Tapered hull Stock Photos and Images

Upcycled boat Shed ; Voluntary payment business purchase; a donation point at Colbost Folk Museum, Duirinish peninsula, Isle of Skye, Scotland, UK Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-upcycled-boat-shed-voluntary-payment-business-purchase-a-donation-23948265.html

Upcycled boat Shed ; Voluntary payment business purchase; a donation point at Colbost Folk Museum, Duirinish peninsula, Isle of Skye, Scotland, UK Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-upcycled-boat-shed-voluntary-payment-business-purchase-a-donation-23948265.htmlRFBAXX75–Upcycled boat Shed ; Voluntary payment business purchase; a donation point at Colbost Folk Museum, Duirinish peninsula, Isle of Skye, Scotland, UK

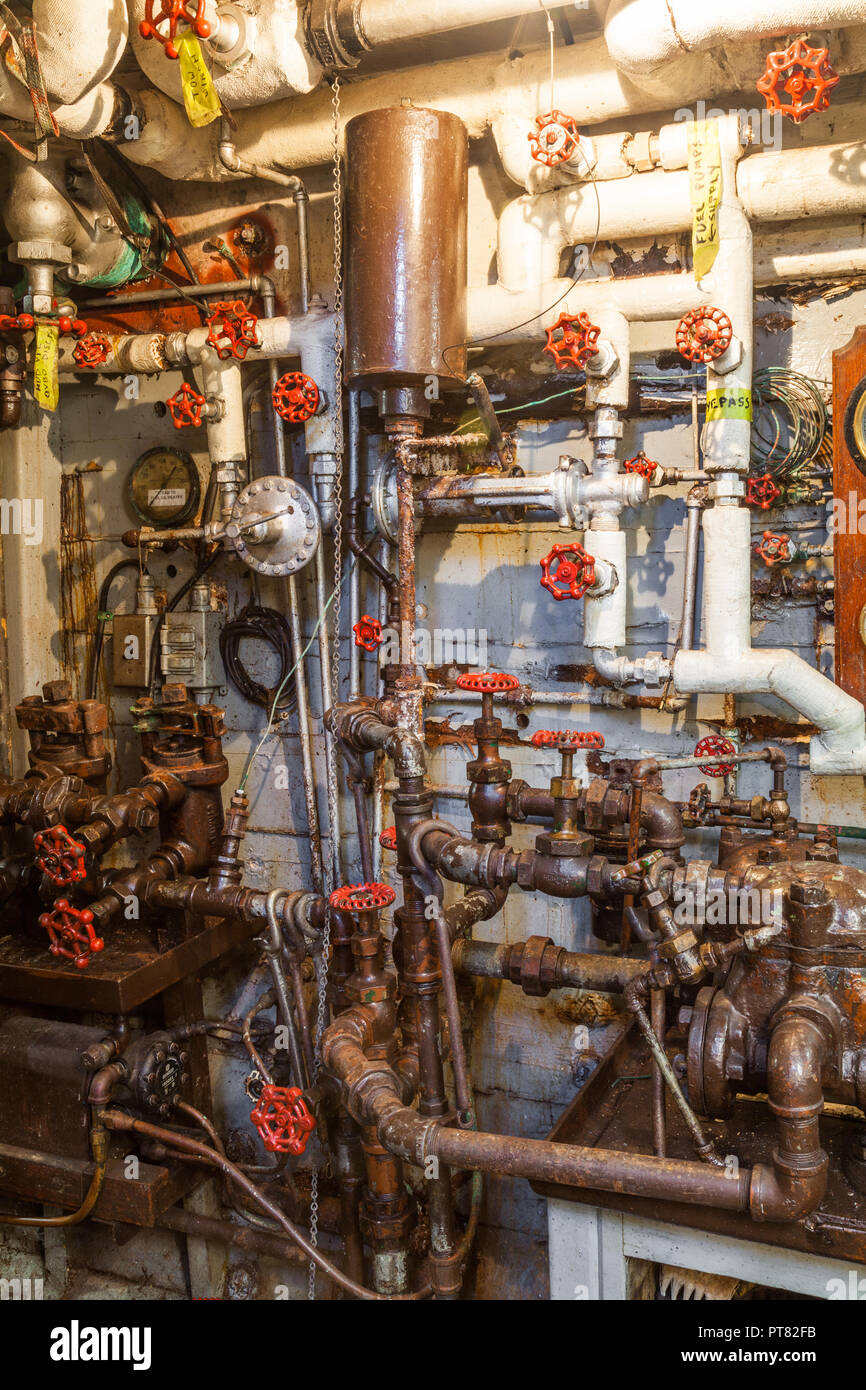

Plumbing network and valve array in the engine room of the steam powered tugboat SS Master Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/plumbing-network-and-valve-array-in-the-engine-room-of-the-steam-powered-tugboat-ss-master-image221453775.html

Plumbing network and valve array in the engine room of the steam powered tugboat SS Master Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/plumbing-network-and-valve-array-in-the-engine-room-of-the-steam-powered-tugboat-ss-master-image221453775.htmlRMPT82FB–Plumbing network and valve array in the engine room of the steam powered tugboat SS Master

