. Copper and copper base alloys : the physical and mechanical properties of copper and its commercial alloys in wrought form. Copper; Copper alloys. 114 0.050 Q040 Copper and Copper-base Alloys 0.030 R eady + Code' 1 3 finish grain 1 size ^^ 0.015 mm. X" X^ ^ / .X* ^ X* -^ / / ^ l^ / / / 4 / / ^j"* ^X y â S ao20 0.010 700 800 900 1000 1100 1200 1300 1400 Annealing Temp, in Deg.F. (I Hr.a+ Temp.) Chart 74.âThe effect of annealing on the grain-growing character- istics of leaded-brass strip, previously cold-rolled 6 B. & S. Nos. (50 per cent reduction of area) from two different

Image details

Contributor:

The Book Worm / Alamy Stock PhotoImage ID:

RE8BB0File size:

7.1 MB (376.1 KB Compressed download)Releases:

Model - no | Property - noDo I need a release?Dimensions:

1491 x 1676 px | 25.2 x 28.4 cm | 9.9 x 11.2 inches | 150dpiMore information:

This image is a public domain image, which means either that copyright has expired in the image or the copyright holder has waived their copyright. Alamy charges you a fee for access to the high resolution copy of the image.

This image could have imperfections as it’s either historical or reportage.

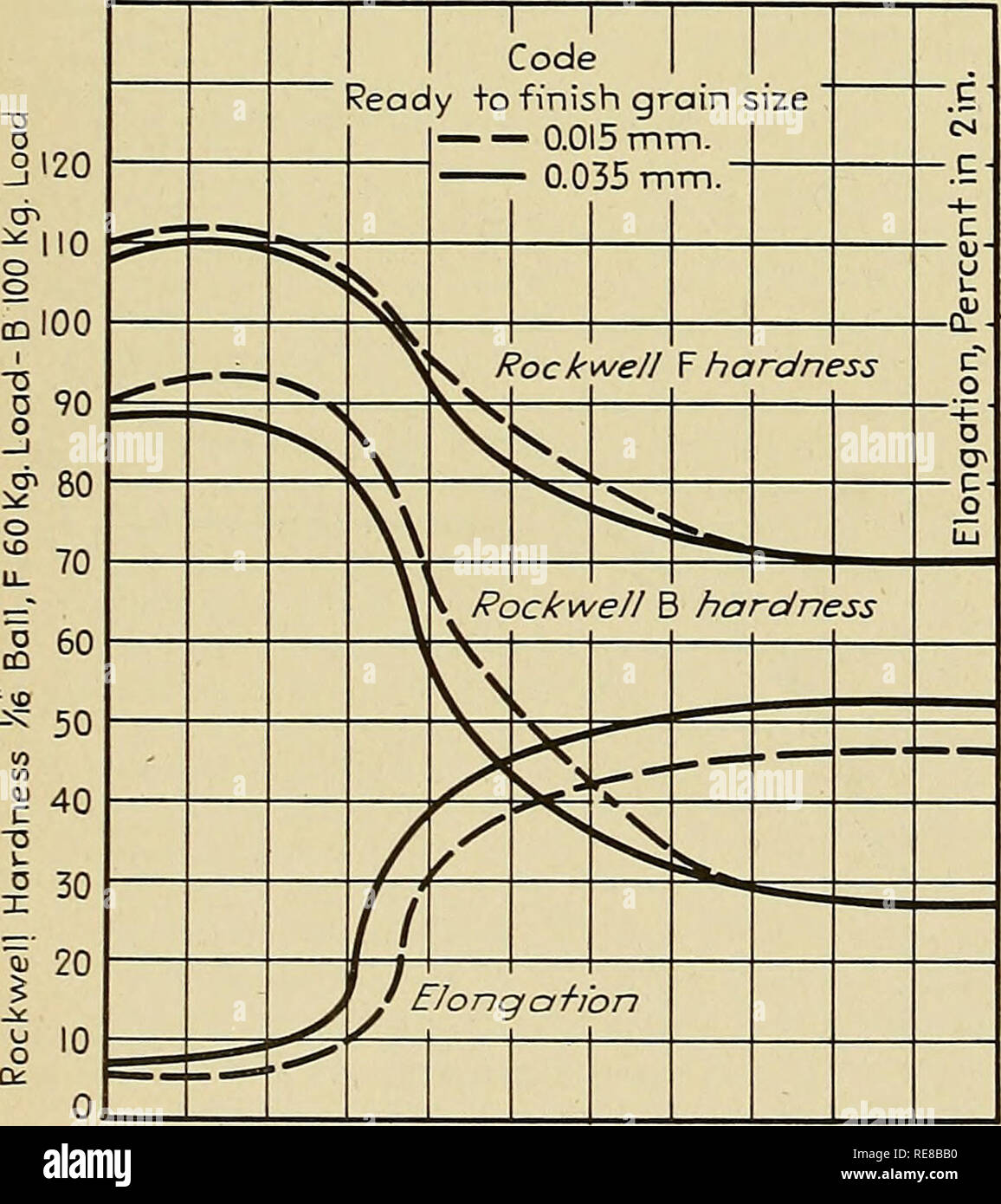

. Copper and copper base alloys : the physical and mechanical properties of copper and its commercial alloys in wrought form. Copper; Copper alloys. 114 0.050 Q040 Copper and Copper-base Alloys 0.030 R eady + Code' 1 3 finish grain 1 size ^^ _ 0.015 mm. X" X^ ^ / .X* ^ X* -^ / / ^ l^ / / / 4 / / ^j"* ^X y â S ao20 0.010 700 800 900 1000 1100 1200 1300 1400 Annealing Temp, in Deg.F. (I Hr.a+ Temp.) Chart 74.