Quick filters:

Throttle quadrant Stock Photos and Images

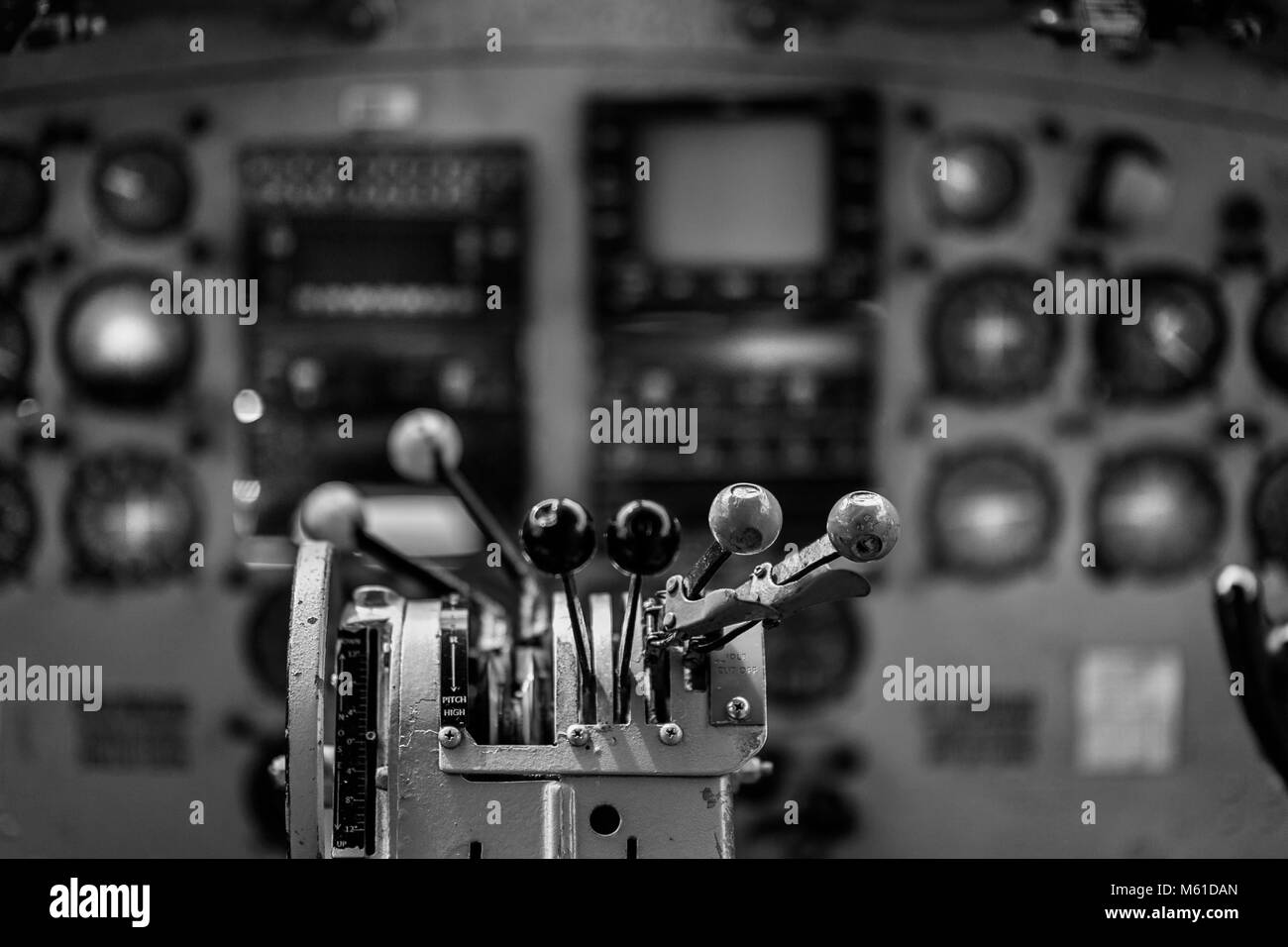

A throttle quadrant is seen in the cockpit of a Douglas DC-3 aircraft during a routine maintenance check at the airport of Villavicencio, Colombia. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-a-throttle-quadrant-is-seen-in-the-cockpit-of-a-douglas-dc-3-aircraft-173980458.html

A throttle quadrant is seen in the cockpit of a Douglas DC-3 aircraft during a routine maintenance check at the airport of Villavicencio, Colombia. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-a-throttle-quadrant-is-seen-in-the-cockpit-of-a-douglas-dc-3-aircraft-173980458.htmlRMM31DRP–A throttle quadrant is seen in the cockpit of a Douglas DC-3 aircraft during a routine maintenance check at the airport of Villavicencio, Colombia.

