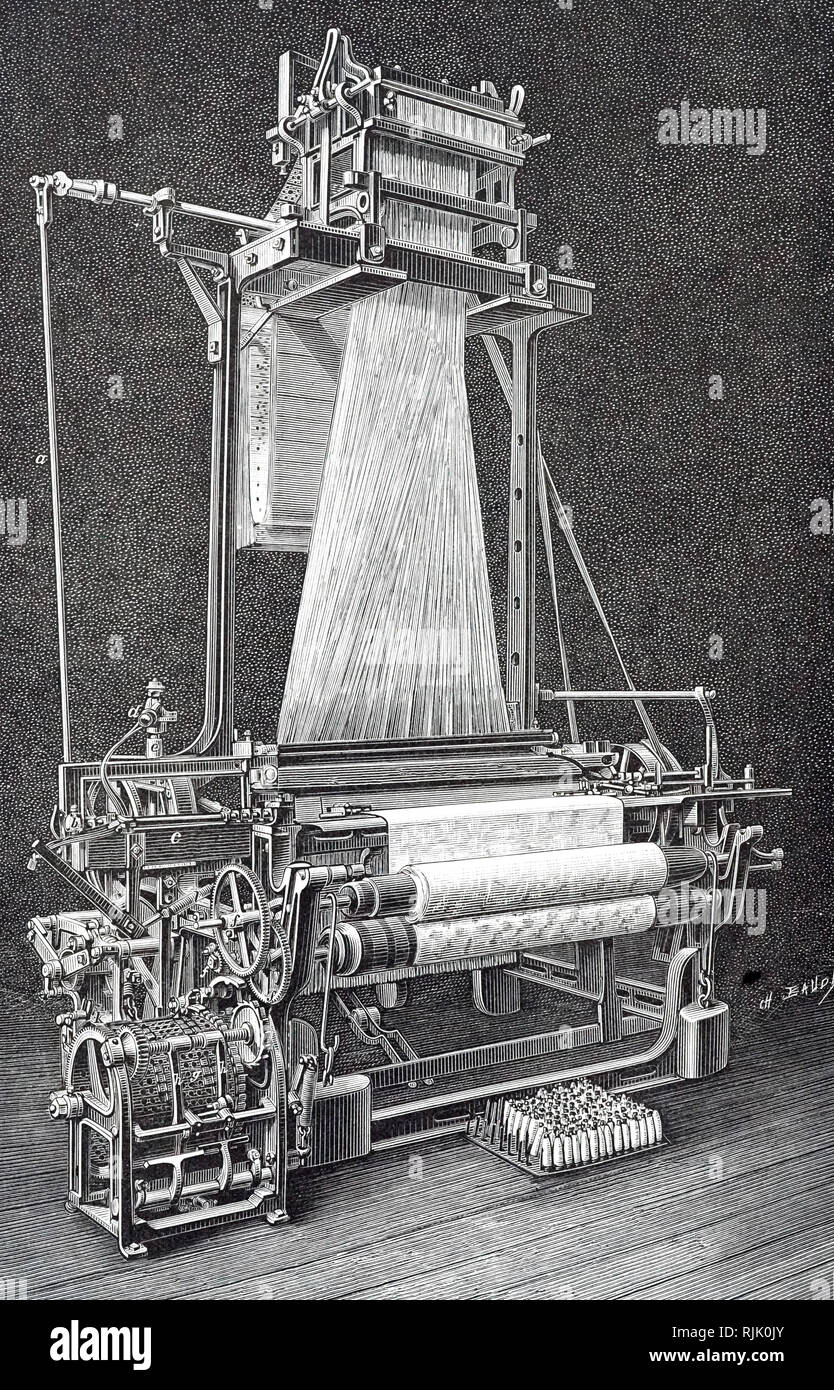

POWER LOOM WEAVING in England in the 1850s Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-power-loom-weaving-in-england-in-the-1850s-38751543.html

POWER LOOM WEAVING in England in the 1850s Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-power-loom-weaving-in-england-in-the-1850s-38751543.htmlRMC717YK–POWER LOOM WEAVING in England in the 1850s

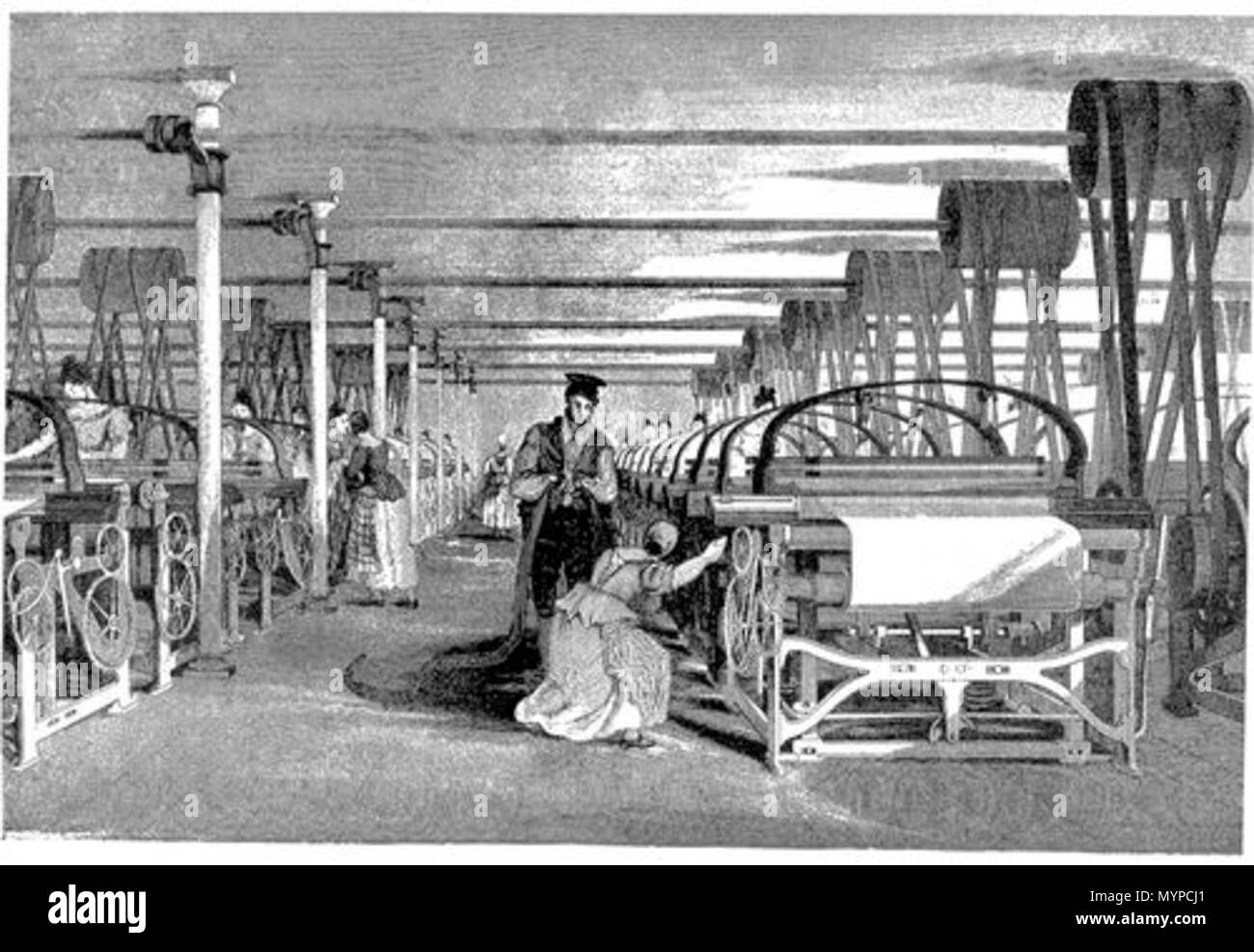

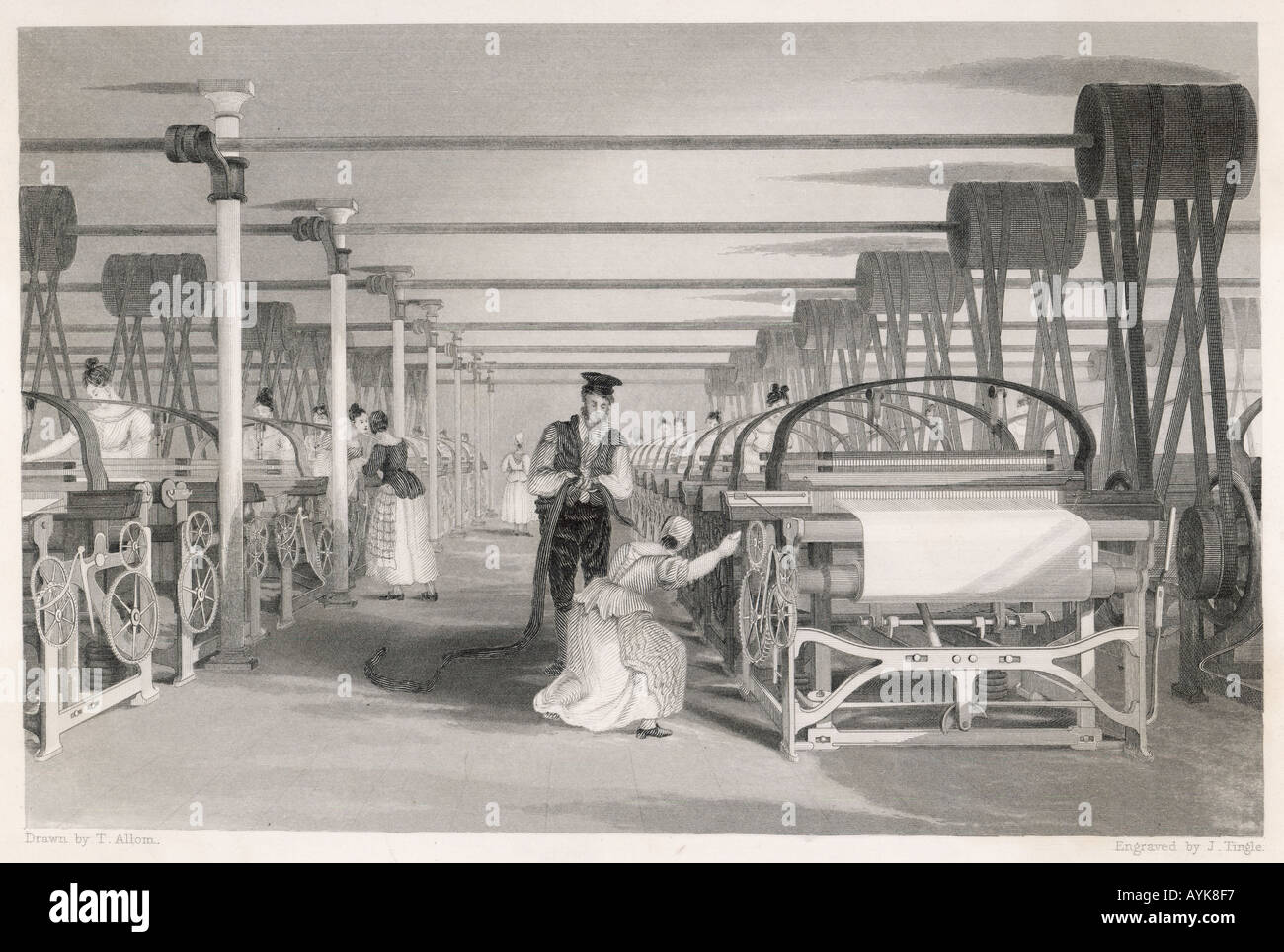

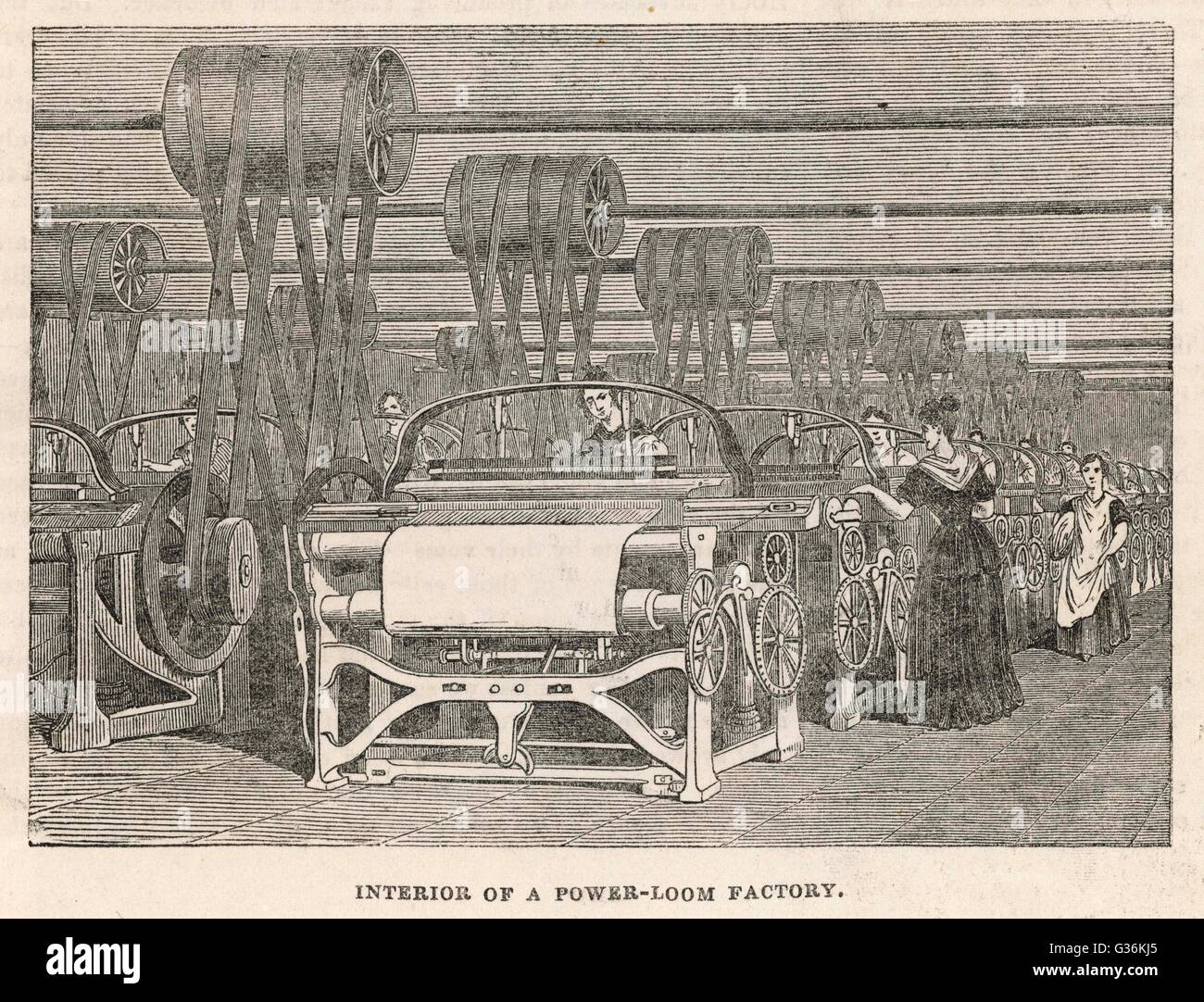

. Illustration of power loom weaving . 1835. Illustrator T. Allom 435 Powerloom weaving in 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/illustration-of-power-loom-weaving-1835-illustrator-t-allom-435-powerloom-weaving-in-1835-image189192249.html

. Illustration of power loom weaving . 1835. Illustrator T. Allom 435 Powerloom weaving in 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/illustration-of-power-loom-weaving-1835-illustrator-t-allom-435-powerloom-weaving-in-1835-image189192249.htmlRMMYPCJ1–. Illustration of power loom weaving . 1835. Illustrator T. Allom 435 Powerloom weaving in 1835

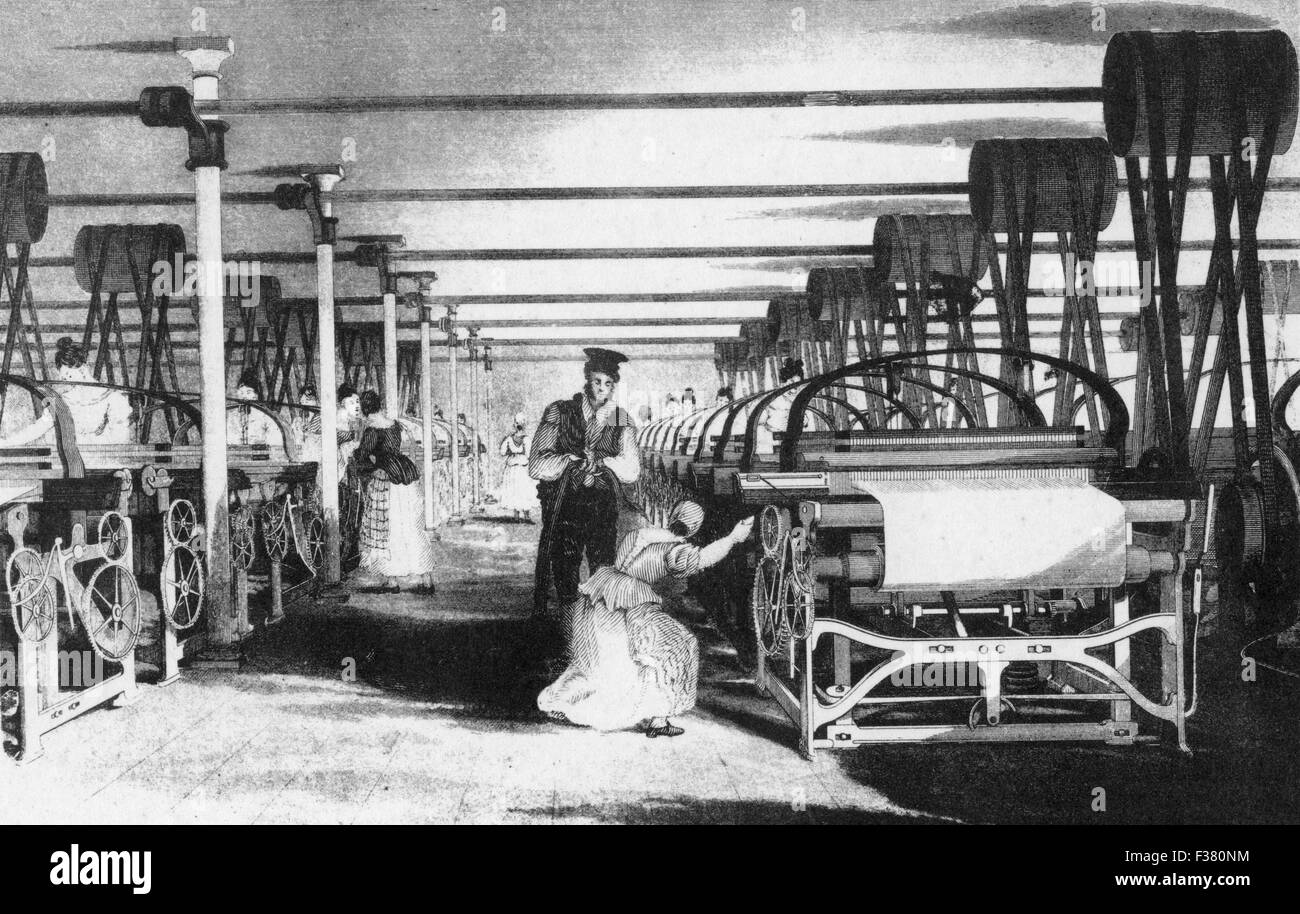

POWER LOOM WEAVING from Baines's History of the Cotton Manufacture, 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-power-loom-weaving-from-bainess-history-of-the-cotton-manufacture-88072032.html

POWER LOOM WEAVING from Baines's History of the Cotton Manufacture, 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-power-loom-weaving-from-bainess-history-of-the-cotton-manufacture-88072032.htmlRMF380NM–POWER LOOM WEAVING from Baines's History of the Cotton Manufacture, 1835

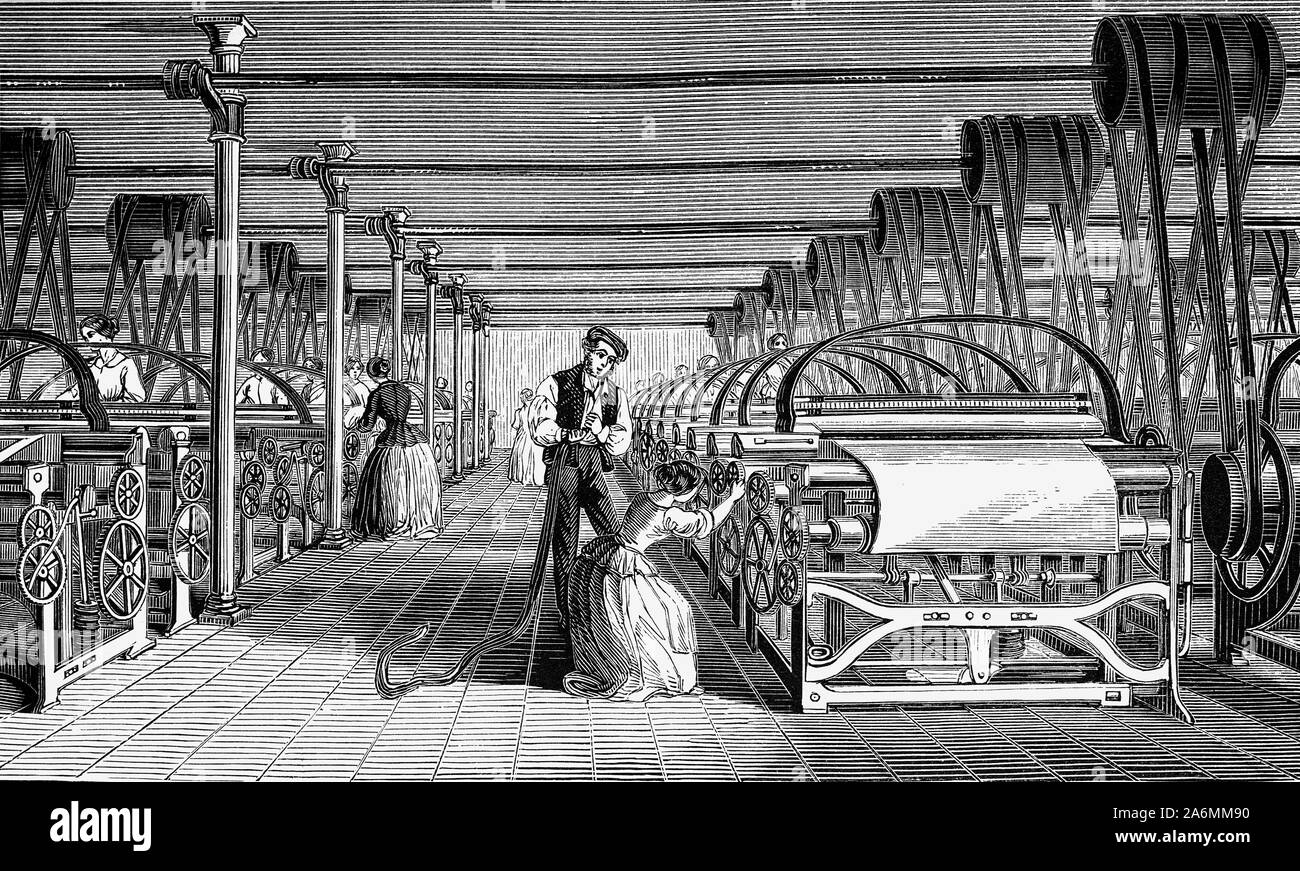

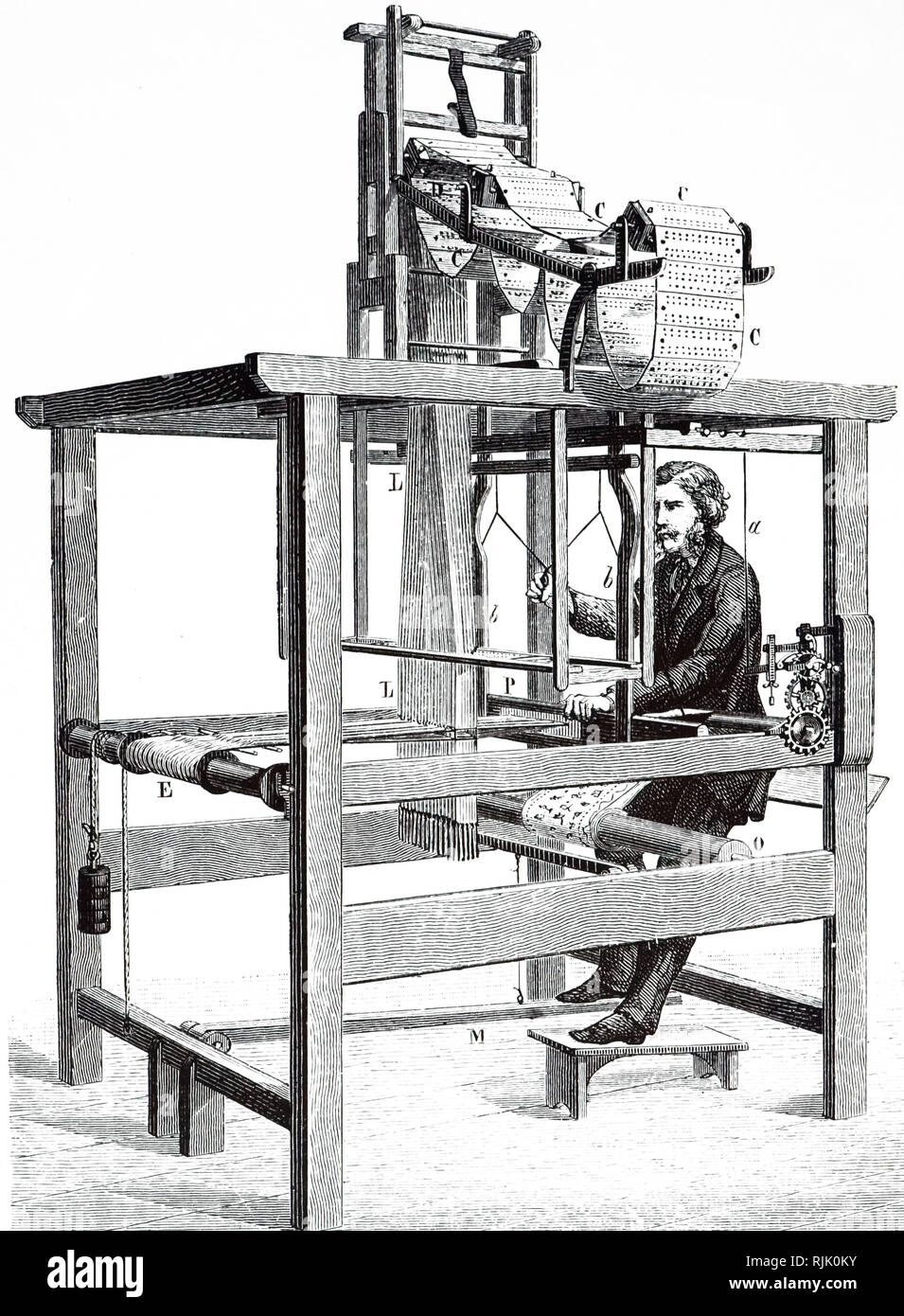

The 19th Century power loom is a mechanised loom, and one of the key developments in the industrialization of weaving during the early Industrial Revolution. The first power loom was designed in 1784 by Edmund Cartwright and first built in 1785. It was refined over the next 47 years until a design by Kenworthy and Bullough made the operation completely automatic. By 1850 there were 260,000 power looms in operation in England. Fifty years later came the Northrop loom which replenished the shuttle when it was empty. This replaced the Lancashire loom. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-19th-century-power-loom-is-a-mechanised-loom-and-one-of-the-key-developments-in-the-industrialization-of-weaving-during-the-early-industrial-revolution-the-first-power-loom-was-designed-in-1784-by-edmund-cartwright-and-first-built-in-1785-it-was-refined-over-the-next-47-years-until-a-design-by-kenworthy-and-bullough-made-the-operation-completely-automatic-by-1850-there-were-260000-power-looms-in-operation-in-england-fifty-years-later-came-the-northrop-loom-which-replenished-the-shuttle-when-it-was-empty-this-replaced-the-lancashire-loom-image331139900.html

The 19th Century power loom is a mechanised loom, and one of the key developments in the industrialization of weaving during the early Industrial Revolution. The first power loom was designed in 1784 by Edmund Cartwright and first built in 1785. It was refined over the next 47 years until a design by Kenworthy and Bullough made the operation completely automatic. By 1850 there were 260,000 power looms in operation in England. Fifty years later came the Northrop loom which replenished the shuttle when it was empty. This replaced the Lancashire loom. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-19th-century-power-loom-is-a-mechanised-loom-and-one-of-the-key-developments-in-the-industrialization-of-weaving-during-the-early-industrial-revolution-the-first-power-loom-was-designed-in-1784-by-edmund-cartwright-and-first-built-in-1785-it-was-refined-over-the-next-47-years-until-a-design-by-kenworthy-and-bullough-made-the-operation-completely-automatic-by-1850-there-were-260000-power-looms-in-operation-in-england-fifty-years-later-came-the-northrop-loom-which-replenished-the-shuttle-when-it-was-empty-this-replaced-the-lancashire-loom-image331139900.htmlRM2A6MM90–The 19th Century power loom is a mechanised loom, and one of the key developments in the industrialization of weaving during the early Industrial Revolution. The first power loom was designed in 1784 by Edmund Cartwright and first built in 1785. It was refined over the next 47 years until a design by Kenworthy and Bullough made the operation completely automatic. By 1850 there were 260,000 power looms in operation in England. Fifty years later came the Northrop loom which replenished the shuttle when it was empty. This replaced the Lancashire loom.