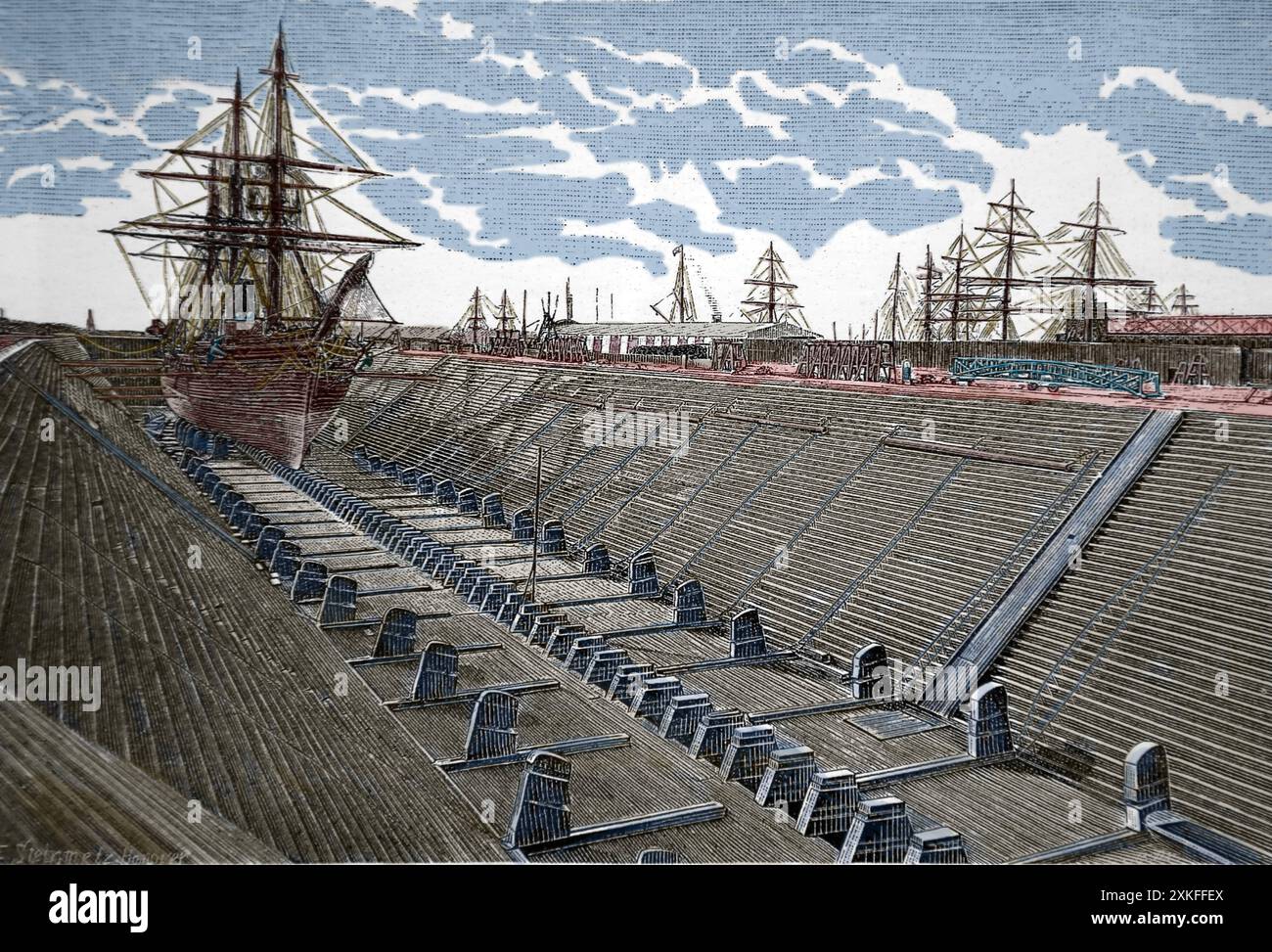

Dry dock in Erie basin, ca. 1880. Brooklyen. New York. Usa. Engraving. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/dry-dock-in-erie-basin-ca-1880-brooklyen-new-york-usa-engraving-image614382802.html

Dry dock in Erie basin, ca. 1880. Brooklyen. New York. Usa. Engraving. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/dry-dock-in-erie-basin-ca-1880-brooklyen-new-york-usa-engraving-image614382802.htmlRM2XKFFEX–Dry dock in Erie basin, ca. 1880. Brooklyen. New York. Usa. Engraving.

Twenty years at Hull-house, with autobiographical notes . , he suddenly forgot them all in agush of gratitude for mere bread, exclaiming,How it stands, that golden yellow corn, on itsfine tapered stem; the meek earth, at Gods kindbidding, has produced itonce again ! At leastthe toiling poor had thiscomfort of bread labor,and perhaps it did notmatter that they gainedit unknowingly and pain-fully, if only they walkedin the path of labor. Inthe exercise of that curi-ous power possessed bythe theorists to inhibit allexperiences which do notenhance his doctrine, Idid not permit myself to recall tha Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/twenty-years-at-hull-house-with-autobiographical-notes-he-suddenly-forgot-them-all-in-agush-of-gratitude-for-mere-bread-exclaiminghow-it-stands-that-golden-yellow-corn-on-itsfine-tapered-stem-the-meek-earth-at-gods-kindbidding-has-produced-itonce-again-!-at-leastthe-toiling-poor-had-thiscomfort-of-bread-laborand-perhaps-it-did-notmatter-that-they-gainedit-unknowingly-and-pain-fully-if-only-they-walkedin-the-path-of-labor-inthe-exercise-of-that-curi-ous-power-possessed-bythe-theorists-to-inhibit-allexperiences-which-do-notenhance-his-doctrine-idid-not-permit-myself-to-recall-tha-image343145125.html

Twenty years at Hull-house, with autobiographical notes . , he suddenly forgot them all in agush of gratitude for mere bread, exclaiming,How it stands, that golden yellow corn, on itsfine tapered stem; the meek earth, at Gods kindbidding, has produced itonce again ! At leastthe toiling poor had thiscomfort of bread labor,and perhaps it did notmatter that they gainedit unknowingly and pain-fully, if only they walkedin the path of labor. Inthe exercise of that curi-ous power possessed bythe theorists to inhibit allexperiences which do notenhance his doctrine, Idid not permit myself to recall tha Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/twenty-years-at-hull-house-with-autobiographical-notes-he-suddenly-forgot-them-all-in-agush-of-gratitude-for-mere-bread-exclaiminghow-it-stands-that-golden-yellow-corn-on-itsfine-tapered-stem-the-meek-earth-at-gods-kindbidding-has-produced-itonce-again-!-at-leastthe-toiling-poor-had-thiscomfort-of-bread-laborand-perhaps-it-did-notmatter-that-they-gainedit-unknowingly-and-pain-fully-if-only-they-walkedin-the-path-of-labor-inthe-exercise-of-that-curi-ous-power-possessed-bythe-theorists-to-inhibit-allexperiences-which-do-notenhance-his-doctrine-idid-not-permit-myself-to-recall-tha-image343145125.htmlRM2AX7H31–Twenty years at Hull-house, with autobiographical notes . , he suddenly forgot them all in agush of gratitude for mere bread, exclaiming,How it stands, that golden yellow corn, on itsfine tapered stem; the meek earth, at Gods kindbidding, has produced itonce again ! At leastthe toiling poor had thiscomfort of bread labor,and perhaps it did notmatter that they gainedit unknowingly and pain-fully, if only they walkedin the path of labor. Inthe exercise of that curi-ous power possessed bythe theorists to inhibit allexperiences which do notenhance his doctrine, Idid not permit myself to recall tha

Red yellow boat. Front view. 3d render. Isolated on white background Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/red-yellow-boat-front-view-3d-render-isolated-on-white-background-image566369190.html

Red yellow boat. Front view. 3d render. Isolated on white background Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/red-yellow-boat-front-view-3d-render-isolated-on-white-background-image566369190.htmlRF2RWC9K2–Red yellow boat. Front view. 3d render. Isolated on white background