A throttle quadrant is seen in the cockpit of a Douglas DC-3 aircraft during a routine maintenance check at the airport of Villavicencio, Colombia, 5 December 2016. Although most of the airplanes of the DC-3 series were built in 1940s, today, almost 80 years after, some of them still continue to fly in a daily service, traversing the endless savannas and jungles in the in southeastern Colombia. Transporting people, groceries, livestock, or even small vehicles, a legendary American airplane is sometimes the only connection between remote jungle villages and the rest of the world. The DC-3 pilot Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-a-throttle-quadrant-is-seen-in-the-cockpit-of-a-douglas-dc-3-aircraft-175824061.html

A throttle quadrant is seen in the cockpit of a Douglas DC-3 aircraft during a routine maintenance check at the airport of Villavicencio, Colombia, 5 December 2016. Although most of the airplanes of the DC-3 series were built in 1940s, today, almost 80 years after, some of them still continue to fly in a daily service, traversing the endless savannas and jungles in the in southeastern Colombia. Transporting people, groceries, livestock, or even small vehicles, a legendary American airplane is sometimes the only connection between remote jungle villages and the rest of the world. The DC-3 pilot Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-a-throttle-quadrant-is-seen-in-the-cockpit-of-a-douglas-dc-3-aircraft-175824061.htmlRMM61DAN–A throttle quadrant is seen in the cockpit of a Douglas DC-3 aircraft during a routine maintenance check at the airport of Villavicencio, Colombia, 5 December 2016. Although most of the airplanes of the DC-3 series were built in 1940s, today, almost 80 years after, some of them still continue to fly in a daily service, traversing the endless savannas and jungles in the in southeastern Colombia. Transporting people, groceries, livestock, or even small vehicles, a legendary American airplane is sometimes the only connection between remote jungle villages and the rest of the world. The DC-3 pilot

Ken Eveland, 20th Maintenance Group Air Force engineering and technical services lead, climbs into an F-16CM Fighting Falcon at Shaw Air Force Base, S.C., Sept. 20, 2016. Eveland demonstrated a 50-hour throttle quadrant inspection for a training video that will be used to instruct F-16 crew chiefs on how to check the functionality of the aircraft throttle, ensuring the safety of pilots. (U.S. Air Force photo by Airman 1st Class Destinee Sweeney) Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/ken-eveland-20th-maintenance-group-air-force-engineering-and-technical-services-lead-climbs-into-an-f-16cm-fighting-falcon-at-shaw-air-force-base-sc-sept-20-2016-eveland-demonstrated-a-50-hour-throttle-quadrant-inspection-for-a-training-video-that-will-be-used-to-instruct-f-16-crew-chiefs-on-how-to-check-the-functionality-of-the-aircraft-throttle-ensuring-the-safety-of-pilots-us-air-force-photo-by-airman-1st-class-destinee-sweeney-image208118518.html

Ken Eveland, 20th Maintenance Group Air Force engineering and technical services lead, climbs into an F-16CM Fighting Falcon at Shaw Air Force Base, S.C., Sept. 20, 2016. Eveland demonstrated a 50-hour throttle quadrant inspection for a training video that will be used to instruct F-16 crew chiefs on how to check the functionality of the aircraft throttle, ensuring the safety of pilots. (U.S. Air Force photo by Airman 1st Class Destinee Sweeney) Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/ken-eveland-20th-maintenance-group-air-force-engineering-and-technical-services-lead-climbs-into-an-f-16cm-fighting-falcon-at-shaw-air-force-base-sc-sept-20-2016-eveland-demonstrated-a-50-hour-throttle-quadrant-inspection-for-a-training-video-that-will-be-used-to-instruct-f-16-crew-chiefs-on-how-to-check-the-functionality-of-the-aircraft-throttle-ensuring-the-safety-of-pilots-us-air-force-photo-by-airman-1st-class-destinee-sweeney-image208118518.htmlRMP2GH86–Ken Eveland, 20th Maintenance Group Air Force engineering and technical services lead, climbs into an F-16CM Fighting Falcon at Shaw Air Force Base, S.C., Sept. 20, 2016. Eveland demonstrated a 50-hour throttle quadrant inspection for a training video that will be used to instruct F-16 crew chiefs on how to check the functionality of the aircraft throttle, ensuring the safety of pilots. (U.S. Air Force photo by Airman 1st Class Destinee Sweeney)