EDMUND CARTWRIGHT (1743-1823) English inventor of the power loom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/edmund-cartwright-1743-1823-english-inventor-of-the-power-loom-image185377670.html

EDMUND CARTWRIGHT (1743-1823) English inventor of the power loom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/edmund-cartwright-1743-1823-english-inventor-of-the-power-loom-image185377670.htmlRMMNGK32–EDMUND CARTWRIGHT (1743-1823) English inventor of the power loom

Power Loom Weaving Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/power-loom-weaving-image5075031.html

Power Loom Weaving Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/power-loom-weaving-image5075031.htmlRMANJT58–Power Loom Weaving

POWER LOOM WEAVING at a UK cotton factory in 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/power-loom-weaving-at-a-uk-cotton-factory-in-1835-image627101749.html

POWER LOOM WEAVING at a UK cotton factory in 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/power-loom-weaving-at-a-uk-cotton-factory-in-1835-image627101749.htmlRM2YC6XK1–POWER LOOM WEAVING at a UK cotton factory in 1835

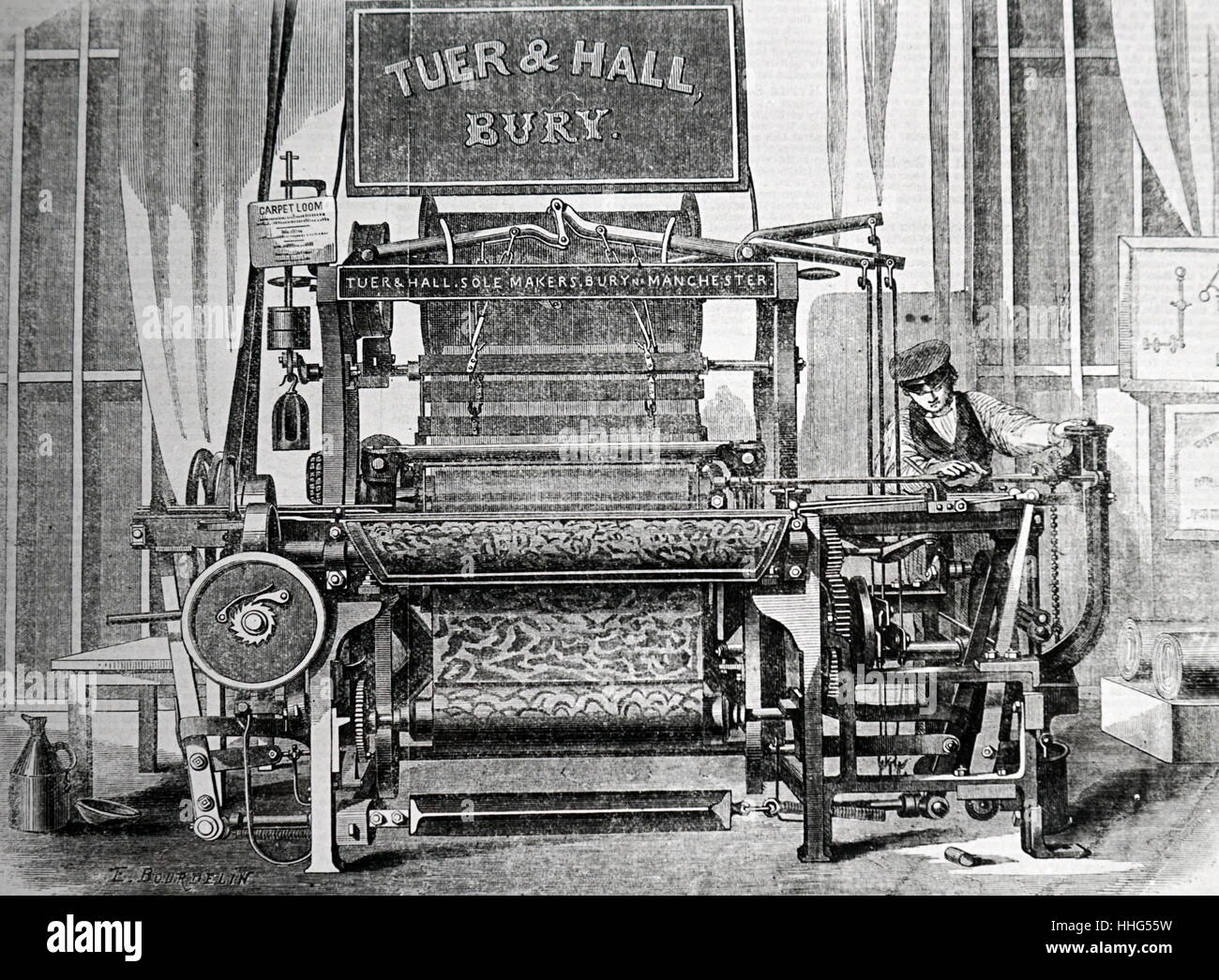

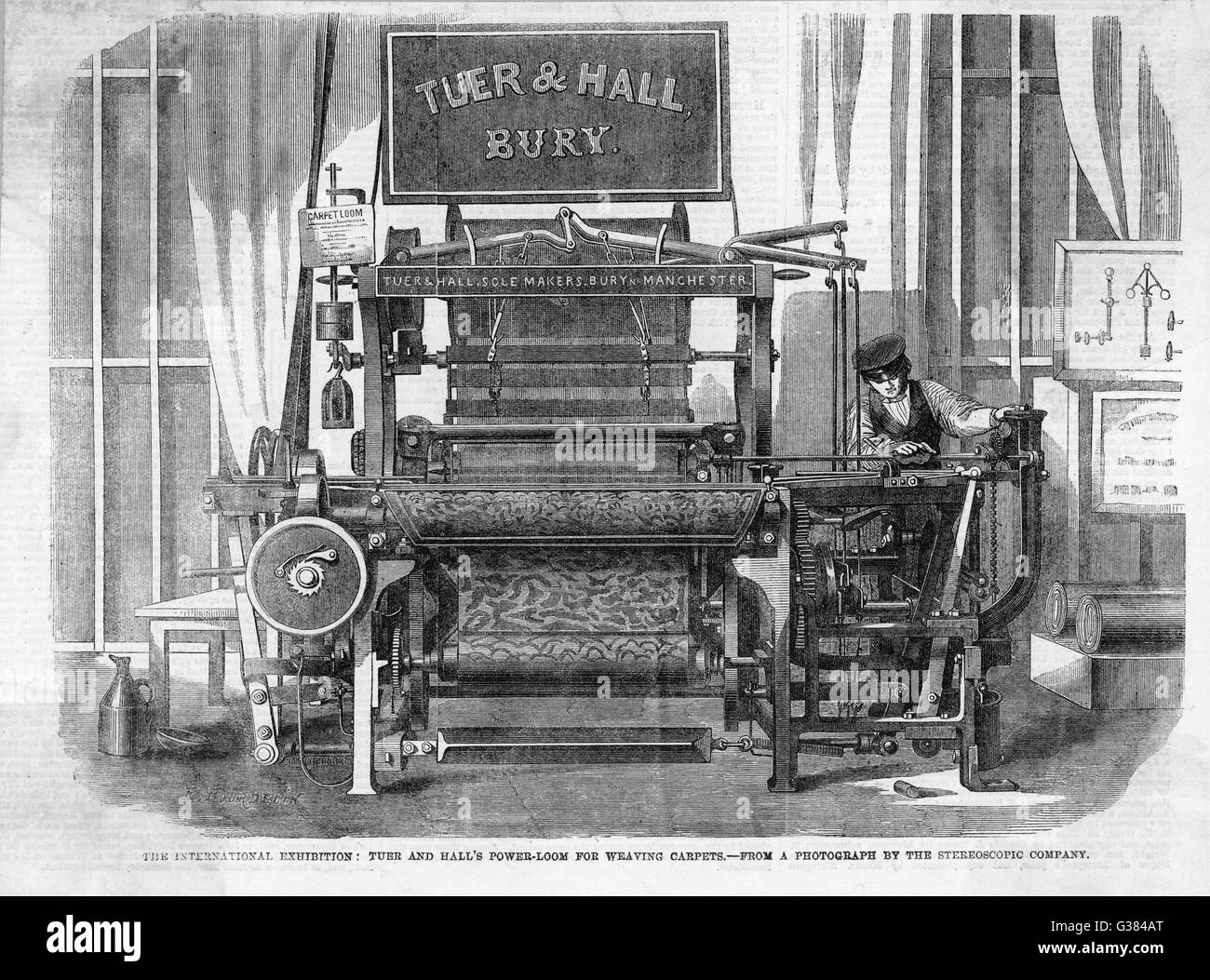

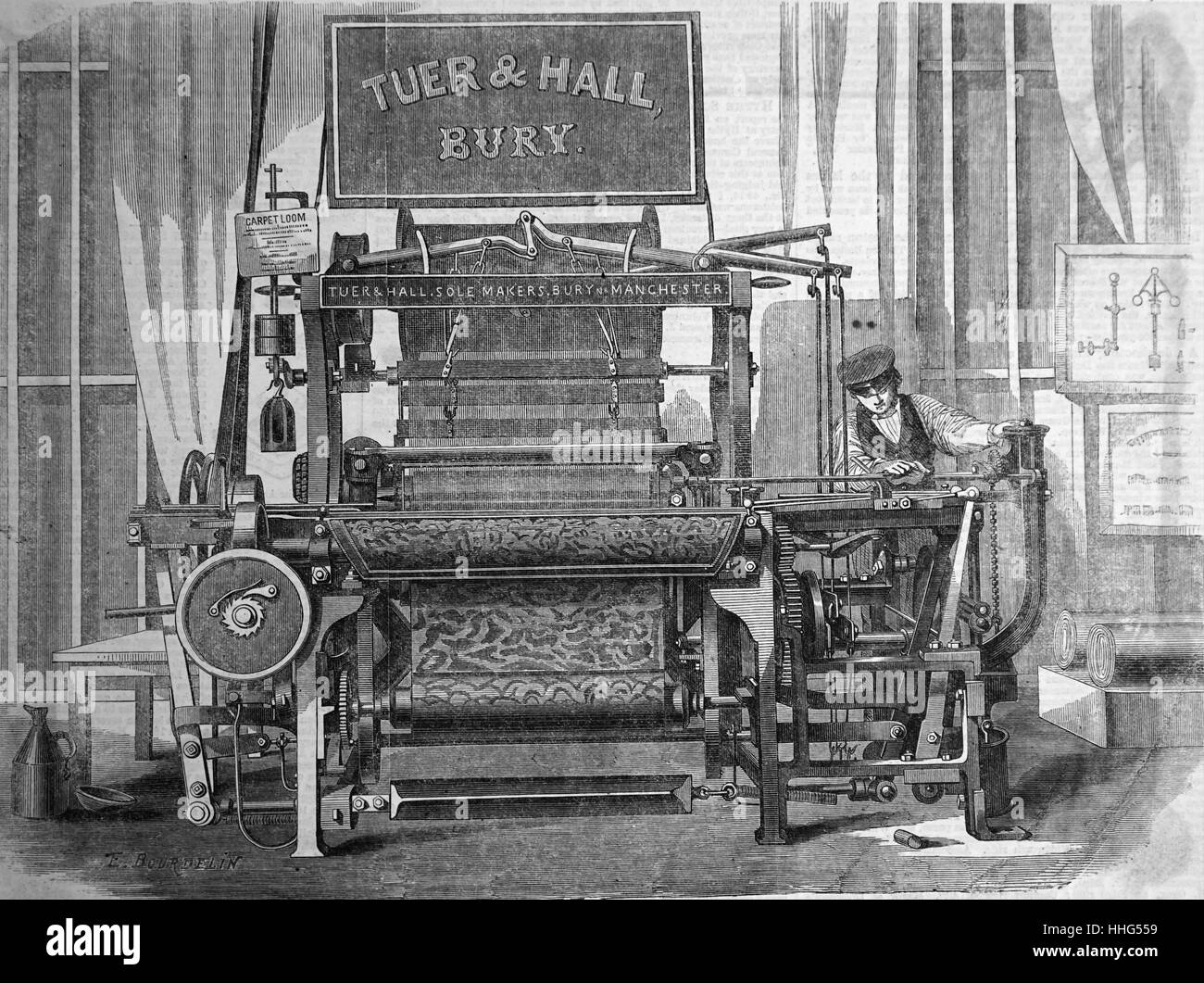

Tuer & Hall's power loom for weaving Brussels carpets. Dated August, 1862 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-tuer-halls-power-loom-for-weaving-brussels-carpets-dated-august-1862-131277045.html

Tuer & Hall's power loom for weaving Brussels carpets. Dated August, 1862 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-tuer-halls-power-loom-for-weaving-brussels-carpets-dated-august-1862-131277045.htmlRMHHG55W–Tuer & Hall's power loom for weaving Brussels carpets. Dated August, 1862

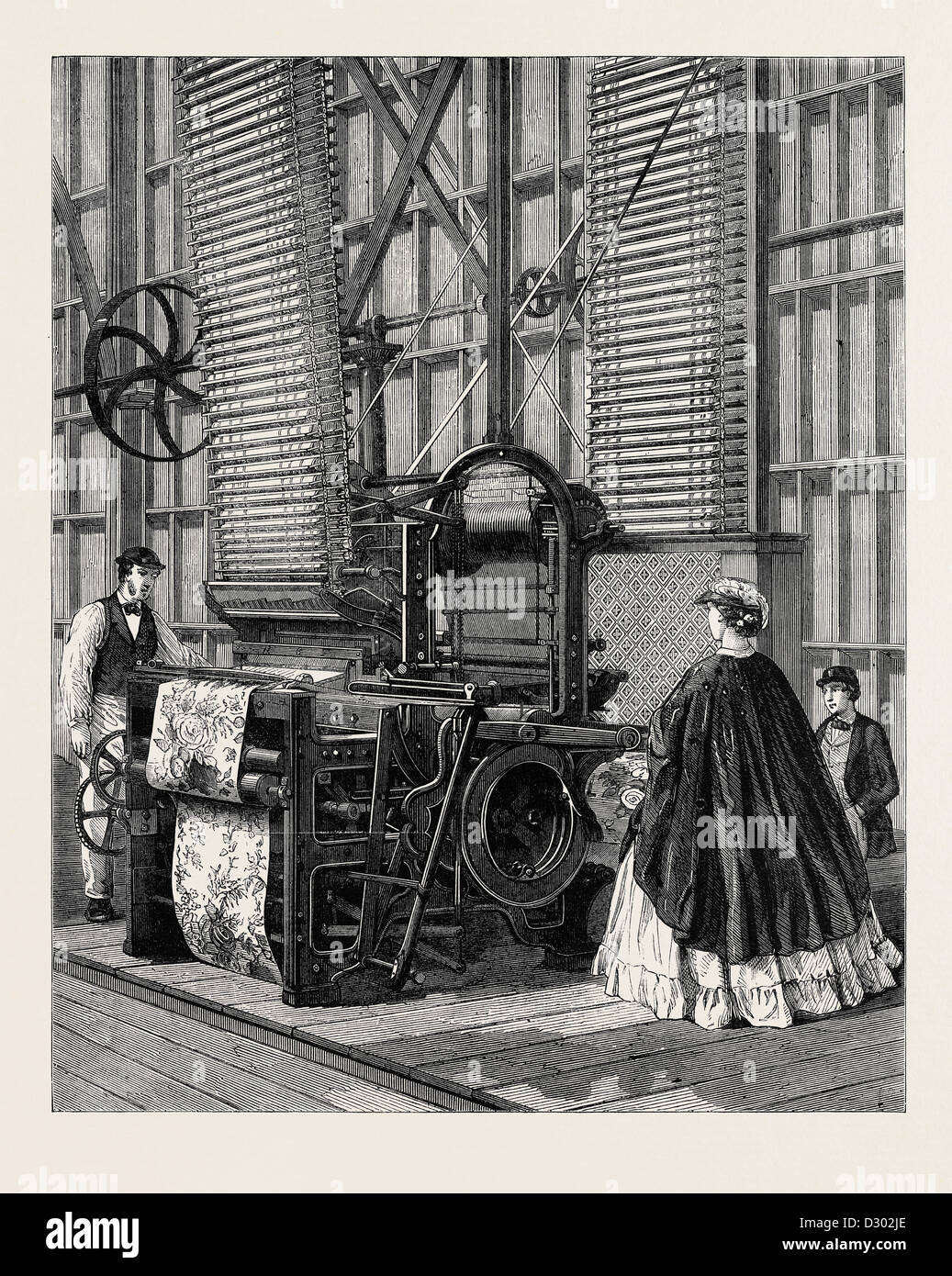

THE INTERNATIONAL EXHIBITION: SMITH'S POWER-LOOM FOR WEAVING TUFTED PILE CARPETS 1862 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-the-international-exhibition-smiths-power-loom-for-weaving-tufted-53477158.html

THE INTERNATIONAL EXHIBITION: SMITH'S POWER-LOOM FOR WEAVING TUFTED PILE CARPETS 1862 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-the-international-exhibition-smiths-power-loom-for-weaving-tufted-53477158.htmlRMD302JE–THE INTERNATIONAL EXHIBITION: SMITH'S POWER-LOOM FOR WEAVING TUFTED PILE CARPETS 1862

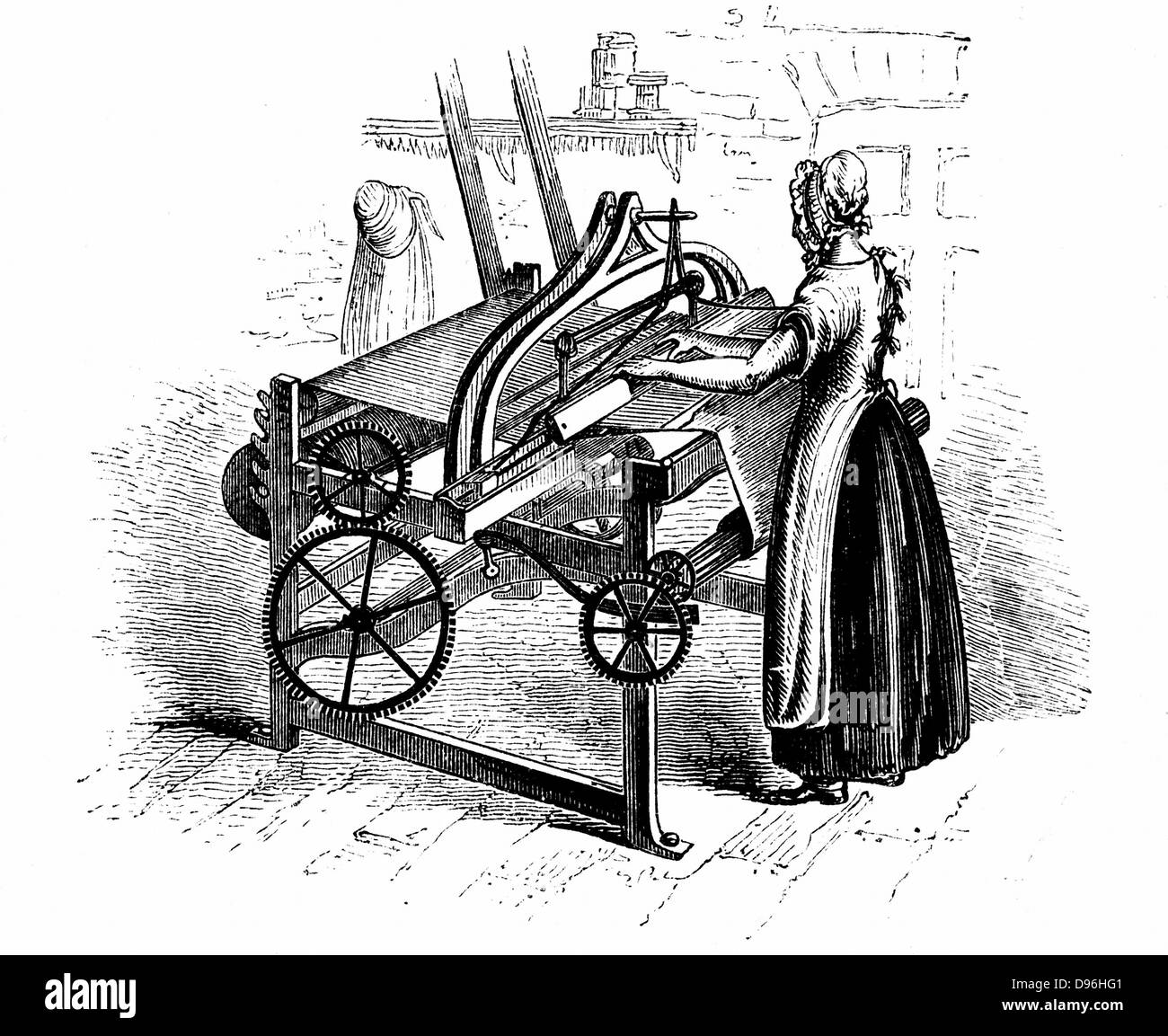

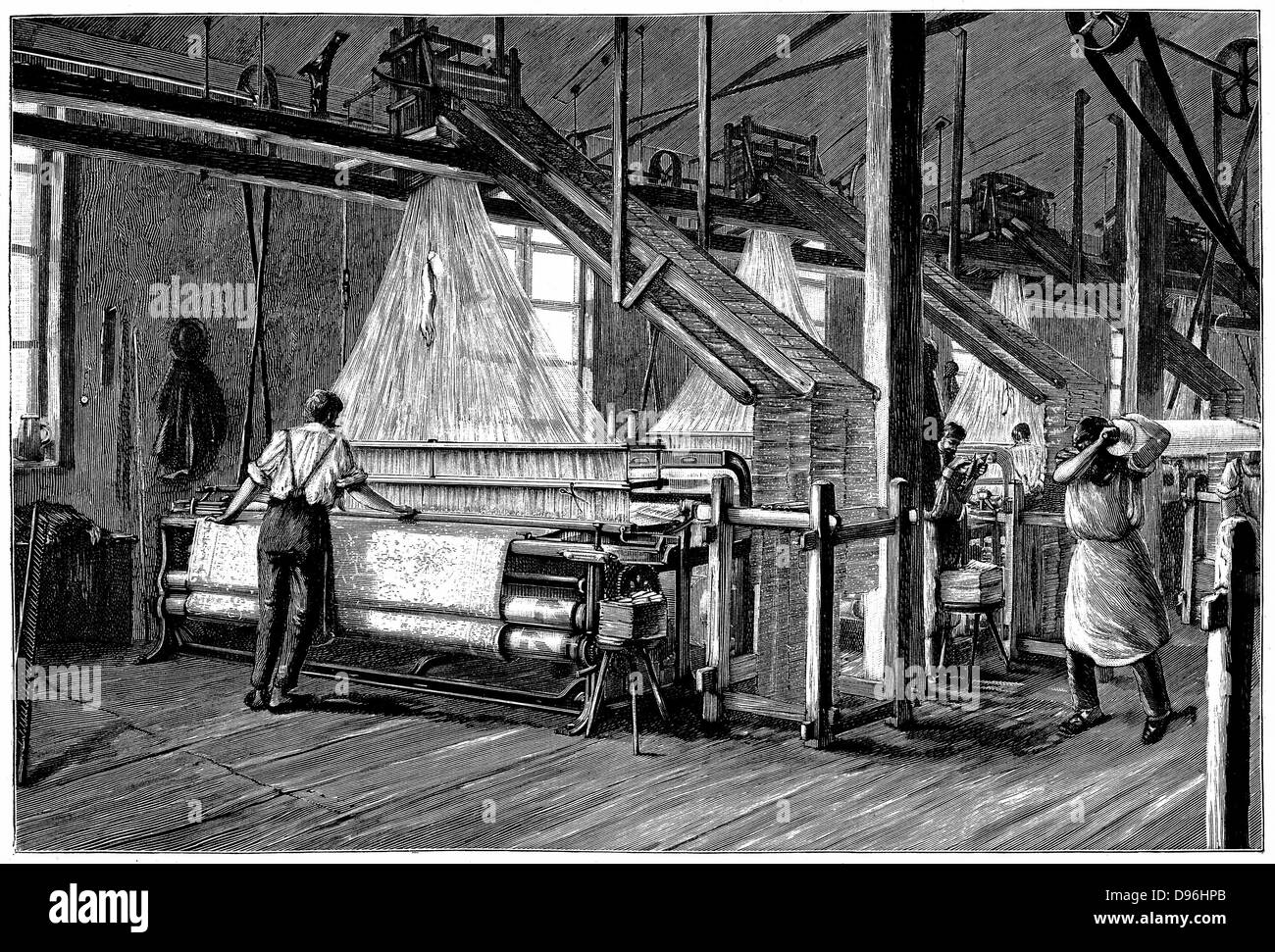

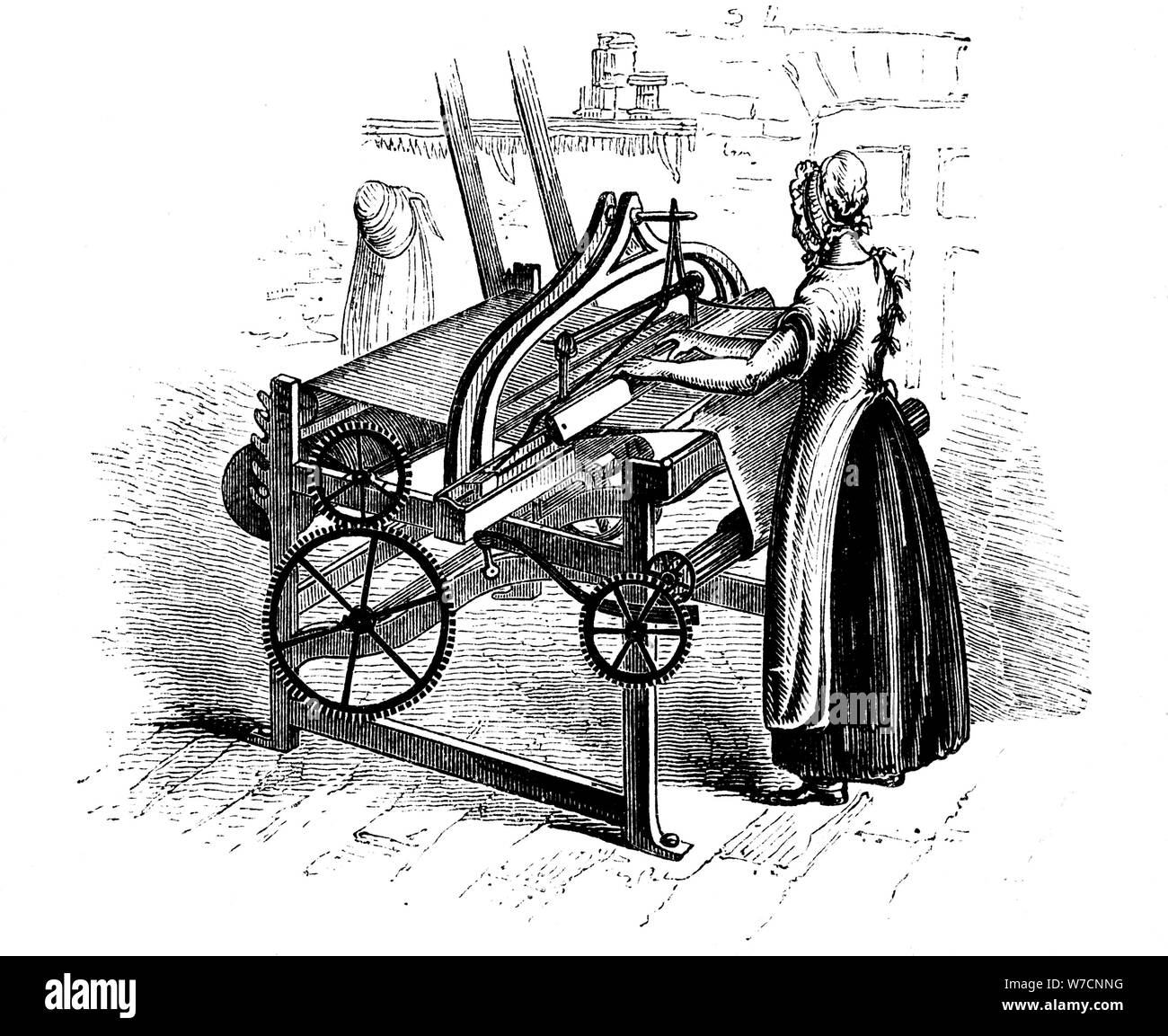

Power loom for weaving cotton. Model illustrated is that invented by Roberts (c1815-20). Belting connecting to drive shaft is shown at centre back of picture. Female operative. Wood engraving c1840. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-power-loom-for-weaving-cotton-model-illustrated-is-that-invented-by-57308497.html

Power loom for weaving cotton. Model illustrated is that invented by Roberts (c1815-20). Belting connecting to drive shaft is shown at centre back of picture. Female operative. Wood engraving c1840. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-power-loom-for-weaving-cotton-model-illustrated-is-that-invented-by-57308497.htmlRMD96HG1–Power loom for weaving cotton. Model illustrated is that invented by Roberts (c1815-20). Belting connecting to drive shaft is shown at centre back of picture. Female operative. Wood engraving c1840.

The International Exhibition: Smith's Power-Loom for Weaving Tufted Pile Carpets 1862 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-international-exhibition-smiths-power-loom-for-weaving-tufted-pile-carpets-1862-image240512060.html

The International Exhibition: Smith's Power-Loom for Weaving Tufted Pile Carpets 1862 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-international-exhibition-smiths-power-loom-for-weaving-tufted-pile-carpets-1862-image240512060.htmlRMRY87GC–The International Exhibition: Smith's Power-Loom for Weaving Tufted Pile Carpets 1862

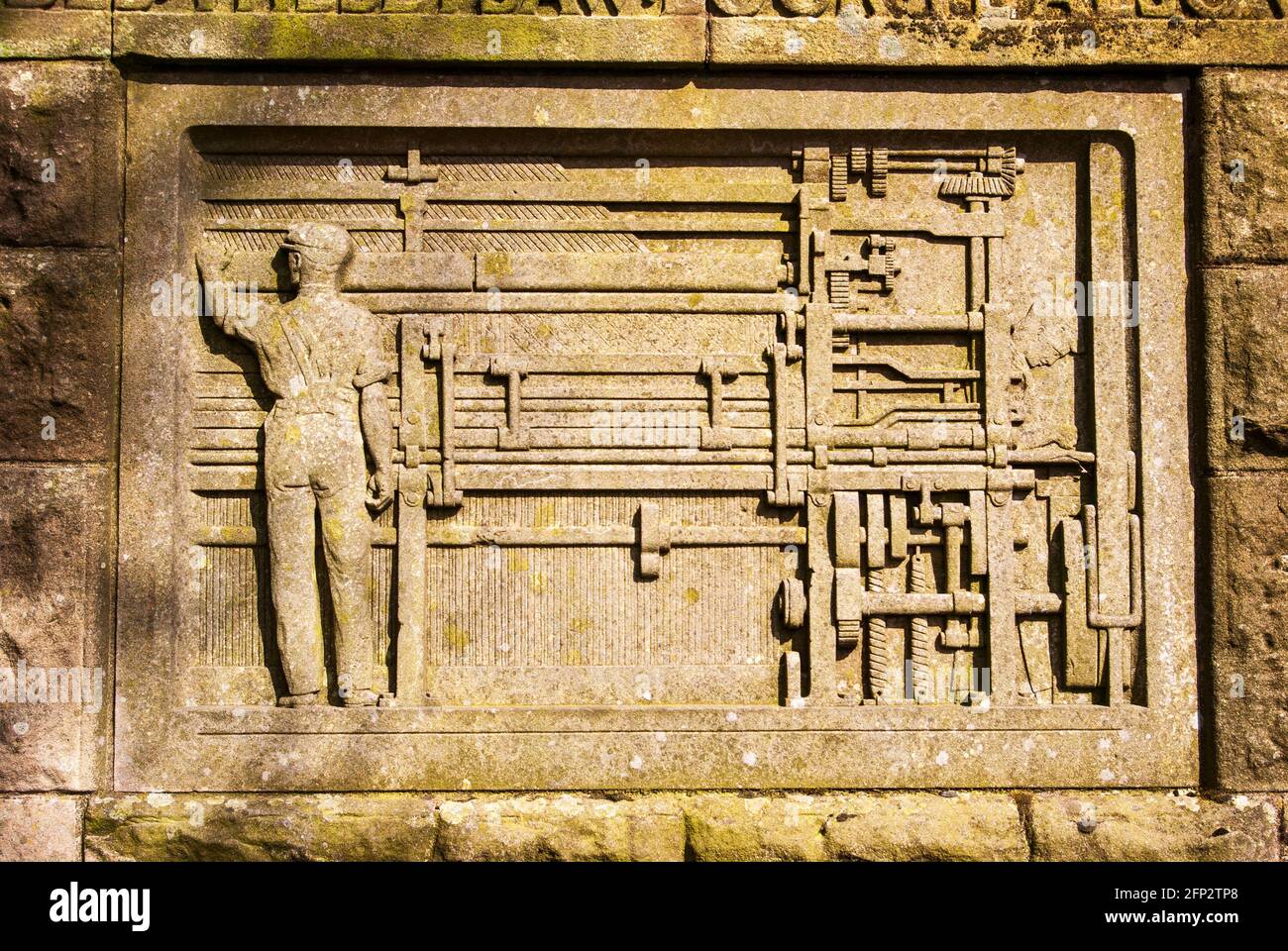

A stone plaque commemorating the power loom weaving industry on the monument to Alexander Morton, on the A71 near Darvel, East Ayrshire, Scotland. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/a-stone-plaque-commemorating-the-power-loom-weaving-industry-on-the-monument-to-alexander-morton-on-the-a71-near-darvel-east-ayrshire-scotland-image426634608.html

A stone plaque commemorating the power loom weaving industry on the monument to Alexander Morton, on the A71 near Darvel, East Ayrshire, Scotland. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/a-stone-plaque-commemorating-the-power-loom-weaving-industry-on-the-monument-to-alexander-morton-on-the-a71-near-darvel-east-ayrshire-scotland-image426634608.htmlRF2FP2TP8–A stone plaque commemorating the power loom weaving industry on the monument to Alexander Morton, on the A71 near Darvel, East Ayrshire, Scotland.