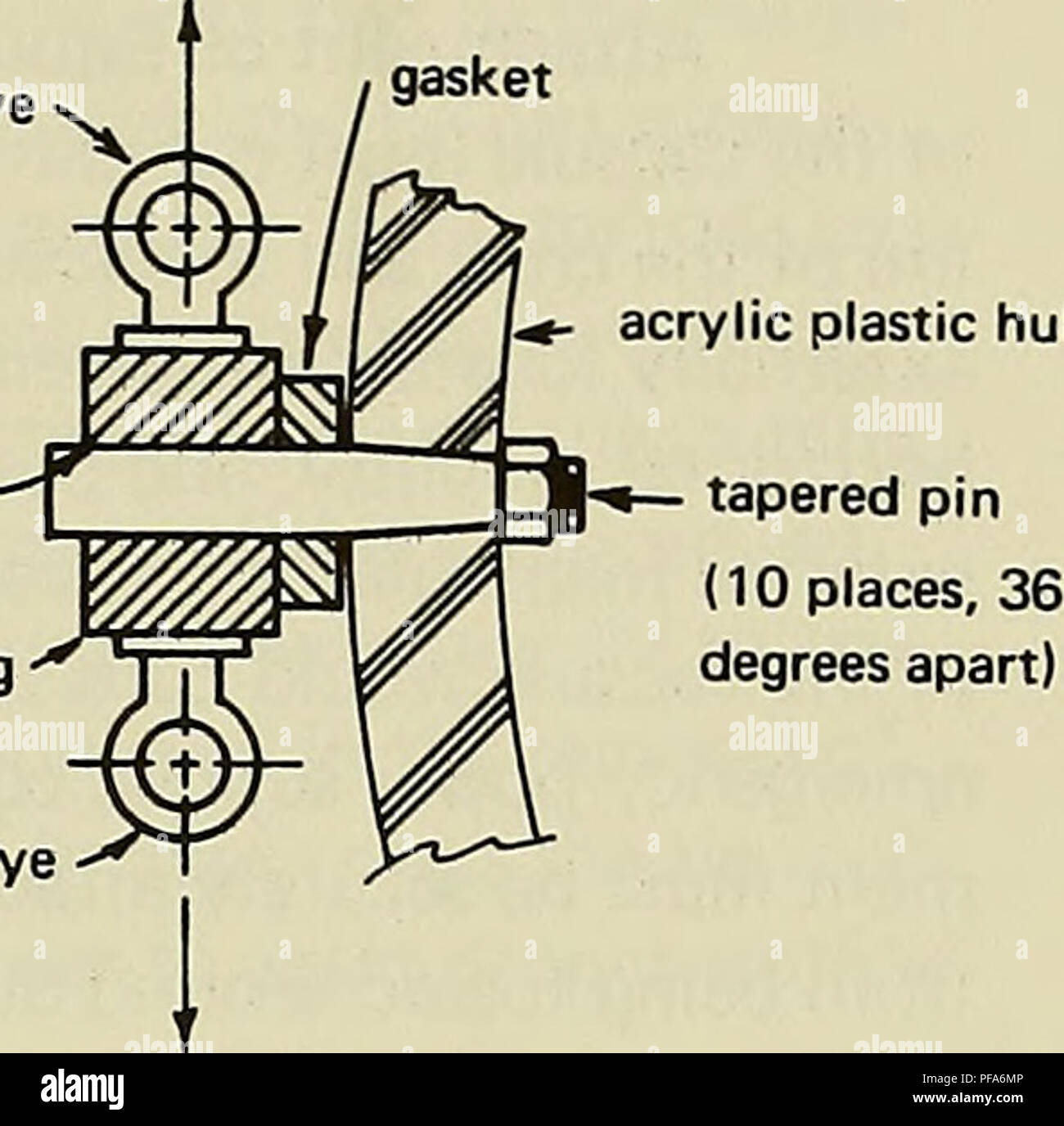

Archive image from page 193 of Development of a spherical acrylic. Development of a spherical acrylic plastic pressure hull for hydrospace application . developmentofsph00stac Year: 1970 (a) Inserting the pin. (b) Securing the pin. Figure D-3. Installation of the tapered pins into the radially tapered holes in the acrylic plastic hull. 190 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/archive-image-from-page-193-of-development-of-a-spherical-acrylic-development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-developmentofsph00stac-year-1970-a-inserting-the-pin-b-securing-the-pin-figure-d-3-installation-of-the-tapered-pins-into-the-radially-tapered-holes-in-the-acrylic-plastic-hull-190-image258901606.html

Archive image from page 193 of Development of a spherical acrylic. Development of a spherical acrylic plastic pressure hull for hydrospace application . developmentofsph00stac Year: 1970 (a) Inserting the pin. (b) Securing the pin. Figure D-3. Installation of the tapered pins into the radially tapered holes in the acrylic plastic hull. 190 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/archive-image-from-page-193-of-development-of-a-spherical-acrylic-development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-developmentofsph00stac-year-1970-a-inserting-the-pin-b-securing-the-pin-figure-d-3-installation-of-the-tapered-pins-into-the-radially-tapered-holes-in-the-acrylic-plastic-hull-190-image258901606.htmlRMW15YHX–Archive image from page 193 of Development of a spherical acrylic. Development of a spherical acrylic plastic pressure hull for hydrospace application . developmentofsph00stac Year: 1970 (a) Inserting the pin. (b) Securing the pin. Figure D-3. Installation of the tapered pins into the radially tapered holes in the acrylic plastic hull. 190

. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. (a) Inserting the pin.. (b) Securing the pin. Figure D-3. Installation of the tapered pins into the radially tapered holes in the acrylic plastic hull. 190. Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability - coloration and appearance of these illustrations may not perfectly resemble the original work.. Stachiw, Jerry D. , 1931-; Naval Civil Engineering Laboratory (Port Hueneme, Calif. ). Port H Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-hulls-naval-architecture-submersibles-a-inserting-the-pin-b-securing-the-pin-figure-d-3-installation-of-the-tapered-pins-into-the-radially-tapered-holes-in-the-acrylic-plastic-hull-190-please-note-that-these-images-are-extracted-from-scanned-page-images-that-may-have-been-digitally-enhanced-for-readability-coloration-and-appearance-of-these-illustrations-may-not-perfectly-resemble-the-original-work-stachiw-jerry-d-1931-naval-civil-engineering-laboratory-port-hueneme-calif-port-h-image215968597.html

. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. (a) Inserting the pin.. (b) Securing the pin. Figure D-3. Installation of the tapered pins into the radially tapered holes in the acrylic plastic hull. 190. Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability - coloration and appearance of these illustrations may not perfectly resemble the original work.. Stachiw, Jerry D. , 1931-; Naval Civil Engineering Laboratory (Port Hueneme, Calif. ). Port H Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-hulls-naval-architecture-submersibles-a-inserting-the-pin-b-securing-the-pin-figure-d-3-installation-of-the-tapered-pins-into-the-radially-tapered-holes-in-the-acrylic-plastic-hull-190-please-note-that-these-images-are-extracted-from-scanned-page-images-that-may-have-been-digitally-enhanced-for-readability-coloration-and-appearance-of-these-illustrations-may-not-perfectly-resemble-the-original-work-stachiw-jerry-d-1931-naval-civil-engineering-laboratory-port-hueneme-calif-port-h-image215968597.htmlRMPFA645–. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. (a) Inserting the pin.. (b) Securing the pin. Figure D-3. Installation of the tapered pins into the radially tapered holes in the acrylic plastic hull. 190. Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability - coloration and appearance of these illustrations may not perfectly resemble the original work.. Stachiw, Jerry D. , 1931-; Naval Civil Engineering Laboratory (Port Hueneme, Calif. ). Port H

. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. (a) Inserting the pin.. (b) Securing the pin. Figure D-3. Installation of the tapered pins into the radially tapered holes in the acrylic plastic hull. 190. Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability - coloration and appearance of these illustrations may not perfectly resemble the original work.. Stachiw, Jerry D. , 1931-; Naval Civil Engineering Laboratory (Port Hueneme, Calif. ). Port H Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-hulls-naval-architecture-submersibles-a-inserting-the-pin-b-securing-the-pin-figure-d-3-installation-of-the-tapered-pins-into-the-radially-tapered-holes-in-the-acrylic-plastic-hull-190-please-note-that-these-images-are-extracted-from-scanned-page-images-that-may-have-been-digitally-enhanced-for-readability-coloration-and-appearance-of-these-illustrations-may-not-perfectly-resemble-the-original-work-stachiw-jerry-d-1931-naval-civil-engineering-laboratory-port-hueneme-calif-port-h-image231664518.html

. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. (a) Inserting the pin.. (b) Securing the pin. Figure D-3. Installation of the tapered pins into the radially tapered holes in the acrylic plastic hull. 190. Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability - coloration and appearance of these illustrations may not perfectly resemble the original work.. Stachiw, Jerry D. , 1931-; Naval Civil Engineering Laboratory (Port Hueneme, Calif. ). Port H Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-hulls-naval-architecture-submersibles-a-inserting-the-pin-b-securing-the-pin-figure-d-3-installation-of-the-tapered-pins-into-the-radially-tapered-holes-in-the-acrylic-plastic-hull-190-please-note-that-these-images-are-extracted-from-scanned-page-images-that-may-have-been-digitally-enhanced-for-readability-coloration-and-appearance-of-these-illustrations-may-not-perfectly-resemble-the-original-work-stachiw-jerry-d-1931-naval-civil-engineering-laboratory-port-hueneme-calif-port-h-image231664518.htmlRMRCW6CP–. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. (a) Inserting the pin.. (b) Securing the pin. Figure D-3. Installation of the tapered pins into the radially tapered holes in the acrylic plastic hull. 190. Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability - coloration and appearance of these illustrations may not perfectly resemble the original work.. Stachiw, Jerry D. , 1931-; Naval Civil Engineering Laboratory (Port Hueneme, Calif. ). Port H

Archive image from page 194 of Development of a spherical acrylic. Development of a spherical acrylic plastic pressure hull for hydrospace application . developmentofsph00stac Year: 1970 T •3 , typical radially taper; iole / located at the equator of the caps :..J.H (a) Overall view of the capsule (b) Detail of the radially tapered hole. Figure D-4. Acrylic plastic capsule prior to being outfitted with polar steel end closures, pins, and equatorial ring. 191 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/archive-image-from-page-194-of-development-of-a-spherical-acrylic-development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-developmentofsph00stac-year-1970-t-3-typical-radially-taper-iole-located-at-the-equator-of-the-caps-jh-a-overall-view-of-the-capsule-b-detail-of-the-radially-tapered-hole-figure-d-4-acrylic-plastic-capsule-prior-to-being-outfitted-with-polar-steel-end-closures-pins-and-equatorial-ring-191-image258901718.html

Archive image from page 194 of Development of a spherical acrylic. Development of a spherical acrylic plastic pressure hull for hydrospace application . developmentofsph00stac Year: 1970 T •3 , typical radially taper; iole / located at the equator of the caps :..J.H (a) Overall view of the capsule (b) Detail of the radially tapered hole. Figure D-4. Acrylic plastic capsule prior to being outfitted with polar steel end closures, pins, and equatorial ring. 191 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/archive-image-from-page-194-of-development-of-a-spherical-acrylic-development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-developmentofsph00stac-year-1970-t-3-typical-radially-taper-iole-located-at-the-equator-of-the-caps-jh-a-overall-view-of-the-capsule-b-detail-of-the-radially-tapered-hole-figure-d-4-acrylic-plastic-capsule-prior-to-being-outfitted-with-polar-steel-end-closures-pins-and-equatorial-ring-191-image258901718.htmlRMW15YNX–Archive image from page 194 of Development of a spherical acrylic. Development of a spherical acrylic plastic pressure hull for hydrospace application . developmentofsph00stac Year: 1970 T •3 , typical radially taper; iole / located at the equator of the caps :..J.H (a) Overall view of the capsule (b) Detail of the radially tapered hole. Figure D-4. Acrylic plastic capsule prior to being outfitted with polar steel end closures, pins, and equatorial ring. 191

. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. T •3 , typical radially taper; iole / located at the equator of the caps* :..J.H (a) Overall view of the capsule. (b) Detail of the radially tapered hole. Figure D-4. Acrylic plastic capsule prior to being outfitted with polar steel end closures, pins, and equatorial ring. 191. Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability - coloration and appearance of these illustrations may not perfectly Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-hulls-naval-architecture-submersibles-t-3-typical-radially-taper-iole-located-at-the-equator-of-the-caps-jh-a-overall-view-of-the-capsule-b-detail-of-the-radially-tapered-hole-figure-d-4-acrylic-plastic-capsule-prior-to-being-outfitted-with-polar-steel-end-closures-pins-and-equatorial-ring-191-please-note-that-these-images-are-extracted-from-scanned-page-images-that-may-have-been-digitally-enhanced-for-readability-coloration-and-appearance-of-these-illustrations-may-not-perfectly-image215968596.html

. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. T •3 , typical radially taper; iole / located at the equator of the caps* :..J.H (a) Overall view of the capsule. (b) Detail of the radially tapered hole. Figure D-4. Acrylic plastic capsule prior to being outfitted with polar steel end closures, pins, and equatorial ring. 191. Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability - coloration and appearance of these illustrations may not perfectly Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-hulls-naval-architecture-submersibles-t-3-typical-radially-taper-iole-located-at-the-equator-of-the-caps-jh-a-overall-view-of-the-capsule-b-detail-of-the-radially-tapered-hole-figure-d-4-acrylic-plastic-capsule-prior-to-being-outfitted-with-polar-steel-end-closures-pins-and-equatorial-ring-191-please-note-that-these-images-are-extracted-from-scanned-page-images-that-may-have-been-digitally-enhanced-for-readability-coloration-and-appearance-of-these-illustrations-may-not-perfectly-image215968596.htmlRMPFA644–. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. T •3 , typical radially taper; iole / located at the equator of the caps* :..J.H (a) Overall view of the capsule. (b) Detail of the radially tapered hole. Figure D-4. Acrylic plastic capsule prior to being outfitted with polar steel end closures, pins, and equatorial ring. 191. Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability - coloration and appearance of these illustrations may not perfectly