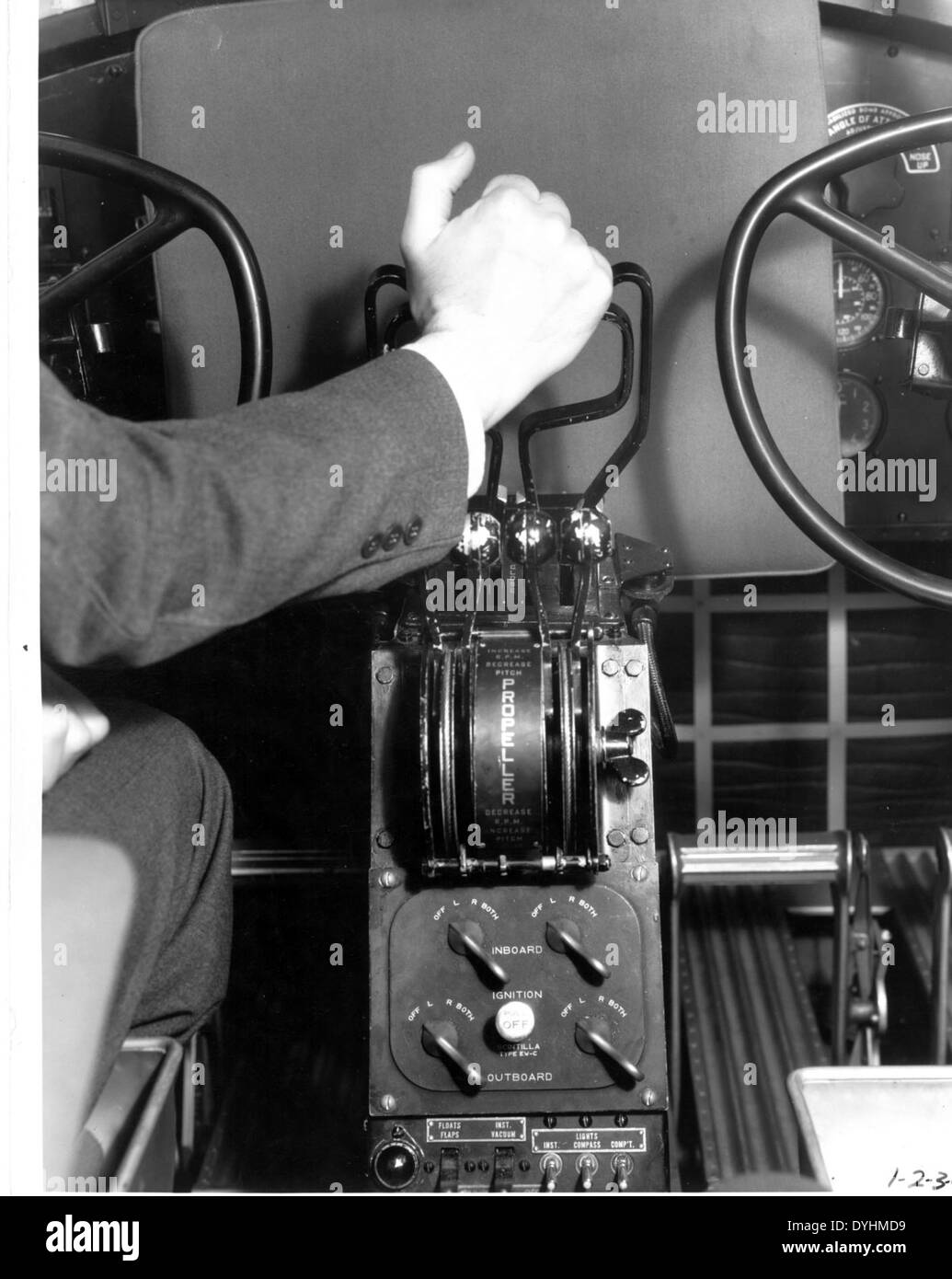

William ''Bill'' Wheatley Collection Photo Consolidated XPB2Y-1 throttle quadrant Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/william-bill-wheatley-collection-photo-consolidated-xpb2y-1-throttle-image68616053.html

William ''Bill'' Wheatley Collection Photo Consolidated XPB2Y-1 throttle quadrant Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/william-bill-wheatley-collection-photo-consolidated-xpb2y-1-throttle-image68616053.htmlRMDYHMD9–William ''Bill'' Wheatley Collection Photo Consolidated XPB2Y-1 throttle quadrant