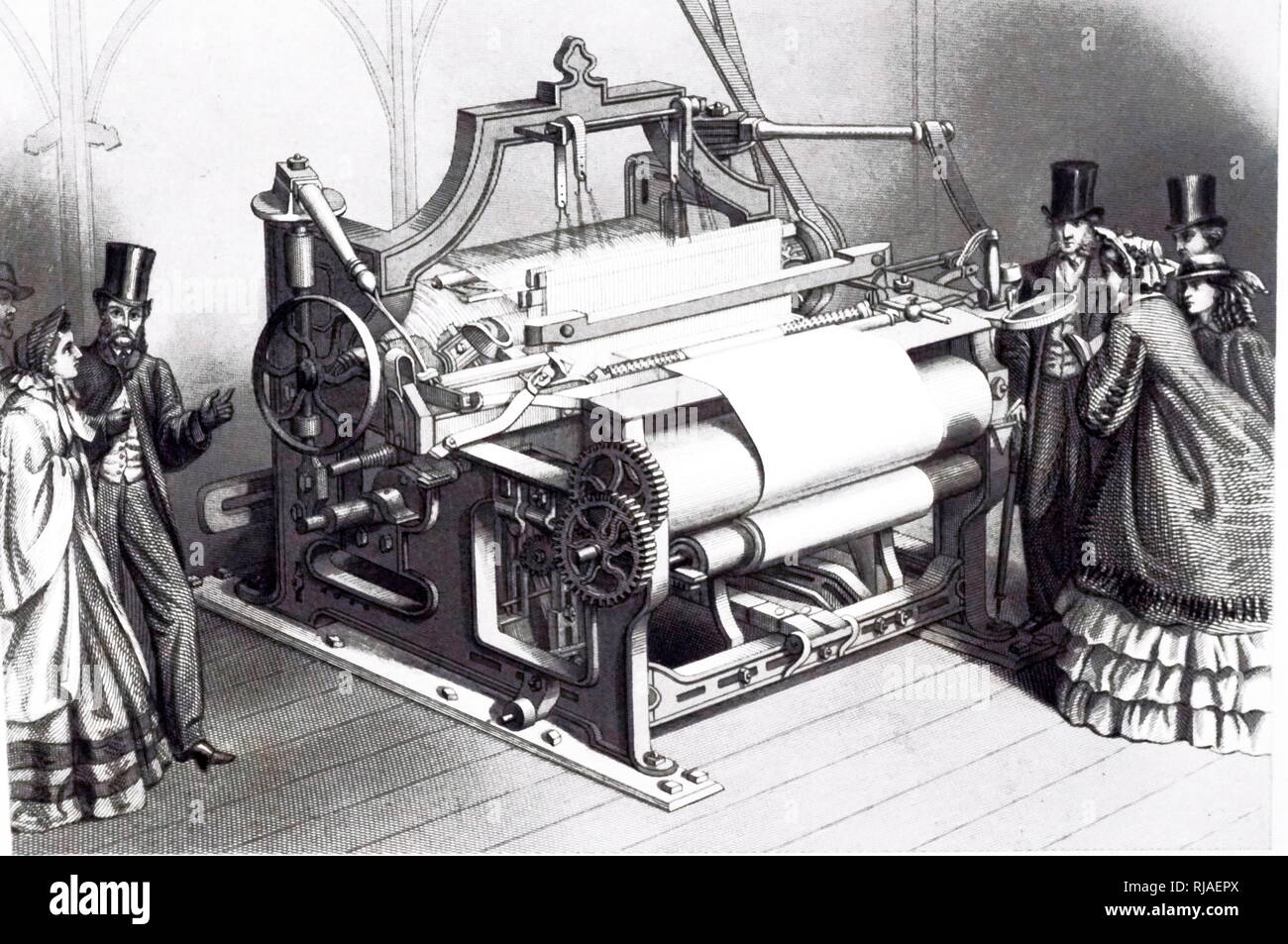

An engraving depicting W.G. Taylor's power loom for weaving calico. The machine was awarded the prize medal at the 1862 Exhibition. Dated 19th century Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-engraving-depicting-wg-taylors-power-loom-for-weaving-calico-the-machine-was-awarded-the-prize-medal-at-the-1862-exhibition-dated-19th-century-image235029730.html

An engraving depicting W.G. Taylor's power loom for weaving calico. The machine was awarded the prize medal at the 1862 Exhibition. Dated 19th century Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-engraving-depicting-wg-taylors-power-loom-for-weaving-calico-the-machine-was-awarded-the-prize-medal-at-the-1862-exhibition-dated-19th-century-image235029730.htmlRMRJAEPX–An engraving depicting W.G. Taylor's power loom for weaving calico. The machine was awarded the prize medal at the 1862 Exhibition. Dated 19th century

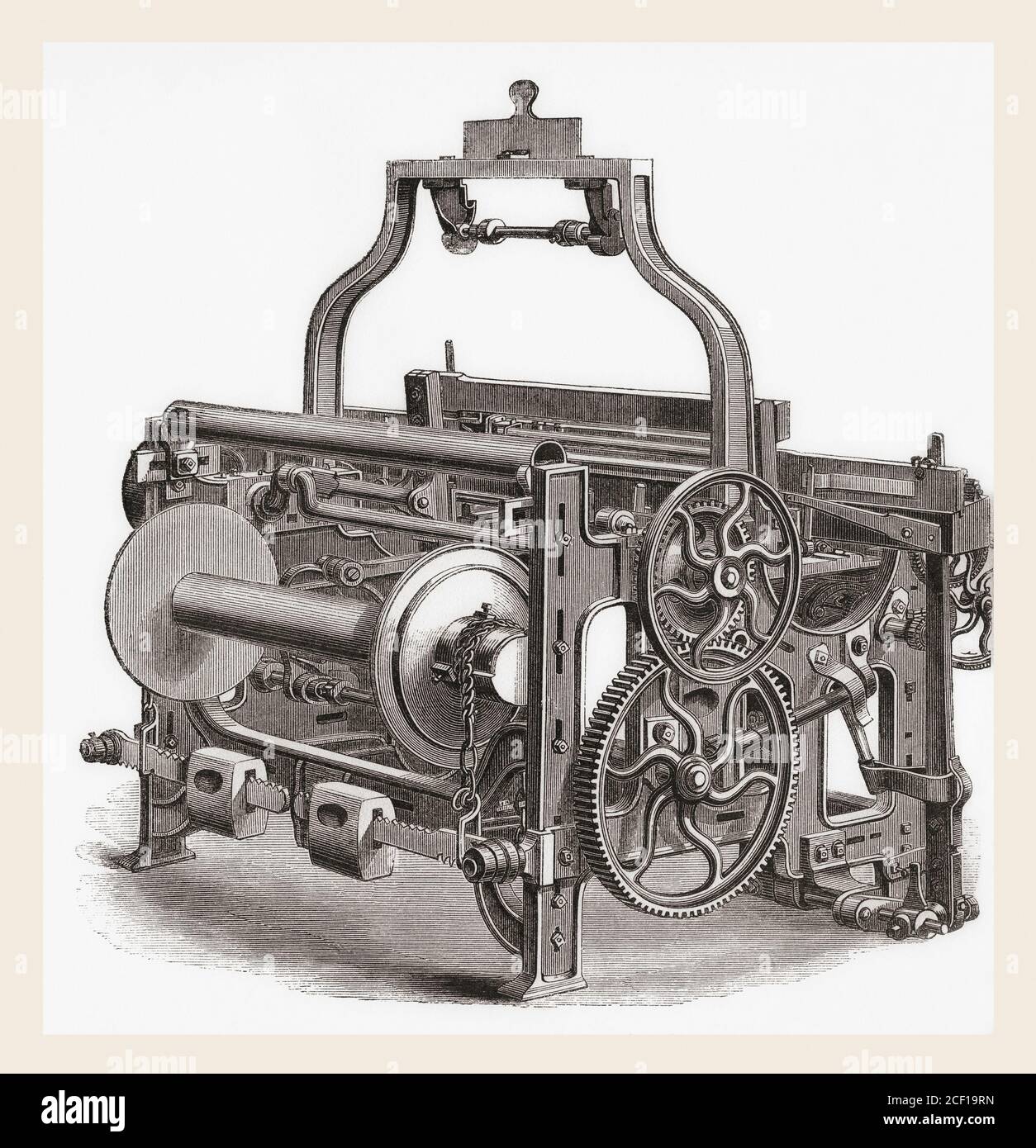

Platt's power loom for plain weaving. From The National Encyclopaedia: A Dictionary of Universal Knowledge, published c.1890 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/platts-power-loom-for-plain-weaving-from-the-national-encyclopaedia-a-dictionary-of-universal-knowledge-published-c1890-image370667241.html

Platt's power loom for plain weaving. From The National Encyclopaedia: A Dictionary of Universal Knowledge, published c.1890 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/platts-power-loom-for-plain-weaving-from-the-national-encyclopaedia-a-dictionary-of-universal-knowledge-published-c1890-image370667241.htmlRM2CF19RN–Platt's power loom for plain weaving. From The National Encyclopaedia: A Dictionary of Universal Knowledge, published c.1890

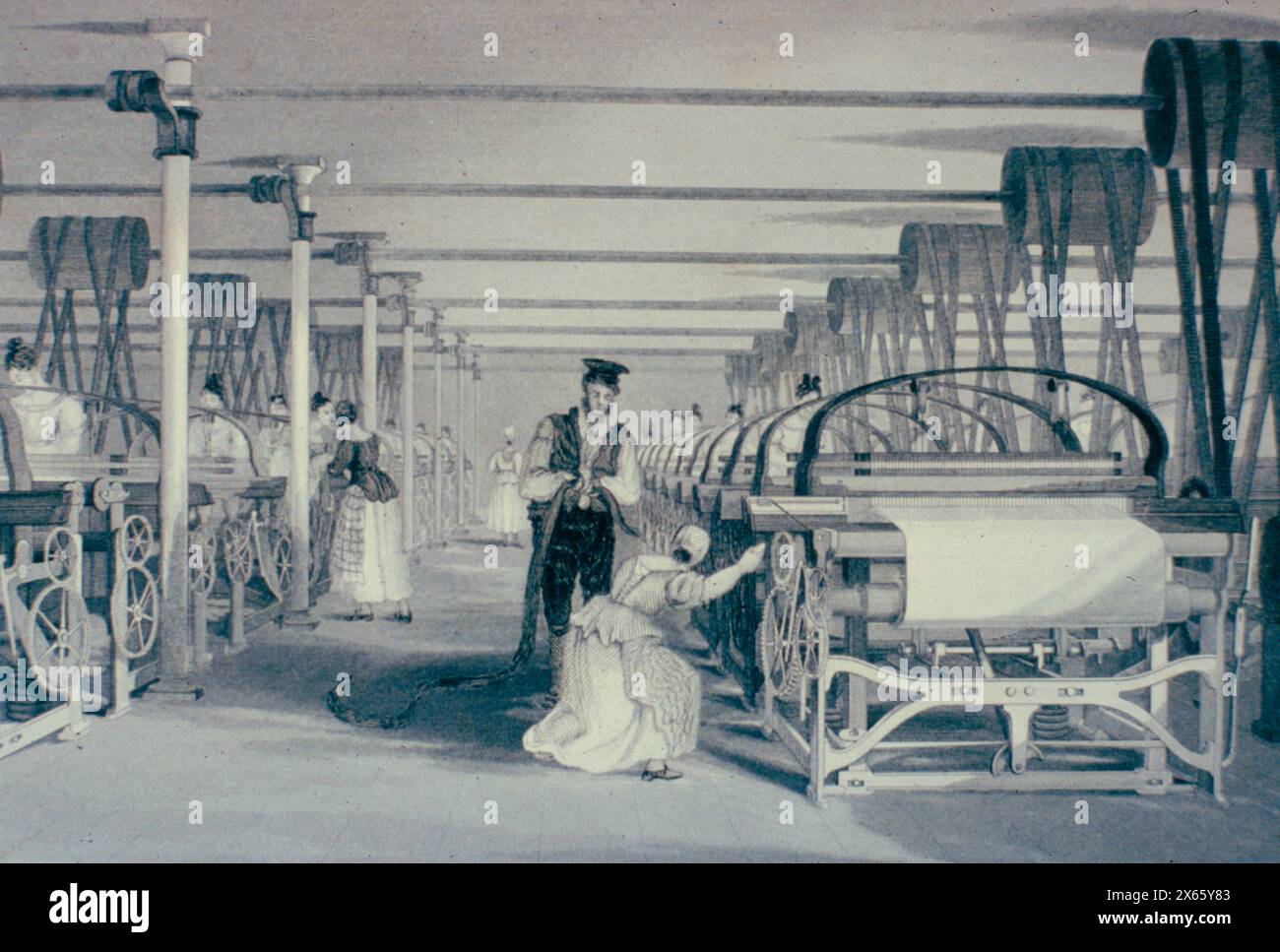

Power-loom weaving, 19th century illustration Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/power-loom-weaving-19th-century-illustration-image606181971.html

Power-loom weaving, 19th century illustration Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/power-loom-weaving-19th-century-illustration-image606181971.htmlRF2X65Y83–Power-loom weaving, 19th century illustration

EDMUND CARTWRIGHT (1743-1823) English inventor of the power loom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/edmund-cartwright-1743-1823-english-inventor-of-the-power-loom-image342354290.html

EDMUND CARTWRIGHT (1743-1823) English inventor of the power loom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/edmund-cartwright-1743-1823-english-inventor-of-the-power-loom-image342354290.htmlRM2ATYGAX–EDMUND CARTWRIGHT (1743-1823) English inventor of the power loom

Power loom factory, 2008 Malegaon bomb blast, Malegaon, Nashik, Maharashtra, India, 29 September 2008 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-power-loom-factory-2008-malegaon-bomb-blast-malegaon-nashik-maharashtra-83607758.html

Power loom factory, 2008 Malegaon bomb blast, Malegaon, Nashik, Maharashtra, India, 29 September 2008 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-power-loom-factory-2008-malegaon-bomb-blast-malegaon-nashik-maharashtra-83607758.htmlRMET0JFA–Power loom factory, 2008 Malegaon bomb blast, Malegaon, Nashik, Maharashtra, India, 29 September 2008

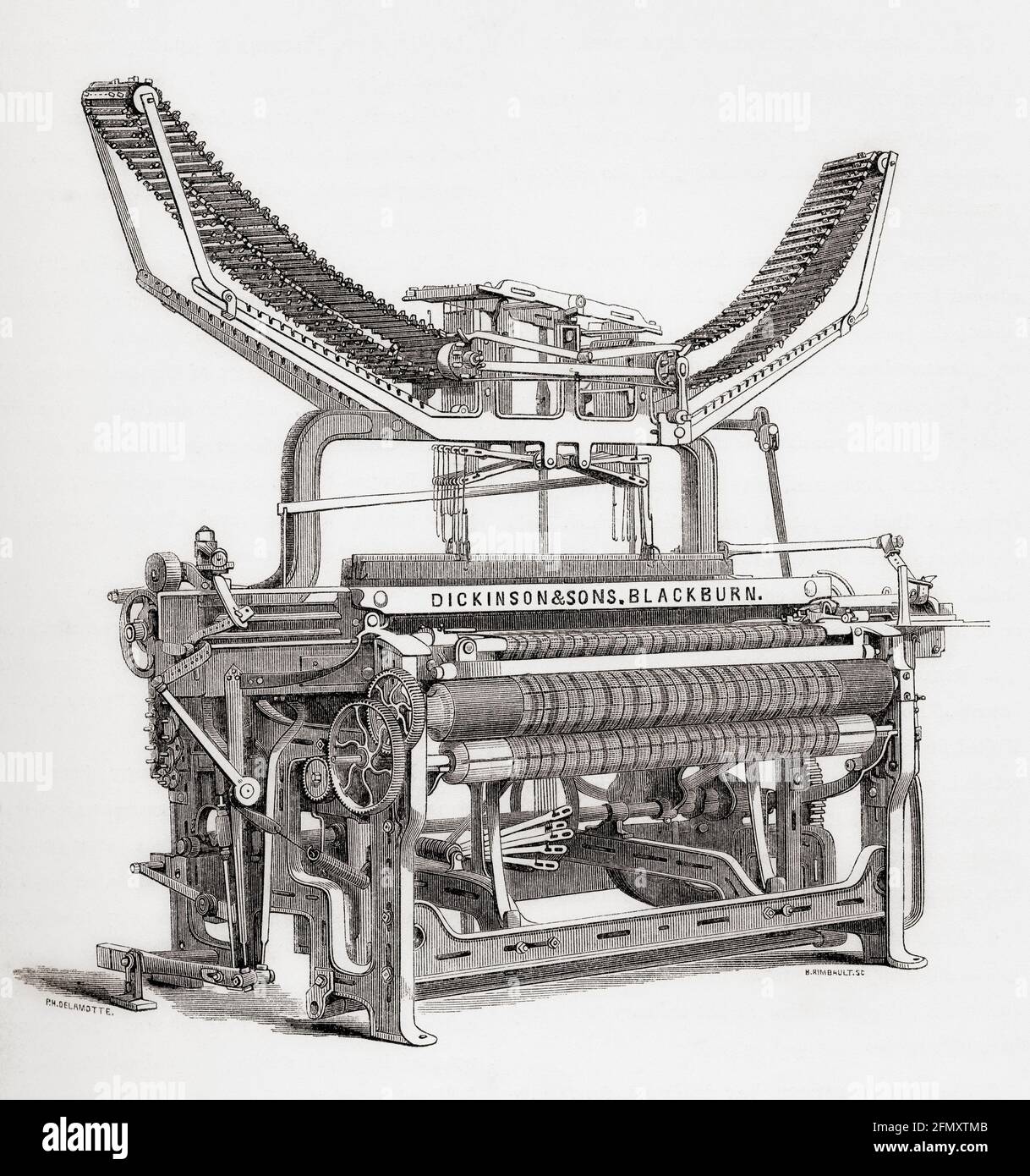

The Blackburn power loom invented by William Dickinson & Sons. From A Concise History of The International Exhibition of 1862, published 1862. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-blackburn-power-loom-invented-by-william-dickinson-sons-from-a-concise-history-of-the-international-exhibition-of-1862-published-1862-image425932091.html

The Blackburn power loom invented by William Dickinson & Sons. From A Concise History of The International Exhibition of 1862, published 1862. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-blackburn-power-loom-invented-by-william-dickinson-sons-from-a-concise-history-of-the-international-exhibition-of-1862-published-1862-image425932091.htmlRM2FMXTMB–The Blackburn power loom invented by William Dickinson & Sons. From A Concise History of The International Exhibition of 1862, published 1862.

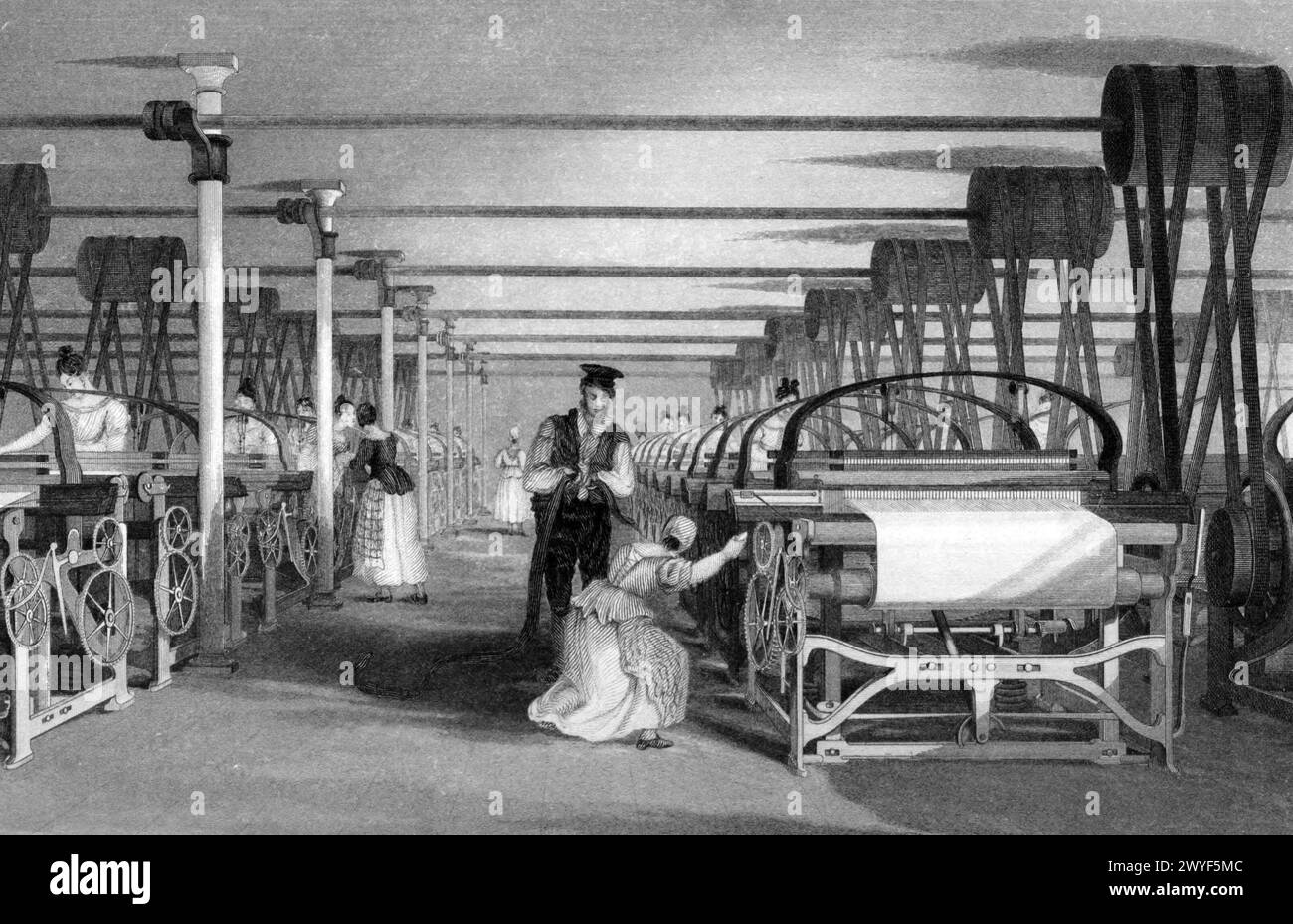

Illustration of power loom weaving. History of the cotton manufacture in Great Britain industrial revolution Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/illustration-of-power-loom-weaving-history-of-the-cotton-manufacture-in-great-britain-industrial-revolution-image602081996.html

Illustration of power loom weaving. History of the cotton manufacture in Great Britain industrial revolution Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/illustration-of-power-loom-weaving-history-of-the-cotton-manufacture-in-great-britain-industrial-revolution-image602081996.htmlRF2WYF5MC–Illustration of power loom weaving. History of the cotton manufacture in Great Britain industrial revolution

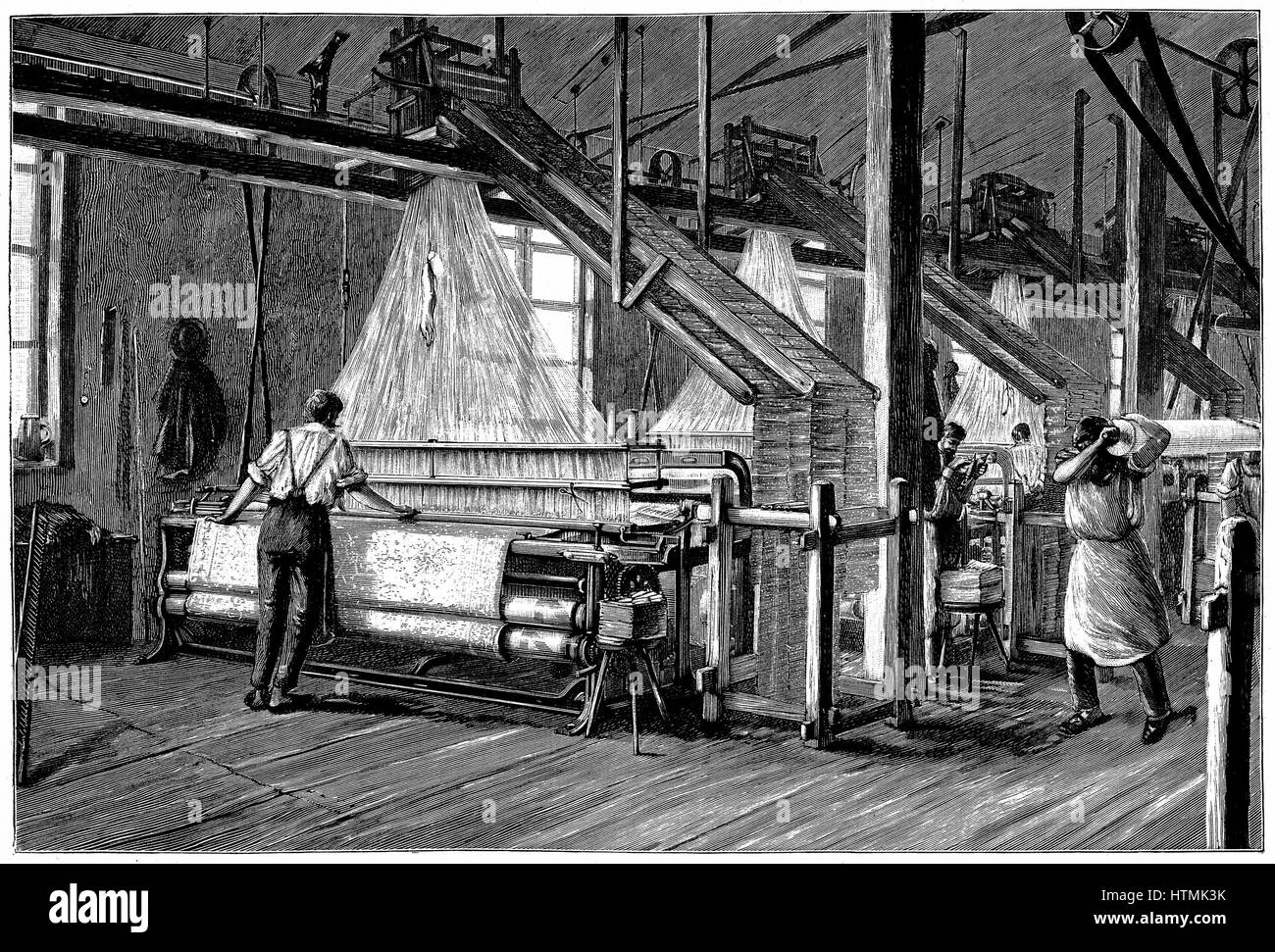

Weaving shed fitted with Jacquard power looms. Swags of punched cards carrying pattern being woven are at right and above each loom. Illustration Paris c1880 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-weaving-shed-fitted-with-jacquard-power-looms-swags-of-punched-cards-135678359.html

Weaving shed fitted with Jacquard power looms. Swags of punched cards carrying pattern being woven are at right and above each loom. Illustration Paris c1880 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-weaving-shed-fitted-with-jacquard-power-looms-swags-of-punched-cards-135678359.htmlRMHTMK3K–Weaving shed fitted with Jacquard power looms. Swags of punched cards carrying pattern being woven are at right and above each loom. Illustration Paris c1880

. Illustration of power loom weaving . 1835. Illustrator T. Allom 499 Powerloom weaving in 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/illustration-of-power-loom-weaving-1835-illustrator-t-allom-499-powerloom-weaving-in-1835-image187488071.html

. Illustration of power loom weaving . 1835. Illustrator T. Allom 499 Powerloom weaving in 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/illustration-of-power-loom-weaving-1835-illustrator-t-allom-499-powerloom-weaving-in-1835-image187488071.htmlRMMW0PXF–. Illustration of power loom weaving . 1835. Illustrator T. Allom 499 Powerloom weaving in 1835

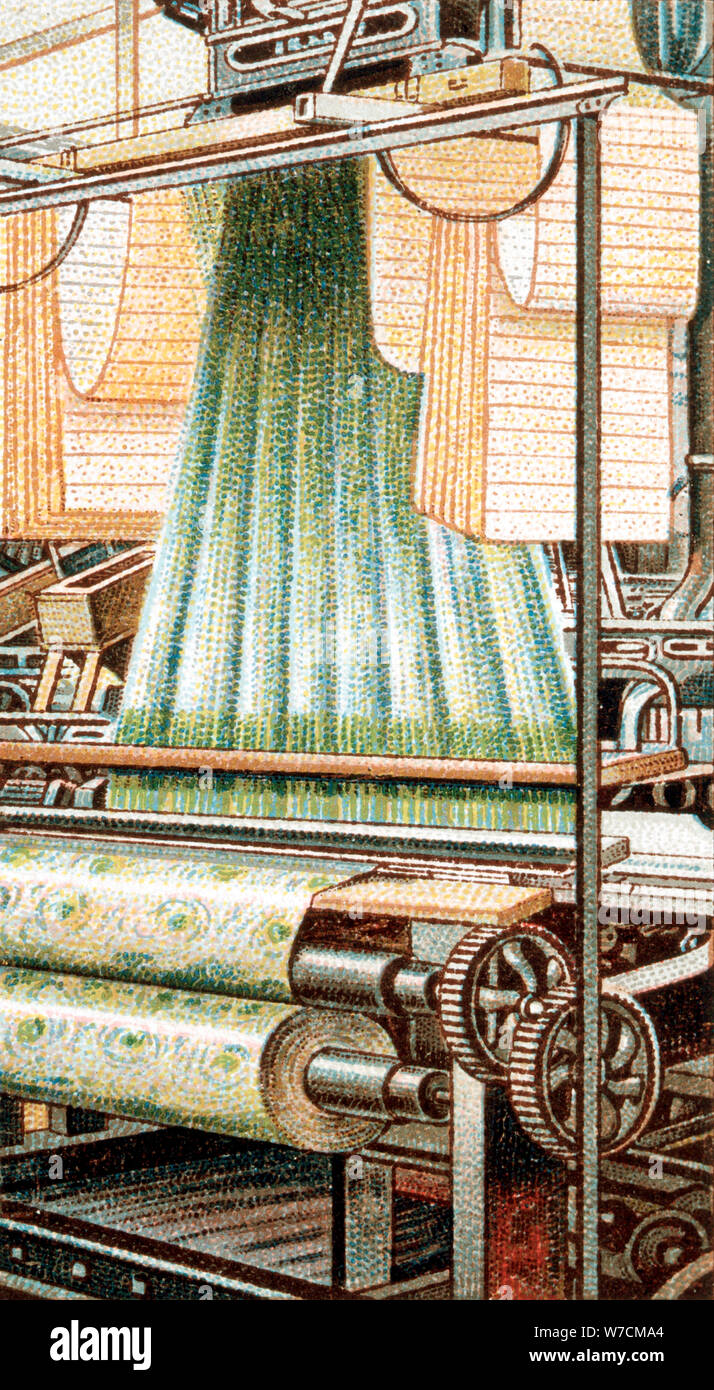

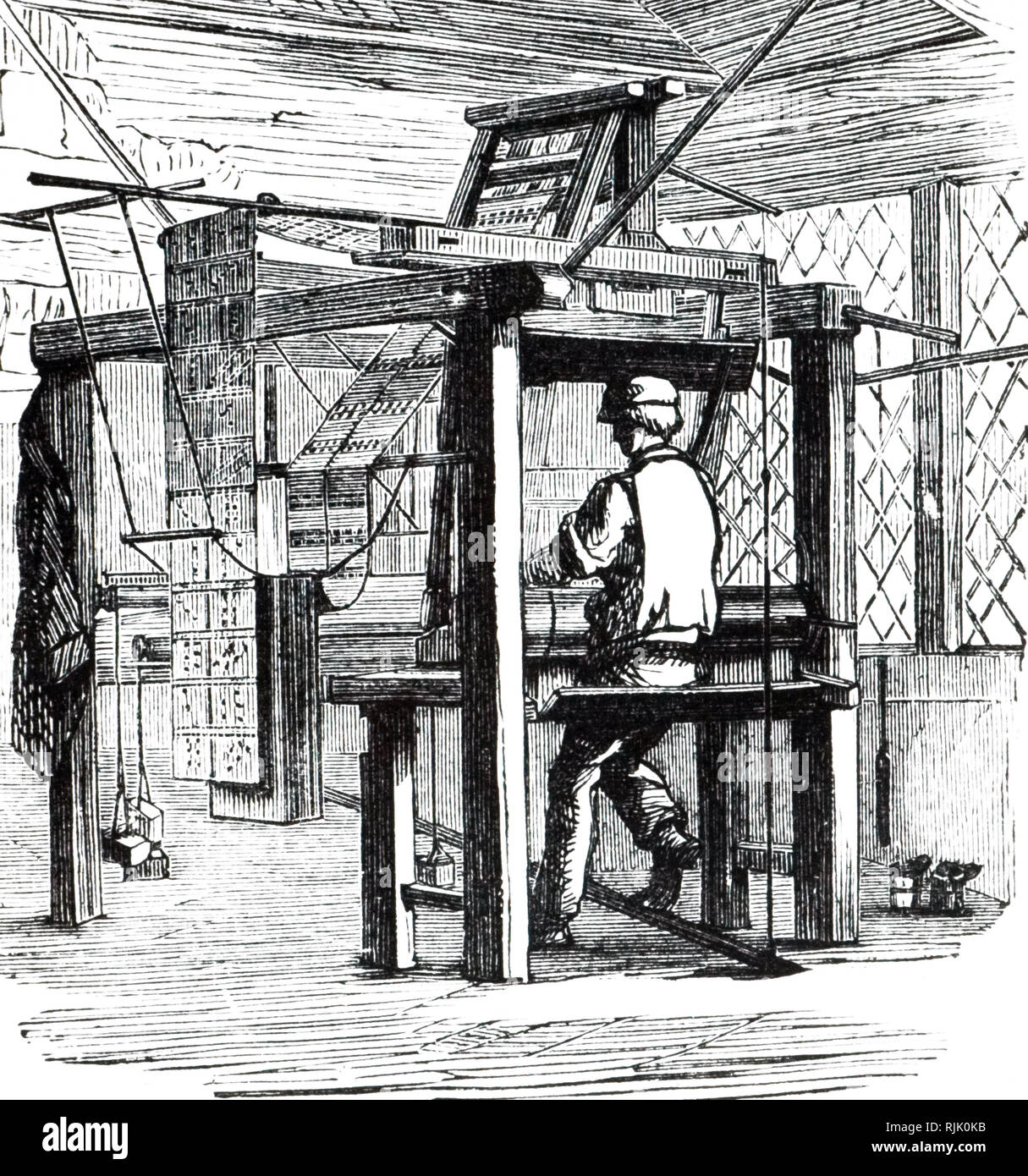

A Jacquard Loom, 1915. Artist: Unknown Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/a-jacquard-loom-1915-artist-unknown-image262737500.html

A Jacquard Loom, 1915. Artist: Unknown Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/a-jacquard-loom-1915-artist-unknown-image262737500.htmlRMW7CMA4–A Jacquard Loom, 1915. Artist: Unknown