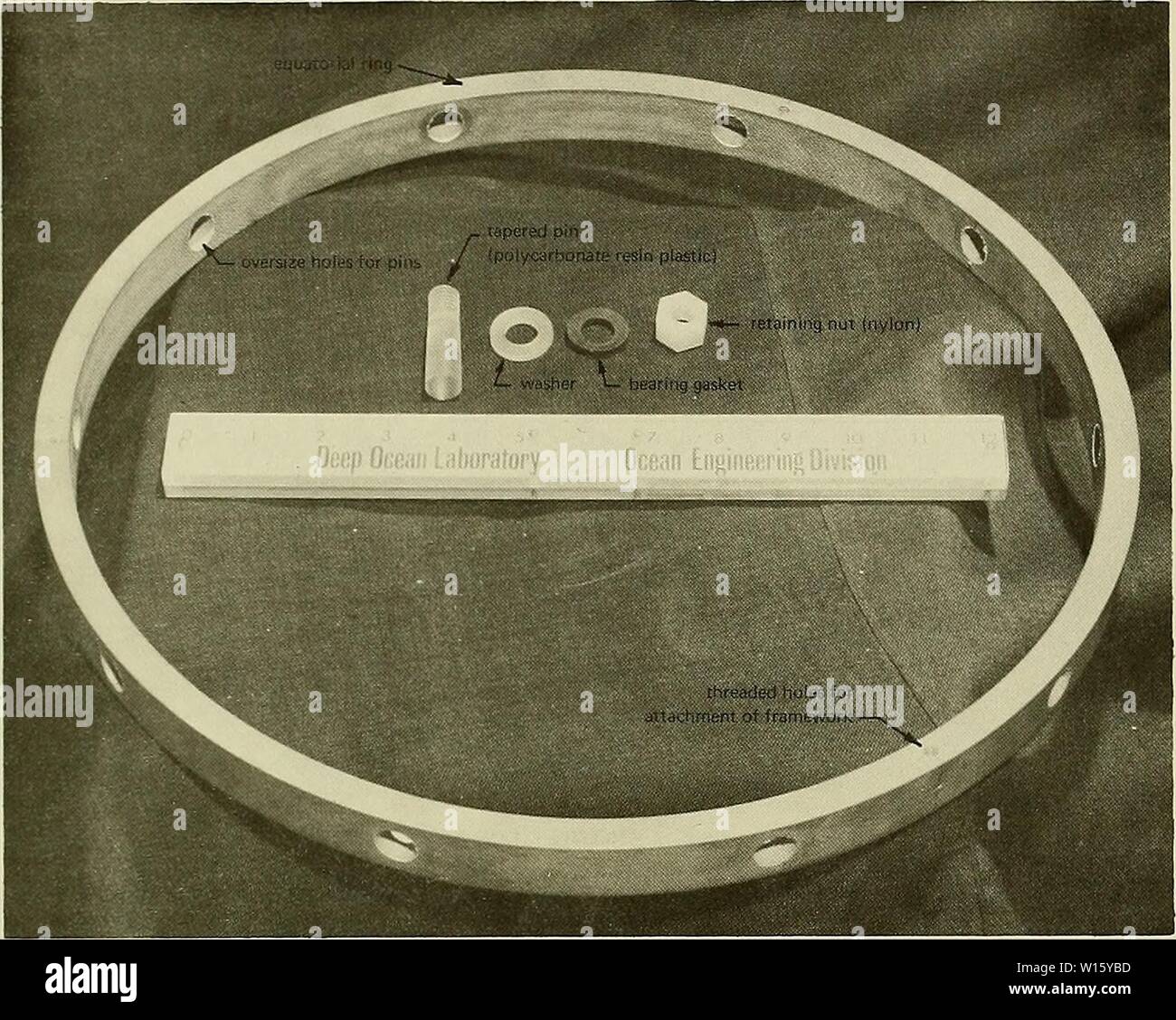

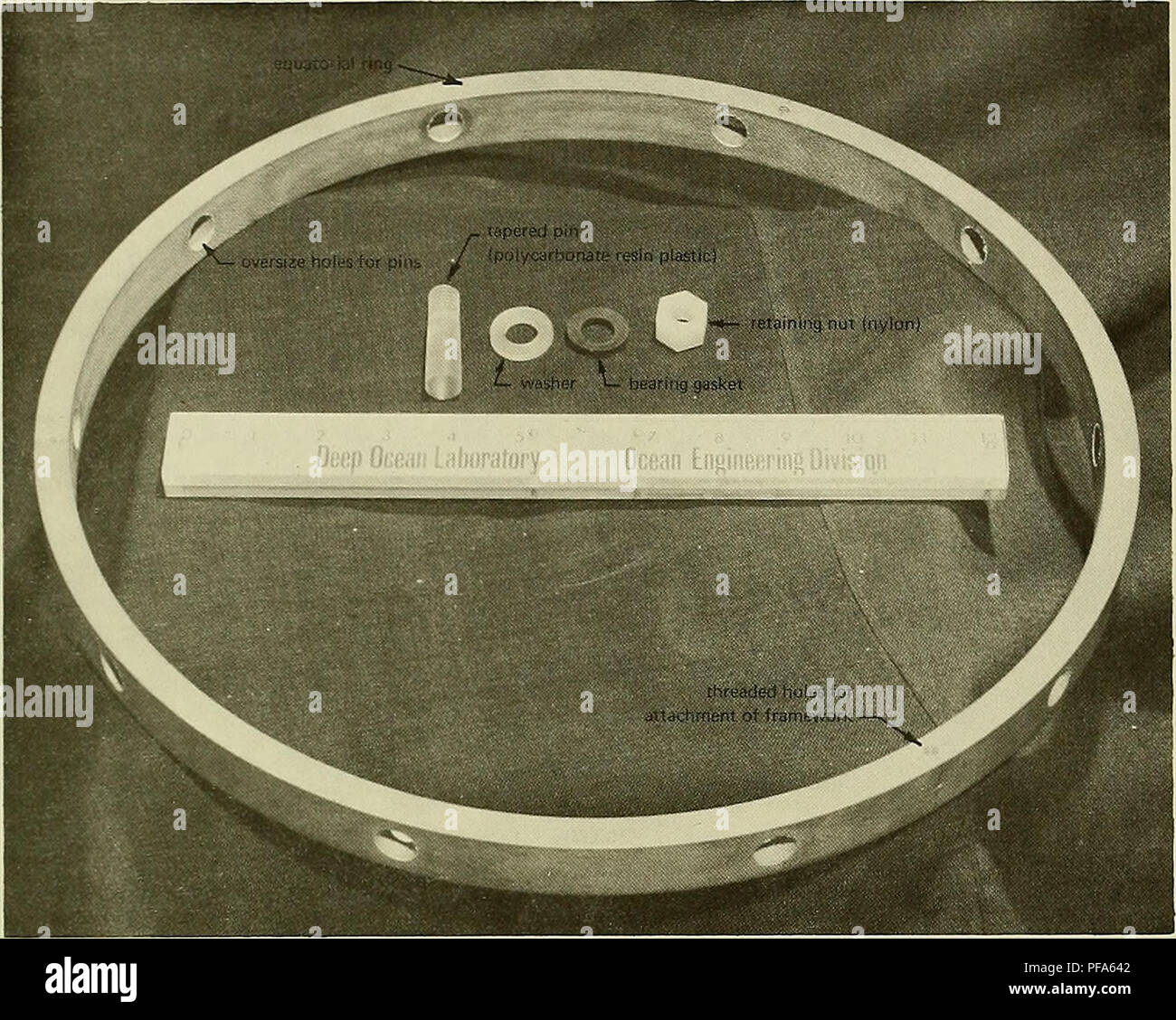

. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. Figure D-2. Equatorial ring and tapered pins needed for attaching the ring to the acrylic plastic capsule. The model capsule was fabricated in an identical manner to those already discussed in the main body of the report (Figure D-4), except that 10 radially tapered holes were drilled through the wall along the capsule's equator (Figure D-4). For implosion testing, the model was equipped (Figure D-5) with the simplified end closures (Figure 63) described in the main Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-hulls-naval-architecture-submersibles-figure-d-2-equatorial-ring-and-tapered-pins-needed-for-attaching-the-ring-to-the-acrylic-plastic-capsule-the-model-capsule-was-fabricated-in-an-identical-manner-to-those-already-discussed-in-the-main-body-of-the-report-figure-d-4-except-that-10-radially-tapered-holes-were-drilled-through-the-wall-along-the-capsules-equator-figure-d-4-for-implosion-testing-the-model-was-equipped-figure-d-5-with-the-simplified-end-closures-figure-63-described-in-the-main-image231664522.html

. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. Figure D-2. Equatorial ring and tapered pins needed for attaching the ring to the acrylic plastic capsule. The model capsule was fabricated in an identical manner to those already discussed in the main body of the report (Figure D-4), except that 10 radially tapered holes were drilled through the wall along the capsule's equator (Figure D-4). For implosion testing, the model was equipped (Figure D-5) with the simplified end closures (Figure 63) described in the main Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-hulls-naval-architecture-submersibles-figure-d-2-equatorial-ring-and-tapered-pins-needed-for-attaching-the-ring-to-the-acrylic-plastic-capsule-the-model-capsule-was-fabricated-in-an-identical-manner-to-those-already-discussed-in-the-main-body-of-the-report-figure-d-4-except-that-10-radially-tapered-holes-were-drilled-through-the-wall-along-the-capsules-equator-figure-d-4-for-implosion-testing-the-model-was-equipped-figure-d-5-with-the-simplified-end-closures-figure-63-described-in-the-main-image231664522.htmlRMRCW6CX–. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. Figure D-2. Equatorial ring and tapered pins needed for attaching the ring to the acrylic plastic capsule. The model capsule was fabricated in an identical manner to those already discussed in the main body of the report (Figure D-4), except that 10 radially tapered holes were drilled through the wall along the capsule's equator (Figure D-4). For implosion testing, the model was equipped (Figure D-5) with the simplified end closures (Figure 63) described in the main