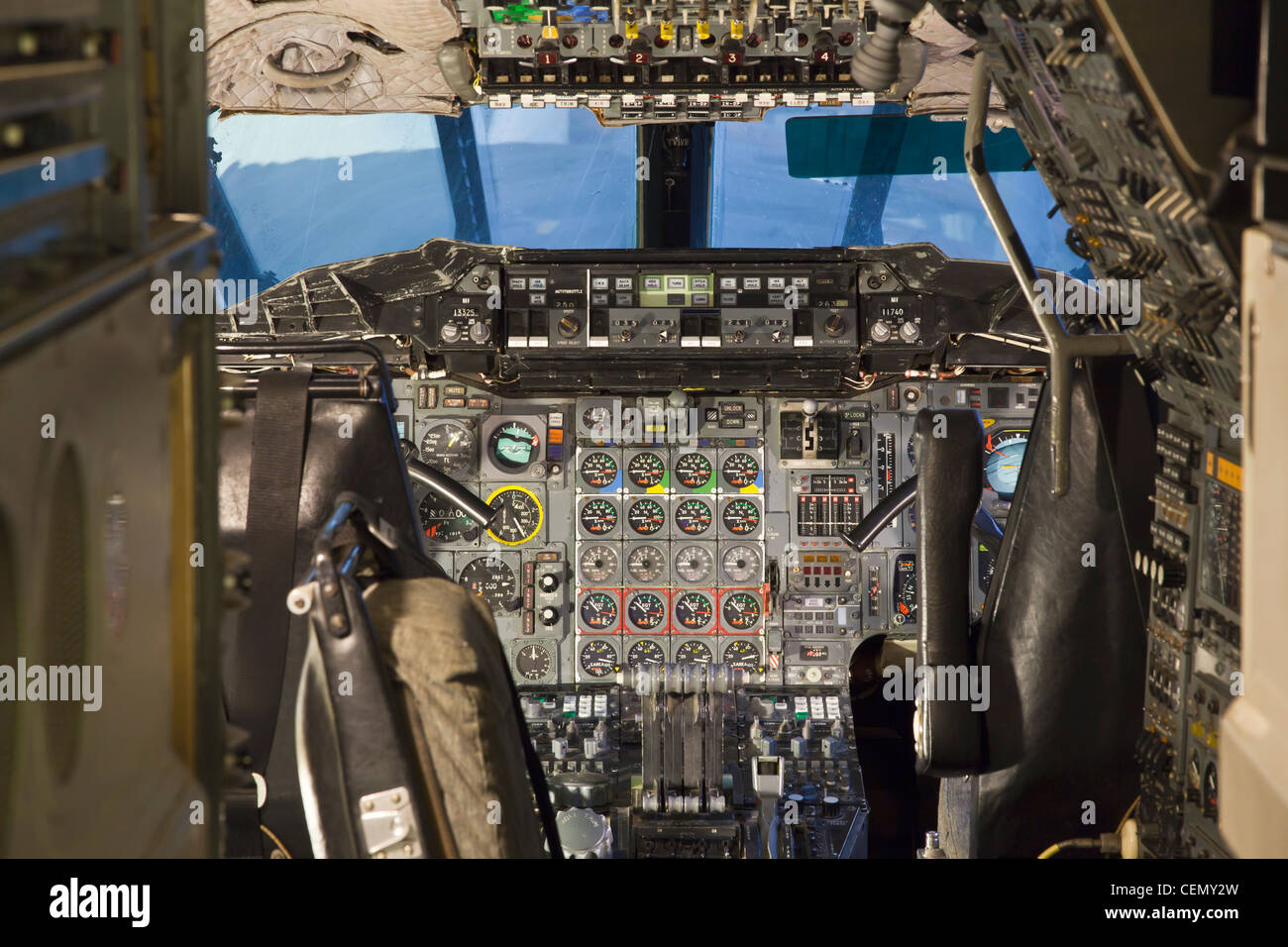

Concorde 101 cockpit. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-concorde-101-cockpit-43486209.html

Concorde 101 cockpit. Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-concorde-101-cockpit-43486209.htmlRMCEMY2W–Concorde 101 cockpit.

19 Airplane pilots know this mechanism as a: Throttle quadrant. July 6, 1950. (Photo by Cowles Syndicate). Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/19-airplane-pilots-know-this-mechanism-as-a-throttle-quadrant-july-6-1950-photo-by-cowles-syndicate-image463588124.html

19 Airplane pilots know this mechanism as a: Throttle quadrant. July 6, 1950. (Photo by Cowles Syndicate). Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/19-airplane-pilots-know-this-mechanism-as-a-throttle-quadrant-july-6-1950-photo-by-cowles-syndicate-image463588124.htmlRM2HX67AM–19 Airplane pilots know this mechanism as a: Throttle quadrant. July 6, 1950. (Photo by Cowles Syndicate).

. Railway mechanical engineer . le. This construction permits of any combinationof valve diameters desired. It will be noted from the drawing that the upper valvehas a conical baffle whereas the lower valve has a straightcylindrical base. This provides a gradual flow of steaminto the dry jiipe when the tlirottlc is opened. There is anindicator placed on the throttle handle in the back head(Fig. 14) which gives tlie engineer indication of the throttleopening. The action of the baffles is such that the differentpositions of the throttle quadrant provide a steam area ac-cording to the following t Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/railway-mechanical-engineer-le-this-construction-permits-of-any-combinationof-valve-diameters-desired-it-will-be-noted-from-the-drawing-that-the-upper-valvehas-a-conical-baffle-whereas-the-lower-valve-has-a-straightcylindrical-base-this-provides-a-gradual-flow-of-steaminto-the-dry-jiipe-when-the-tlirottlc-is-opened-there-is-anindicator-placed-on-the-throttle-handle-in-the-back-headfig-14-which-gives-tlie-engineer-indication-of-the-throttleopening-the-action-of-the-baffles-is-such-that-the-differentpositions-of-the-throttle-quadrant-provide-a-steam-area-ac-cording-to-the-following-t-image371836186.html

. Railway mechanical engineer . le. This construction permits of any combinationof valve diameters desired. It will be noted from the drawing that the upper valvehas a conical baffle whereas the lower valve has a straightcylindrical base. This provides a gradual flow of steaminto the dry jiipe when the tlirottlc is opened. There is anindicator placed on the throttle handle in the back head(Fig. 14) which gives tlie engineer indication of the throttleopening. The action of the baffles is such that the differentpositions of the throttle quadrant provide a steam area ac-cording to the following t Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/railway-mechanical-engineer-le-this-construction-permits-of-any-combinationof-valve-diameters-desired-it-will-be-noted-from-the-drawing-that-the-upper-valvehas-a-conical-baffle-whereas-the-lower-valve-has-a-straightcylindrical-base-this-provides-a-gradual-flow-of-steaminto-the-dry-jiipe-when-the-tlirottlc-is-opened-there-is-anindicator-placed-on-the-throttle-handle-in-the-back-headfig-14-which-gives-tlie-engineer-indication-of-the-throttleopening-the-action-of-the-baffles-is-such-that-the-differentpositions-of-the-throttle-quadrant-provide-a-steam-area-ac-cording-to-the-following-t-image371836186.htmlRM2CGXGRP–. Railway mechanical engineer . le. This construction permits of any combinationof valve diameters desired. It will be noted from the drawing that the upper valvehas a conical baffle whereas the lower valve has a straightcylindrical base. This provides a gradual flow of steaminto the dry jiipe when the tlirottlc is opened. There is anindicator placed on the throttle handle in the back head(Fig. 14) which gives tlie engineer indication of the throttleopening. The action of the baffles is such that the differentpositions of the throttle quadrant provide a steam area ac-cording to the following t

A throttle quadrant is seen in the cockpit of a Douglas DC-3 aircraft during a routine maintenance check at the airport of Villavicencio, Colombia, 5 December 2016. Although most of the airplanes of the DC-3 series were built in 1940s, today, almost 80 years after, some of them still continue to fly in a daily service, traversing the endless savannas and jungles in the in southeastern Colombia. Transporting people, groceries, livestock, or even small vehicles, a legendary American airplane is sometimes the only connection between remote jungle villages and the rest of the world. The DC-3 pilot Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-a-throttle-quadrant-is-seen-in-the-cockpit-of-a-douglas-dc-3-aircraft-174555597.html