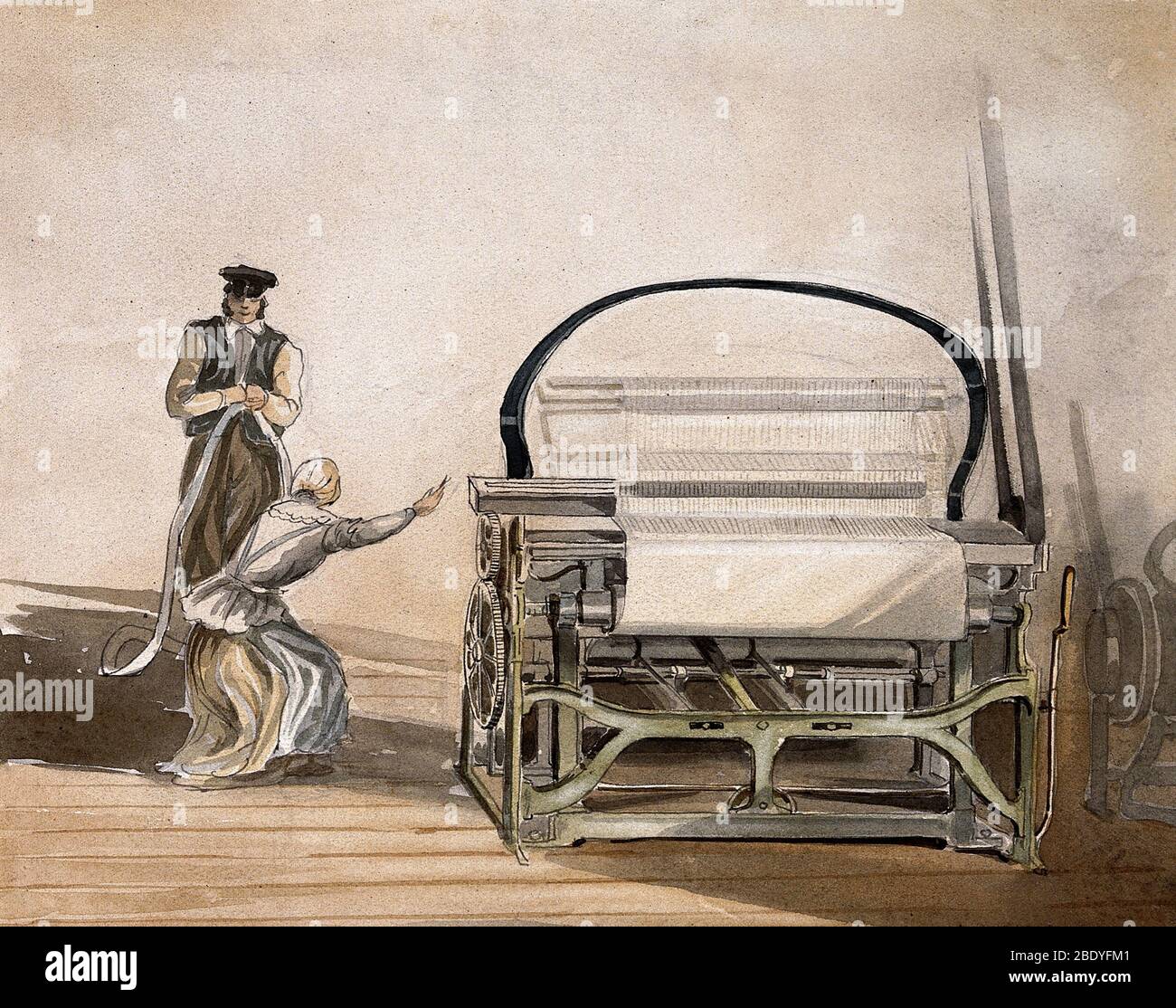

Crompton's Belt-Driven Power Loom, 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/cromptons-belt-driven-power-loom-1835-image352802913.html

Crompton's Belt-Driven Power Loom, 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/cromptons-belt-driven-power-loom-1835-image352802913.htmlRM2BDYFM1–Crompton's Belt-Driven Power Loom, 1835

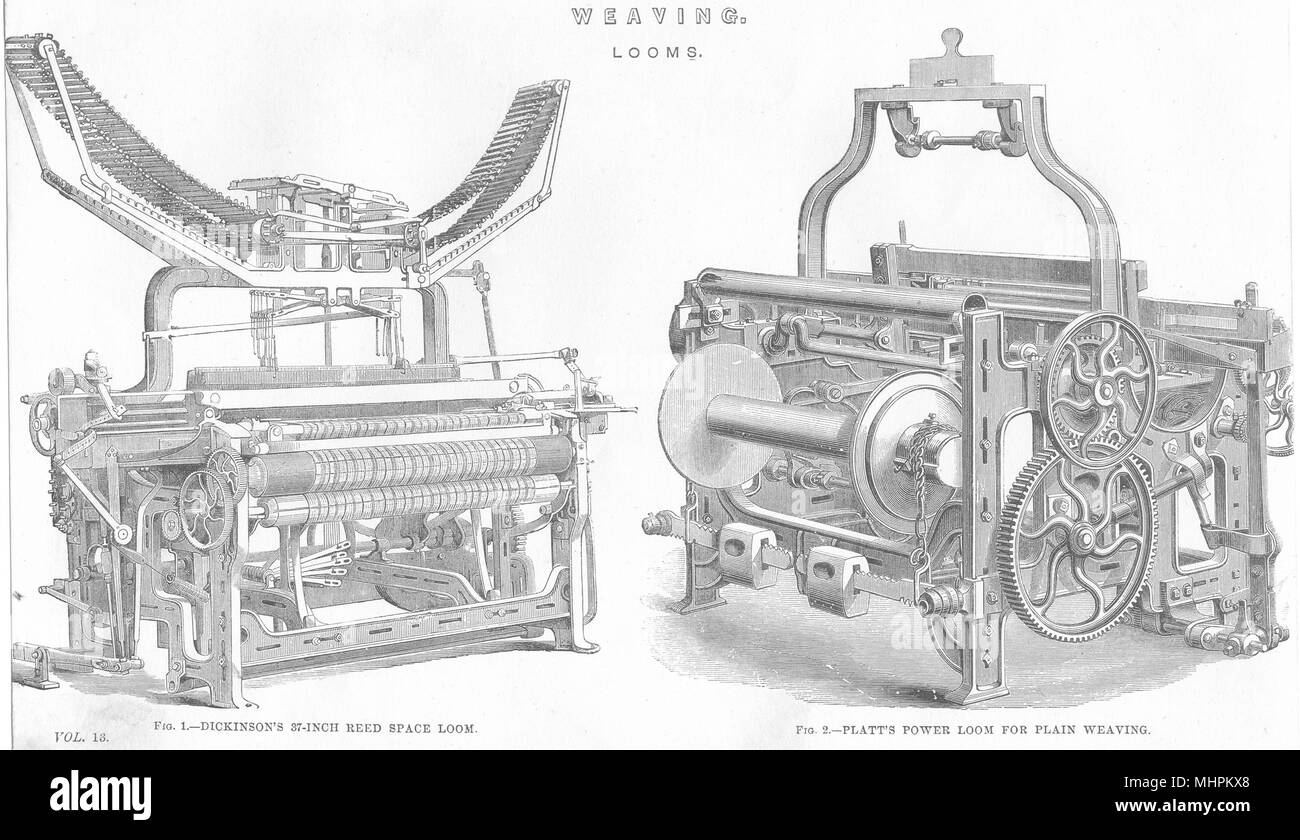

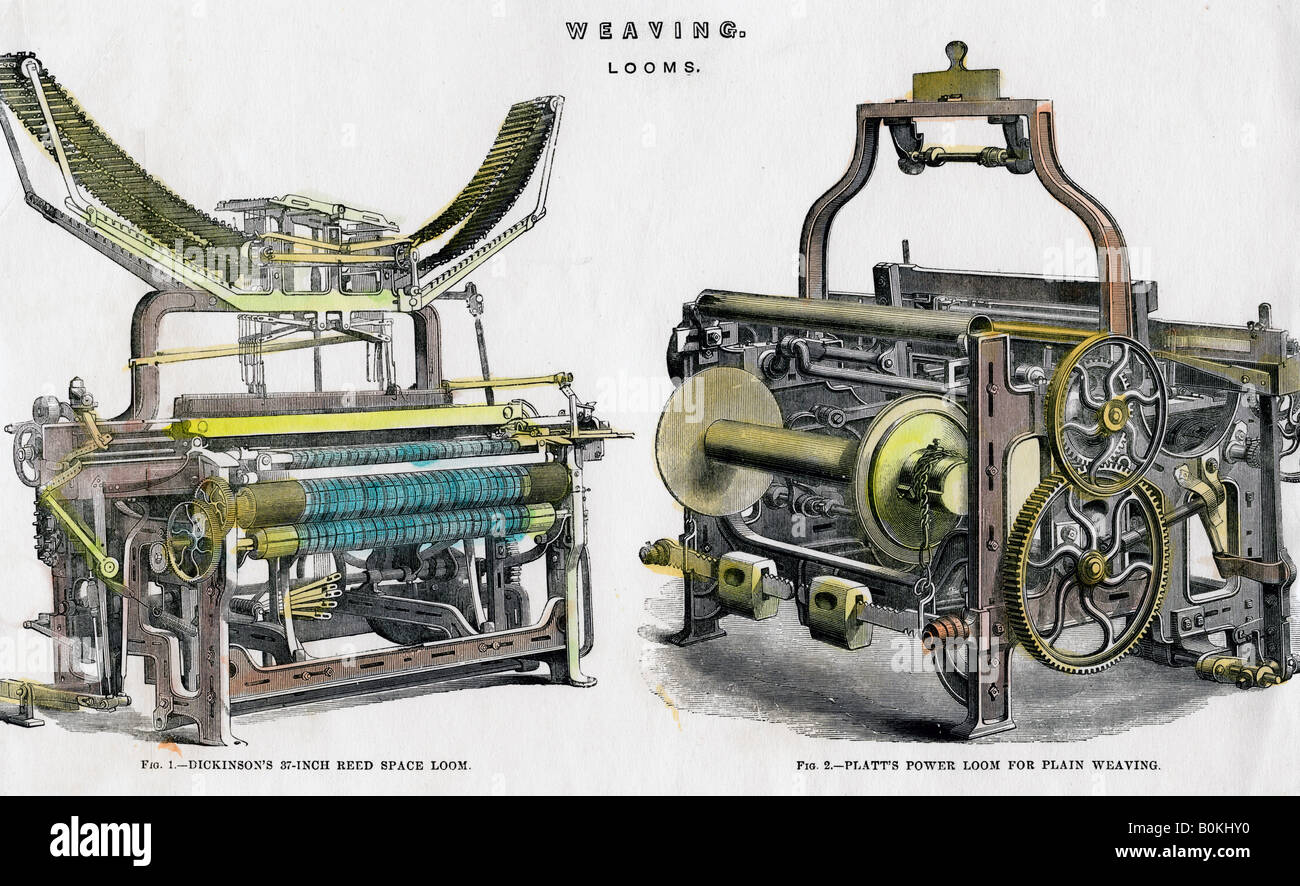

WEAVING LOOMS. Dickinson's 37- inch reed space loom; - Platt's power plain 1880 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/weaving-looms-dickinsons-37-inch-reed-space-loom-platts-power-plain-1880-image183051408.html

WEAVING LOOMS. Dickinson's 37- inch reed space loom; - Platt's power plain 1880 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/weaving-looms-dickinsons-37-inch-reed-space-loom-platts-power-plain-1880-image183051408.htmlRFMHPKX8–WEAVING LOOMS. Dickinson's 37- inch reed space loom; - Platt's power plain 1880

Power Loom Weaving Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/power-loom-weaving-image3176694.html

Power Loom Weaving Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/power-loom-weaving-image3176694.htmlRMAYK8F7–Power Loom Weaving

Power Loom circa 1830's. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/power-loom-circa-1830s-image5316417.html

Power Loom circa 1830's. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/power-loom-circa-1830s-image5316417.htmlRMATDK42–Power Loom circa 1830's.

Interior of cotton mill in Lancashire: power loom weaving- man and woman tend machine. Date: 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-interior-of-cotton-mill-in-lancashire-power-loom-weaving-man-and-woman-105279635.html

Interior of cotton mill in Lancashire: power loom weaving- man and woman tend machine. Date: 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-interior-of-cotton-mill-in-lancashire-power-loom-weaving-man-and-woman-105279635.htmlRMG37W6Y–Interior of cotton mill in Lancashire: power loom weaving- man and woman tend machine. Date: 1835

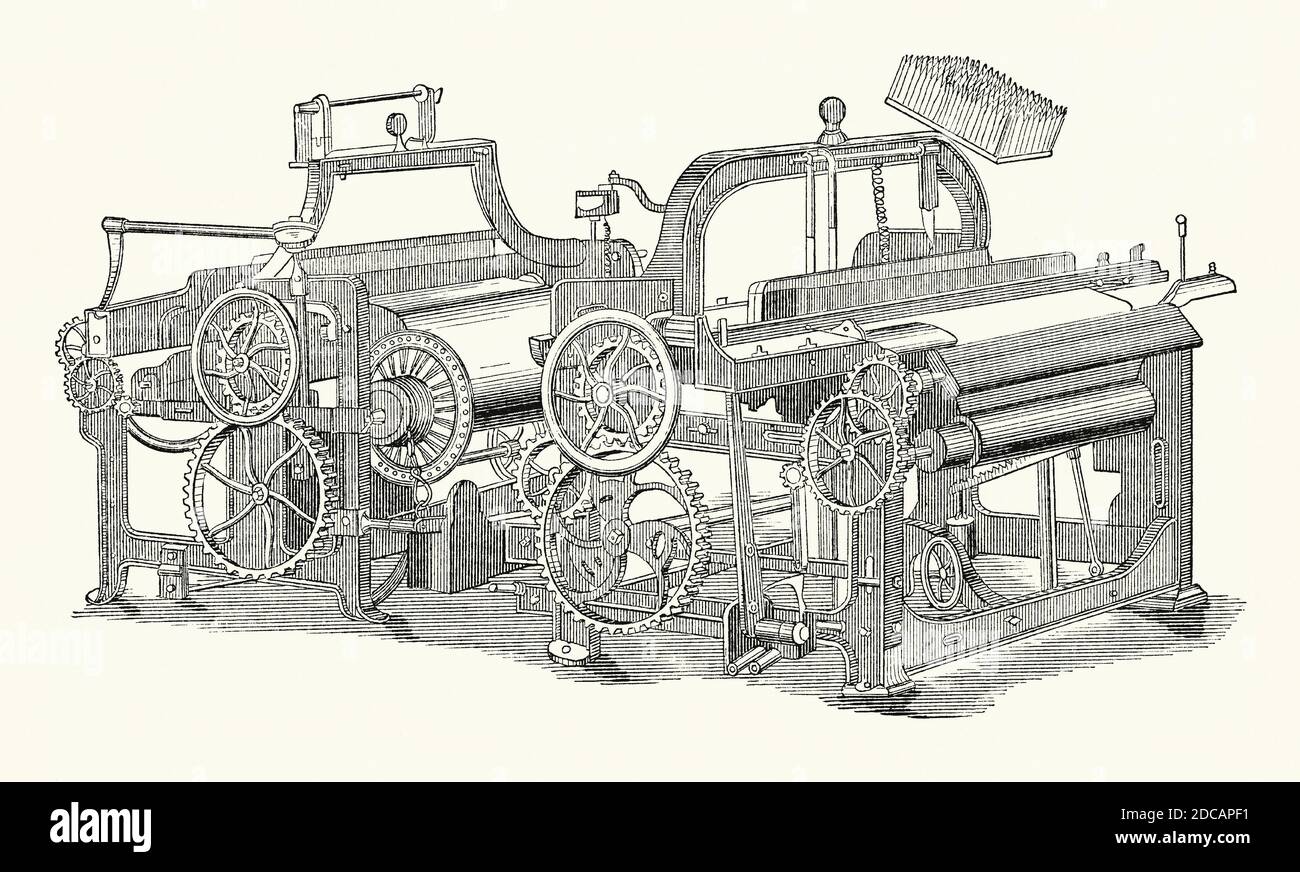

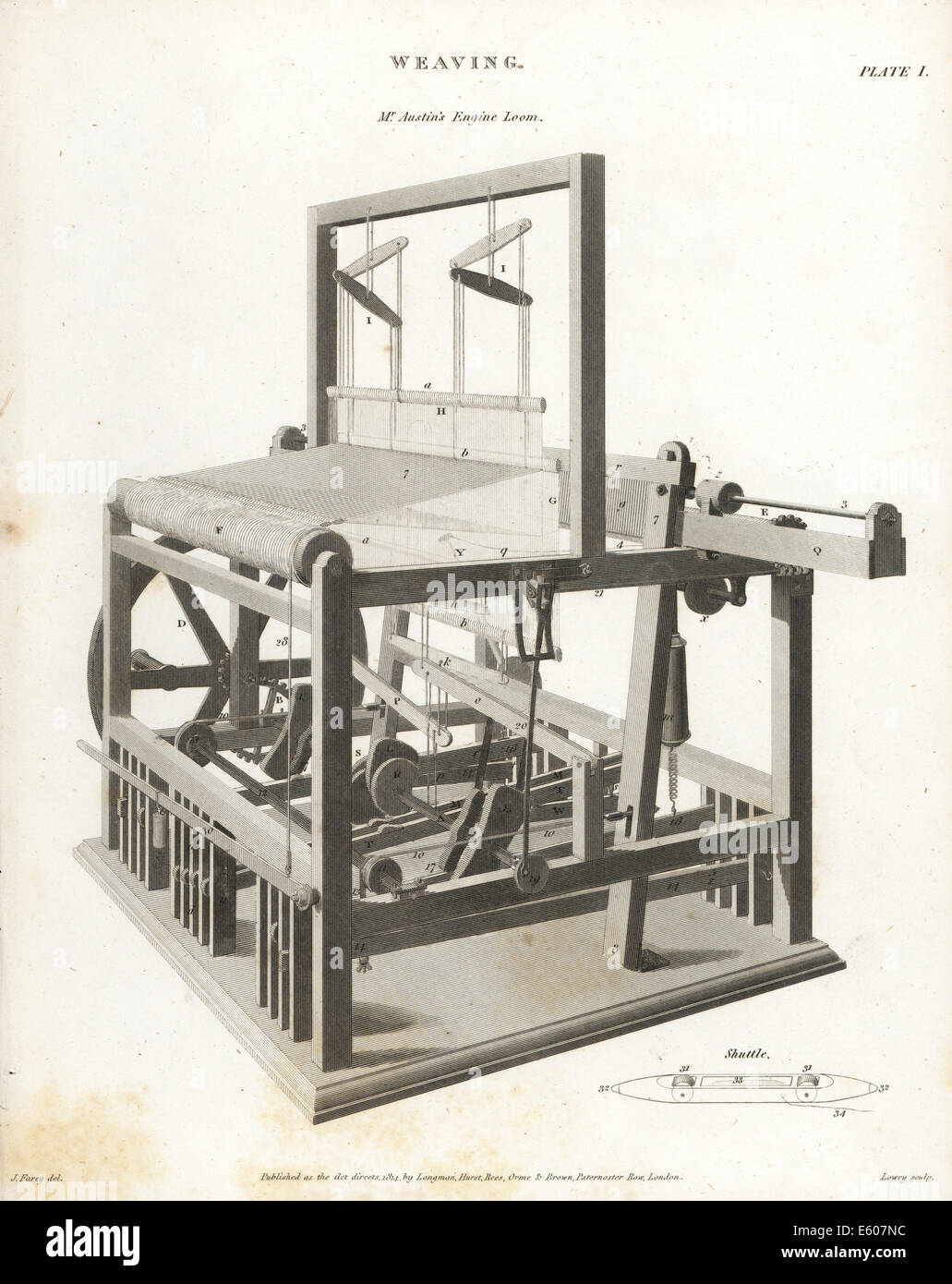

An old engraving of a cotton loom (left) and a linen loom (right). It is from a Victorian mechanical engineering book of the 1880s. A loom is a device used to weave cloth. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. Englishman Edmund Cartwright built and patented a power loom in 1785, and it was this that was adopted by cotton industry. Water and/or steam provided the power needed to run the looms, usually by belt drives to the individual looms. The loom shape and its mechanics varied enormously. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-cotton-loom-left-and-a-linen-loom-right-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-a-loom-is-a-device-used-to-weave-cloth-the-basic-purpose-of-any-loom-is-to-hold-the-warp-threads-under-tension-to-facilitate-the-interweaving-of-the-weft-threads-englishman-edmund-cartwright-built-and-patented-a-power-loom-in-1785-and-it-was-this-that-was-adopted-by-cotton-industry-water-andor-steam-provided-the-power-needed-to-run-the-looms-usually-by-belt-drives-to-the-individual-looms-the-loom-shape-and-its-mechanics-varied-enormously-image386241157.html

An old engraving of a cotton loom (left) and a linen loom (right). It is from a Victorian mechanical engineering book of the 1880s. A loom is a device used to weave cloth. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. Englishman Edmund Cartwright built and patented a power loom in 1785, and it was this that was adopted by cotton industry. Water and/or steam provided the power needed to run the looms, usually by belt drives to the individual looms. The loom shape and its mechanics varied enormously. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-cotton-loom-left-and-a-linen-loom-right-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-a-loom-is-a-device-used-to-weave-cloth-the-basic-purpose-of-any-loom-is-to-hold-the-warp-threads-under-tension-to-facilitate-the-interweaving-of-the-weft-threads-englishman-edmund-cartwright-built-and-patented-a-power-loom-in-1785-and-it-was-this-that-was-adopted-by-cotton-industry-water-andor-steam-provided-the-power-needed-to-run-the-looms-usually-by-belt-drives-to-the-individual-looms-the-loom-shape-and-its-mechanics-varied-enormously-image386241157.htmlRM2DCAPF1–An old engraving of a cotton loom (left) and a linen loom (right). It is from a Victorian mechanical engineering book of the 1880s. A loom is a device used to weave cloth. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. Englishman Edmund Cartwright built and patented a power loom in 1785, and it was this that was adopted by cotton industry. Water and/or steam provided the power needed to run the looms, usually by belt drives to the individual looms. The loom shape and its mechanics varied enormously.

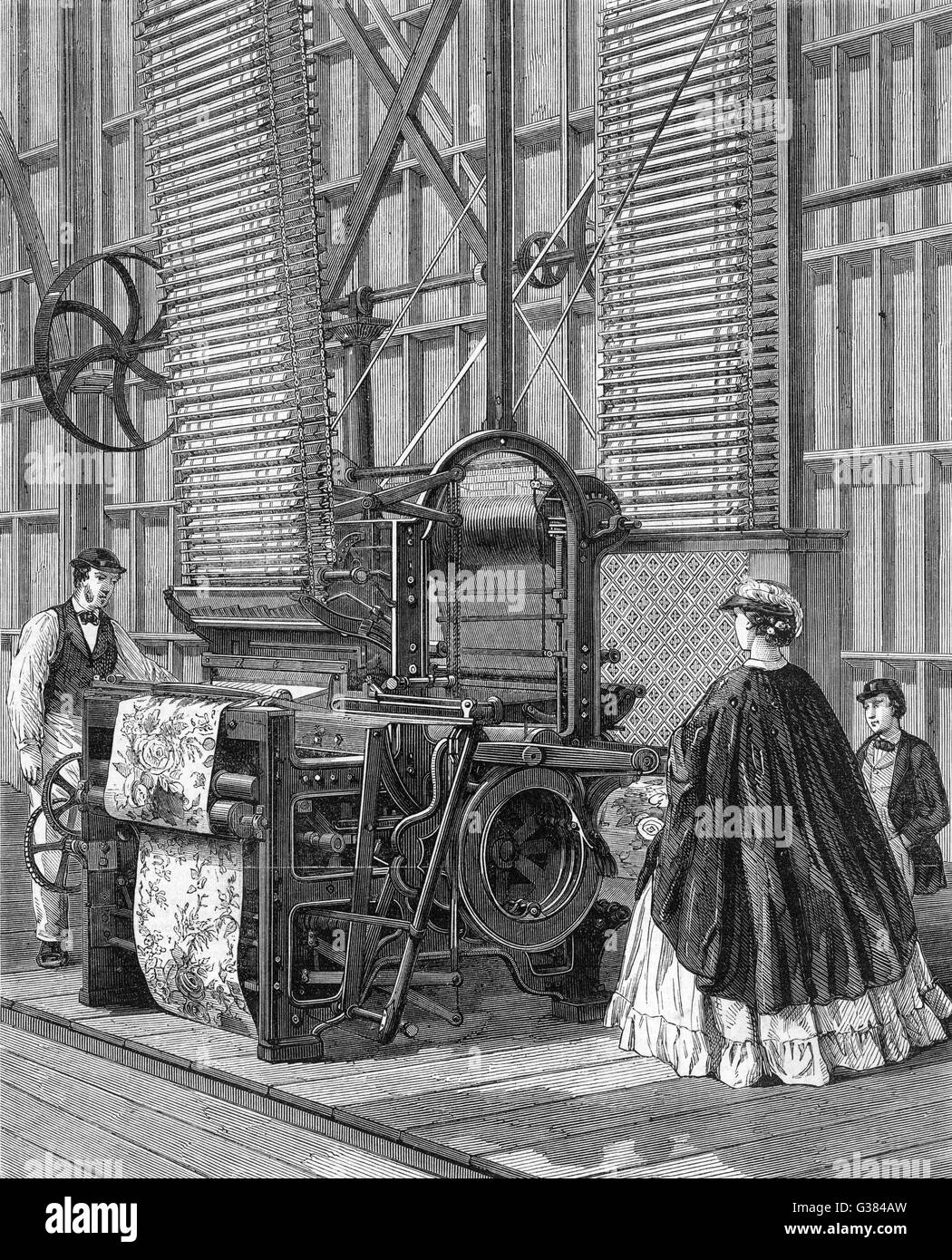

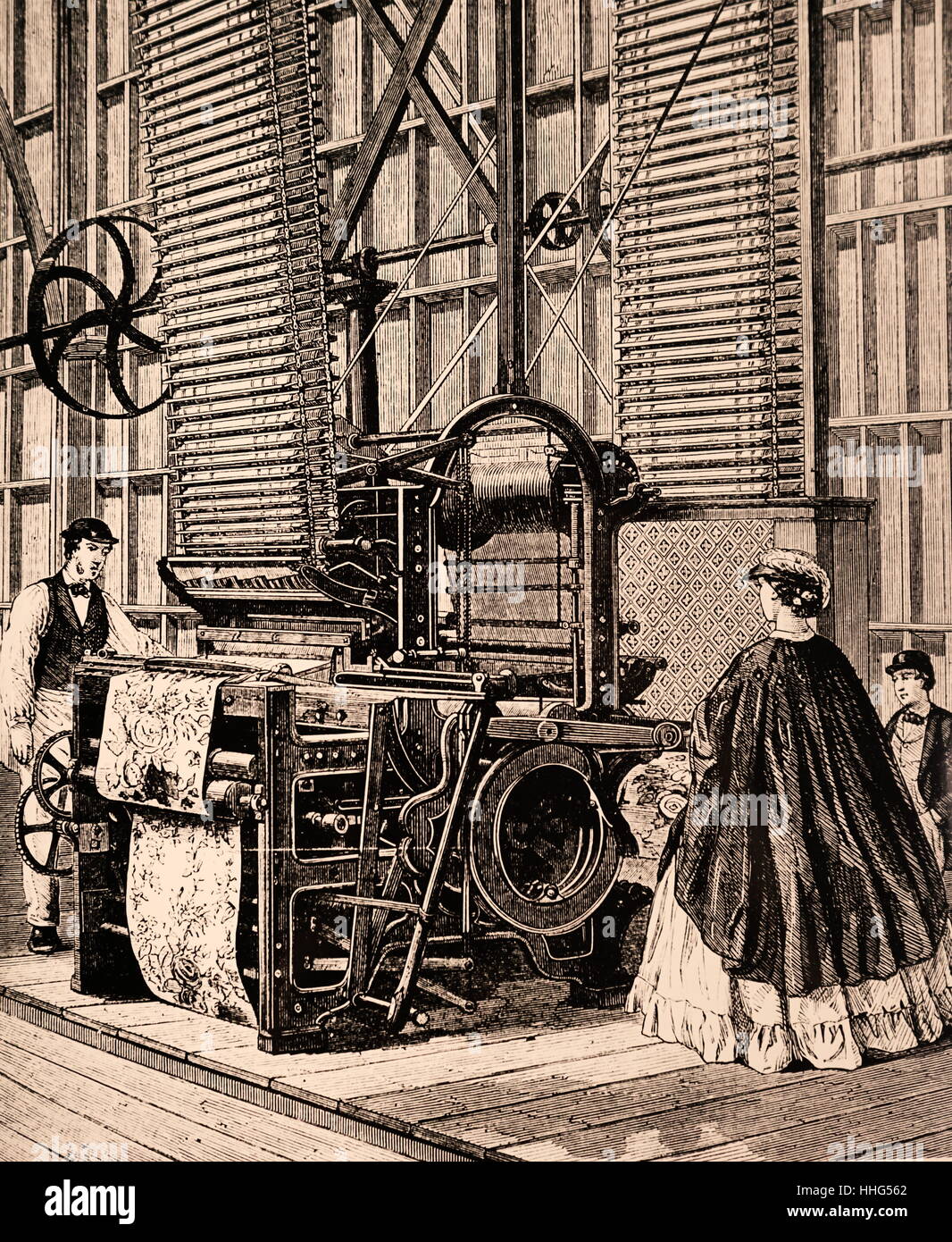

Smith's Power-Loom for weaving tufted pile carpets. (Exhibited at the 1862 Exhibition, London). Date: 1862 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-smiths-power-loom-for-weaving-tufted-pile-carpets-exhibited-at-the-105285233.html

Smith's Power-Loom for weaving tufted pile carpets. (Exhibited at the 1862 Exhibition, London). Date: 1862 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-smiths-power-loom-for-weaving-tufted-pile-carpets-exhibited-at-the-105285233.htmlRMG384AW–Smith's Power-Loom for weaving tufted pile carpets. (Exhibited at the 1862 Exhibition, London). Date: 1862

Woman worker using a mechanized Jacquard loom, 1880s. Hand-colored woodcut Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-woman-worker-using-a-mechanized-jacquard-loom-1880s-hand-colored-woodcut-28512473.html

Woman worker using a mechanized Jacquard loom, 1880s. Hand-colored woodcut Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-woman-worker-using-a-mechanized-jacquard-loom-1880s-hand-colored-woodcut-28512473.htmlRMBJARXH–Woman worker using a mechanized Jacquard loom, 1880s. Hand-colored woodcut