Archive image from page 192 of Development of a spherical acrylic. Development of a spherical acrylic plastic pressure hull for hydrospace application . developmentofsph00stac Year: 1970 Figure D-2. Equatorial ring and tapered pins needed for attaching the ring to the acrylic plastic capsule. The model capsule was fabricated in an identical manner to those already discussed in the main body of the report (Figure D-4), except that 10 radially tapered holes were drilled through the wall along the capsule's equator (Figure D-4). For implosion testing, the model was equipped (Figure D-5) with the Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/archive-image-from-page-192-of-development-of-a-spherical-acrylic-development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-developmentofsph00stac-year-1970-figure-d-2-equatorial-ring-and-tapered-pins-needed-for-attaching-the-ring-to-the-acrylic-plastic-capsule-the-model-capsule-was-fabricated-in-an-identical-manner-to-those-already-discussed-in-the-main-body-of-the-report-figure-d-4-except-that-10-radially-tapered-holes-were-drilled-through-the-wall-along-the-capsules-equator-figure-d-4-for-implosion-testing-the-model-was-equipped-figure-d-5-with-the-image258901425.html

Archive image from page 192 of Development of a spherical acrylic. Development of a spherical acrylic plastic pressure hull for hydrospace application . developmentofsph00stac Year: 1970 Figure D-2. Equatorial ring and tapered pins needed for attaching the ring to the acrylic plastic capsule. The model capsule was fabricated in an identical manner to those already discussed in the main body of the report (Figure D-4), except that 10 radially tapered holes were drilled through the wall along the capsule's equator (Figure D-4). For implosion testing, the model was equipped (Figure D-5) with the Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/archive-image-from-page-192-of-development-of-a-spherical-acrylic-development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-developmentofsph00stac-year-1970-figure-d-2-equatorial-ring-and-tapered-pins-needed-for-attaching-the-ring-to-the-acrylic-plastic-capsule-the-model-capsule-was-fabricated-in-an-identical-manner-to-those-already-discussed-in-the-main-body-of-the-report-figure-d-4-except-that-10-radially-tapered-holes-were-drilled-through-the-wall-along-the-capsules-equator-figure-d-4-for-implosion-testing-the-model-was-equipped-figure-d-5-with-the-image258901425.htmlRMW15YBD–Archive image from page 192 of Development of a spherical acrylic. Development of a spherical acrylic plastic pressure hull for hydrospace application . developmentofsph00stac Year: 1970 Figure D-2. Equatorial ring and tapered pins needed for attaching the ring to the acrylic plastic capsule. The model capsule was fabricated in an identical manner to those already discussed in the main body of the report (Figure D-4), except that 10 radially tapered holes were drilled through the wall along the capsule's equator (Figure D-4). For implosion testing, the model was equipped (Figure D-5) with the

. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. Figure D-2. Equatorial ring and tapered pins needed for attaching the ring to the acrylic plastic capsule. The model capsule was fabricated in an identical manner to those already discussed in the main body of the report (Figure D-4), except that 10 radially tapered holes were drilled through the wall along the capsule's equator (Figure D-4). For implosion testing, the model was equipped (Figure D-5) with the simplified end closures (Figure 63) described in the main Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-hulls-naval-architecture-submersibles-figure-d-2-equatorial-ring-and-tapered-pins-needed-for-attaching-the-ring-to-the-acrylic-plastic-capsule-the-model-capsule-was-fabricated-in-an-identical-manner-to-those-already-discussed-in-the-main-body-of-the-report-figure-d-4-except-that-10-radially-tapered-holes-were-drilled-through-the-wall-along-the-capsules-equator-figure-d-4-for-implosion-testing-the-model-was-equipped-figure-d-5-with-the-simplified-end-closures-figure-63-described-in-the-main-image215968594.html

. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. Figure D-2. Equatorial ring and tapered pins needed for attaching the ring to the acrylic plastic capsule. The model capsule was fabricated in an identical manner to those already discussed in the main body of the report (Figure D-4), except that 10 radially tapered holes were drilled through the wall along the capsule's equator (Figure D-4). For implosion testing, the model was equipped (Figure D-5) with the simplified end closures (Figure 63) described in the main Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-hulls-naval-architecture-submersibles-figure-d-2-equatorial-ring-and-tapered-pins-needed-for-attaching-the-ring-to-the-acrylic-plastic-capsule-the-model-capsule-was-fabricated-in-an-identical-manner-to-those-already-discussed-in-the-main-body-of-the-report-figure-d-4-except-that-10-radially-tapered-holes-were-drilled-through-the-wall-along-the-capsules-equator-figure-d-4-for-implosion-testing-the-model-was-equipped-figure-d-5-with-the-simplified-end-closures-figure-63-described-in-the-main-image215968594.htmlRMPFA642–. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. Figure D-2. Equatorial ring and tapered pins needed for attaching the ring to the acrylic plastic capsule. The model capsule was fabricated in an identical manner to those already discussed in the main body of the report (Figure D-4), except that 10 radially tapered holes were drilled through the wall along the capsule's equator (Figure D-4). For implosion testing, the model was equipped (Figure D-5) with the simplified end closures (Figure 63) described in the main

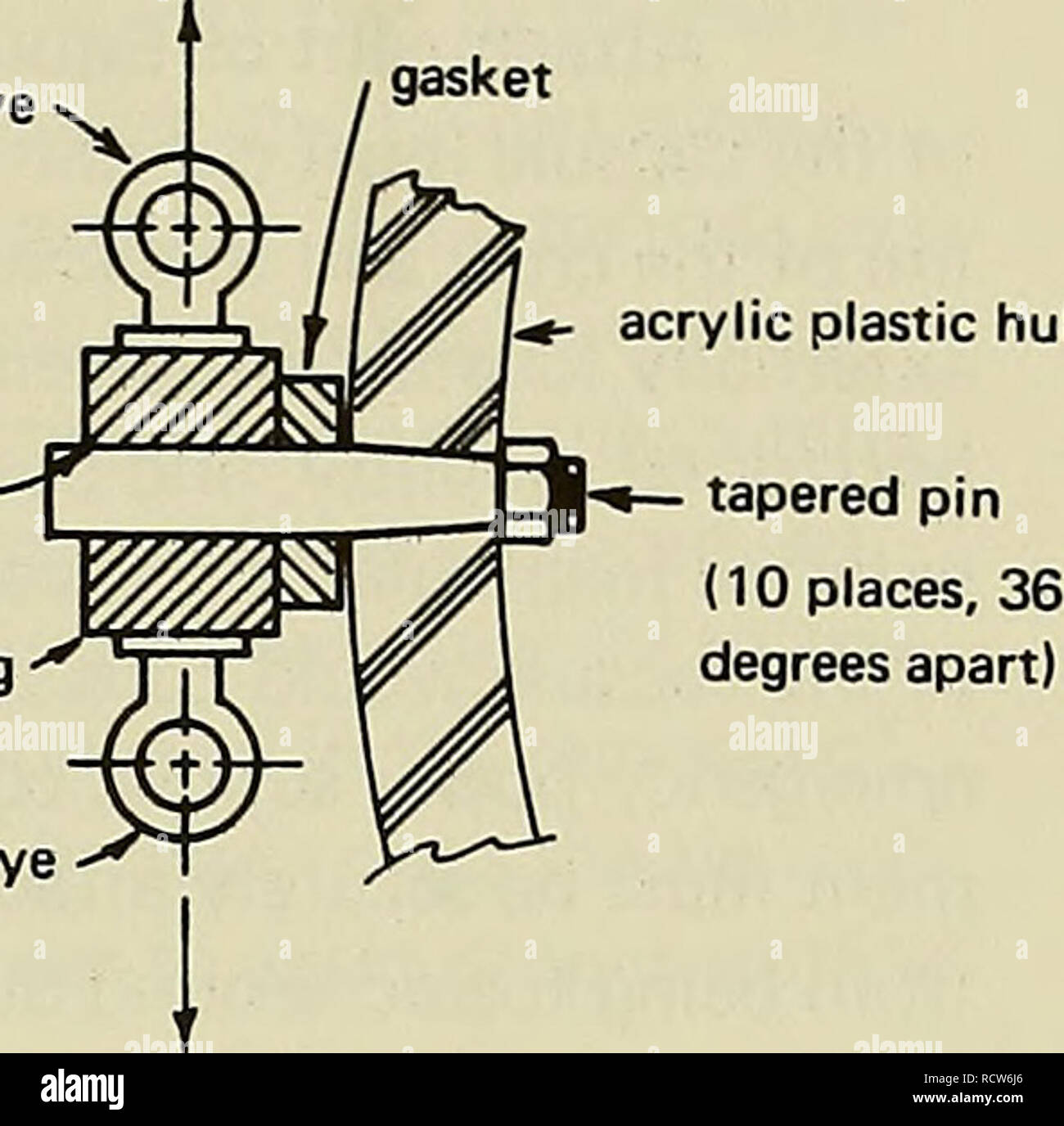

. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. padeye >. free-sliding fit between pin and opening in equatorial ring equatorial ring padeye .*- acrylic plastic hull permanently attached support framework. Figure 9. Equatorial ring and pin restraint for attaching the acrylic plastic cap- sule to the NEMO service module. Another approach that was considered was an equatorial ring held in place by radial sphere penetrators (Figure 9). The sphere penetrators were to be tapered and made from plastic with elastic pr Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-hulls-naval-architecture-submersibles-padeye-gt-free-sliding-fit-between-pin-and-opening-in-equatorial-ring-equatorial-ring-padeye-acrylic-plastic-hull-permanently-attached-support-framework-figure-9-equatorial-ring-and-pin-restraint-for-attaching-the-acrylic-plastic-cap-sule-to-the-nemo-service-module-another-approach-that-was-considered-was-an-equatorial-ring-held-in-place-by-radial-sphere-penetrators-figure-9-the-sphere-penetrators-were-to-be-tapered-and-made-from-plastic-with-elastic-pr-image231664670.html

. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. padeye >. free-sliding fit between pin and opening in equatorial ring equatorial ring padeye .*- acrylic plastic hull permanently attached support framework. Figure 9. Equatorial ring and pin restraint for attaching the acrylic plastic cap- sule to the NEMO service module. Another approach that was considered was an equatorial ring held in place by radial sphere penetrators (Figure 9). The sphere penetrators were to be tapered and made from plastic with elastic pr Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-hulls-naval-architecture-submersibles-padeye-gt-free-sliding-fit-between-pin-and-opening-in-equatorial-ring-equatorial-ring-padeye-acrylic-plastic-hull-permanently-attached-support-framework-figure-9-equatorial-ring-and-pin-restraint-for-attaching-the-acrylic-plastic-cap-sule-to-the-nemo-service-module-another-approach-that-was-considered-was-an-equatorial-ring-held-in-place-by-radial-sphere-penetrators-figure-9-the-sphere-penetrators-were-to-be-tapered-and-made-from-plastic-with-elastic-pr-image231664670.htmlRMRCW6J6–. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. padeye >. free-sliding fit between pin and opening in equatorial ring equatorial ring padeye .*- acrylic plastic hull permanently attached support framework. Figure 9. Equatorial ring and pin restraint for attaching the acrylic plastic cap- sule to the NEMO service module. Another approach that was considered was an equatorial ring held in place by radial sphere penetrators (Figure 9). The sphere penetrators were to be tapered and made from plastic with elastic pr

. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. padeye >. free-sliding fit between pin and opening in equatorial ring equatorial ring padeye .*- acrylic plastic hull permanently attached support framework. Figure 9. Equatorial ring and pin restraint for attaching the acrylic plastic cap- sule to the NEMO service module. Another approach that was considered was an equatorial ring held in place by radial sphere penetrators (Figure 9). The sphere penetrators were to be tapered and made from plastic with elastic pr Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-hulls-naval-architecture-submersibles-padeye-gt-free-sliding-fit-between-pin-and-opening-in-equatorial-ring-equatorial-ring-padeye-acrylic-plastic-hull-permanently-attached-support-framework-figure-9-equatorial-ring-and-pin-restraint-for-attaching-the-acrylic-plastic-cap-sule-to-the-nemo-service-module-another-approach-that-was-considered-was-an-equatorial-ring-held-in-place-by-radial-sphere-penetrators-figure-9-the-sphere-penetrators-were-to-be-tapered-and-made-from-plastic-with-elastic-pr-image215969062.html

. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. padeye >. free-sliding fit between pin and opening in equatorial ring equatorial ring padeye .*- acrylic plastic hull permanently attached support framework. Figure 9. Equatorial ring and pin restraint for attaching the acrylic plastic cap- sule to the NEMO service module. Another approach that was considered was an equatorial ring held in place by radial sphere penetrators (Figure 9). The sphere penetrators were to be tapered and made from plastic with elastic pr Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-hulls-naval-architecture-submersibles-padeye-gt-free-sliding-fit-between-pin-and-opening-in-equatorial-ring-equatorial-ring-padeye-acrylic-plastic-hull-permanently-attached-support-framework-figure-9-equatorial-ring-and-pin-restraint-for-attaching-the-acrylic-plastic-cap-sule-to-the-nemo-service-module-another-approach-that-was-considered-was-an-equatorial-ring-held-in-place-by-radial-sphere-penetrators-figure-9-the-sphere-penetrators-were-to-be-tapered-and-made-from-plastic-with-elastic-pr-image215969062.htmlRMPFA6MP–. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. padeye >. free-sliding fit between pin and opening in equatorial ring equatorial ring padeye .*- acrylic plastic hull permanently attached support framework. Figure 9. Equatorial ring and pin restraint for attaching the acrylic plastic cap- sule to the NEMO service module. Another approach that was considered was an equatorial ring held in place by radial sphere penetrators (Figure 9). The sphere penetrators were to be tapered and made from plastic with elastic pr

. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. T •3 , typical radially taper; iole / located at the equator of the caps* :..J.H (a) Overall view of the capsule. (b) Detail of the radially tapered hole. Figure D-4. Acrylic plastic capsule prior to being outfitted with polar steel end closures, pins, and equatorial ring. 191. Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability - coloration and appearance of these illustrations may not perfectly Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-hulls-naval-architecture-submersibles-t-3-typical-radially-taper-iole-located-at-the-equator-of-the-caps-jh-a-overall-view-of-the-capsule-b-detail-of-the-radially-tapered-hole-figure-d-4-acrylic-plastic-capsule-prior-to-being-outfitted-with-polar-steel-end-closures-pins-and-equatorial-ring-191-please-note-that-these-images-are-extracted-from-scanned-page-images-that-may-have-been-digitally-enhanced-for-readability-coloration-and-appearance-of-these-illustrations-may-not-perfectly-image231664516.html

. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. T •3 , typical radially taper; iole / located at the equator of the caps* :..J.H (a) Overall view of the capsule. (b) Detail of the radially tapered hole. Figure D-4. Acrylic plastic capsule prior to being outfitted with polar steel end closures, pins, and equatorial ring. 191. Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability - coloration and appearance of these illustrations may not perfectly Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/development-of-a-spherical-acrylic-plastic-pressure-hull-for-hydrospace-application-hulls-naval-architecture-submersibles-t-3-typical-radially-taper-iole-located-at-the-equator-of-the-caps-jh-a-overall-view-of-the-capsule-b-detail-of-the-radially-tapered-hole-figure-d-4-acrylic-plastic-capsule-prior-to-being-outfitted-with-polar-steel-end-closures-pins-and-equatorial-ring-191-please-note-that-these-images-are-extracted-from-scanned-page-images-that-may-have-been-digitally-enhanced-for-readability-coloration-and-appearance-of-these-illustrations-may-not-perfectly-image231664516.htmlRMRCW6CM–. Development of a spherical acrylic plastic pressure hull for hydrospace application. Hulls (Naval architecture); Submersibles. T •3 , typical radially taper; iole / located at the equator of the caps* :..J.H (a) Overall view of the capsule. (b) Detail of the radially tapered hole. Figure D-4. Acrylic plastic capsule prior to being outfitted with polar steel end closures, pins, and equatorial ring. 191. Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability - coloration and appearance of these illustrations may not perfectly