A throttle quadrant is seen in the cockpit of a Douglas DC-3 aircraft during a routine maintenance check at the airport of Villavicencio, Colombia, 5 December 2016. Although most of the airplanes of the DC-3 series were built in 1940s, today, almost 80 years after, some of them still continue to fly in a daily service, traversing the endless savannas and jungles in the in southeastern Colombia. Transporting people, groceries, livestock, or even small vehicles, a legendary American airplane is sometimes the only connection between remote jungle villages and the rest of the world. The DC-3 pilot Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/stock-photo-a-throttle-quadrant-is-seen-in-the-cockpit-of-a-douglas-dc-3-aircraft-174555597.htmlRMM3YKCD–A throttle quadrant is seen in the cockpit of a Douglas DC-3 aircraft during a routine maintenance check at the airport of Villavicencio, Colombia, 5 December 2016. Although most of the airplanes of the DC-3 series were built in 1940s, today, almost 80 years after, some of them still continue to fly in a daily service, traversing the endless savannas and jungles in the in southeastern Colombia. Transporting people, groceries, livestock, or even small vehicles, a legendary American airplane is sometimes the only connection between remote jungle villages and the rest of the world. The DC-3 pilot

William ''Bill'' Wheatley Collection Photo Consolidated XPB2Y-1 throttle quadrant Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/william-bill-wheatley-collection-photo-consolidated-xpb2y-1-throttle-image68616539.html

William ''Bill'' Wheatley Collection Photo Consolidated XPB2Y-1 throttle quadrant Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/william-bill-wheatley-collection-photo-consolidated-xpb2y-1-throttle-image68616539.htmlRMDYHN2K–William ''Bill'' Wheatley Collection Photo Consolidated XPB2Y-1 throttle quadrant

. Railway mechanical engineer . ig. 4 shows a method of milling throttle quadrant latcheswith a cutter similar to that shown in Fig. 3. The latchesarc Iield in a vise, two rows, six latches in a row, makine12 latches completed in one setting of the machine and withtwo traverses of the table. The time for this operation mill-mg the teeth in 12 latches is 40 min. or about 3 min. perlatch. The cutter is 3 in, in diameter, 1 >4 in. wide, witha lJ4-in. arbor hole and is of carbon steel. Theface of the cutter is formed, on the segment of a circle having 72S 726 RAILWAY MECHANICAL ENGINEER Vol. 93 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/railway-mechanical-engineer-ig-4-shows-a-method-of-milling-throttle-quadrant-latcheswith-a-cutter-similar-to-that-shown-in-fig-3-the-latchesarc-iield-in-a-vise-two-rows-six-latches-in-a-row-makine12-latches-completed-in-one-setting-of-the-machine-and-withtwo-traverses-of-the-table-the-time-for-this-operation-mill-mg-the-teeth-in-12-latches-is-40-min-or-about-3-min-perlatch-the-cutter-is-3-in-in-diameter-1-gt4-in-wide-witha-lj4-in-arbor-hole-and-is-of-carbon-steel-theface-of-the-cutter-is-formed-on-the-segment-of-a-circle-having-72s-726-railway-mechanical-engineer-vol-93-image374738783.html

. Railway mechanical engineer . ig. 4 shows a method of milling throttle quadrant latcheswith a cutter similar to that shown in Fig. 3. The latchesarc Iield in a vise, two rows, six latches in a row, makine12 latches completed in one setting of the machine and withtwo traverses of the table. The time for this operation mill-mg the teeth in 12 latches is 40 min. or about 3 min. perlatch. The cutter is 3 in, in diameter, 1 >4 in. wide, witha lJ4-in. arbor hole and is of carbon steel. Theface of the cutter is formed, on the segment of a circle having 72S 726 RAILWAY MECHANICAL ENGINEER Vol. 93 Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/railway-mechanical-engineer-ig-4-shows-a-method-of-milling-throttle-quadrant-latcheswith-a-cutter-similar-to-that-shown-in-fig-3-the-latchesarc-iield-in-a-vise-two-rows-six-latches-in-a-row-makine12-latches-completed-in-one-setting-of-the-machine-and-withtwo-traverses-of-the-table-the-time-for-this-operation-mill-mg-the-teeth-in-12-latches-is-40-min-or-about-3-min-perlatch-the-cutter-is-3-in-in-diameter-1-gt4-in-wide-witha-lj4-in-arbor-hole-and-is-of-carbon-steel-theface-of-the-cutter-is-formed-on-the-segment-of-a-circle-having-72s-726-railway-mechanical-engineer-vol-93-image374738783.htmlRM2CNJR3Y–. Railway mechanical engineer . ig. 4 shows a method of milling throttle quadrant latcheswith a cutter similar to that shown in Fig. 3. The latchesarc Iield in a vise, two rows, six latches in a row, makine12 latches completed in one setting of the machine and withtwo traverses of the table. The time for this operation mill-mg the teeth in 12 latches is 40 min. or about 3 min. perlatch. The cutter is 3 in, in diameter, 1 >4 in. wide, witha lJ4-in. arbor hole and is of carbon steel. Theface of the cutter is formed, on the segment of a circle having 72S 726 RAILWAY MECHANICAL ENGINEER Vol. 93

William ''Bill'' Wheatley Collection Photo Consolidated XPB2Y-1 throttle quadrant Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/william-bill-wheatley-collection-photo-consolidated-xpb2y-1-throttle-image68616062.html