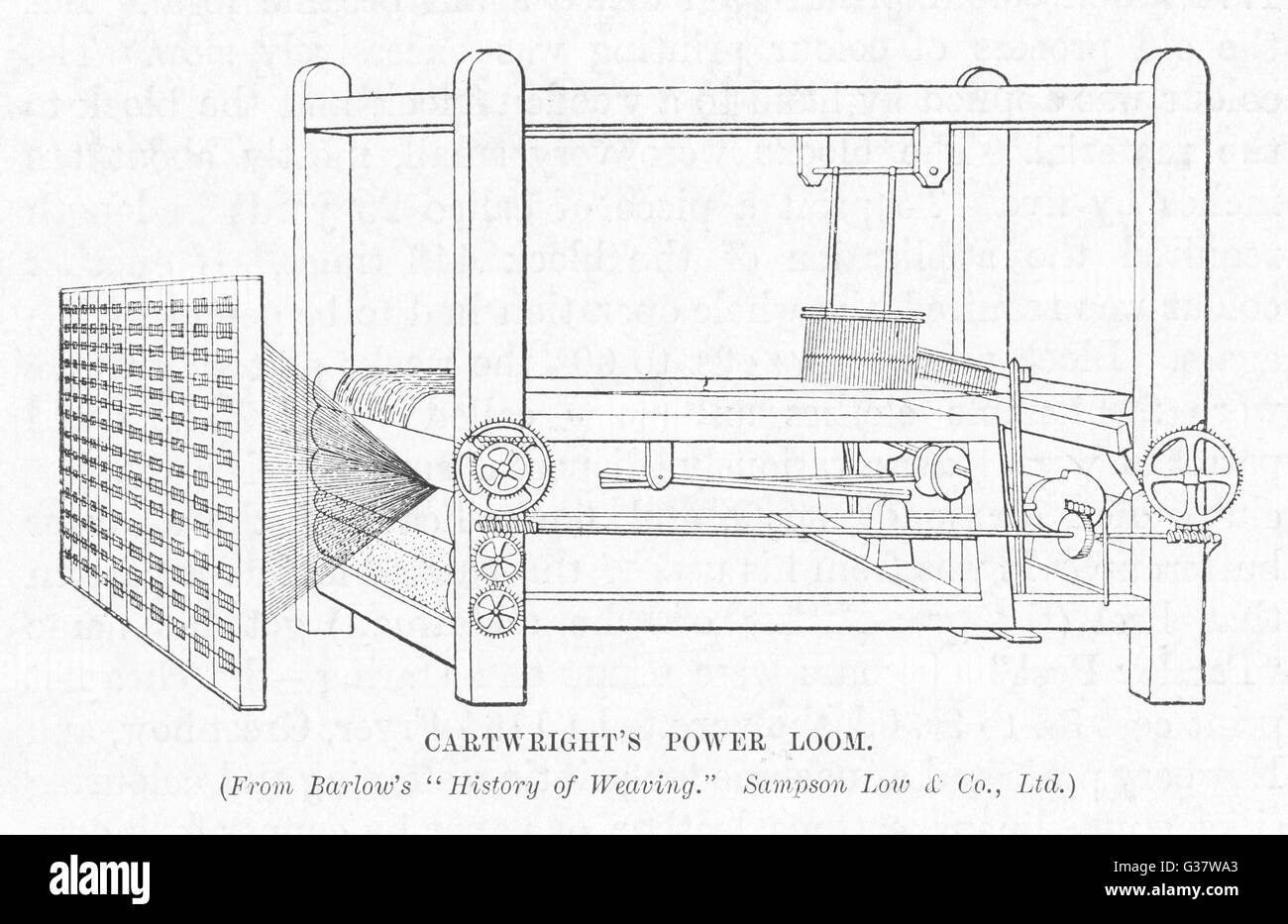

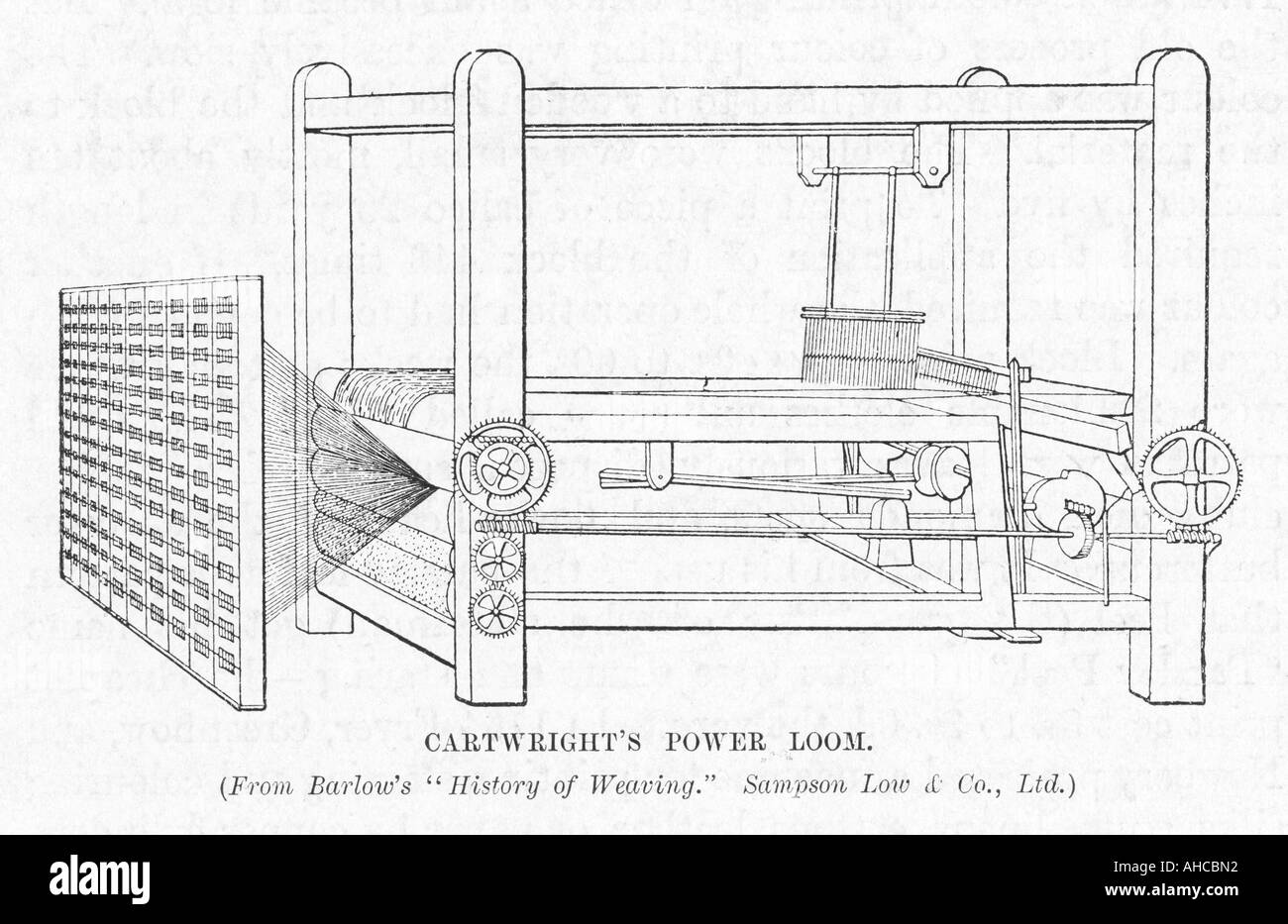

CARTWRIGHT'S POWER LOOM Edmund Cartwright's steam- powered loom of 1785 enabled weaving to be carried out at vastly greater speed Date: 1785 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-cartwrights-power-loom-edmund-cartwrights-steam-powered-loom-of-1785-105279723.html

CARTWRIGHT'S POWER LOOM Edmund Cartwright's steam- powered loom of 1785 enabled weaving to be carried out at vastly greater speed Date: 1785 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-cartwrights-power-loom-edmund-cartwrights-steam-powered-loom-of-1785-105279723.htmlRMG37WA3–CARTWRIGHT'S POWER LOOM Edmund Cartwright's steam- powered loom of 1785 enabled weaving to be carried out at vastly greater speed Date: 1785

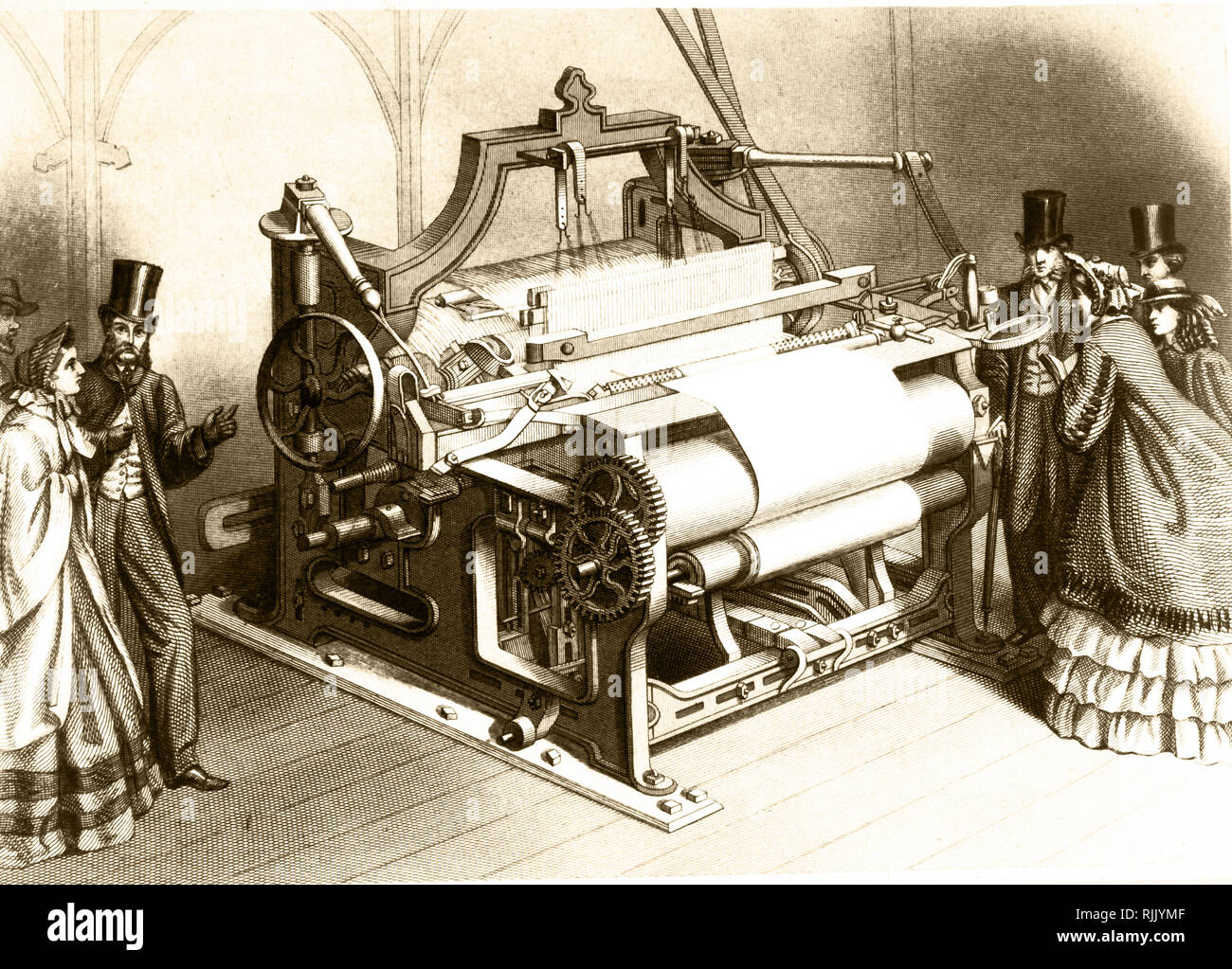

An engraving depicting W.G. Taylor's power loom for weaving calico. The machine was awarded the prize medal at the 1862 Exhibition. Dated 19th century Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-engraving-depicting-wg-taylors-power-loom-for-weaving-calico-the-machine-was-awarded-the-prize-medal-at-the-1862-exhibition-dated-19th-century-image235215471.html

An engraving depicting W.G. Taylor's power loom for weaving calico. The machine was awarded the prize medal at the 1862 Exhibition. Dated 19th century Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-engraving-depicting-wg-taylors-power-loom-for-weaving-calico-the-machine-was-awarded-the-prize-medal-at-the-1862-exhibition-dated-19th-century-image235215471.htmlRMRJJYMF–An engraving depicting W.G. Taylor's power loom for weaving calico. The machine was awarded the prize medal at the 1862 Exhibition. Dated 19th century

Tuers Carpet Loom 1862 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/tuers-carpet-loom-1862-image5541232.html

Tuers Carpet Loom 1862 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/tuers-carpet-loom-1862-image5541232.htmlRMAY2N71–Tuers Carpet Loom 1862

Alexander Smith's power loom for weaving Axminster carpets. Dated November 1862. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-alexander-smiths-power-loom-for-weaving-axminster-carpets-dated-november-131277050.html

Alexander Smith's power loom for weaving Axminster carpets. Dated November 1862. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-alexander-smiths-power-loom-for-weaving-axminster-carpets-dated-november-131277050.htmlRMHHG562–Alexander Smith's power loom for weaving Axminster carpets. Dated November 1862.

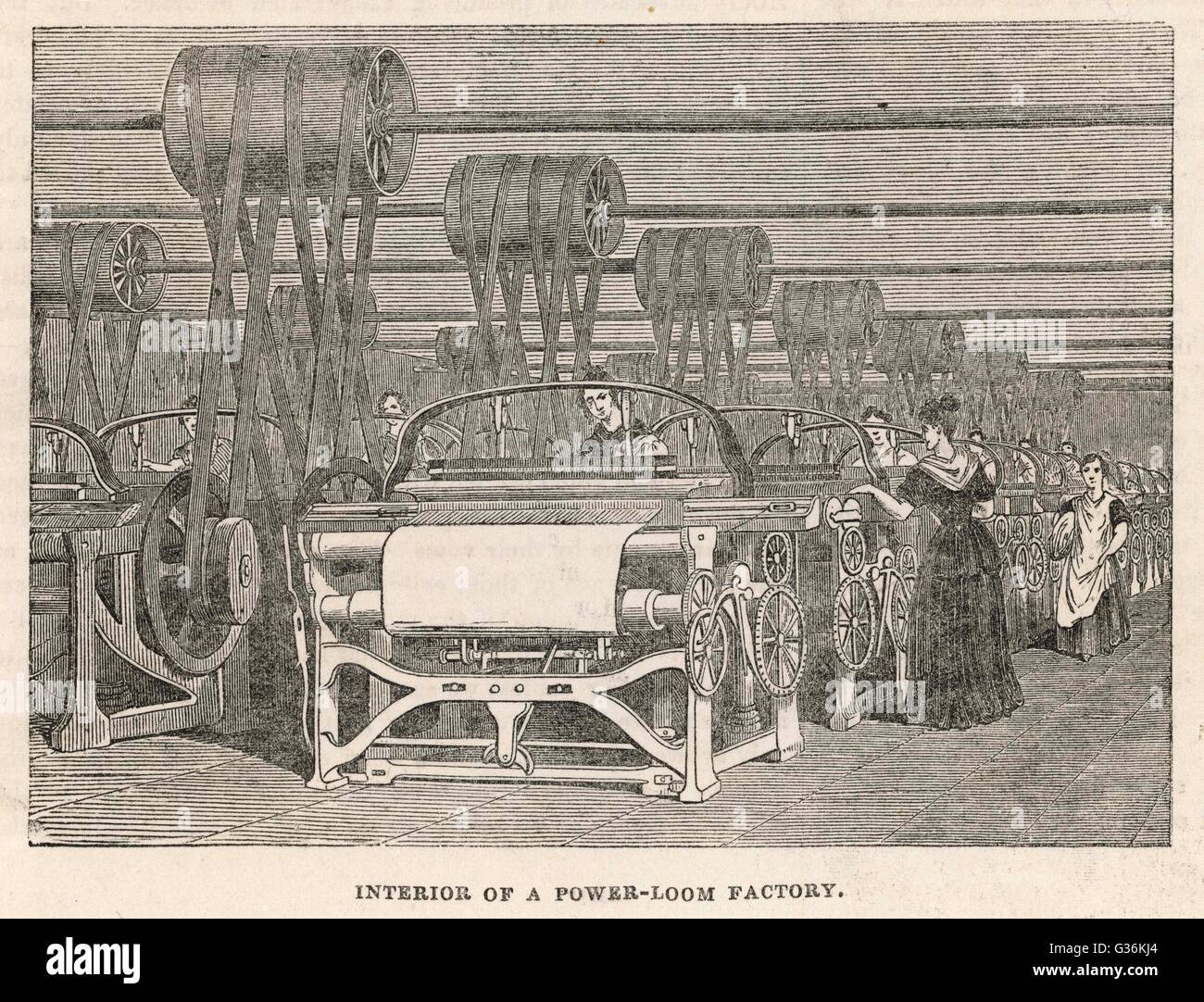

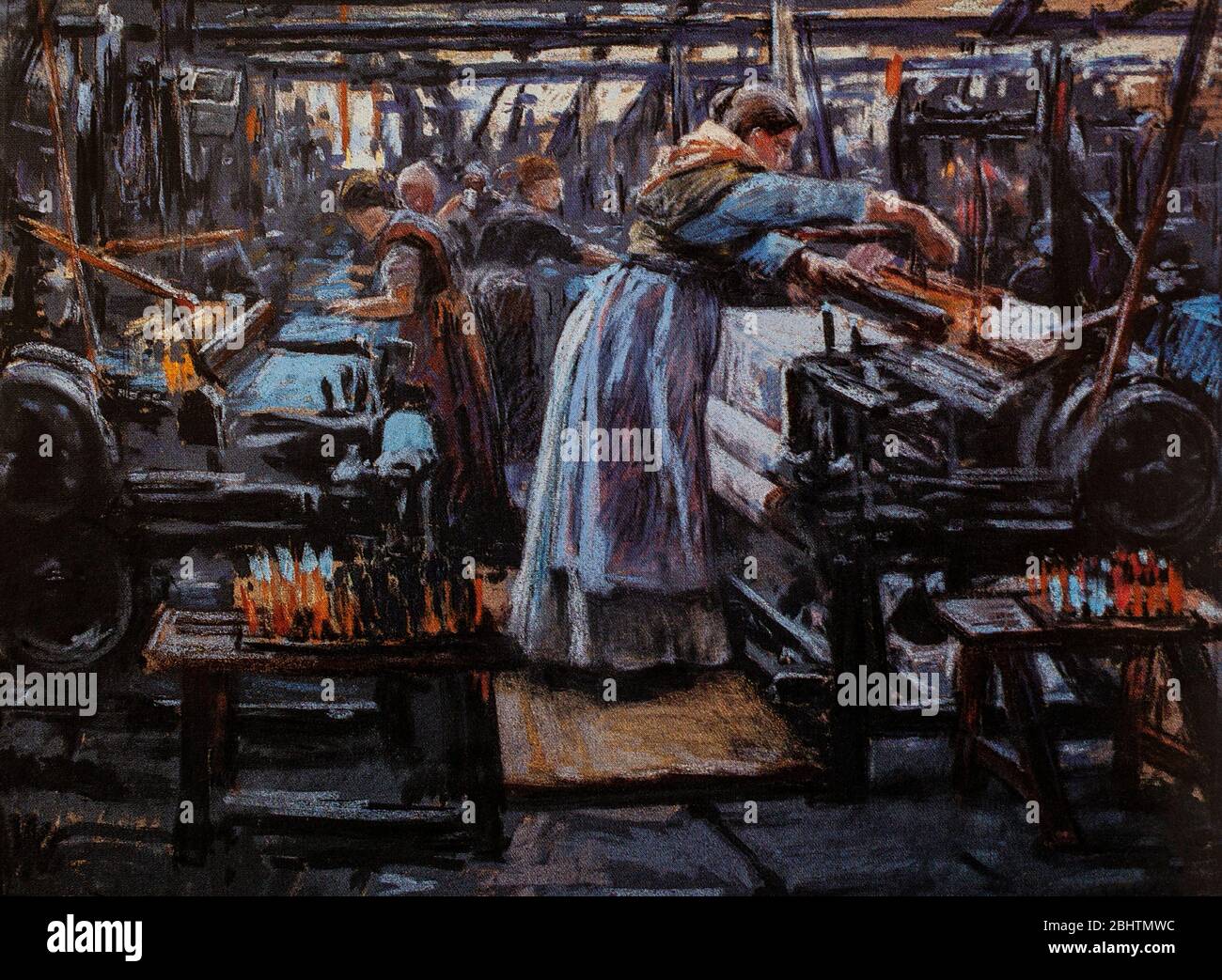

Women at work in a power-loom factory, Lancashire Date: 1844 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-women-at-work-in-a-power-loom-factory-lancashire-date-1844-105253292.html

Women at work in a power-loom factory, Lancashire Date: 1844 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-women-at-work-in-a-power-loom-factory-lancashire-date-1844-105253292.htmlRMG36KJ4–Women at work in a power-loom factory, Lancashire Date: 1844

A weaving loom with a carpet on it, Crete, Greece Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-a-weaving-loom-with-a-carpet-on-it-crete-greece-13095674.html

A weaving loom with a carpet on it, Crete, Greece Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-a-weaving-loom-with-a-carpet-on-it-crete-greece-13095674.htmlRMACAHTY–A weaving loom with a carpet on it, Crete, Greece

Women at work in a power-loom factory, Lancashire Date: 1844 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-women-at-work-in-a-power-loom-factory-lancashire-date-1844-105253293.html

Women at work in a power-loom factory, Lancashire Date: 1844 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-women-at-work-in-a-power-loom-factory-lancashire-date-1844-105253293.htmlRMG36KJ5–Women at work in a power-loom factory, Lancashire Date: 1844

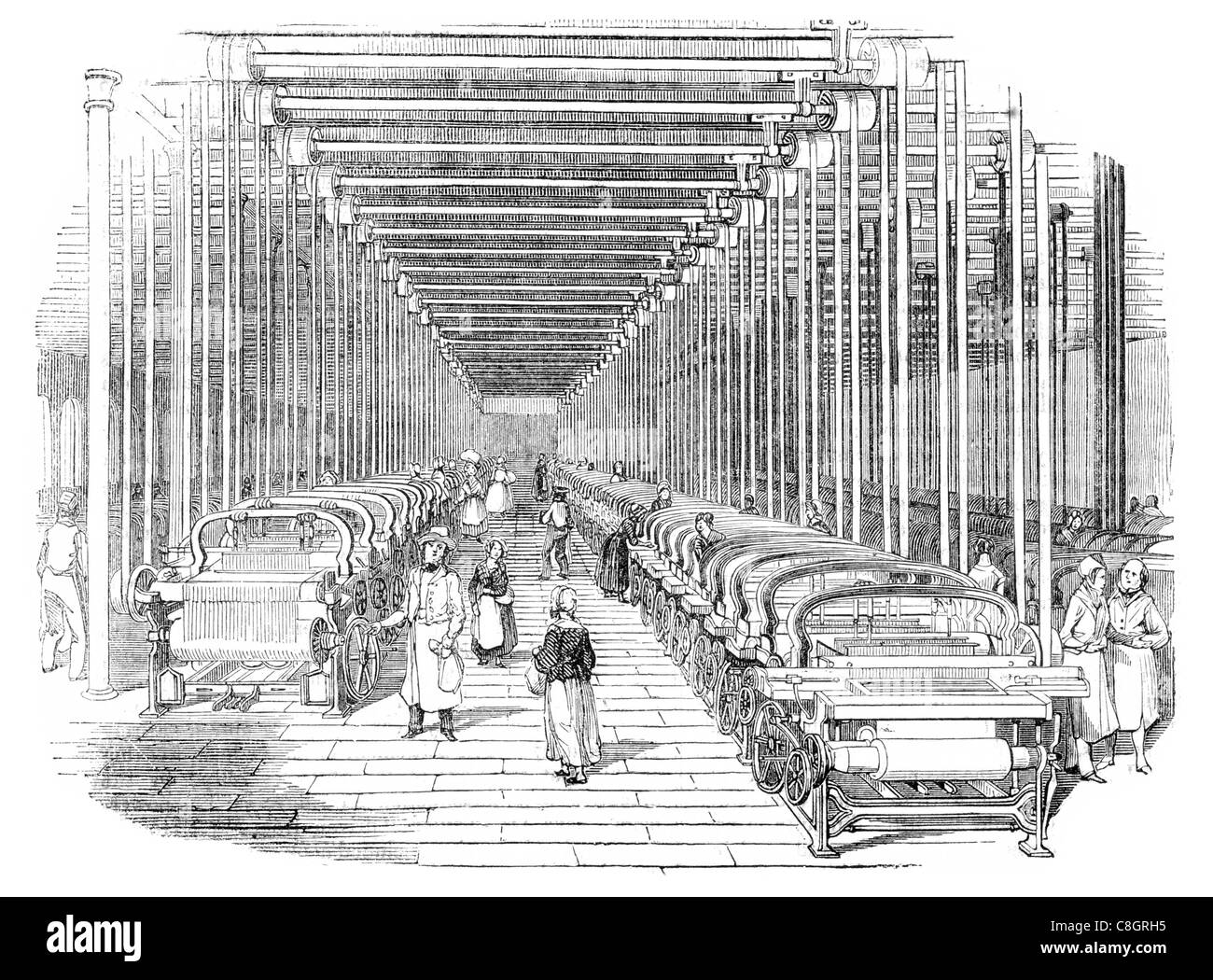

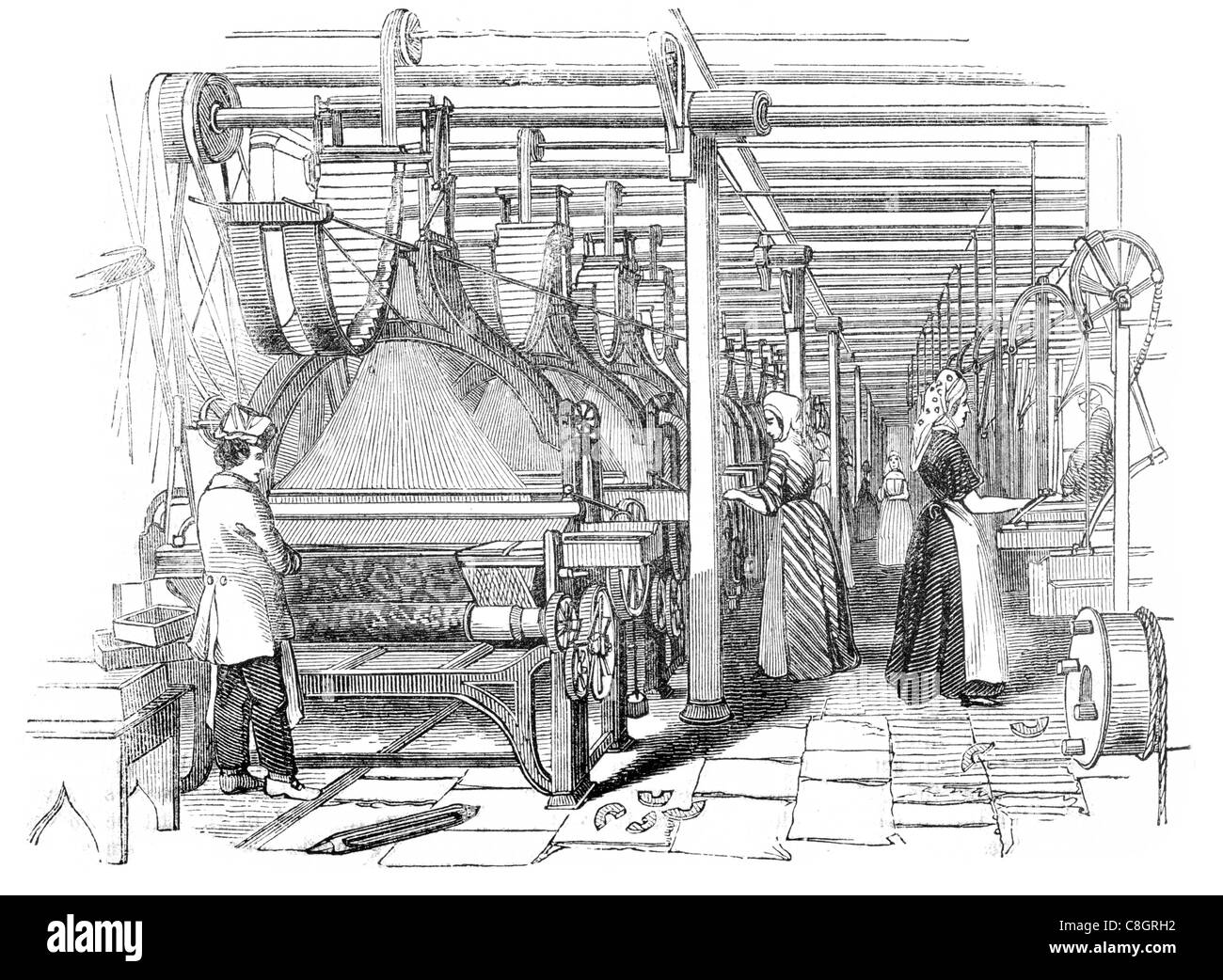

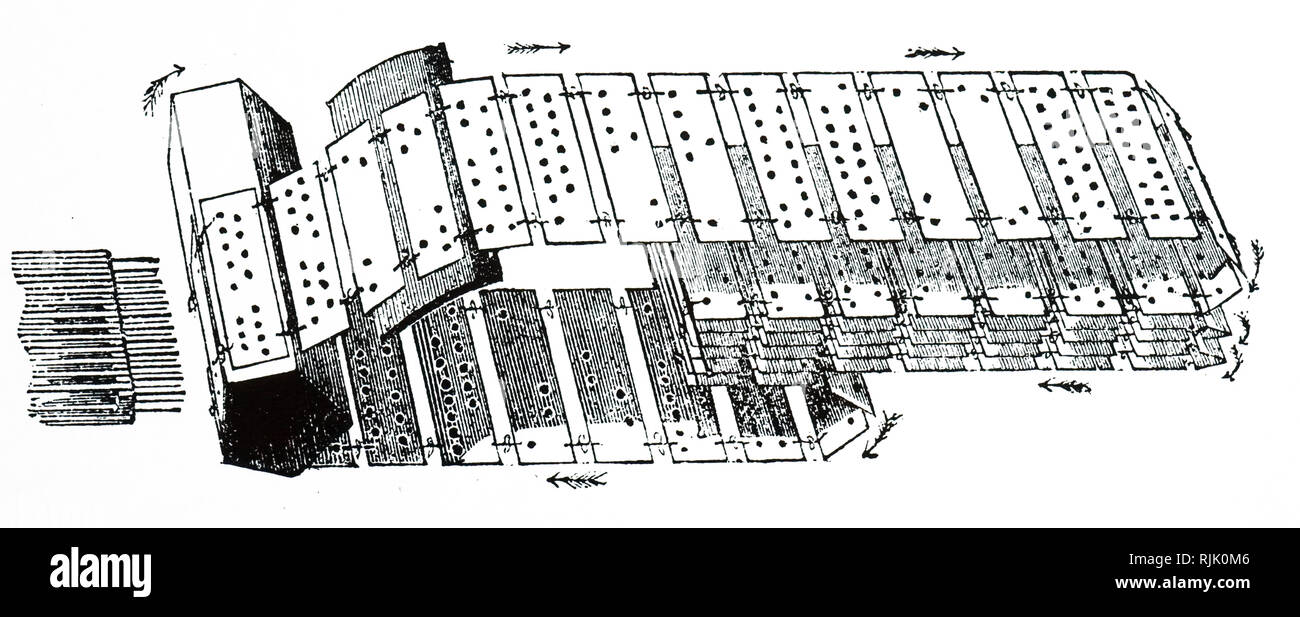

power looms loom cotton manufacture shuttle reed heddles war beam Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-power-looms-loom-cotton-manufacture-shuttle-reed-heddles-war-beam-39707729.html

power looms loom cotton manufacture shuttle reed heddles war beam Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-power-looms-loom-cotton-manufacture-shuttle-reed-heddles-war-beam-39707729.htmlRFC8GRH5–power looms loom cotton manufacture shuttle reed heddles war beam

Cartwrights Loom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/cartwrights-loom-image8245393.html

Cartwrights Loom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/cartwrights-loom-image8245393.htmlRMAHCBN2–Cartwrights Loom

. Illustration of power loom weaving . 1835. Illustrator T. Allom 500 Powerloom weaving in 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/illustration-of-power-loom-weaving-1835-illustrator-t-allom-500-powerloom-weaving-in-1835-image187960938.html

. Illustration of power loom weaving . 1835. Illustrator T. Allom 500 Powerloom weaving in 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/illustration-of-power-loom-weaving-1835-illustrator-t-allom-500-powerloom-weaving-in-1835-image187960938.htmlRMMWPA2J–. Illustration of power loom weaving . 1835. Illustrator T. Allom 500 Powerloom weaving in 1835

Worker working at power loom workshop factory in the textile town of Malegaon Maharashtra India Asia Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-worker-working-at-power-loom-workshop-factory-in-the-textile-town-83607759.html

Worker working at power loom workshop factory in the textile town of Malegaon Maharashtra India Asia Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-worker-working-at-power-loom-workshop-factory-in-the-textile-town-83607759.htmlRMET0JFB–Worker working at power loom workshop factory in the textile town of Malegaon Maharashtra India Asia

Crompton's Belt-Driven Power Loom, 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/cromptons-belt-driven-power-loom-1835-image352802893.html

Crompton's Belt-Driven Power Loom, 1835 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/cromptons-belt-driven-power-loom-1835-image352802893.htmlRM2BDYFK9–Crompton's Belt-Driven Power Loom, 1835

An employee in a textile company in Krefeld adjusting the yarn in the big power loom, Germany 1930s Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-employee-in-a-textile-company-in-krefeld-adjusting-the-yarn-in-the-big-power-loom-germany-1930s-image328548649.html

An employee in a textile company in Krefeld adjusting the yarn in the big power loom, Germany 1930s Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-employee-in-a-textile-company-in-krefeld-adjusting-the-yarn-in-the-big-power-loom-germany-1930s-image328548649.htmlRM2A2EK49–An employee in a textile company in Krefeld adjusting the yarn in the big power loom, Germany 1930s

Erastus Brigham Bigelow (April 2, 1814 - December 6, 1879) was an American inventor of weaving machines. He showed an inventive genius at the early age of 14, when he invented a machine to manufacture piping cord. He then devised a hand loom for suspender webbing. His work on Stenography (1832), a short manual on shorthand writing, was written and published about this time. In 1838, he invented a power loom for weaving knotted counterpanes, and later a power loom to weave coach lace. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/erastus-brigham-bigelow-april-2-1814-december-6-1879-was-an-american-inventor-of-weaving-machines-he-showed-an-inventive-genius-at-the-early-age-of-14-when-he-invented-a-machine-to-manufacture-piping-cord-he-then-devised-a-hand-loom-for-suspender-webbing-his-work-on-stenography-1832-a-short-manual-on-shorthand-writing-was-written-and-published-about-this-time-in-1838-he-invented-a-power-loom-for-weaving-knotted-counterpanes-and-later-a-power-loom-to-weave-coach-lace-image246613360.html

Erastus Brigham Bigelow (April 2, 1814 - December 6, 1879) was an American inventor of weaving machines. He showed an inventive genius at the early age of 14, when he invented a machine to manufacture piping cord. He then devised a hand loom for suspender webbing. His work on Stenography (1832), a short manual on shorthand writing, was written and published about this time. In 1838, he invented a power loom for weaving knotted counterpanes, and later a power loom to weave coach lace. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/erastus-brigham-bigelow-april-2-1814-december-6-1879-was-an-american-inventor-of-weaving-machines-he-showed-an-inventive-genius-at-the-early-age-of-14-when-he-invented-a-machine-to-manufacture-piping-cord-he-then-devised-a-hand-loom-for-suspender-webbing-his-work-on-stenography-1832-a-short-manual-on-shorthand-writing-was-written-and-published-about-this-time-in-1838-he-invented-a-power-loom-for-weaving-knotted-counterpanes-and-later-a-power-loom-to-weave-coach-lace-image246613360.htmlRMT965T0–Erastus Brigham Bigelow (April 2, 1814 - December 6, 1879) was an American inventor of weaving machines. He showed an inventive genius at the early age of 14, when he invented a machine to manufacture piping cord. He then devised a hand loom for suspender webbing. His work on Stenography (1832), a short manual on shorthand writing, was written and published about this time. In 1838, he invented a power loom for weaving knotted counterpanes, and later a power loom to weave coach lace.