âThe effect of annealing on the grain-growing character- istics of leaded-brass strip, previously cold-rolled 6 B. & S. Nos. (50 per cent reduction of area) from two different grain sizes, 0.015 and 0.035 mm. (60.96 % copper, 1.53 % lead, balance zinc) (0.040-in. stock). ZoAp Ready to finish grain size 0.035 mm. 1 1 1 1 â """ ^^s S'. K Tensile sirengfh ^^ ^ "N, fV ^-- , ^ , , - -^ k s V * 'v Apparenf e/ash'c limii =. _.^ .^. 100 90 ^ 60 - Q- 50 Xi o 40 o o -- 30 20 400 500 600 700 800 900 1000 1100 1200 1300 Annealing Temp.in Deg. F(IHr.at Temp.) Chart 75.âThe effect of annealing on the tensile strength and apparent elastic limit of leaded-brass strip, previously cold-rolled 6 B. & S. Nos. (50 per cent reduction of area) from two different grain sizes, 0.015 and 0.035 mm. (60.96 % copper, 1.53 % lead, balance zinc) (0.040-in. stock).. 400 500 600 700 800 900 1000 1100 1200 1300 1400 Anneah'ng Temp, in Deg. F.(IHrat Temp.) Chart 76.âThe effect of annealing on the Rockwell hardness and percentage elongation in 2 in. of leaded-brass strip, previously cold- roUed 6 B. & S. Nos. (50 per cent reduction of area) from two different grain sizes, 0.015 and 0.035 mm. (60.96 % copper, 1.53 % lead, balance zinc) (0.040-in. stock). r â > . c ode (T) 0 20% " " " (?) 0.50 °7o " " (exte 1 nsion) © ^#^- N ^ ^' '-«^, ^ ^ ^V ^^ â """â ^â *" ' 90 80 70 C 60 cr ^ 50 01 ^40 xi o 30 o o -~ 20 400 500 600 700 800 900 1000 1100 1200 1300 WOO Annealing Temp, in Deg.F f IH