William ''Bill'' Wheatley Collection Photo Consolidated XPB2Y-1 throttle quadrant Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/william-bill-wheatley-collection-photo-consolidated-xpb2y-1-throttle-image68616062.htmlRMDYHMDJ–William ''Bill'' Wheatley Collection Photo Consolidated XPB2Y-1 throttle quadrant

. American engineer . Casting Which Supports the Lever and Its Connections. its connections before the parts are sent to the erecting shopand requires the laying out and drilling of but two holes for ap-plying it to the boiler. It has the further advantage of permit-ting an adjustment in the height of the throttle lever handle, if Stuffing Ccx Arranged to Carry the Throttle Lever Rigging. at one end and the quadrant at the other. The bearing on thestuffing box in the application illustrated, which is the design asapplied to Mikado locomotives for the Grand Trunk, has alength of 34 in. and a di Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/american-engineer-casting-which-supports-the-lever-and-its-connections-its-connections-before-the-parts-are-sent-to-the-erecting-shopand-requires-the-laying-out-and-drilling-of-but-two-holes-for-ap-plying-it-to-the-boiler-it-has-the-further-advantage-of-permit-ting-an-adjustment-in-the-height-of-the-throttle-lever-handle-if-stuffing-ccx-arranged-to-carry-the-throttle-lever-rigging-at-one-end-and-the-quadrant-at-the-other-the-bearing-on-thestuffing-box-in-the-application-illustrated-which-is-the-design-asapplied-to-mikado-locomotives-for-the-grand-trunk-has-alength-of-34-in-and-a-di-image372014757.html

. American engineer . Casting Which Supports the Lever and Its Connections. its connections before the parts are sent to the erecting shopand requires the laying out and drilling of but two holes for ap-plying it to the boiler. It has the further advantage of permit-ting an adjustment in the height of the throttle lever handle, if Stuffing Ccx Arranged to Carry the Throttle Lever Rigging. at one end and the quadrant at the other. The bearing on thestuffing box in the application illustrated, which is the design asapplied to Mikado locomotives for the Grand Trunk, has alength of 34 in. and a di Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/american-engineer-casting-which-supports-the-lever-and-its-connections-its-connections-before-the-parts-are-sent-to-the-erecting-shopand-requires-the-laying-out-and-drilling-of-but-two-holes-for-ap-plying-it-to-the-boiler-it-has-the-further-advantage-of-permit-ting-an-adjustment-in-the-height-of-the-throttle-lever-handle-if-stuffing-ccx-arranged-to-carry-the-throttle-lever-rigging-at-one-end-and-the-quadrant-at-the-other-the-bearing-on-thestuffing-box-in-the-application-illustrated-which-is-the-design-asapplied-to-mikado-locomotives-for-the-grand-trunk-has-alength-of-34-in-and-a-di-image372014757.htmlRM2CH6MH9–. American engineer . Casting Which Supports the Lever and Its Connections. its connections before the parts are sent to the erecting shopand requires the laying out and drilling of but two holes for ap-plying it to the boiler. It has the further advantage of permit-ting an adjustment in the height of the throttle lever handle, if Stuffing Ccx Arranged to Carry the Throttle Lever Rigging. at one end and the quadrant at the other. The bearing on thestuffing box in the application illustrated, which is the design asapplied to Mikado locomotives for the Grand Trunk, has alength of 34 in. and a di

William ''Bill'' Wheatley Collection Photo Consolidated XPB2Y-1 throttle quadrant Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/william-bill-wheatley-collection-photo-consolidated-xpb2y-1-throttle-image68616538.html

William ''Bill'' Wheatley Collection Photo Consolidated XPB2Y-1 throttle quadrant Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/william-bill-wheatley-collection-photo-consolidated-xpb2y-1-throttle-image68616538.htmlRMDYHN2J–William ''Bill'' Wheatley Collection Photo Consolidated XPB2Y-1 throttle quadrant

. American engineer . r3 Sechon BS. %BoHs ra f : i i= r3. Casting Which Supports the Lever and Its Connections. its connections before the parts are sent to the erecting shopand requires the laying out and drilling of but two holes for ap-plying it to the boiler. It has the further advantage of permit-ting an adjustment in the height of the throttle lever handle, if Stuffing Ccx Arranged to Carry the Throttle Lever Rigging. at one end and the quadrant at the other. The bearing on thestuffing box in the application illustrated, which is the design asapplied to Mikado locomotives for the Grand Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/american-engineer-r3-sechon-bs-bohs-ra-f-i-i=-r3-casting-which-supports-the-lever-and-its-connections-its-connections-before-the-parts-are-sent-to-the-erecting-shopand-requires-the-laying-out-and-drilling-of-but-two-holes-for-ap-plying-it-to-the-boiler-it-has-the-further-advantage-of-permit-ting-an-adjustment-in-the-height-of-the-throttle-lever-handle-if-stuffing-ccx-arranged-to-carry-the-throttle-lever-rigging-at-one-end-and-the-quadrant-at-the-other-the-bearing-on-thestuffing-box-in-the-application-illustrated-which-is-the-design-asapplied-to-mikado-locomotives-for-the-grand-image372014798.html