Four views of a Power Loom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/four-views-of-a-power-loom-image5316388.html

Four views of a Power Loom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/four-views-of-a-power-loom-image5316388.htmlRMATDK25–Four views of a Power Loom

Factory woman seated at her frame, preparing the wasp for a handloom. At the time the population of upwards of 18,000 people, with the principal portion of whom were engaged in cotton and the silk industry. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/factory-woman-seated-at-her-frame-preparing-the-wasp-for-a-handloom-at-the-time-the-population-of-upwards-of-18000-people-with-the-principal-portion-of-whom-were-engaged-in-cotton-and-the-silk-industry-image560764841.html

Factory woman seated at her frame, preparing the wasp for a handloom. At the time the population of upwards of 18,000 people, with the principal portion of whom were engaged in cotton and the silk industry. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/factory-woman-seated-at-her-frame-preparing-the-wasp-for-a-handloom-at-the-time-the-population-of-upwards-of-18000-people-with-the-principal-portion-of-whom-were-engaged-in-cotton-and-the-silk-industry-image560764841.htmlRM2RG917N–Factory woman seated at her frame, preparing the wasp for a handloom. At the time the population of upwards of 18,000 people, with the principal portion of whom were engaged in cotton and the silk industry.

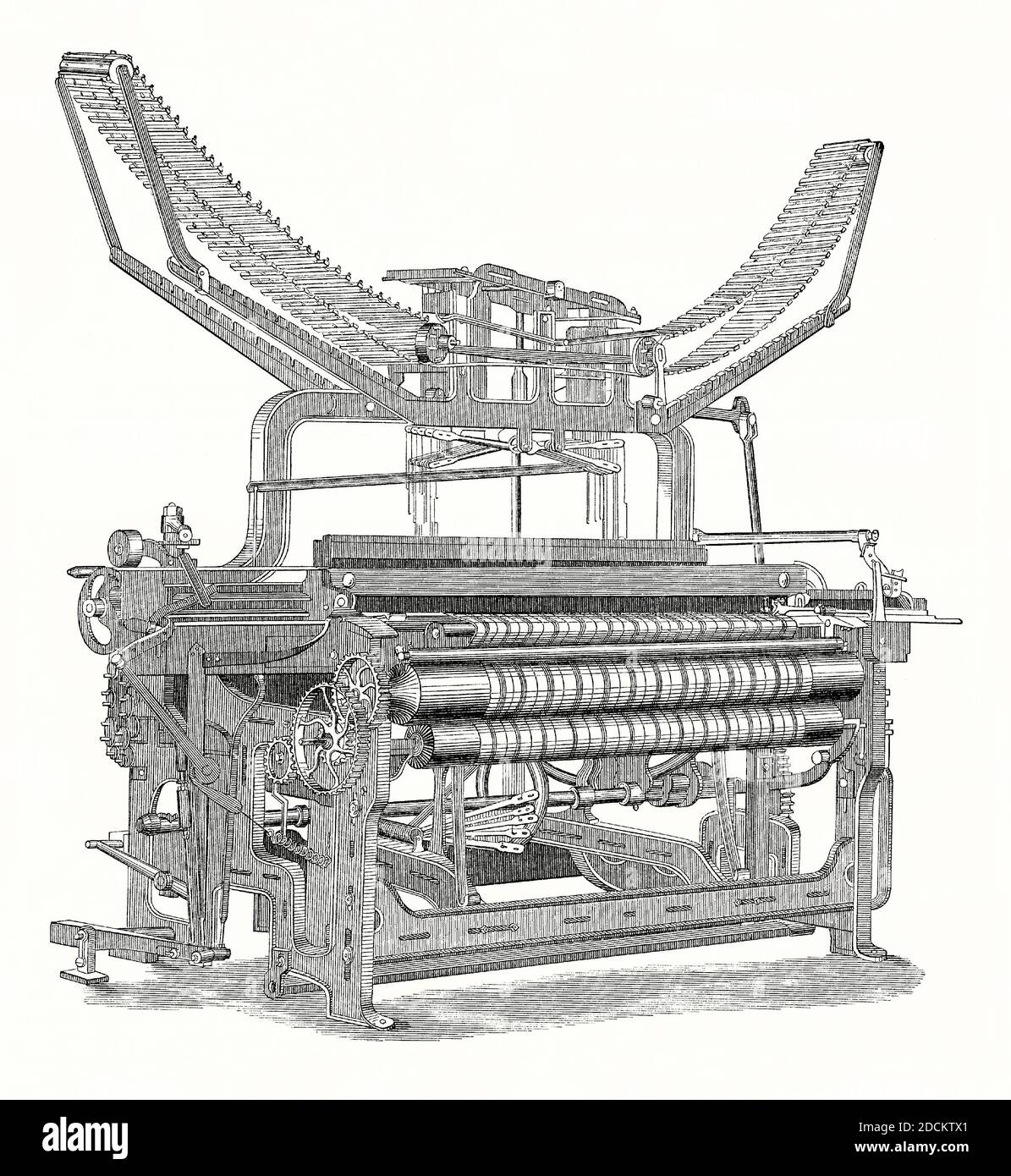

An old engraving of a figure loom, using a ‘dobby’ in the manufacture of patterned cloth in the 1800s. It is from a Victorian mechanical engineering book of the 1880s. Dobby (or dobbie) is a woven fabric produced on the dobby loom. The fabric produced is characterised by small geometric patterns and extra texture in the cloth. The warp and weft threads may of different colours. A harness-controlling mechanism is located at the centre of the loom. This connects to pattern chains that are mounted at the top of the loom. Englishman Edmund Cartwright built and patented a power loom in 1785. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-figure-loom-using-a-dobby-in-the-manufacture-of-patterned-cloth-in-the-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-dobby-or-dobbie-is-a-woven-fabric-produced-on-the-dobby-loom-the-fabric-produced-is-characterised-by-small-geometric-patterns-and-extra-texture-in-the-cloth-the-warp-and-weft-threads-may-of-different-colours-a-harness-controlling-mechanism-is-located-at-the-centre-of-the-loom-this-connects-to-pattern-chains-that-are-mounted-at-the-top-of-the-loom-englishman-edmund-cartwright-built-and-patented-a-power-loom-in-1785-image386440601.html

An old engraving of a figure loom, using a ‘dobby’ in the manufacture of patterned cloth in the 1800s. It is from a Victorian mechanical engineering book of the 1880s. Dobby (or dobbie) is a woven fabric produced on the dobby loom. The fabric produced is characterised by small geometric patterns and extra texture in the cloth. The warp and weft threads may of different colours. A harness-controlling mechanism is located at the centre of the loom. This connects to pattern chains that are mounted at the top of the loom. Englishman Edmund Cartwright built and patented a power loom in 1785. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-figure-loom-using-a-dobby-in-the-manufacture-of-patterned-cloth-in-the-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-dobby-or-dobbie-is-a-woven-fabric-produced-on-the-dobby-loom-the-fabric-produced-is-characterised-by-small-geometric-patterns-and-extra-texture-in-the-cloth-the-warp-and-weft-threads-may-of-different-colours-a-harness-controlling-mechanism-is-located-at-the-centre-of-the-loom-this-connects-to-pattern-chains-that-are-mounted-at-the-top-of-the-loom-englishman-edmund-cartwright-built-and-patented-a-power-loom-in-1785-image386440601.htmlRM2DCKTX1–An old engraving of a figure loom, using a ‘dobby’ in the manufacture of patterned cloth in the 1800s. It is from a Victorian mechanical engineering book of the 1880s. Dobby (or dobbie) is a woven fabric produced on the dobby loom. The fabric produced is characterised by small geometric patterns and extra texture in the cloth. The warp and weft threads may of different colours. A harness-controlling mechanism is located at the centre of the loom. This connects to pattern chains that are mounted at the top of the loom. Englishman Edmund Cartwright built and patented a power loom in 1785.

Syria: Carpet weaving in the Souq-al-Hamadiyeh, Damascus. Damascus was first settled in the 2nd millennium BCE, it was chosen as the capital of the Umayyad Caliphate from 661 to 750. After the victory of the Abbasid dynasty, the seat of Islamic power was moved to Baghdad. Damascus saw a political decline throughout the Abbasid era, only to regain significant importance in the Ayyubid and Mamluk periods. During Ottoman rule, the city decayed completely while maintaining a certain cultural prestige. Today, it is the seat of the central government and all of the government ministries. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/syria-carpet-weaving-in-the-souq-al-hamadiyeh-damascus-damascus-was-first-settled-in-the-2nd-millennium-bce-it-was-chosen-as-the-capital-of-the-umayyad-caliphate-from-661-to-750-after-the-victory-of-the-abbasid-dynasty-the-seat-of-islamic-power-was-moved-to-baghdad-damascus-saw-a-political-decline-throughout-the-abbasid-era-only-to-regain-significant-importance-in-the-ayyubid-and-mamluk-periods-during-ottoman-rule-the-city-decayed-completely-while-maintaining-a-certain-cultural-prestige-today-it-is-the-seat-of-the-central-government-and-all-of-the-government-ministries-image344248773.html

Syria: Carpet weaving in the Souq-al-Hamadiyeh, Damascus. Damascus was first settled in the 2nd millennium BCE, it was chosen as the capital of the Umayyad Caliphate from 661 to 750. After the victory of the Abbasid dynasty, the seat of Islamic power was moved to Baghdad. Damascus saw a political decline throughout the Abbasid era, only to regain significant importance in the Ayyubid and Mamluk periods. During Ottoman rule, the city decayed completely while maintaining a certain cultural prestige. Today, it is the seat of the central government and all of the government ministries. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/syria-carpet-weaving-in-the-souq-al-hamadiyeh-damascus-damascus-was-first-settled-in-the-2nd-millennium-bce-it-was-chosen-as-the-capital-of-the-umayyad-caliphate-from-661-to-750-after-the-victory-of-the-abbasid-dynasty-the-seat-of-islamic-power-was-moved-to-baghdad-damascus-saw-a-political-decline-throughout-the-abbasid-era-only-to-regain-significant-importance-in-the-ayyubid-and-mamluk-periods-during-ottoman-rule-the-city-decayed-completely-while-maintaining-a-certain-cultural-prestige-today-it-is-the-seat-of-the-central-government-and-all-of-the-government-ministries-image344248773.htmlRM2B01TR1–Syria: Carpet weaving in the Souq-al-Hamadiyeh, Damascus. Damascus was first settled in the 2nd millennium BCE, it was chosen as the capital of the Umayyad Caliphate from 661 to 750. After the victory of the Abbasid dynasty, the seat of Islamic power was moved to Baghdad. Damascus saw a political decline throughout the Abbasid era, only to regain significant importance in the Ayyubid and Mamluk periods. During Ottoman rule, the city decayed completely while maintaining a certain cultural prestige. Today, it is the seat of the central government and all of the government ministries.

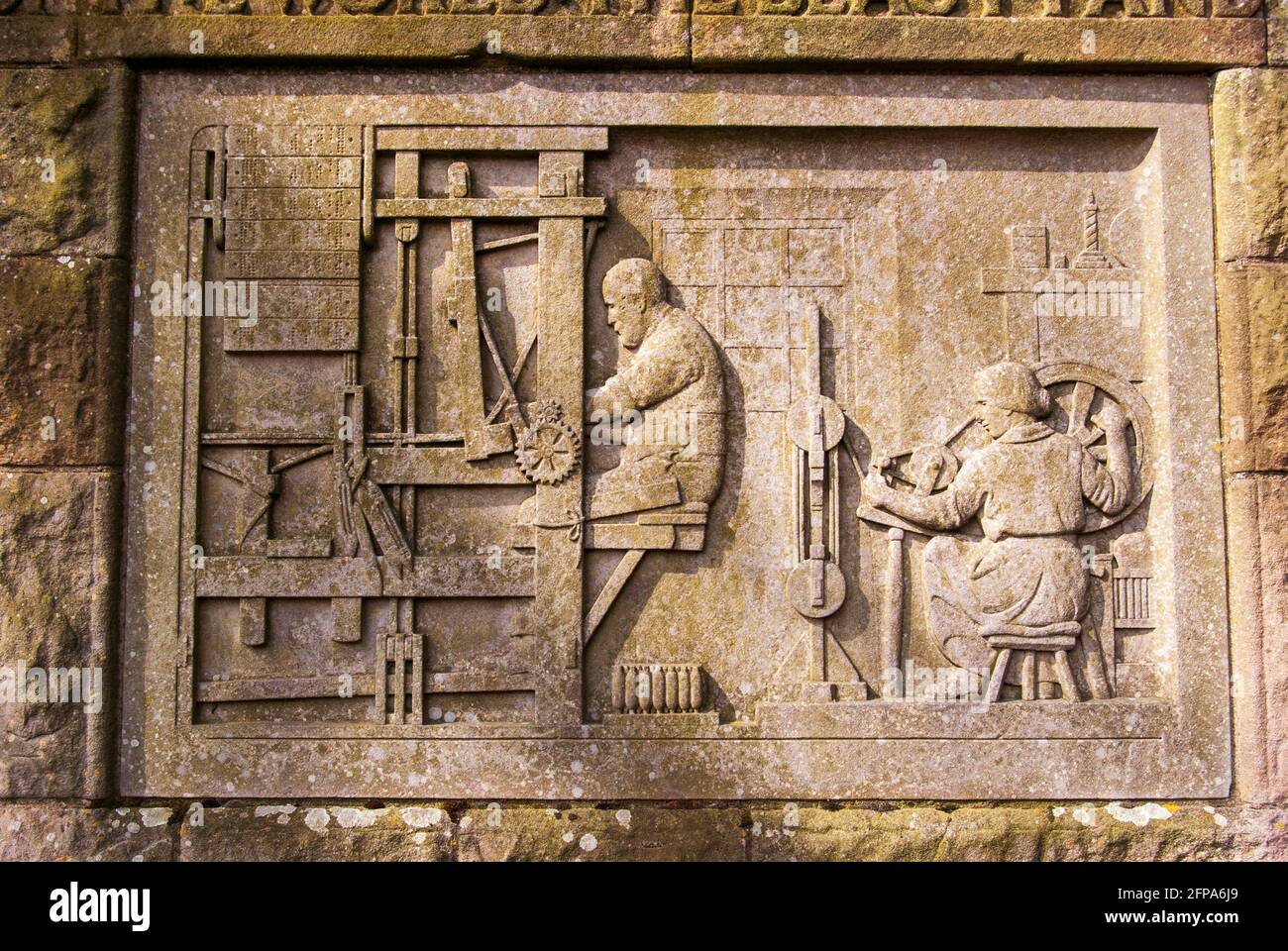

A stone plaque commemorating the hand loom weaving industry on the monument to Alexander Morton, on the A71 near Darvel, East Ayrshire, Scotland. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/a-stone-plaque-commemorating-the-hand-loom-weaving-industry-on-the-monument-to-alexander-morton-on-the-a71-near-darvel-east-ayrshire-scotland-image426796001.html

A stone plaque commemorating the hand loom weaving industry on the monument to Alexander Morton, on the A71 near Darvel, East Ayrshire, Scotland. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/a-stone-plaque-commemorating-the-hand-loom-weaving-industry-on-the-monument-to-alexander-morton-on-the-a71-near-darvel-east-ayrshire-scotland-image426796001.htmlRF2FPA6J9–A stone plaque commemorating the hand loom weaving industry on the monument to Alexander Morton, on the A71 near Darvel, East Ayrshire, Scotland.

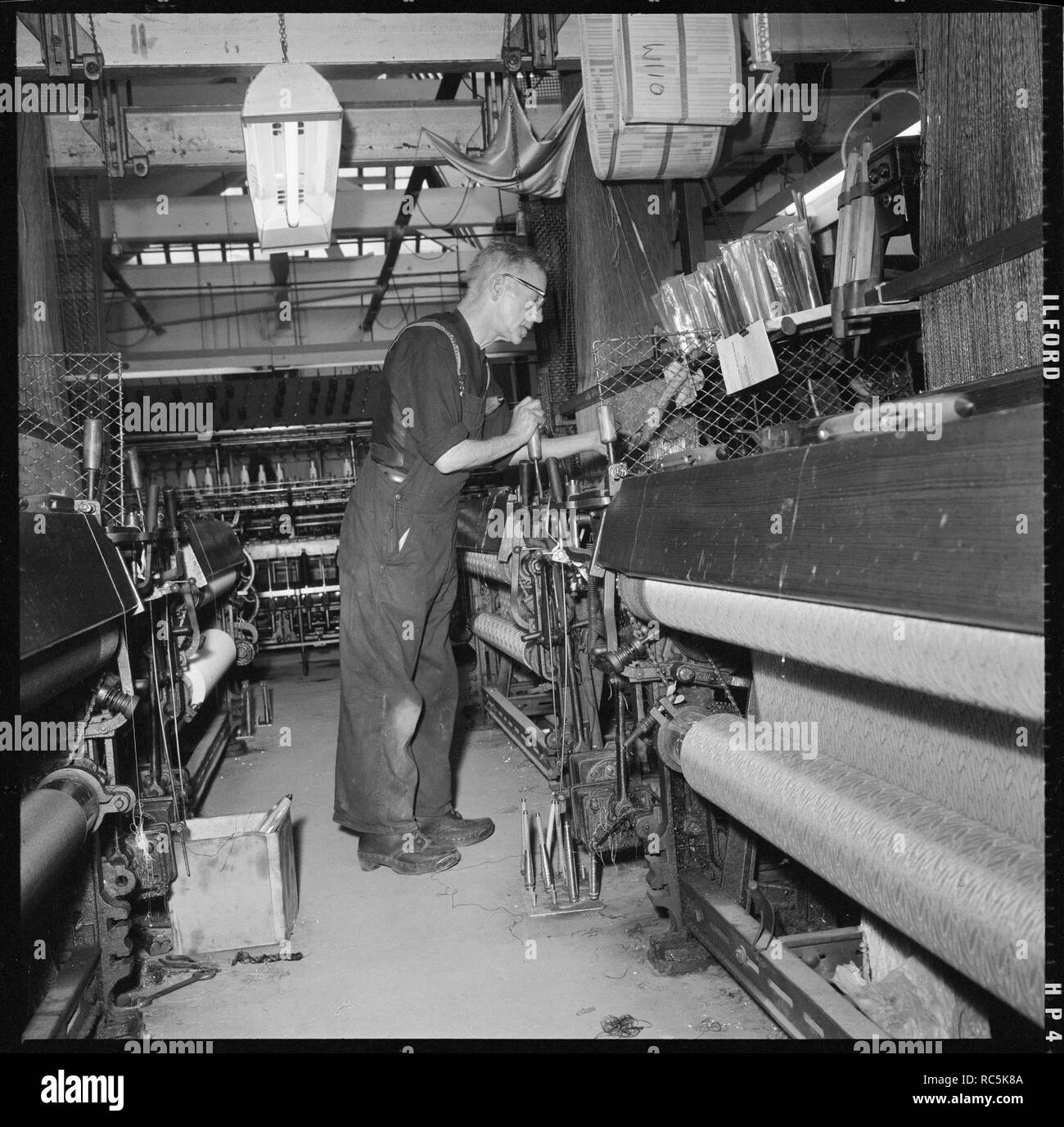

Weaver operating a Jacquard power loom, 1966-1974. Creator: Eileen Deste. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/weaver-operating-a-jacquard-power-loom-1966-1974-creator-eileen-deste-image231235546.html

Weaver operating a Jacquard power loom, 1966-1974. Creator: Eileen Deste. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/weaver-operating-a-jacquard-power-loom-1966-1974-creator-eileen-deste-image231235546.htmlRMRC5K8A–Weaver operating a Jacquard power loom, 1966-1974. Creator: Eileen Deste.

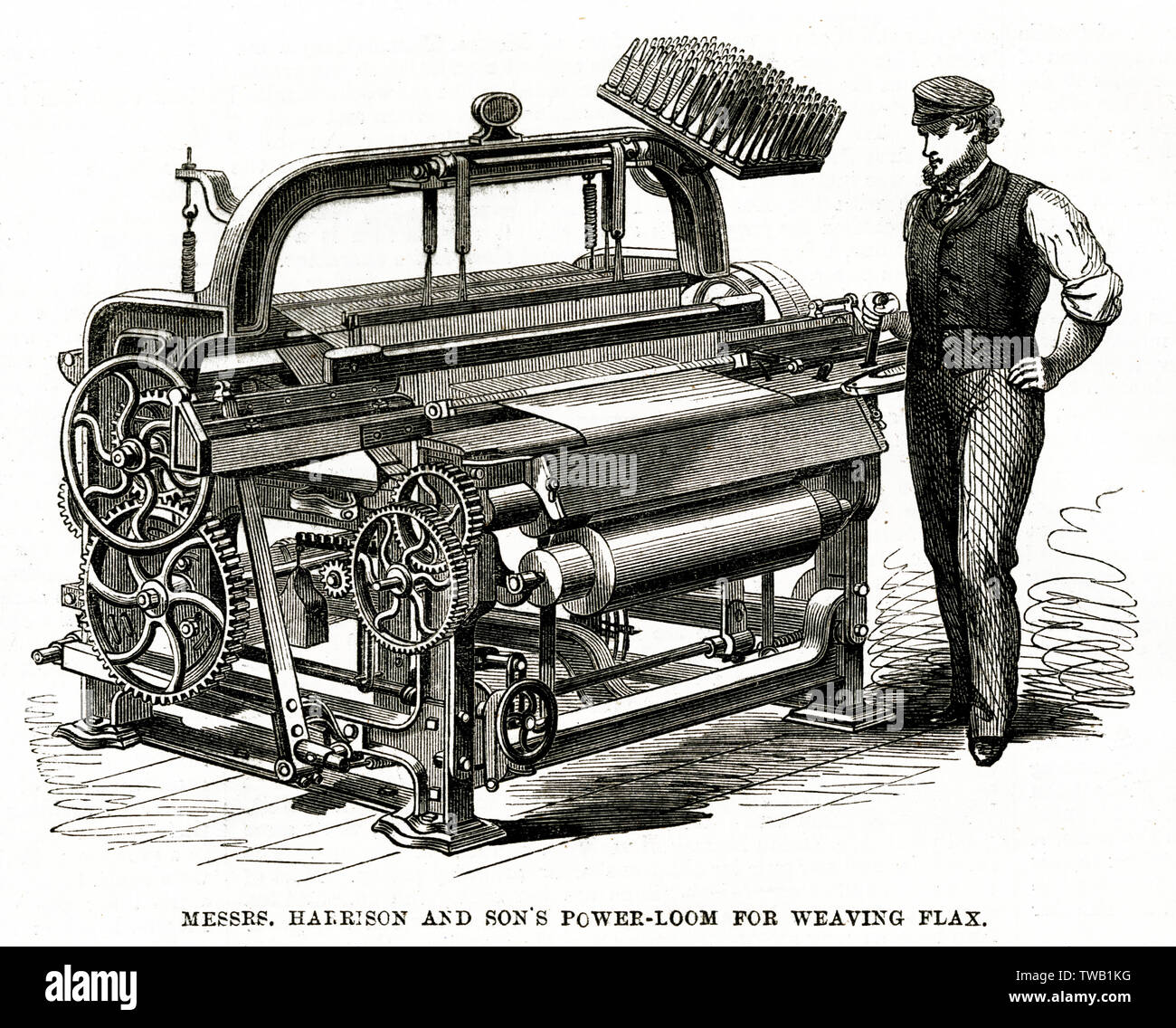

Harrison & Son's power-loom for weaving flax. Date: 1862 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/harrison-amp-sons-power-loom-for-weaving-flax-date-1862-image256554356.html

Harrison & Son's power-loom for weaving flax. Date: 1862 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/harrison-amp-sons-power-loom-for-weaving-flax-date-1862-image256554356.htmlRMTWB1KG–Harrison & Son's power-loom for weaving flax. Date: 1862

1950s, historical, Irish female operator working on her own monitoring a number of mechanised power looms for weaving cloth, Northern Ireland. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/1950s-historical-irish-female-operator-working-on-her-own-monitoring-image159441098.html

1950s, historical, Irish female operator working on her own monitoring a number of mechanised power looms for weaving cloth, Northern Ireland. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/1950s-historical-irish-female-operator-working-on-her-own-monitoring-image159441098.htmlRMK7B4MX–1950s, historical, Irish female operator working on her own monitoring a number of mechanised power looms for weaving cloth, Northern Ireland.

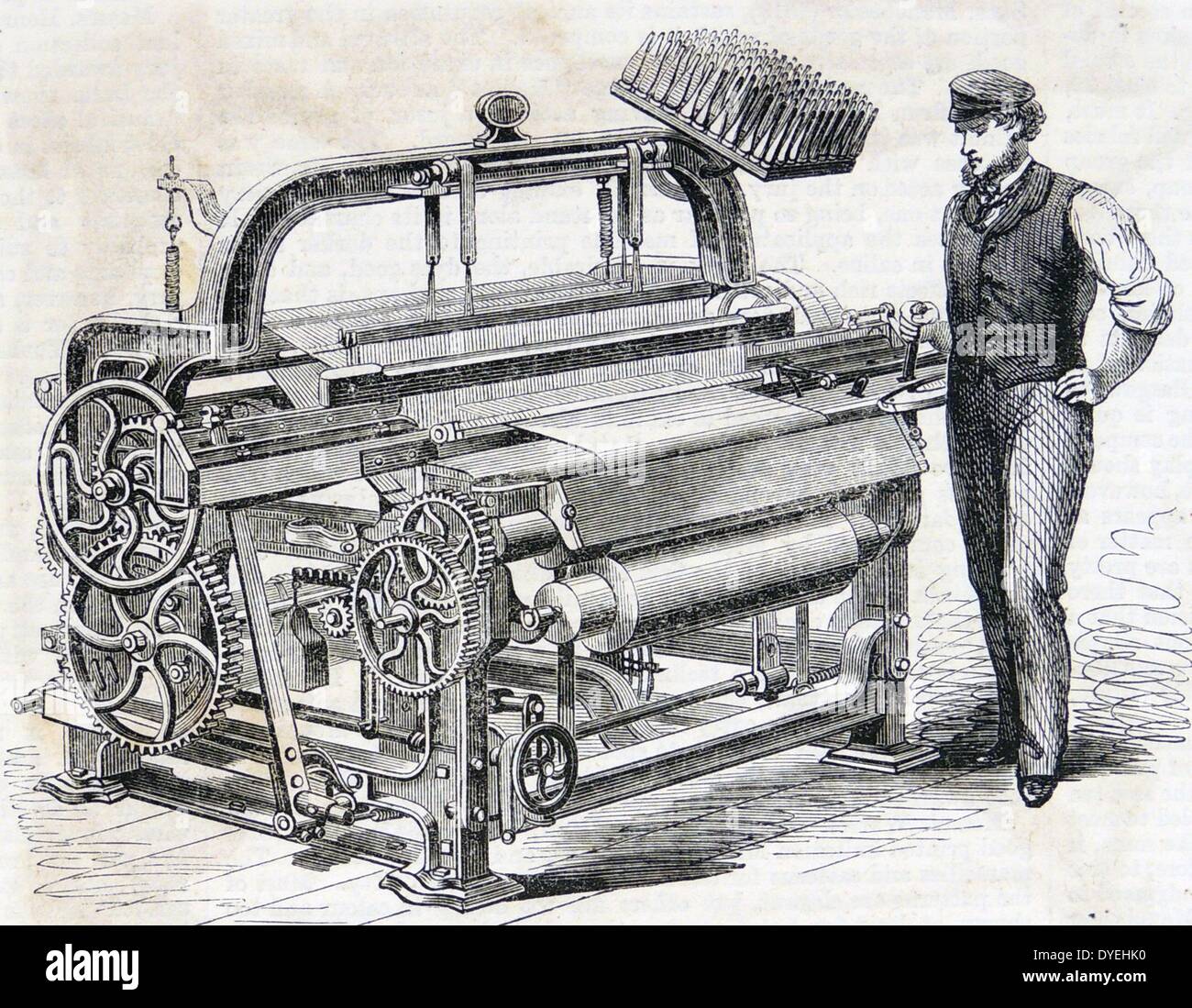

Harrison & Son's power loom for weaving flax (linen). Engraving, London, 1862. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/harrison-sons-power-loom-for-weaving-flax-linen-engraving-london-1862-image68548004.html

Harrison & Son's power loom for weaving flax (linen). Engraving, London, 1862. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/harrison-sons-power-loom-for-weaving-flax-linen-engraving-london-1862-image68548004.htmlRMDYEHK0–Harrison & Son's power loom for weaving flax (linen). Engraving, London, 1862.

Portrait of Edmund Cartwright, 1743 - 1823, a Church of England minister, inventor of the power loom for mechanical spinning, Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/portrait-of-edmund-cartwright-1743-1823-a-church-of-england-minister-image63069885.html

Portrait of Edmund Cartwright, 1743 - 1823, a Church of England minister, inventor of the power loom for mechanical spinning, Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/portrait-of-edmund-cartwright-1743-1823-a-church-of-england-minister-image63069885.htmlRMDJH27W–Portrait of Edmund Cartwright, 1743 - 1823, a Church of England minister, inventor of the power loom for mechanical spinning,

Weaving shed fitted with Jacquard power looms. Swags of punched cards carrying pattern being woven are at right and above each loom. Illustration Paris c1880 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-weaving-shed-fitted-with-jacquard-power-looms-swags-of-punched-cards-57308675.html

Weaving shed fitted with Jacquard power looms. Swags of punched cards carrying pattern being woven are at right and above each loom. Illustration Paris c1880 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-weaving-shed-fitted-with-jacquard-power-looms-swags-of-punched-cards-57308675.htmlRMD96HPB–Weaving shed fitted with Jacquard power looms. Swags of punched cards carrying pattern being woven are at right and above each loom. Illustration Paris c1880

Weaving Loom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-weaving-loom-92967434.html

Weaving Loom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-weaving-loom-92967434.htmlRFFB70WE–Weaving Loom

jacquard power looms loom stuff manufacture shuttle reed heddles war beam Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-jacquard-power-looms-loom-stuff-manufacture-shuttle-reed-heddles-war-39707726.html

jacquard power looms loom stuff manufacture shuttle reed heddles war beam Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-jacquard-power-looms-loom-stuff-manufacture-shuttle-reed-heddles-war-39707726.htmlRFC8GRH2–jacquard power looms loom stuff manufacture shuttle reed heddles war beam

Closeup Detail of cog wheel winding mechanism on wooden hand weaving loom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/closeup-detail-of-cog-wheel-winding-mechanism-on-wooden-hand-weaving-loom-image260114743.html

Closeup Detail of cog wheel winding mechanism on wooden hand weaving loom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/closeup-detail-of-cog-wheel-winding-mechanism-on-wooden-hand-weaving-loom-image260114743.htmlRFW35707–Closeup Detail of cog wheel winding mechanism on wooden hand weaving loom

. English: William Radcliffe (1761–1842) was a British inventor and author of the essay Origin of the New System of Manufacture, Commonly Called Power loom Weaving. 1825. Unknown 565 William Radcliffe Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/english-william-radcliffe-17611842-was-a-british-inventor-and-author-of-the-essay-origin-of-the-new-system-of-manufacture-commonly-called-power-loom-weaving-1825-unknown-565-william-radcliffe-image188767689.html

. English: William Radcliffe (1761–1842) was a British inventor and author of the essay Origin of the New System of Manufacture, Commonly Called Power loom Weaving. 1825. Unknown 565 William Radcliffe Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/english-william-radcliffe-17611842-was-a-british-inventor-and-author-of-the-essay-origin-of-the-new-system-of-manufacture-commonly-called-power-loom-weaving-1825-unknown-565-william-radcliffe-image188767689.htmlRMMY3335–. English: William Radcliffe (1761–1842) was a British inventor and author of the essay Origin of the New System of Manufacture, Commonly Called Power loom Weaving. 1825. Unknown 565 William Radcliffe

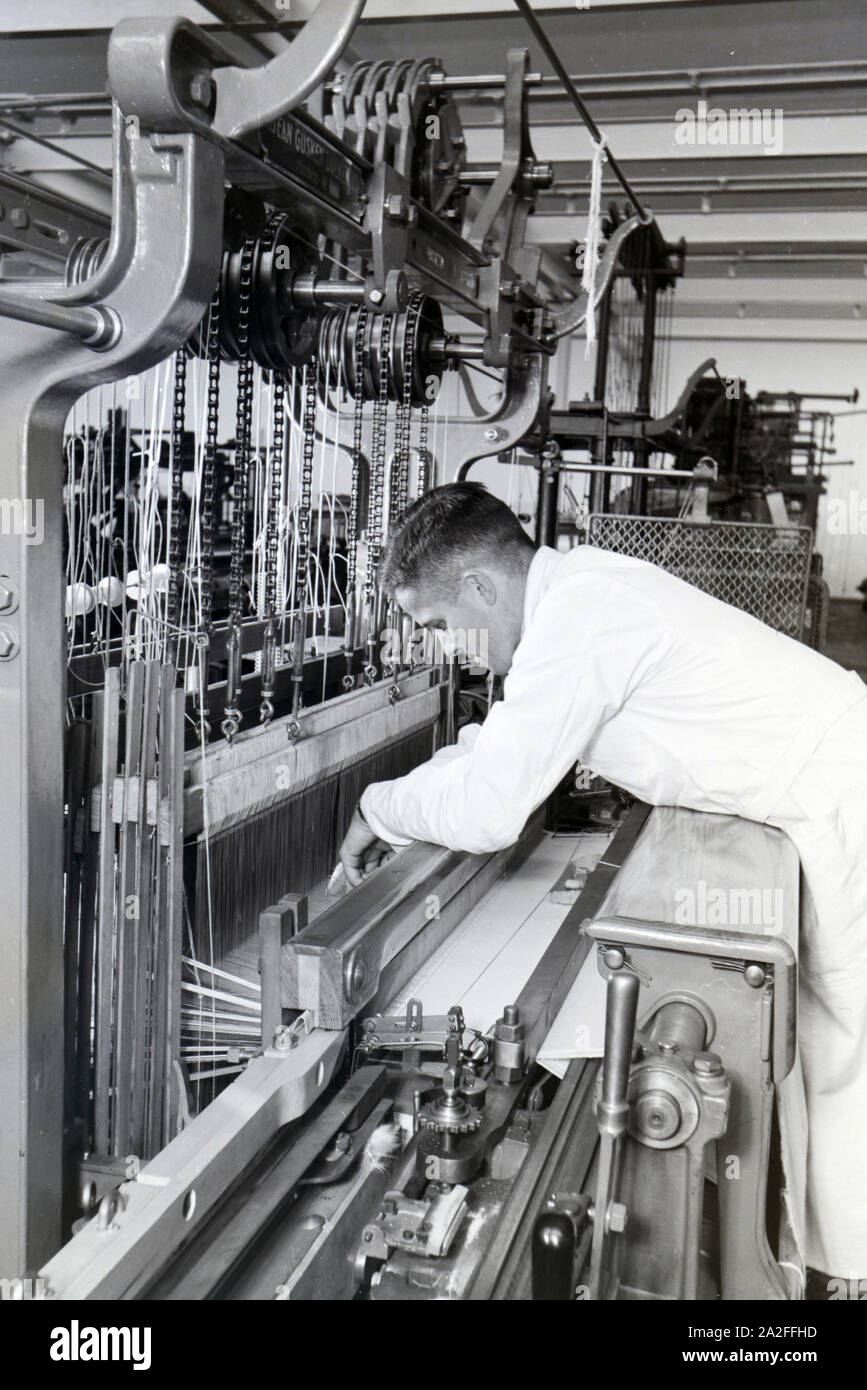

Ein Angestellter einer Textilfirma in Krefeld justiert das Garn in der großen Webmaschine, Deutschland 1930er Jahre. An employee in a textile company in Krefeld adjusting the yarn in the big power loom, Germany 1930s. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/ein-angestellter-einer-textilfirma-in-krefeld-justiert-das-garn-in-der-groen-webmaschine-deutschland-1930er-jahre-an-employee-in-a-textile-company-in-krefeld-adjusting-the-yarn-in-the-big-power-loom-germany-1930s-image328567833.html

Ein Angestellter einer Textilfirma in Krefeld justiert das Garn in der großen Webmaschine, Deutschland 1930er Jahre. An employee in a textile company in Krefeld adjusting the yarn in the big power loom, Germany 1930s. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/ein-angestellter-einer-textilfirma-in-krefeld-justiert-das-garn-in-der-groen-webmaschine-deutschland-1930er-jahre-an-employee-in-a-textile-company-in-krefeld-adjusting-the-yarn-in-the-big-power-loom-germany-1930s-image328567833.htmlRM2A2FFHD–Ein Angestellter einer Textilfirma in Krefeld justiert das Garn in der großen Webmaschine, Deutschland 1930er Jahre. An employee in a textile company in Krefeld adjusting the yarn in the big power loom, Germany 1930s.