. American engineer . r3 Sechon BS. %BoHs ra f : i i= r3. Casting Which Supports the Lever and Its Connections. its connections before the parts are sent to the erecting shopand requires the laying out and drilling of but two holes for ap-plying it to the boiler. It has the further advantage of permit-ting an adjustment in the height of the throttle lever handle, if Stuffing Ccx Arranged to Carry the Throttle Lever Rigging. at one end and the quadrant at the other. The bearing on thestuffing box in the application illustrated, which is the design asapplied to Mikado locomotives for the Grand Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/american-engineer-r3-sechon-bs-bohs-ra-f-i-i=-r3-casting-which-supports-the-lever-and-its-connections-its-connections-before-the-parts-are-sent-to-the-erecting-shopand-requires-the-laying-out-and-drilling-of-but-two-holes-for-ap-plying-it-to-the-boiler-it-has-the-further-advantage-of-permit-ting-an-adjustment-in-the-height-of-the-throttle-lever-handle-if-stuffing-ccx-arranged-to-carry-the-throttle-lever-rigging-at-one-end-and-the-quadrant-at-the-other-the-bearing-on-thestuffing-box-in-the-application-illustrated-which-is-the-design-asapplied-to-mikado-locomotives-for-the-grand-image372014798.htmlRM2CH6MJP–. American engineer . r3 Sechon BS. %BoHs ra f : i i= r3. Casting Which Supports the Lever and Its Connections. its connections before the parts are sent to the erecting shopand requires the laying out and drilling of but two holes for ap-plying it to the boiler. It has the further advantage of permit-ting an adjustment in the height of the throttle lever handle, if Stuffing Ccx Arranged to Carry the Throttle Lever Rigging. at one end and the quadrant at the other. The bearing on thestuffing box in the application illustrated, which is the design asapplied to Mikado locomotives for the Grand

. Railway and locomotive engineering : a practical journal of railway motive power and rolling stock . d. All the engineer has September, 1920 RAILWAY AND LOCOMOTIVE ENGINEERING 267 to do is to raise the latch on the reversequadrant. Operating the locomotive inthe usual way automatically operates theBooster. It can only be brought into op-eration when the latch on the reverselever quadrant is in operating position,when the main locomotive throttle is open,the reverse lever in the corner and whenthe locomotive cylinders are getting steam.After steam is admitted to the cylindersthe crankshaft pi Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/railway-and-locomotive-engineering-a-practical-journal-of-railway-motive-power-and-rolling-stock-d-all-the-engineer-has-september-1920-railway-and-locomotive-engineering-267-to-do-is-to-raise-the-latch-on-the-reversequadrant-operating-the-locomotive-inthe-usual-way-automatically-operates-thebooster-it-can-only-be-brought-into-op-eration-when-the-latch-on-the-reverselever-quadrant-is-in-operating-positionwhen-the-main-locomotive-throttle-is-openthe-reverse-lever-in-the-corner-and-whenthe-locomotive-cylinders-are-getting-steamafter-steam-is-admitted-to-the-cylindersthe-crankshaft-pi-image371934768.html

. Railway and locomotive engineering : a practical journal of railway motive power and rolling stock . d. All the engineer has September, 1920 RAILWAY AND LOCOMOTIVE ENGINEERING 267 to do is to raise the latch on the reversequadrant. Operating the locomotive inthe usual way automatically operates theBooster. It can only be brought into op-eration when the latch on the reverselever quadrant is in operating position,when the main locomotive throttle is open,the reverse lever in the corner and whenthe locomotive cylinders are getting steam.After steam is admitted to the cylindersthe crankshaft pi Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/railway-and-locomotive-engineering-a-practical-journal-of-railway-motive-power-and-rolling-stock-d-all-the-engineer-has-september-1920-railway-and-locomotive-engineering-267-to-do-is-to-raise-the-latch-on-the-reversequadrant-operating-the-locomotive-inthe-usual-way-automatically-operates-thebooster-it-can-only-be-brought-into-op-eration-when-the-latch-on-the-reverselever-quadrant-is-in-operating-positionwhen-the-main-locomotive-throttle-is-openthe-reverse-lever-in-the-corner-and-whenthe-locomotive-cylinders-are-getting-steamafter-steam-is-admitted-to-the-cylindersthe-crankshaft-pi-image371934768.htmlRM2CH32GG–. Railway and locomotive engineering : a practical journal of railway motive power and rolling stock . d. All the engineer has September, 1920 RAILWAY AND LOCOMOTIVE ENGINEERING 267 to do is to raise the latch on the reversequadrant. Operating the locomotive inthe usual way automatically operates theBooster. It can only be brought into op-eration when the latch on the reverselever quadrant is in operating position,when the main locomotive throttle is open,the reverse lever in the corner and whenthe locomotive cylinders are getting steam.After steam is admitted to the cylindersthe crankshaft pi

. Railway mechanical engineer . figures arestenciled. The spindle is then given a part of a revolution,just enough to roll the figures over the shank of the work.The collars that are used in this machine are also a homeproduct and are arranged so that any combination of frac-tions and thread numbers can be obtained. For sizes over THROTTLE SAFETY APPLIANCE The Missouri, Kansas & Texas has recently issued in-structions to equip all locomotive throttle quadrants with apin and Safety-First tag as shown in the illustration. Thepin is placed in a hole drilled in the quadrant just behindthe throttle Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/railway-mechanical-engineer-figures-arestenciled-the-spindle-is-then-given-a-part-of-a-revolutionjust-enough-to-roll-the-figures-over-the-shank-of-the-workthe-collars-that-are-used-in-this-machine-are-also-a-homeproduct-and-are-arranged-so-that-any-combination-of-frac-tions-and-thread-numbers-can-be-obtained-for-sizes-over-throttle-safety-appliance-the-missouri-kansas-texas-has-recently-issued-in-structions-to-equip-all-locomotive-throttle-quadrants-with-apin-and-safety-first-tag-as-shown-in-the-illustration-thepin-is-placed-in-a-hole-drilled-in-the-quadrant-just-behindthe-throttle-image371920757.html