Weaving Hampshire tweeds at an old mill that stood idle for a hundred years . An old mill at Fordingbridge in the New Forest , Hampshire , that has stood idle for 100 years has come to life again . It is weaving into tweeds wool from the flocks that graze on Salisbury Plain and it is hoped to make Hampshire tweeds as famous as the Harris variety . The machines for which the ancient sluices are providing power have been brought down from Westmorland and expert woolmen have been brought from the North also . The new mill owner is Major C T Napier . Photo shows ; The manager explaining the proces Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/weaving-hampshire-tweeds-at-an-old-mill-that-stood-idle-for-a-hundred-years-an-old-mill-at-fordingbridge-in-the-new-forest-hampshire-that-has-stood-idle-for-100-years-has-come-to-life-again-it-is-weaving-into-tweeds-wool-from-the-flocks-that-graze-on-salisbury-plain-and-it-is-hoped-to-make-hampshire-tweeds-as-famous-as-the-harris-variety-the-machines-for-which-the-ancient-sluices-are-providing-power-have-been-brought-down-from-westmorland-and-expert-woolmen-have-been-brought-from-the-north-also-the-new-mill-owner-is-major-c-t-napier-photo-shows-the-manager-explaining-the-proces-image359646700.html

Weaving Hampshire tweeds at an old mill that stood idle for a hundred years . An old mill at Fordingbridge in the New Forest , Hampshire , that has stood idle for 100 years has come to life again . It is weaving into tweeds wool from the flocks that graze on Salisbury Plain and it is hoped to make Hampshire tweeds as famous as the Harris variety . The machines for which the ancient sluices are providing power have been brought down from Westmorland and expert woolmen have been brought from the North also . The new mill owner is Major C T Napier . Photo shows ; The manager explaining the proces Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/weaving-hampshire-tweeds-at-an-old-mill-that-stood-idle-for-a-hundred-years-an-old-mill-at-fordingbridge-in-the-new-forest-hampshire-that-has-stood-idle-for-100-years-has-come-to-life-again-it-is-weaving-into-tweeds-wool-from-the-flocks-that-graze-on-salisbury-plain-and-it-is-hoped-to-make-hampshire-tweeds-as-famous-as-the-harris-variety-the-machines-for-which-the-ancient-sluices-are-providing-power-have-been-brought-down-from-westmorland-and-expert-woolmen-have-been-brought-from-the-north-also-the-new-mill-owner-is-major-c-t-napier-photo-shows-the-manager-explaining-the-proces-image359646700.htmlRM2BW3910–Weaving Hampshire tweeds at an old mill that stood idle for a hundred years . An old mill at Fordingbridge in the New Forest , Hampshire , that has stood idle for 100 years has come to life again . It is weaving into tweeds wool from the flocks that graze on Salisbury Plain and it is hoped to make Hampshire tweeds as famous as the Harris variety . The machines for which the ancient sluices are providing power have been brought down from Westmorland and expert woolmen have been brought from the North also . The new mill owner is Major C T Napier . Photo shows ; The manager explaining the proces

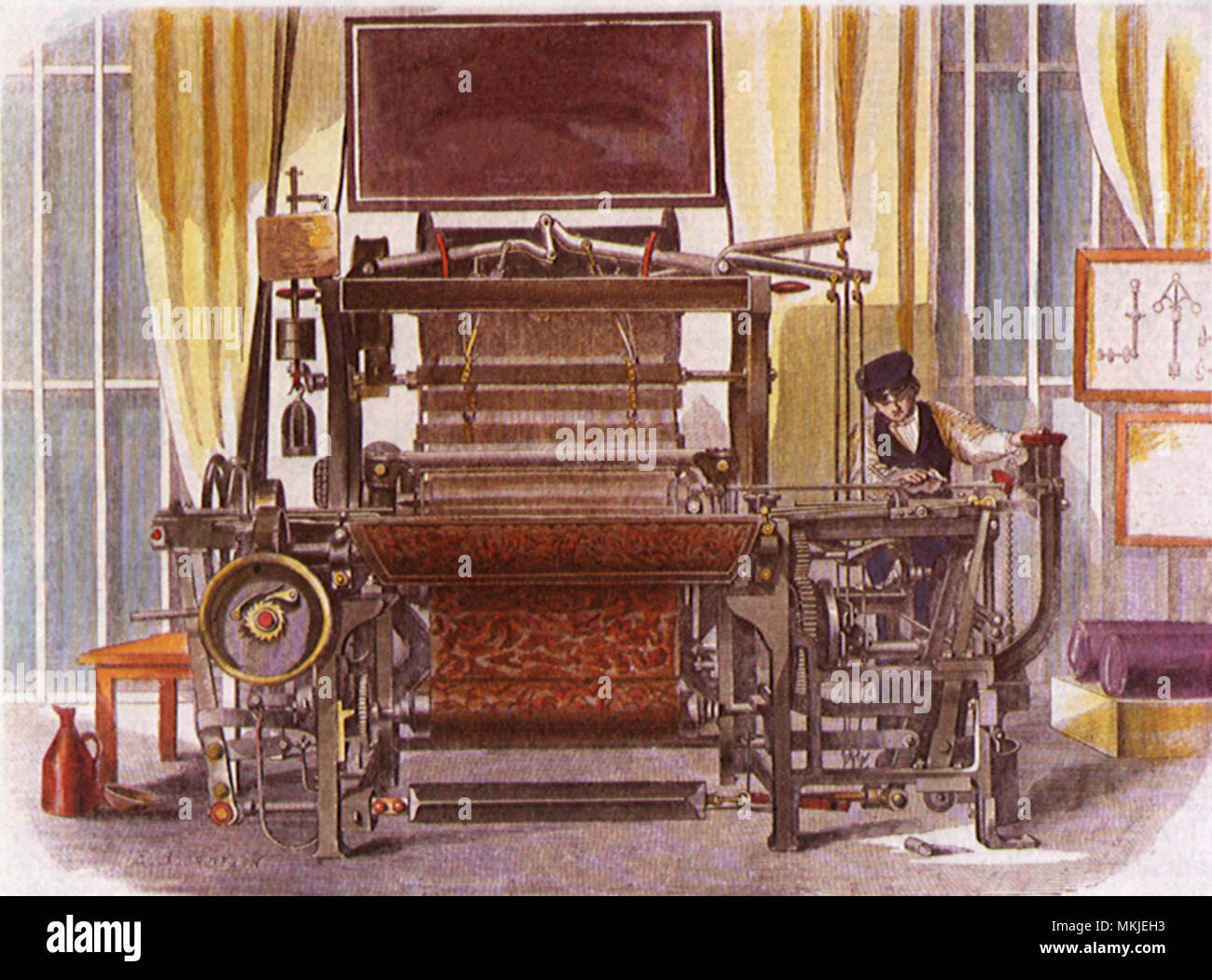

Textile Loom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/textile-loom-image184188735.html

Textile Loom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/textile-loom-image184188735.htmlRMMKJEH3–Textile Loom

TUER'S CARPET LOOM 1862 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-tuers-carpet-loom-1862-105285232.html

TUER'S CARPET LOOM 1862 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-tuers-carpet-loom-1862-105285232.htmlRMG384AT–TUER'S CARPET LOOM 1862

Woman operating a power loom for weaving cotton, c1840. Artist: Unknown Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/woman-operating-a-power-loom-for-weaving-cotton-c1840-artist-unknown-image262738604.html

Woman operating a power loom for weaving cotton, c1840. Artist: Unknown Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/woman-operating-a-power-loom-for-weaving-cotton-c1840-artist-unknown-image262738604.htmlRMW7CNNG–Woman operating a power loom for weaving cotton, c1840. Artist: Unknown

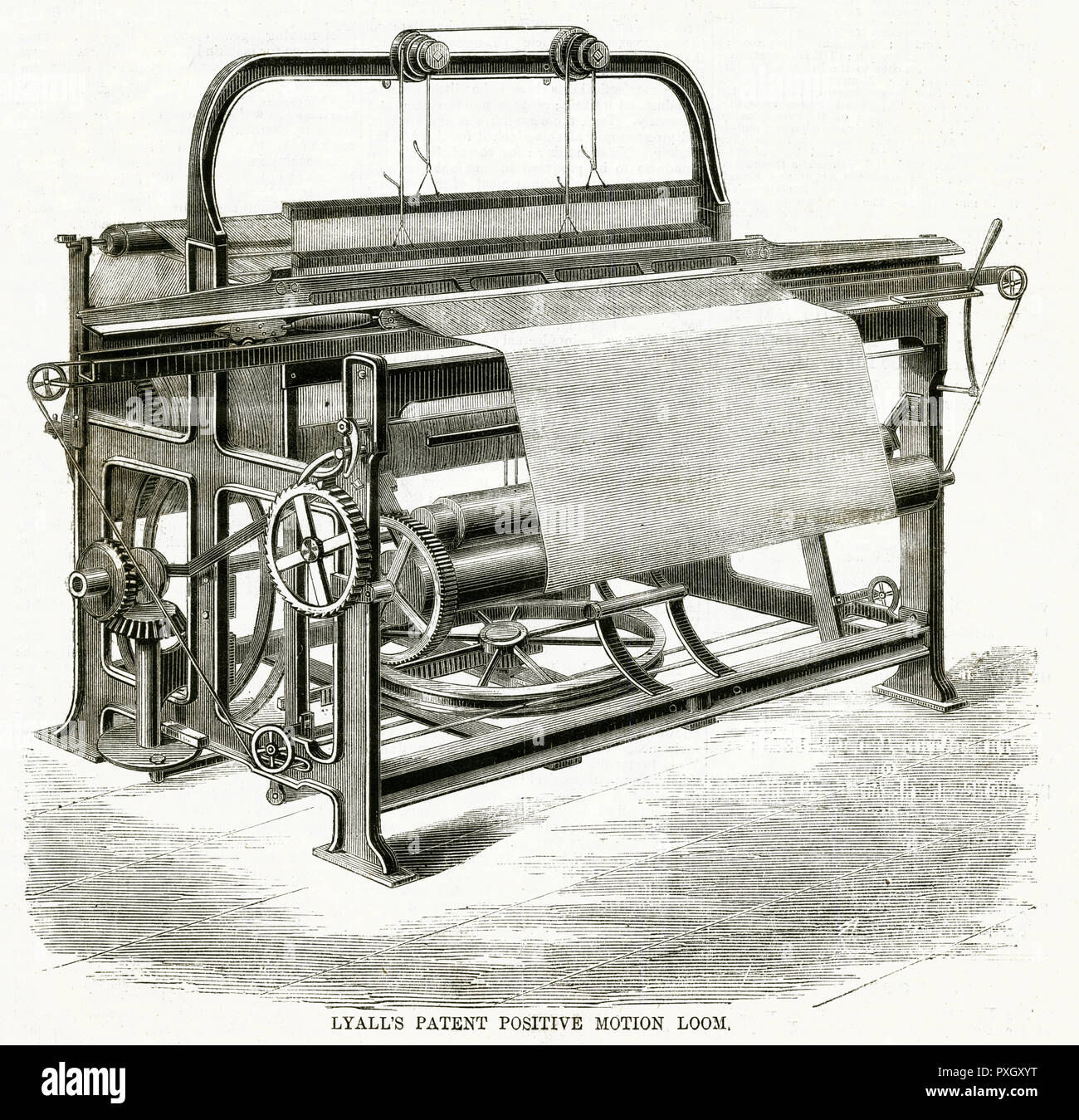

Lyall's patent postive motion loom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/lyalls-patent-postive-motion-loom-image222877868.html

Lyall's patent postive motion loom Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/lyalls-patent-postive-motion-loom-image222877868.htmlRMPXGXYT–Lyall's patent postive motion loom

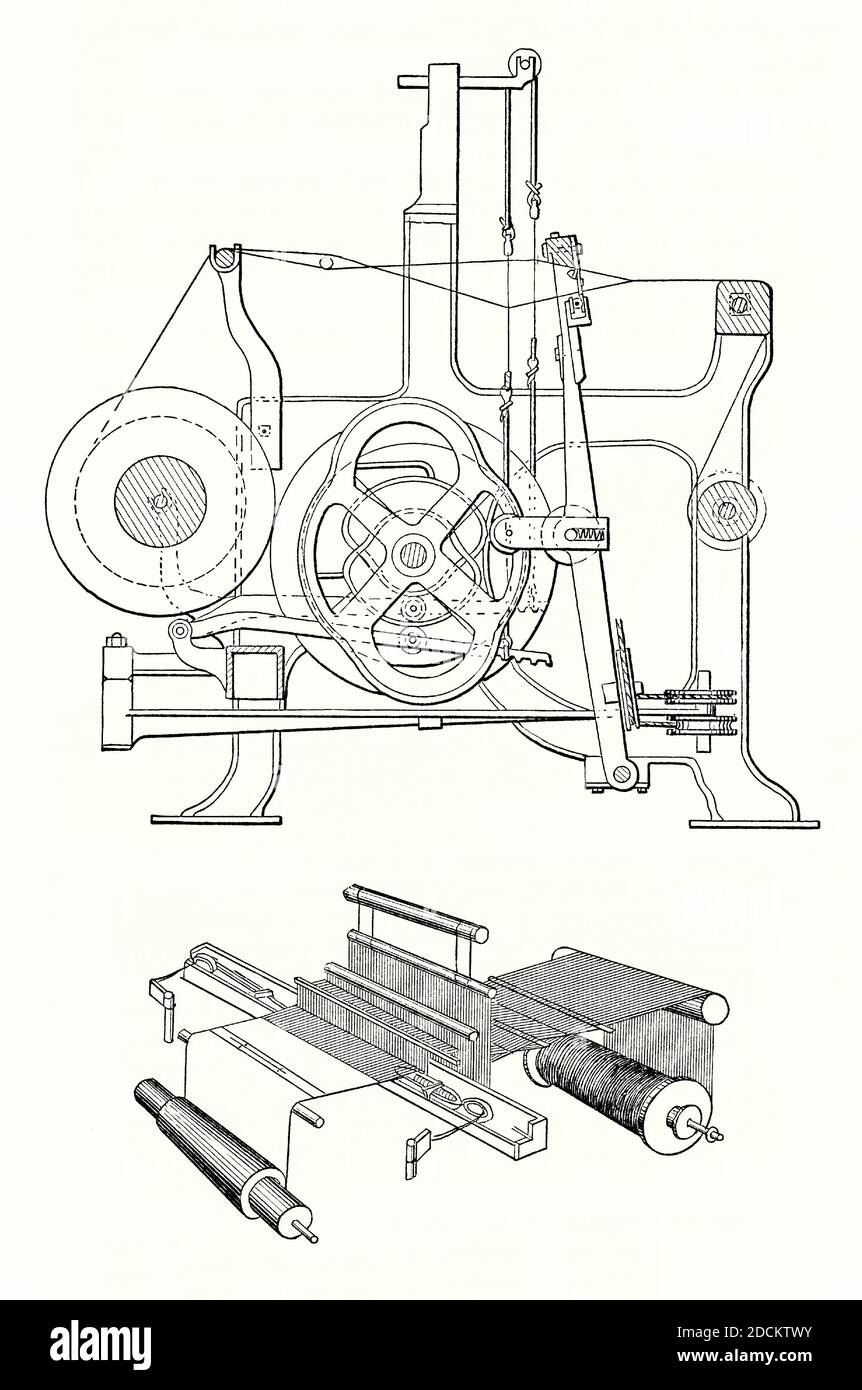

An old engraving of two views of the workings of a power loom. It is from a Victorian mechanical engineering book of the 1880s. A loom is a device used to weave cloth. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. Englishman Edmund Cartwright built and patented a power loom in 1785, and it was this that was adopted by cotton industry. Water and/or steam provided the power needed to run the looms, usually by belt drives to the individual looms. The loom shape and its mechanics varied enormously Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-two-views-of-the-workings-of-a-power-loom-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-a-loom-is-a-device-used-to-weave-cloth-the-basic-purpose-of-any-loom-is-to-hold-the-warp-threads-under-tension-to-facilitate-the-interweaving-of-the-weft-threads-englishman-edmund-cartwright-built-and-patented-a-power-loom-in-1785-and-it-was-this-that-was-adopted-by-cotton-industry-water-andor-steam-provided-the-power-needed-to-run-the-looms-usually-by-belt-drives-to-the-individual-looms-the-loom-shape-and-its-mechanics-varied-enormously-image386440599.html

An old engraving of two views of the workings of a power loom. It is from a Victorian mechanical engineering book of the 1880s. A loom is a device used to weave cloth. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. Englishman Edmund Cartwright built and patented a power loom in 1785, and it was this that was adopted by cotton industry. Water and/or steam provided the power needed to run the looms, usually by belt drives to the individual looms. The loom shape and its mechanics varied enormously Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-two-views-of-the-workings-of-a-power-loom-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-a-loom-is-a-device-used-to-weave-cloth-the-basic-purpose-of-any-loom-is-to-hold-the-warp-threads-under-tension-to-facilitate-the-interweaving-of-the-weft-threads-englishman-edmund-cartwright-built-and-patented-a-power-loom-in-1785-and-it-was-this-that-was-adopted-by-cotton-industry-water-andor-steam-provided-the-power-needed-to-run-the-looms-usually-by-belt-drives-to-the-individual-looms-the-loom-shape-and-its-mechanics-varied-enormously-image386440599.htmlRM2DCKTWY–An old engraving of two views of the workings of a power loom. It is from a Victorian mechanical engineering book of the 1880s. A loom is a device used to weave cloth. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. Englishman Edmund Cartwright built and patented a power loom in 1785, and it was this that was adopted by cotton industry. Water and/or steam provided the power needed to run the looms, usually by belt drives to the individual looms. The loom shape and its mechanics varied enormously

Syria: Carpet weaving in the Souq-al-Hamadiyeh, Damascus. Damascus was first settled in the 2nd millennium BCE, it was chosen as the capital of the Umayyad Caliphate from 661 to 750. After the victory of the Abbasid dynasty, the seat of Islamic power was moved to Baghdad. Damascus saw a political decline throughout the Abbasid era, only to regain significant importance in the Ayyubid and Mamluk periods. During Ottoman rule, the city decayed completely while maintaining a certain cultural prestige. Today, it is the seat of the central government and all of the government ministries. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/syria-carpet-weaving-in-the-souq-al-hamadiyeh-damascus-damascus-was-first-settled-in-the-2nd-millennium-bce-it-was-chosen-as-the-capital-of-the-umayyad-caliphate-from-661-to-750-after-the-victory-of-the-abbasid-dynasty-the-seat-of-islamic-power-was-moved-to-baghdad-damascus-saw-a-political-decline-throughout-the-abbasid-era-only-to-regain-significant-importance-in-the-ayyubid-and-mamluk-periods-during-ottoman-rule-the-city-decayed-completely-while-maintaining-a-certain-cultural-prestige-today-it-is-the-seat-of-the-central-government-and-all-of-the-government-ministries-image344248772.html

Syria: Carpet weaving in the Souq-al-Hamadiyeh, Damascus. Damascus was first settled in the 2nd millennium BCE, it was chosen as the capital of the Umayyad Caliphate from 661 to 750. After the victory of the Abbasid dynasty, the seat of Islamic power was moved to Baghdad. Damascus saw a political decline throughout the Abbasid era, only to regain significant importance in the Ayyubid and Mamluk periods. During Ottoman rule, the city decayed completely while maintaining a certain cultural prestige. Today, it is the seat of the central government and all of the government ministries. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/syria-carpet-weaving-in-the-souq-al-hamadiyeh-damascus-damascus-was-first-settled-in-the-2nd-millennium-bce-it-was-chosen-as-the-capital-of-the-umayyad-caliphate-from-661-to-750-after-the-victory-of-the-abbasid-dynasty-the-seat-of-islamic-power-was-moved-to-baghdad-damascus-saw-a-political-decline-throughout-the-abbasid-era-only-to-regain-significant-importance-in-the-ayyubid-and-mamluk-periods-during-ottoman-rule-the-city-decayed-completely-while-maintaining-a-certain-cultural-prestige-today-it-is-the-seat-of-the-central-government-and-all-of-the-government-ministries-image344248772.htmlRM2B01TR0–Syria: Carpet weaving in the Souq-al-Hamadiyeh, Damascus. Damascus was first settled in the 2nd millennium BCE, it was chosen as the capital of the Umayyad Caliphate from 661 to 750. After the victory of the Abbasid dynasty, the seat of Islamic power was moved to Baghdad. Damascus saw a political decline throughout the Abbasid era, only to regain significant importance in the Ayyubid and Mamluk periods. During Ottoman rule, the city decayed completely while maintaining a certain cultural prestige. Today, it is the seat of the central government and all of the government ministries.

An old engraving of a warping mill (left), a winding machine (centre) and a power loom (right) used in producing cotton in the 1800s. It is from a Victorian mechanical engineering book of the 1880s. A loom is a device used to weave cloth. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. Englishman Edmund Cartwright built and patented a power loom in 1785, and it was this that was adopted by cotton industry. Water and/or steam provided the power needed to run the looms, usually by belt drives to the individual looms. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-warping-mill-left-a-winding-machine-centre-and-a-power-loom-right-used-in-producing-cotton-in-the-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-a-loom-is-a-device-used-to-weave-cloth-the-basic-purpose-of-any-loom-is-to-hold-the-warp-threads-under-tension-to-facilitate-the-interweaving-of-the-weft-threads-englishman-edmund-cartwright-built-and-patented-a-power-loom-in-1785-and-it-was-this-that-was-adopted-by-cotton-industry-water-andor-steam-provided-the-power-needed-to-run-the-looms-usually-by-belt-drives-to-the-individual-looms-image559321655.html

An old engraving of a warping mill (left), a winding machine (centre) and a power loom (right) used in producing cotton in the 1800s. It is from a Victorian mechanical engineering book of the 1880s. A loom is a device used to weave cloth. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. Englishman Edmund Cartwright built and patented a power loom in 1785, and it was this that was adopted by cotton industry. Water and/or steam provided the power needed to run the looms, usually by belt drives to the individual looms. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-old-engraving-of-a-warping-mill-left-a-winding-machine-centre-and-a-power-loom-right-used-in-producing-cotton-in-the-1800s-it-is-from-a-victorian-mechanical-engineering-book-of-the-1880s-a-loom-is-a-device-used-to-weave-cloth-the-basic-purpose-of-any-loom-is-to-hold-the-warp-threads-under-tension-to-facilitate-the-interweaving-of-the-weft-threads-englishman-edmund-cartwright-built-and-patented-a-power-loom-in-1785-and-it-was-this-that-was-adopted-by-cotton-industry-water-andor-steam-provided-the-power-needed-to-run-the-looms-usually-by-belt-drives-to-the-individual-looms-image559321655.htmlRM2RDY8DB–An old engraving of a warping mill (left), a winding machine (centre) and a power loom (right) used in producing cotton in the 1800s. It is from a Victorian mechanical engineering book of the 1880s. A loom is a device used to weave cloth. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. Englishman Edmund Cartwright built and patented a power loom in 1785, and it was this that was adopted by cotton industry. Water and/or steam provided the power needed to run the looms, usually by belt drives to the individual looms.

Weaver preparing a shuttle for use in a power loom, 1966-1974. Creator: Eileen Deste. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/weaver-preparing-a-shuttle-for-use-in-a-power-loom-1966-1974-creator-eileen-deste-image231235563.html

Weaver preparing a shuttle for use in a power loom, 1966-1974. Creator: Eileen Deste. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/weaver-preparing-a-shuttle-for-use-in-a-power-loom-1966-1974-creator-eileen-deste-image231235563.htmlRMRC5K8Y–Weaver preparing a shuttle for use in a power loom, 1966-1974. Creator: Eileen Deste.

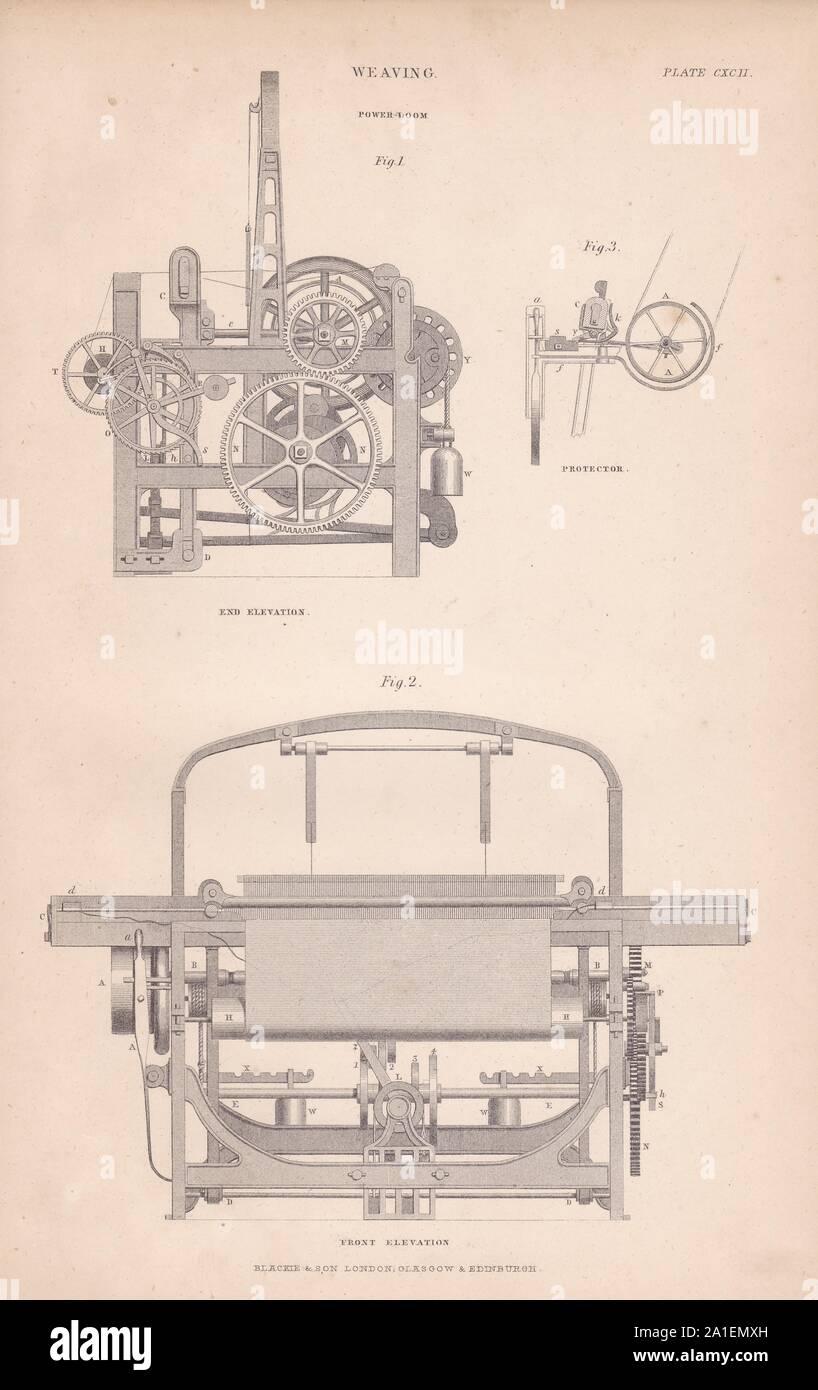

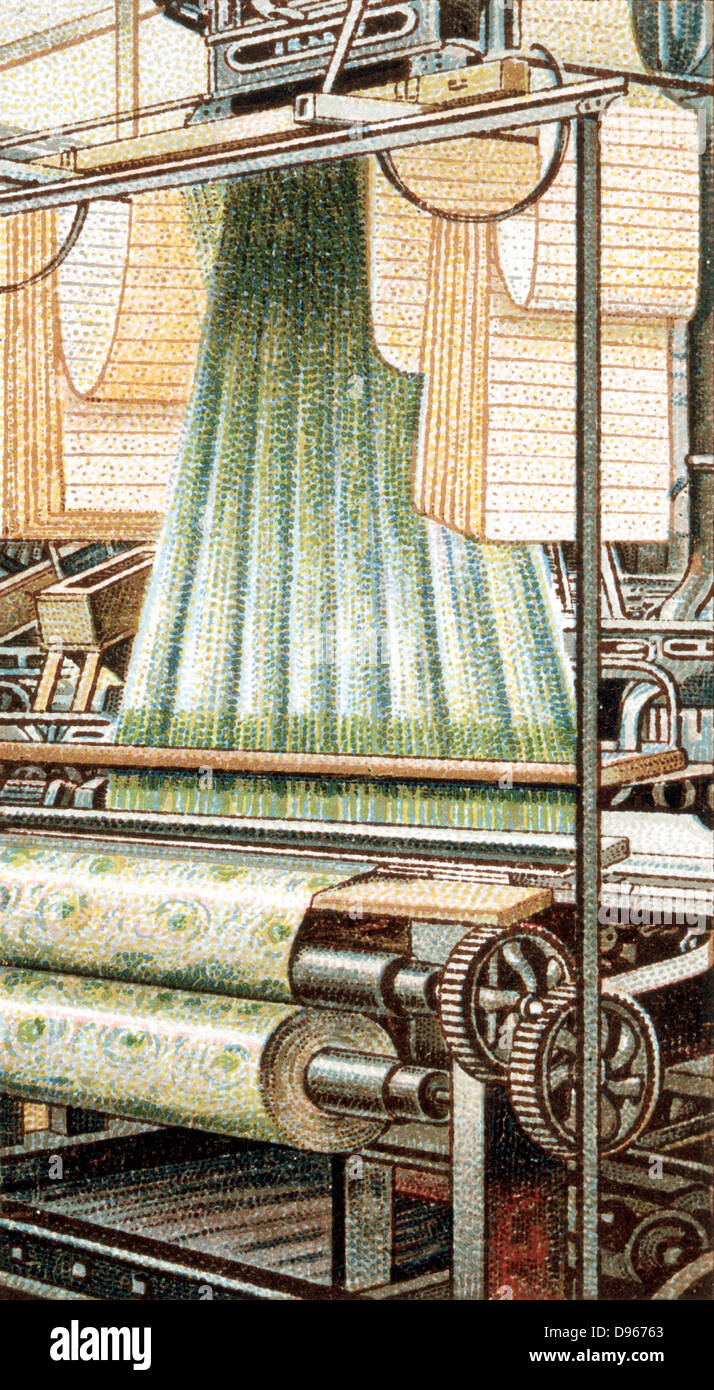

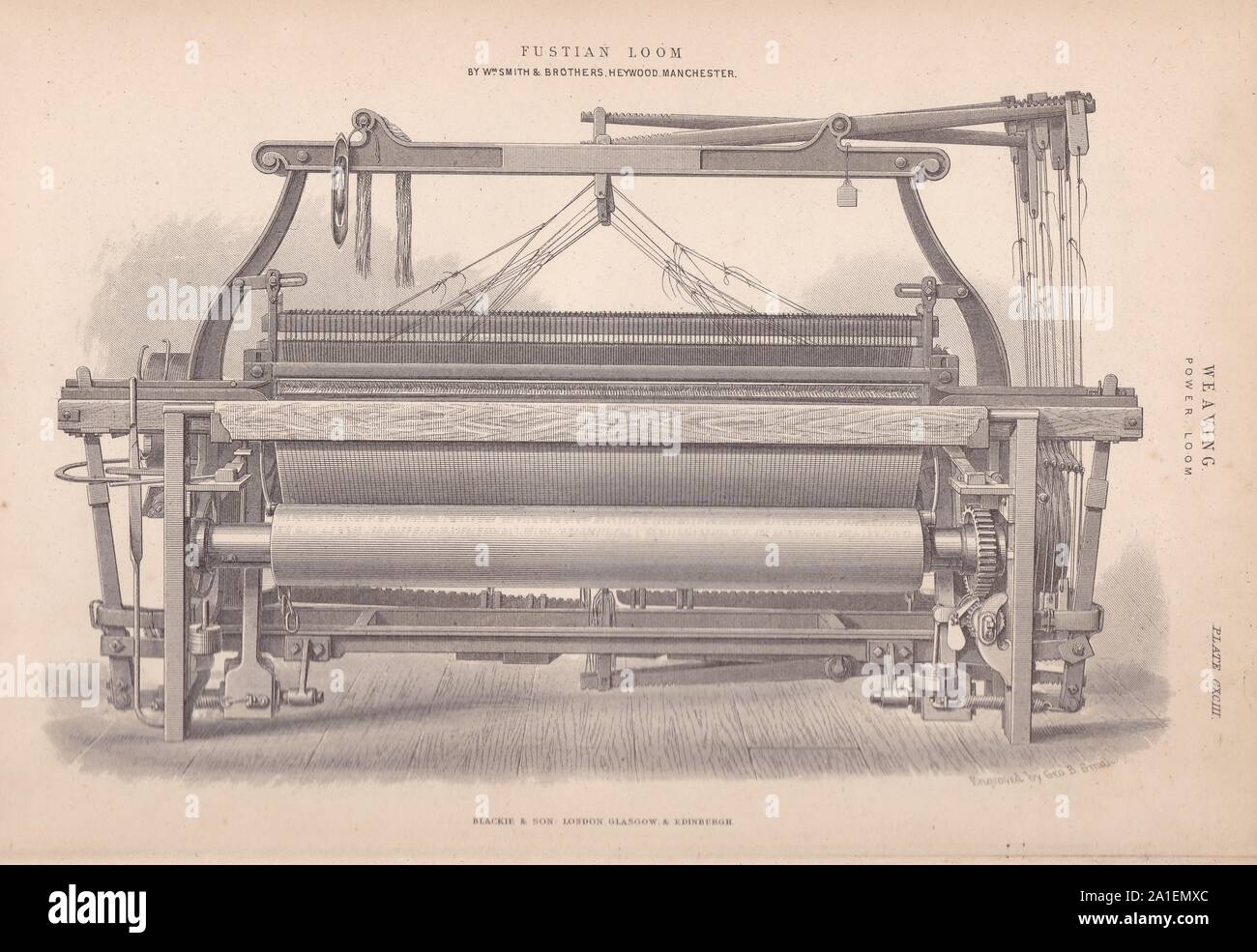

Book plate of Weaving - Power Loom. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/book-plate-of-weaving-power-loom-image327935401.html

Book plate of Weaving - Power Loom. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/book-plate-of-weaving-power-loom-image327935401.htmlRF2A1EMXH–Book plate of Weaving - Power Loom.

1950s, historical, a Irish female operator working at a textile factory, monitoring a number of mechanised power looms for weaving linen cloth, Northern Ireland. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/1950s-historical-a-irish-female-operator-working-at-a-textile-factory-image159440952.html

1950s, historical, a Irish female operator working at a textile factory, monitoring a number of mechanised power looms for weaving linen cloth, Northern Ireland. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/1950s-historical-a-irish-female-operator-working-at-a-textile-factory-image159440952.htmlRMK7B4FM–1950s, historical, a Irish female operator working at a textile factory, monitoring a number of mechanised power looms for weaving linen cloth, Northern Ireland.

A loom in Alan Bush's house in Scoraig, in NW Scotland. Scoraig is one of the most remote communities on mainland Britain, Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/a-loom-in-alan-bushs-house-in-scoraig-in-nw-scotland-scoraig-is-one-image62792544.html

A loom in Alan Bush's house in Scoraig, in NW Scotland. Scoraig is one of the most remote communities on mainland Britain, Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/a-loom-in-alan-bushs-house-in-scoraig-in-nw-scotland-scoraig-is-one-image62792544.htmlRMDJ4CET–A loom in Alan Bush's house in Scoraig, in NW Scotland. Scoraig is one of the most remote communities on mainland Britain,

Girl weaving sari on handloom uttar pradesh India Asia Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/girl-weaving-sari-on-handloom-uttar-pradesh-india-asia-image62117076.html

Girl weaving sari on handloom uttar pradesh India Asia Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/girl-weaving-sari-on-handloom-uttar-pradesh-india-asia-image62117076.htmlRMDH1JY0–Girl weaving sari on handloom uttar pradesh India Asia

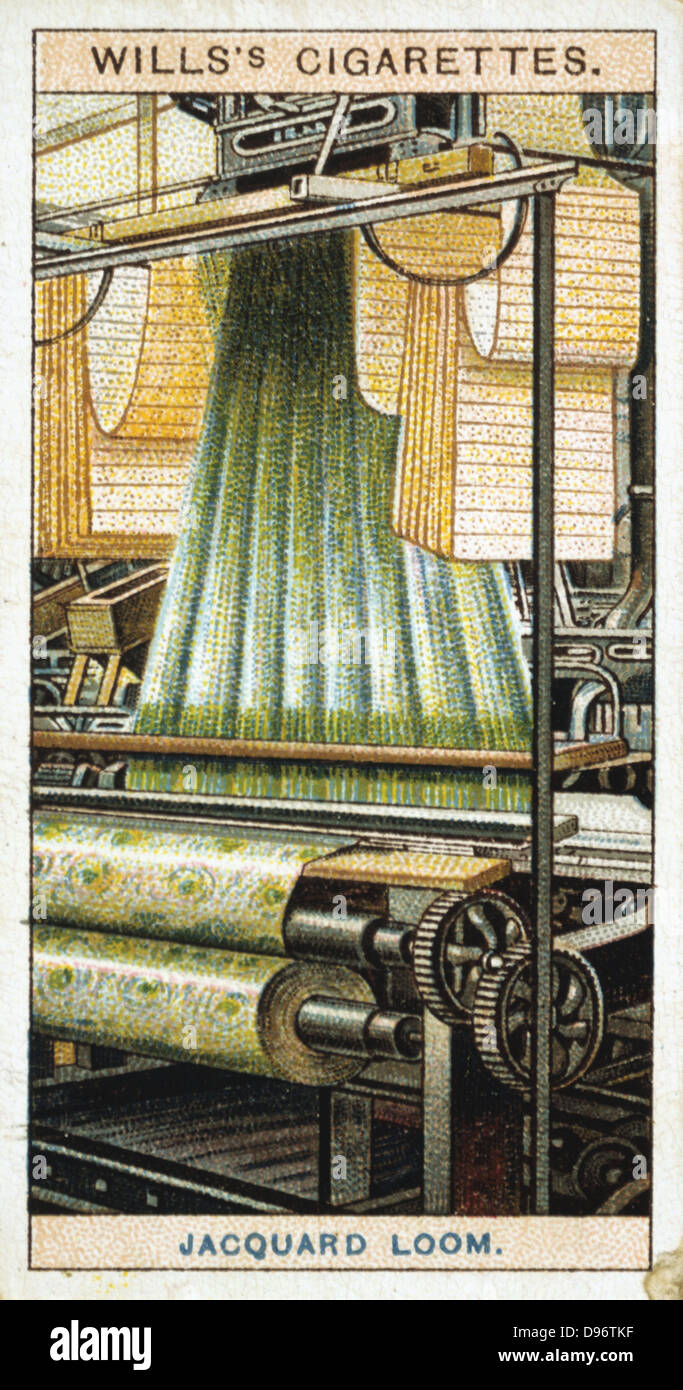

Jacquard power loom. In 1801 Joseph-Marie Jacquard (1752-1834) invented a method of weaving intricate patterns which were encoded on punched cards. The swags of punched cards carrying the pattern for this early 20th century power operated loom are clearly visible. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-jacquard-power-loom-in-1801-joseph-marie-jacquard-1752-1834-invented-57314083.html

Jacquard power loom. In 1801 Joseph-Marie Jacquard (1752-1834) invented a method of weaving intricate patterns which were encoded on punched cards. The swags of punched cards carrying the pattern for this early 20th century power operated loom are clearly visible. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-jacquard-power-loom-in-1801-joseph-marie-jacquard-1752-1834-invented-57314083.htmlRMD96TKF–Jacquard power loom. In 1801 Joseph-Marie Jacquard (1752-1834) invented a method of weaving intricate patterns which were encoded on punched cards. The swags of punched cards carrying the pattern for this early 20th century power operated loom are clearly visible.

The many ranks of looms in the weaving shed at Queen Street Mill in Burnley, seen in panoramic view. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-many-ranks-of-looms-in-the-weaving-shed-at-queen-street-mill-in-image66317049.html

The many ranks of looms in the weaving shed at Queen Street Mill in Burnley, seen in panoramic view. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/the-many-ranks-of-looms-in-the-weaving-shed-at-queen-street-mill-in-image66317049.htmlRMDRW021–The many ranks of looms in the weaving shed at Queen Street Mill in Burnley, seen in panoramic view.

An engraving depicting John Todd's power loom. Dated 19th century Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-engraving-depicting-john-todds-power-loom-dated-19th-century-image235215470.html

An engraving depicting John Todd's power loom. Dated 19th century Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-engraving-depicting-john-todds-power-loom-dated-19th-century-image235215470.htmlRMRJJYME–An engraving depicting John Todd's power loom. Dated 19th century

Weaving Weights Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-weaving-weights-92967433.html

Weaving Weights Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-weaving-weights-92967433.htmlRFFB70WD–Weaving Weights

. English: William Radcliffe (1761–1842) was a British inventor and author of the essay Origin of the New System of Manufacture, Commonly Called Power loom Weaving. 1825. Unknown 649 William Radcliffe Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/english-william-radcliffe-17611842-was-a-british-inventor-and-author-of-the-essay-origin-of-the-new-system-of-manufacture-commonly-called-power-loom-weaving-1825-unknown-649-william-radcliffe-image187516647.html

. English: William Radcliffe (1761–1842) was a British inventor and author of the essay Origin of the New System of Manufacture, Commonly Called Power loom Weaving. 1825. Unknown 649 William Radcliffe Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/english-william-radcliffe-17611842-was-a-british-inventor-and-author-of-the-essay-origin-of-the-new-system-of-manufacture-commonly-called-power-loom-weaving-1825-unknown-649-william-radcliffe-image187516647.htmlRMMW23B3–. English: William Radcliffe (1761–1842) was a British inventor and author of the essay Origin of the New System of Manufacture, Commonly Called Power loom Weaving. 1825. Unknown 649 William Radcliffe

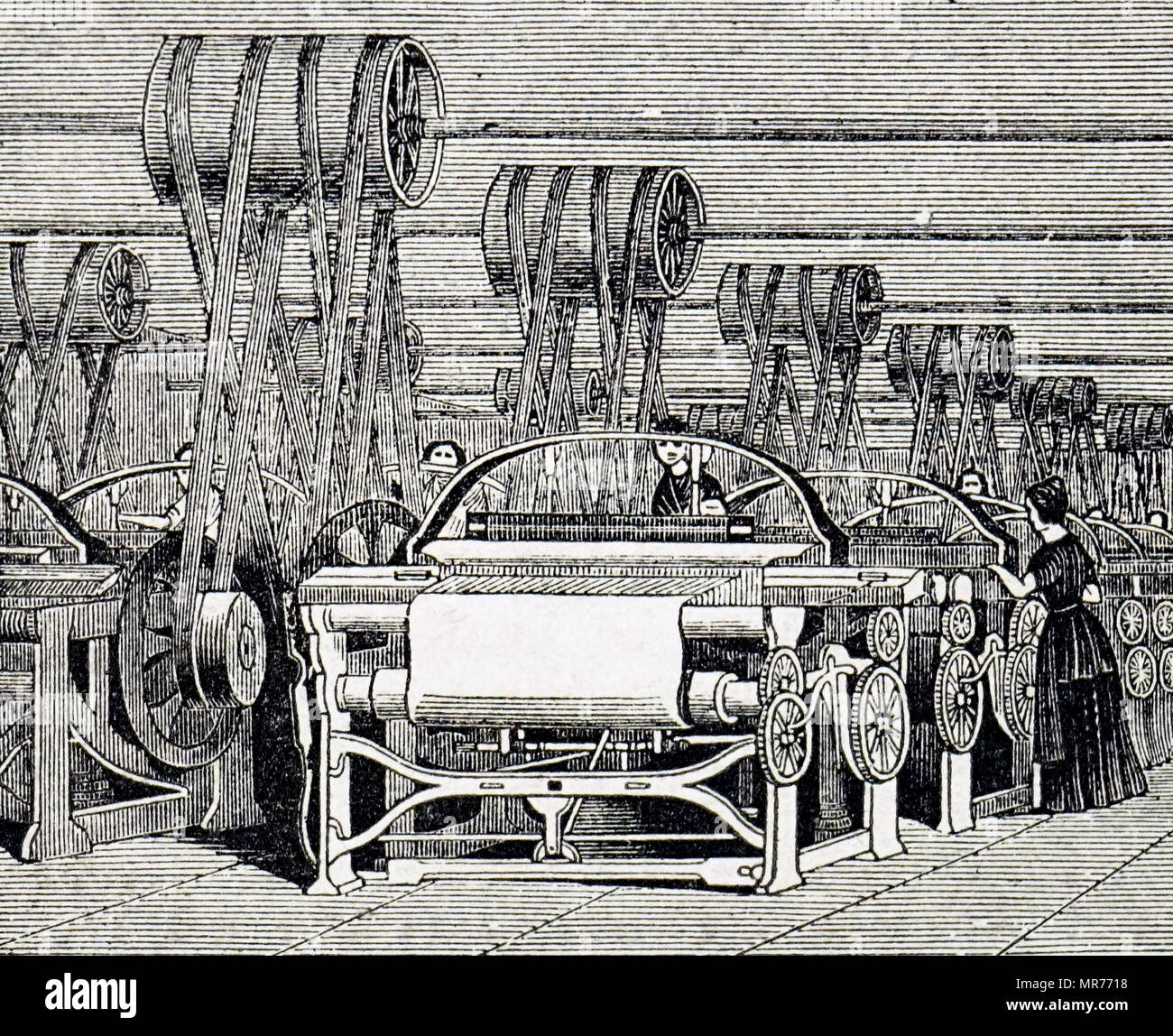

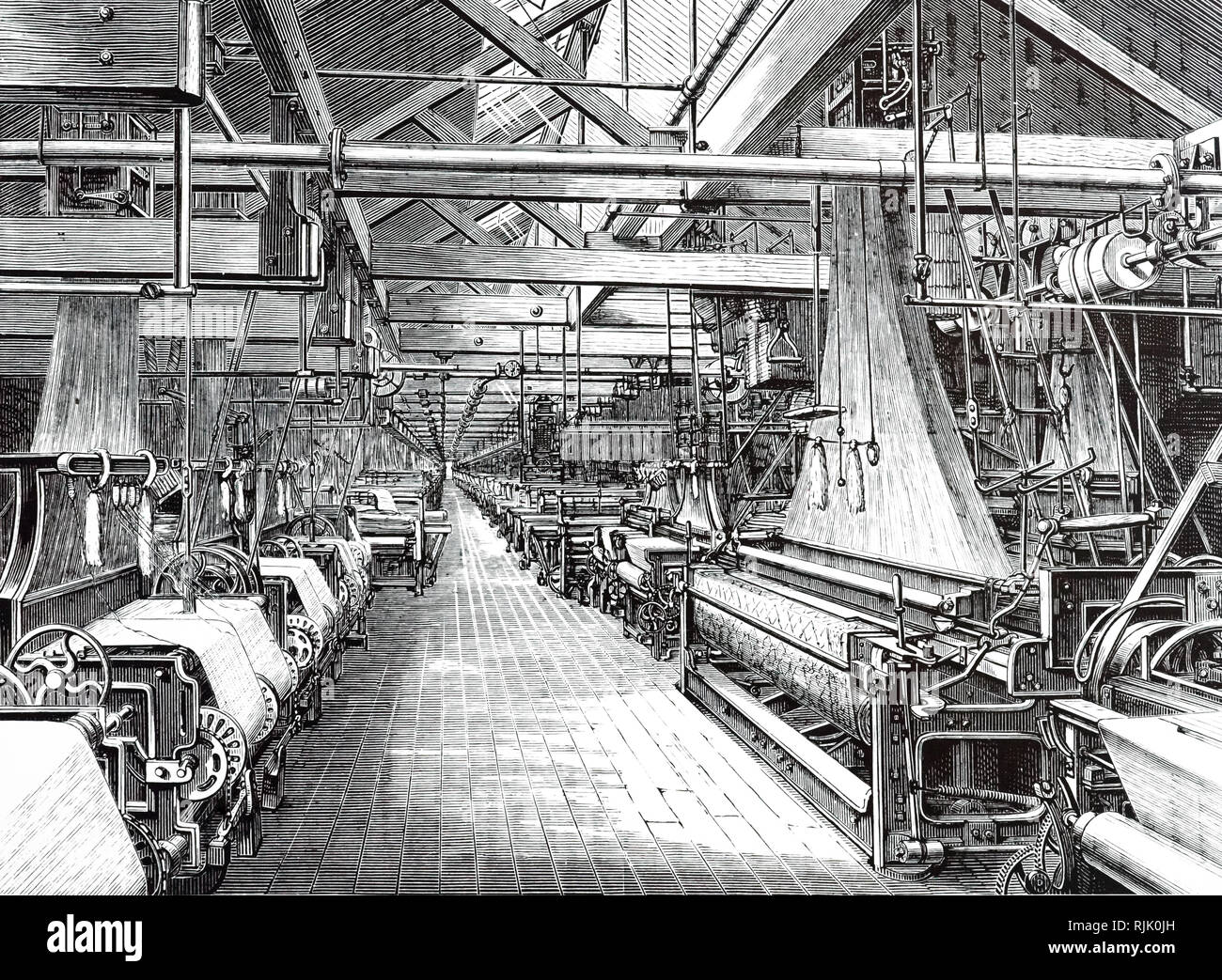

Engraving depicting a weaving shed fitted with power looms driven, via shafts, by steam engines. Dated 19th century Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-depicting-a-weaving-shed-fitted-with-power-looms-driven-via-shafts-by-steam-engines-dated-19th-century-image186399956.html

Engraving depicting a weaving shed fitted with power looms driven, via shafts, by steam engines. Dated 19th century Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/engraving-depicting-a-weaving-shed-fitted-with-power-looms-driven-via-shafts-by-steam-engines-dated-19th-century-image186399956.htmlRMMR7718–Engraving depicting a weaving shed fitted with power looms driven, via shafts, by steam engines. Dated 19th century

Ein Angestellter einer Textilfirma in Krefeld justiert das Garn in der großen Webmaschine, Deutschland 1930er Jahre. An employee in a textile company in Krefeld adjusting the yarn in the big power loom, Germany 1930s. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/ein-angestellter-einer-textilfirma-in-krefeld-justiert-das-garn-in-der-groen-webmaschine-deutschland-1930er-jahre-an-employee-in-a-textile-company-in-krefeld-adjusting-the-yarn-in-the-big-power-loom-germany-1930s-image328568020.html

Ein Angestellter einer Textilfirma in Krefeld justiert das Garn in der großen Webmaschine, Deutschland 1930er Jahre. An employee in a textile company in Krefeld adjusting the yarn in the big power loom, Germany 1930s. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/ein-angestellter-einer-textilfirma-in-krefeld-justiert-das-garn-in-der-groen-webmaschine-deutschland-1930er-jahre-an-employee-in-a-textile-company-in-krefeld-adjusting-the-yarn-in-the-big-power-loom-germany-1930s-image328568020.htmlRM2A2FFT4–Ein Angestellter einer Textilfirma in Krefeld justiert das Garn in der großen Webmaschine, Deutschland 1930er Jahre. An employee in a textile company in Krefeld adjusting the yarn in the big power loom, Germany 1930s.

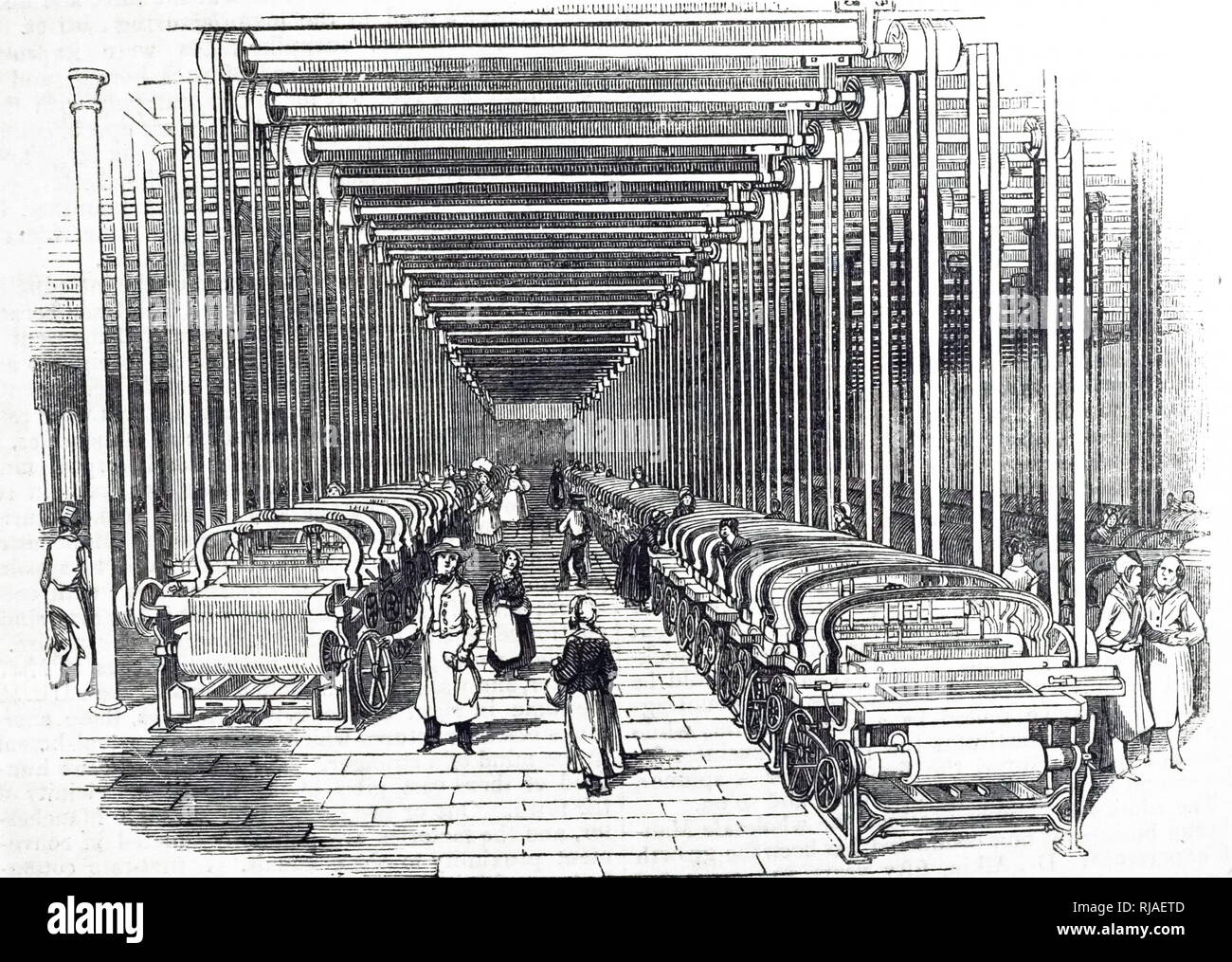

An engraving depicting a weaving shed fitted with power looms at Orrell's cotton mill, Stockport, Lancashire. Dated 19th century Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-engraving-depicting-a-weaving-shed-fitted-with-power-looms-at-orrells-cotton-mill-stockport-lancashire-dated-19th-century-image235029773.html

An engraving depicting a weaving shed fitted with power looms at Orrell's cotton mill, Stockport, Lancashire. Dated 19th century Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-engraving-depicting-a-weaving-shed-fitted-with-power-looms-at-orrells-cotton-mill-stockport-lancashire-dated-19th-century-image235029773.htmlRMRJAETD–An engraving depicting a weaving shed fitted with power looms at Orrell's cotton mill, Stockport, Lancashire. Dated 19th century

Weaving Hampshire tweeds at an old mill that stood idle for a hundred years . An old mill at Fordingbridge in the New Forest , Hampshire , that has stood idle for 100 years has come to life again . It is weaving into tweeds wool from the flocks that graze on Salisbury Plain and it is hoped to make Hampshire tweeds as famous as the Harris variety . The machines for which the ancient sluices are providing power have been brought down from Westmorland and expert woolmen have been brought from the North also . The new mill owner is Major C T Napier . Photo shows ; A young woman worker holding a fl Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/weaving-hampshire-tweeds-at-an-old-mill-that-stood-idle-for-a-hundred-years-an-old-mill-at-fordingbridge-in-the-new-forest-hampshire-that-has-stood-idle-for-100-years-has-come-to-life-again-it-is-weaving-into-tweeds-wool-from-the-flocks-that-graze-on-salisbury-plain-and-it-is-hoped-to-make-hampshire-tweeds-as-famous-as-the-harris-variety-the-machines-for-which-the-ancient-sluices-are-providing-power-have-been-brought-down-from-westmorland-and-expert-woolmen-have-been-brought-from-the-north-also-the-new-mill-owner-is-major-c-t-napier-photo-shows-a-young-woman-worker-holding-a-fl-image359646724.html

Weaving Hampshire tweeds at an old mill that stood idle for a hundred years . An old mill at Fordingbridge in the New Forest , Hampshire , that has stood idle for 100 years has come to life again . It is weaving into tweeds wool from the flocks that graze on Salisbury Plain and it is hoped to make Hampshire tweeds as famous as the Harris variety . The machines for which the ancient sluices are providing power have been brought down from Westmorland and expert woolmen have been brought from the North also . The new mill owner is Major C T Napier . Photo shows ; A young woman worker holding a fl Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/weaving-hampshire-tweeds-at-an-old-mill-that-stood-idle-for-a-hundred-years-an-old-mill-at-fordingbridge-in-the-new-forest-hampshire-that-has-stood-idle-for-100-years-has-come-to-life-again-it-is-weaving-into-tweeds-wool-from-the-flocks-that-graze-on-salisbury-plain-and-it-is-hoped-to-make-hampshire-tweeds-as-famous-as-the-harris-variety-the-machines-for-which-the-ancient-sluices-are-providing-power-have-been-brought-down-from-westmorland-and-expert-woolmen-have-been-brought-from-the-north-also-the-new-mill-owner-is-major-c-t-napier-photo-shows-a-young-woman-worker-holding-a-fl-image359646724.htmlRM2BW391T–Weaving Hampshire tweeds at an old mill that stood idle for a hundred years . An old mill at Fordingbridge in the New Forest , Hampshire , that has stood idle for 100 years has come to life again . It is weaving into tweeds wool from the flocks that graze on Salisbury Plain and it is hoped to make Hampshire tweeds as famous as the Harris variety . The machines for which the ancient sluices are providing power have been brought down from Westmorland and expert woolmen have been brought from the North also . The new mill owner is Major C T Napier . Photo shows ; A young woman worker holding a fl

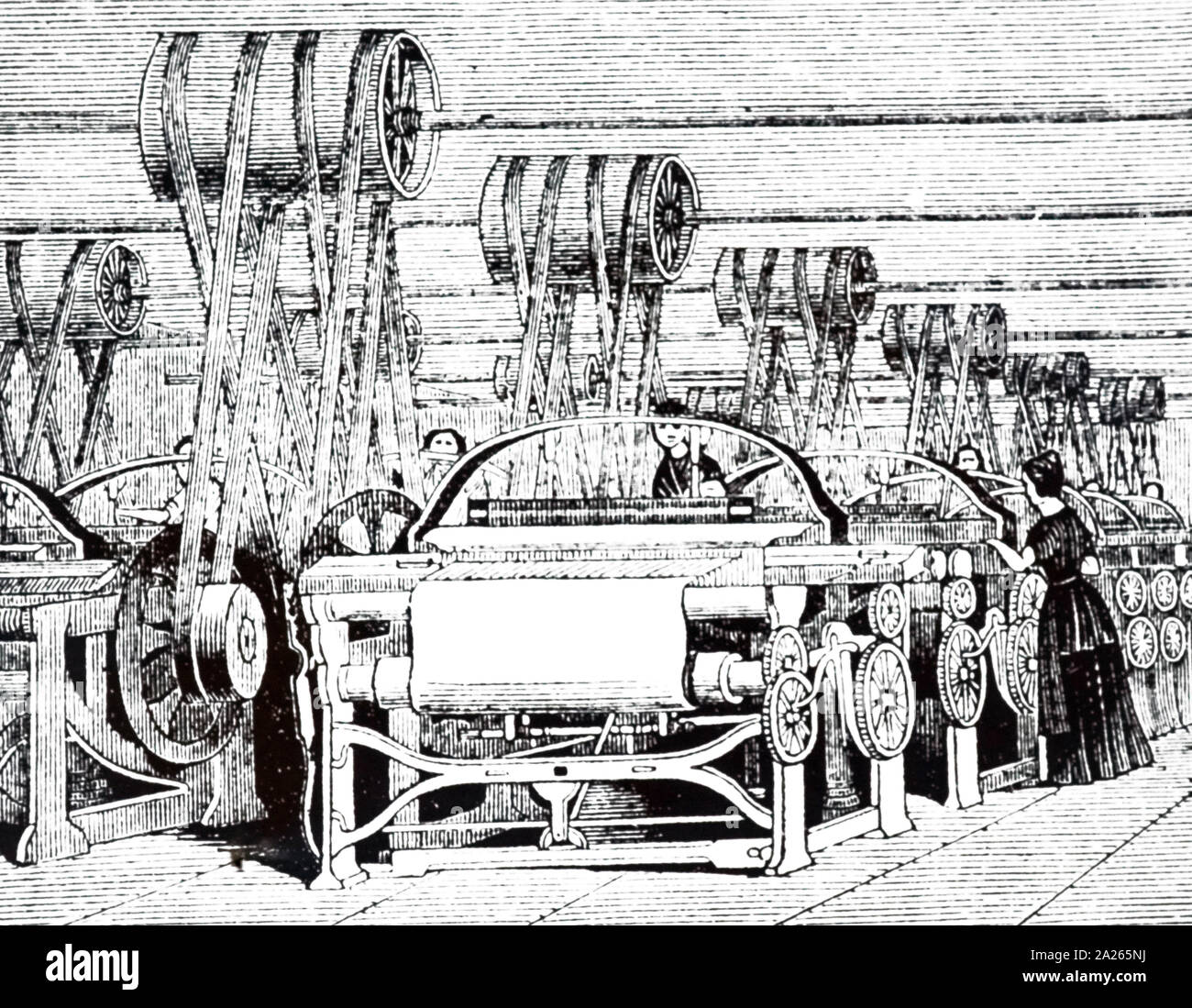

An engraving depicting a cotton weaving shed fitted with power looms driven, via shafts, by steam engines. Dated 19th century Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-engraving-depicting-a-cotton-weaving-shed-fitted-with-power-looms-driven-via-shafts-by-steam-engines-dated-19th-century-image328362542.html

An engraving depicting a cotton weaving shed fitted with power looms driven, via shafts, by steam engines. Dated 19th century Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/an-engraving-depicting-a-cotton-weaving-shed-fitted-with-power-looms-driven-via-shafts-by-steam-engines-dated-19th-century-image328362542.htmlRM2A265NJ–An engraving depicting a cotton weaving shed fitted with power looms driven, via shafts, by steam engines. Dated 19th century