. Railway mechanical engineer . figures arestenciled. The spindle is then given a part of a revolution,just enough to roll the figures over the shank of the work.The collars that are used in this machine are also a homeproduct and are arranged so that any combination of frac-tions and thread numbers can be obtained. For sizes over THROTTLE SAFETY APPLIANCE The Missouri, Kansas & Texas has recently issued in-structions to equip all locomotive throttle quadrants with apin and Safety-First tag as shown in the illustration. Thepin is placed in a hole drilled in the quadrant just behindthe throttle Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/railway-mechanical-engineer-figures-arestenciled-the-spindle-is-then-given-a-part-of-a-revolutionjust-enough-to-roll-the-figures-over-the-shank-of-the-workthe-collars-that-are-used-in-this-machine-are-also-a-homeproduct-and-are-arranged-so-that-any-combination-of-frac-tions-and-thread-numbers-can-be-obtained-for-sizes-over-throttle-safety-appliance-the-missouri-kansas-texas-has-recently-issued-in-structions-to-equip-all-locomotive-throttle-quadrants-with-apin-and-safety-first-tag-as-shown-in-the-illustration-thepin-is-placed-in-a-hole-drilled-in-the-quadrant-just-behindthe-throttle-image371920757.htmlRM2CH2CM5–. Railway mechanical engineer . figures arestenciled. The spindle is then given a part of a revolution,just enough to roll the figures over the shank of the work.The collars that are used in this machine are also a homeproduct and are arranged so that any combination of frac-tions and thread numbers can be obtained. For sizes over THROTTLE SAFETY APPLIANCE The Missouri, Kansas & Texas has recently issued in-structions to equip all locomotive throttle quadrants with apin and Safety-First tag as shown in the illustration. Thepin is placed in a hole drilled in the quadrant just behindthe throttle

. American engineer and railroad journal . HOOK FOB HANDLING TIRES ON AND OFF OF EXPANDING CHUCK. EXPANDING CHUCK FOR TRUCK WHEEL TIRES. A. casting E are attached. The deviceis simple and is giving very satis-factory results. We are indebtedfor this information to Mr. LouisA. Abbott. DEVICE FOB MILLING TEETH IN REVERSE LEVEB QUADBANTS reverse lever and throttle lever quadrants. This device isshown in detail in the accompanying illustration. The arms B,which hold the quadrant A, may be adjusted to suit the lengthof the radius of the quadrant. The cutters in the tool holderH, are made to suit th Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/american-engineer-and-railroad-journal-hook-fob-handling-tires-on-and-off-of-expanding-chuck-expanding-chuck-for-truck-wheel-tires-a-casting-e-are-attached-the-deviceis-simple-and-is-giving-very-satis-factory-results-we-are-indebtedfor-this-information-to-mr-louisa-abbott-device-fob-milling-teeth-in-reverse-leveb-quadbants-reverse-lever-and-throttle-lever-quadrants-this-device-isshown-in-detail-in-the-accompanying-illustration-the-arms-bwhich-hold-the-quadrant-a-may-be-adjusted-to-suit-the-lengthof-the-radius-of-the-quadrant-the-cutters-in-the-tool-holderh-are-made-to-suit-th-image375751615.html

. American engineer and railroad journal . HOOK FOB HANDLING TIRES ON AND OFF OF EXPANDING CHUCK. EXPANDING CHUCK FOR TRUCK WHEEL TIRES. A. casting E are attached. The deviceis simple and is giving very satis-factory results. We are indebtedfor this information to Mr. LouisA. Abbott. DEVICE FOB MILLING TEETH IN REVERSE LEVEB QUADBANTS reverse lever and throttle lever quadrants. This device isshown in detail in the accompanying illustration. The arms B,which hold the quadrant A, may be adjusted to suit the lengthof the radius of the quadrant. The cutters in the tool holderH, are made to suit th Stock Photohttps://www.alamy.com/image-license-details/?v=1https://www.alamy.com/american-engineer-and-railroad-journal-hook-fob-handling-tires-on-and-off-of-expanding-chuck-expanding-chuck-for-truck-wheel-tires-a-casting-e-are-attached-the-deviceis-simple-and-is-giving-very-satis-factory-results-we-are-indebtedfor-this-information-to-mr-louisa-abbott-device-fob-milling-teeth-in-reverse-leveb-quadbants-reverse-lever-and-throttle-lever-quadrants-this-device-isshown-in-detail-in-the-accompanying-illustration-the-arms-bwhich-hold-the-quadrant-a-may-be-adjusted-to-suit-the-lengthof-the-radius-of-the-quadrant-the-cutters-in-the-tool-holderh-are-made-to-suit-th-image375751615.htmlRM2CR8Y0F–. American engineer and railroad journal . HOOK FOB HANDLING TIRES ON AND OFF OF EXPANDING CHUCK. EXPANDING CHUCK FOR TRUCK WHEEL TIRES. A. casting E are attached. The deviceis simple and is giving very satis-factory results. We are indebtedfor this information to Mr. LouisA. Abbott. DEVICE FOB MILLING TEETH IN REVERSE LEVEB QUADBANTS reverse lever and throttle lever quadrants. This device isshown in detail in the accompanying illustration. The arms B,which hold the quadrant A, may be adjusted to suit the lengthof the radius of the quadrant. The cutters in the tool holderH, are made to suit th